设计简介

摘 要

塑料是四大工业材料中发展速度最快的一种材料,塑料工业是新兴的工业。近年来,随着塑料工业的飞速发展,塑料制品的应用领域也在不断扩展,塑料加工设备已渗透到国民经济的各个行业,成为我国机械工业的重要组成部分,在国民经济中起着越来越重要的作用。其中塑料成型机械是塑料工业中的一个重要组成部分,是完成塑料制品生产成型的必要手段,而挤出成型又是塑料成型加工的重要成型方法之一。

本文主要讲述的是塑料挤出成型的原理、特点、结构组成、分类、主要技术参数、主要零部件及有关的调控系统和辅助装置、挤出过程、设备的安全操作和维护保养以及主要故障的排除等内容,并阐述这些内容之间的相互关系及影响。并且在讲解单杆塑料挤出机的工作原理、基本结构和有关专业知识的基础上,具体深入分析问题,理论与实际相结合,并从机理、结构以及塑料成型工艺、设备的调控、安全及维护保养等方面综合分析问题,找出矛盾的主要方面,选择最优的改进方案,来提高单杆塑料挤出机的综合水平,从而获得更好的经济效益和社会效益。

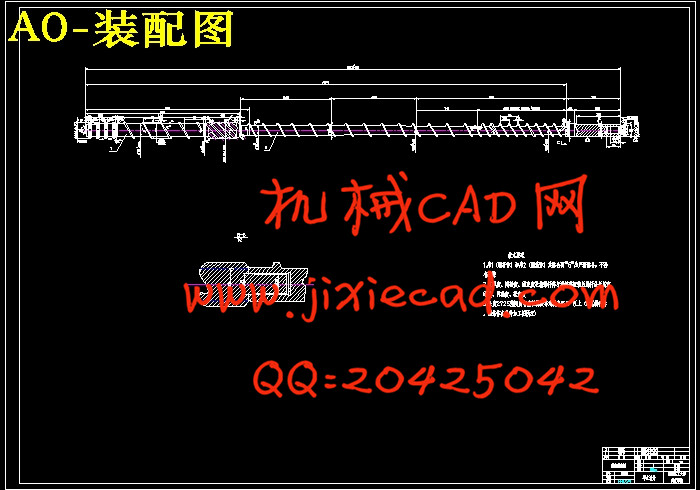

塑料挤出机简称挤出机(又名压出机),它是塑料加工过程中的主要设备之一。一般挤出机有五大部分组成:挤出部分、传动部分、机头、加热冷却系统、电气控制系统。

挤出部分是挤出机的主体部分,主要作用是:剪切、塑化和捏炼塑料,以一定的压力,均匀连续的向机头输送塑料。由加料装置、螺杆、机筒、衬套等组成。其中螺杆分为单头螺杆、双头螺杆和多头螺杆。衬套材料一般为 38CrMoAlA。

传动系统的作用是驱动螺杆旋转和根据工艺要求调节螺杆的转速,传动系统由电动机和减速器等组成。

机头是挤出机的成形部分。它的作用是:使塑料由螺旋运动变为直线运动;在一定的压力下,将塑料挤压成各种所需形状的半成品。

加热冷却系统是指为了使塑料很好的挤出,适时控制温度,以防止塑料温度过低或焦烧。

电气控制系统的作用是满足挤出工艺条件的需要,实现对挤出机机筒割断温度、集体温度、螺杆转速、驱动扭矩或功率、轴向力等的控制和调节。由温控、调速和检测装置组成。

挤出机的基本工作过程:带状塑料加入加料口后,在旋转螺杆的作用下,塑料被搓成团状沿螺杆槽滚动前进,因螺杆的剪切、压缩和搅拌作用塑料受到进一步的混炼和塑化,温度和压力逐步提高,呈现出粘流状态,以一定的压力和温度通过机头,最后得到所需的一定形状的半成品。

关键词:单螺杆; 挤出机; 加热冷却系统; 传动系统; 电气控制系统

Abstract

Plastic materials industry is the four fastest-growing kind of material, the plastics industry is a new industry. In recent years, with the rapid development of the plastics industry, plastic products, applications are expanding, plastics processing equipment has been infiltrated into all sectors of the national economy, has become an important part of China's machinery industry in the national economy plays an increasingly the more important role. Wherein the plastic molding machinery and plastics industry is an important part of the necessary means to complete the production of plastic molding, and extrusion molding is one of the important methods of plastic molding process.

This paper describes a plastic extrusion principle, characteristics, composition, classification, main technical parameters, the main components and related regulatory systems and auxiliary equipment, extrusion process safety, equipment operation and maintenance as well as major fault Exclude other content, and explains the relationship between the content and impact of these. And explain the basis of a single shot plastic extrusion machine works, the basic structure and relevant expertise on specific in-depth analysis of the problem, the combination of theory and practice, and the regulatory mechanism, structure and plastic molding technology, equipment, safety and maintenance maintenance and other aspects of a comprehensive analysis of the problem, identify the main aspects of conflict and choose the best improvement program to improve the single pole plastic extruder comprehensive level, leading to better economic and social benefits.

The plastic rod extruding machine abbreviation extruder (also names extruding press),it is an important implemental of the plastic reclaiming process.The extruder is made of five parts:the part of extruding;the part of passing;the head;the system of heading and cooling;the electrical control system.

The major part of the extruder is the part extruding,it is the most use of shear ,rend and pinch the plastic,under afastness pressure,continuous send plastic to the head ,it made up of fill device ,screw,barrel,liner and so on,And the screw is disport of single screw;double screw;and multi-component screw.The material of liner is 38CrMoAlA.

The part of passing is driving the screw rotation and basic the need of the art factitious process to adjustment the screw royal .The part of passing is made of electrical engineering and reducer.

The head is the extruding machine formed part .Its function is:Causes the sizing material to become the translation by the helical motion ;under the certain pressure,extrudes the sizing materials which need the shape the half-finished product.

The system of heating and cooling is for the plastic well extrusion,we control the temperate to prevent the temperate too low or born.

The electrical control system is for the need of press,control the temperate of the barrel and the head ,the royal of the screw ,drive the torsion or power ,and adjustment the head ,the royal of the screw,driver the torsion or power,and adjustment the force of the axial ,is made of the temperate controller,the speed adjustment system,and the device of test.

The extruder`s fundamental process is this:get the plastic to the filler,under the shear of the screw ,the plastic was made small ball,because of the screw`s shear pressure and stirring,the plastic was futher rend and plastic,the temperate and the pressure get higher,and the plastic get plastic flow,under fastness pressure though the head,the last get the production you need.

Keyword: single-screw; extruder; the heatng cooling system; the transmiss-

ion system; electrical control system

目 录

第一章绪论 1

1.1 引言 1

1.2 国内外发展情况 1

1.3 单螺杆挤出机研究现状 1

1.4 课题研究意义和目的 2

1.5 课题主要研究内容 2

第二章挤出机总体方案的确定 3

2.1 挤出机总体布局的基本要求 3

2.2 挤出机的主要参数 3

2.2.1 挤出机的主要性能参数 3

2.2.2 螺杆转速 4

2.2.3 挤出机功率 4

2.2.4 轴向力 P 5

2.2.5 生产能力 Q 5

2.3 挤出机构设计 5

2.3.1 螺杆设计 5

2.3.2 螺槽深度和压缩比的确定 6

2.3.3 螺距和螺纹升角的确定 8

2.4 本章小结 9

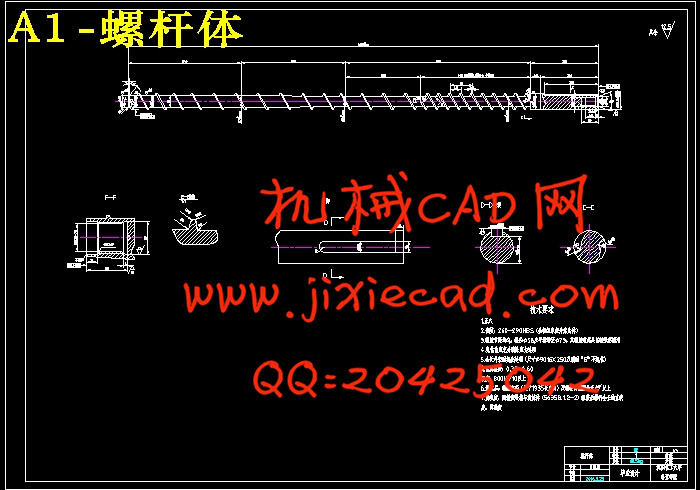

第三章螺杆方案的确定 10

3.1 螺杆类型的确定 10

3.2 螺杆的工作性能指标评定 10

3.3 螺杆的选用原则 10

3.4 螺杆的分类 11

3.5 单螺杆挤出机及其基本操作 11

3.6 本章小结 12

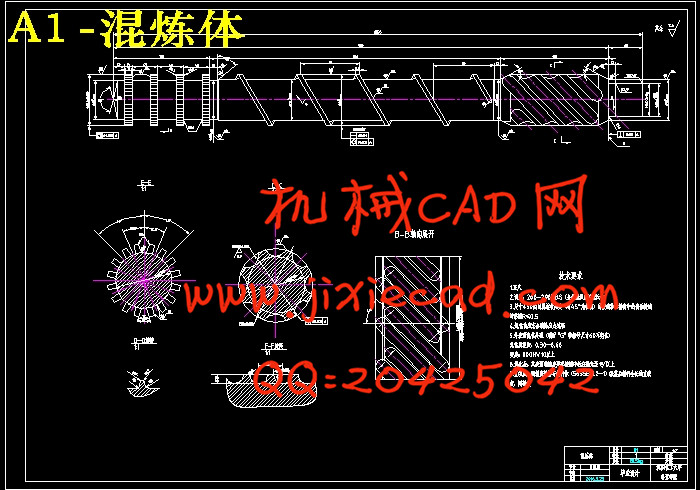

第四章螺杆的设计与校核 14

4.1 螺杆材料 14

4.2 螺杆形式 14

4.3 螺杆参数 14

4.4 螺杆结构 14

4.5 螺纹的断面形状 15

4.6 校核 15

4.7 本章小结 16

第五章机筒的设计及强度校核 17

5.1 机筒的类型 17

5.2 机筒材料的选择 18

5.3 机筒参数 19

5.4 校核 19

5.5 本章小结 19

第六章其他零部件的设计与校核 20

6.1 螺杆与轴联接处的花键的选择与校核 20

6.2 推力轴承的选择与校核 20

6.3 联轴器的选择与校核 21

6.4 机头材料的选择 21

6.5 温度控制 21

6.6 电机的选择 21

6.7 本章小结 22

结 论 23

参考文献 24

致 谢 25

塑料是四大工业材料中发展速度最快的一种材料,塑料工业是新兴的工业。近年来,随着塑料工业的飞速发展,塑料制品的应用领域也在不断扩展,塑料加工设备已渗透到国民经济的各个行业,成为我国机械工业的重要组成部分,在国民经济中起着越来越重要的作用。其中塑料成型机械是塑料工业中的一个重要组成部分,是完成塑料制品生产成型的必要手段,而挤出成型又是塑料成型加工的重要成型方法之一。

本文主要讲述的是塑料挤出成型的原理、特点、结构组成、分类、主要技术参数、主要零部件及有关的调控系统和辅助装置、挤出过程、设备的安全操作和维护保养以及主要故障的排除等内容,并阐述这些内容之间的相互关系及影响。并且在讲解单杆塑料挤出机的工作原理、基本结构和有关专业知识的基础上,具体深入分析问题,理论与实际相结合,并从机理、结构以及塑料成型工艺、设备的调控、安全及维护保养等方面综合分析问题,找出矛盾的主要方面,选择最优的改进方案,来提高单杆塑料挤出机的综合水平,从而获得更好的经济效益和社会效益。

塑料挤出机简称挤出机(又名压出机),它是塑料加工过程中的主要设备之一。一般挤出机有五大部分组成:挤出部分、传动部分、机头、加热冷却系统、电气控制系统。

挤出部分是挤出机的主体部分,主要作用是:剪切、塑化和捏炼塑料,以一定的压力,均匀连续的向机头输送塑料。由加料装置、螺杆、机筒、衬套等组成。其中螺杆分为单头螺杆、双头螺杆和多头螺杆。衬套材料一般为 38CrMoAlA。

传动系统的作用是驱动螺杆旋转和根据工艺要求调节螺杆的转速,传动系统由电动机和减速器等组成。

机头是挤出机的成形部分。它的作用是:使塑料由螺旋运动变为直线运动;在一定的压力下,将塑料挤压成各种所需形状的半成品。

加热冷却系统是指为了使塑料很好的挤出,适时控制温度,以防止塑料温度过低或焦烧。

电气控制系统的作用是满足挤出工艺条件的需要,实现对挤出机机筒割断温度、集体温度、螺杆转速、驱动扭矩或功率、轴向力等的控制和调节。由温控、调速和检测装置组成。

挤出机的基本工作过程:带状塑料加入加料口后,在旋转螺杆的作用下,塑料被搓成团状沿螺杆槽滚动前进,因螺杆的剪切、压缩和搅拌作用塑料受到进一步的混炼和塑化,温度和压力逐步提高,呈现出粘流状态,以一定的压力和温度通过机头,最后得到所需的一定形状的半成品。

关键词:单螺杆; 挤出机; 加热冷却系统; 传动系统; 电气控制系统

Abstract

Plastic materials industry is the four fastest-growing kind of material, the plastics industry is a new industry. In recent years, with the rapid development of the plastics industry, plastic products, applications are expanding, plastics processing equipment has been infiltrated into all sectors of the national economy, has become an important part of China's machinery industry in the national economy plays an increasingly the more important role. Wherein the plastic molding machinery and plastics industry is an important part of the necessary means to complete the production of plastic molding, and extrusion molding is one of the important methods of plastic molding process.

This paper describes a plastic extrusion principle, characteristics, composition, classification, main technical parameters, the main components and related regulatory systems and auxiliary equipment, extrusion process safety, equipment operation and maintenance as well as major fault Exclude other content, and explains the relationship between the content and impact of these. And explain the basis of a single shot plastic extrusion machine works, the basic structure and relevant expertise on specific in-depth analysis of the problem, the combination of theory and practice, and the regulatory mechanism, structure and plastic molding technology, equipment, safety and maintenance maintenance and other aspects of a comprehensive analysis of the problem, identify the main aspects of conflict and choose the best improvement program to improve the single pole plastic extruder comprehensive level, leading to better economic and social benefits.

The plastic rod extruding machine abbreviation extruder (also names extruding press),it is an important implemental of the plastic reclaiming process.The extruder is made of five parts:the part of extruding;the part of passing;the head;the system of heading and cooling;the electrical control system.

The major part of the extruder is the part extruding,it is the most use of shear ,rend and pinch the plastic,under afastness pressure,continuous send plastic to the head ,it made up of fill device ,screw,barrel,liner and so on,And the screw is disport of single screw;double screw;and multi-component screw.The material of liner is 38CrMoAlA.

The part of passing is driving the screw rotation and basic the need of the art factitious process to adjustment the screw royal .The part of passing is made of electrical engineering and reducer.

The head is the extruding machine formed part .Its function is:Causes the sizing material to become the translation by the helical motion ;under the certain pressure,extrudes the sizing materials which need the shape the half-finished product.

The system of heating and cooling is for the plastic well extrusion,we control the temperate to prevent the temperate too low or born.

The electrical control system is for the need of press,control the temperate of the barrel and the head ,the royal of the screw ,drive the torsion or power ,and adjustment the head ,the royal of the screw,driver the torsion or power,and adjustment the force of the axial ,is made of the temperate controller,the speed adjustment system,and the device of test.

The extruder`s fundamental process is this:get the plastic to the filler,under the shear of the screw ,the plastic was made small ball,because of the screw`s shear pressure and stirring,the plastic was futher rend and plastic,the temperate and the pressure get higher,and the plastic get plastic flow,under fastness pressure though the head,the last get the production you need.

Keyword: single-screw; extruder; the heatng cooling system; the transmiss-

ion system; electrical control system

目 录

第一章绪论 1

1.1 引言 1

1.2 国内外发展情况 1

1.3 单螺杆挤出机研究现状 1

1.4 课题研究意义和目的 2

1.5 课题主要研究内容 2

第二章挤出机总体方案的确定 3

2.1 挤出机总体布局的基本要求 3

2.2 挤出机的主要参数 3

2.2.1 挤出机的主要性能参数 3

2.2.2 螺杆转速 4

2.2.3 挤出机功率 4

2.2.4 轴向力 P 5

2.2.5 生产能力 Q 5

2.3 挤出机构设计 5

2.3.1 螺杆设计 5

2.3.2 螺槽深度和压缩比的确定 6

2.3.3 螺距和螺纹升角的确定 8

2.4 本章小结 9

第三章螺杆方案的确定 10

3.1 螺杆类型的确定 10

3.2 螺杆的工作性能指标评定 10

3.3 螺杆的选用原则 10

3.4 螺杆的分类 11

3.5 单螺杆挤出机及其基本操作 11

3.6 本章小结 12

第四章螺杆的设计与校核 14

4.1 螺杆材料 14

4.2 螺杆形式 14

4.3 螺杆参数 14

4.4 螺杆结构 14

4.5 螺纹的断面形状 15

4.6 校核 15

4.7 本章小结 16

第五章机筒的设计及强度校核 17

5.1 机筒的类型 17

5.2 机筒材料的选择 18

5.3 机筒参数 19

5.4 校核 19

5.5 本章小结 19

第六章其他零部件的设计与校核 20

6.1 螺杆与轴联接处的花键的选择与校核 20

6.2 推力轴承的选择与校核 20

6.3 联轴器的选择与校核 21

6.4 机头材料的选择 21

6.5 温度控制 21

6.6 电机的选择 21

6.7 本章小结 22

结 论 23

参考文献 24

致 谢 25