设计简介

摘要

炼胶设备是橡胶工业之中的通用的设备,在所有的橡胶制成品加工中都必须要经过炼胶加工工序。所以,炼胶设备在橡胶机械中最重要的设备之一。目前的炼胶设备里主要有开炼机、密炼机-间歇式生产,(目前通用),连续混炼挤出机-连续式生产,(橡胶方面正在研究之中,塑料方面已全部工业化)。在橡胶工业中,混炼车间是整个行业的核心,是橡胶工厂最重要的部门,也是能 源消耗大户,占全厂 40%,也是目前重点节能的部门或工序之一。它包括烘箱、切胶机、开炼机、密炼机及其辅机。近年来,国外橡胶工业有了迅速的发展,不仅在各个加工技术方面有相当的进步,而且设备方面有很大的发展,广泛地应用电子计算机管理和控制炼胶作业,大大地提高了炼胶系统地自动化水平,同时也引起了炼胶系统的变化。

多年来,国外对炼胶系统的技术改革实践证明:首先改革炼胶机及其装置,并使之现代化,以取得较高的劳动生产率、较高的效率和炼胶作业最佳化,才能真正实现炼胶系统技术创新。经过多年的改革,当代炼胶系统尤其是轮胎厂的炼胶系统已发展成自动化水平较高的工程系统。

开炼机是开放式炼胶机的简称,在橡塑工业中开炼机是使用历史颇为悠久的加工设备之一、其伴随着橡塑工业的产生而出现,伴随着橡塑工业的发展而逐渐发展。是橡塑工业中用来加工橡胶、塑料的最常用设备之一,也作为基本设备之一。据初步统计,当前我国每年生产开炼机的台数是 5000 台。每年也有一定数量的开炼机出口到东南亚等国家。

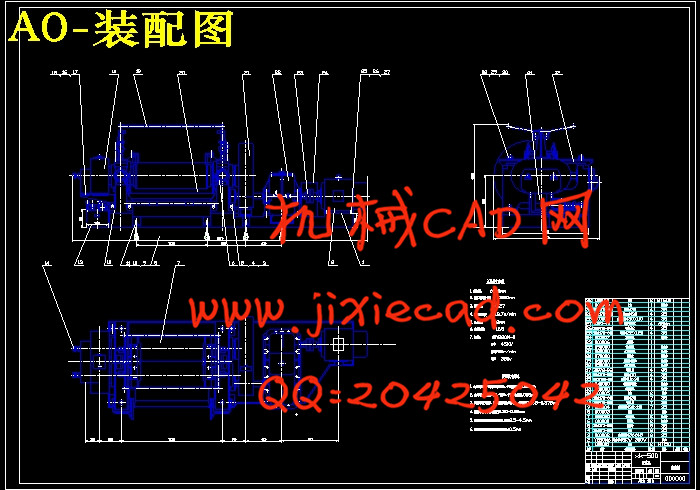

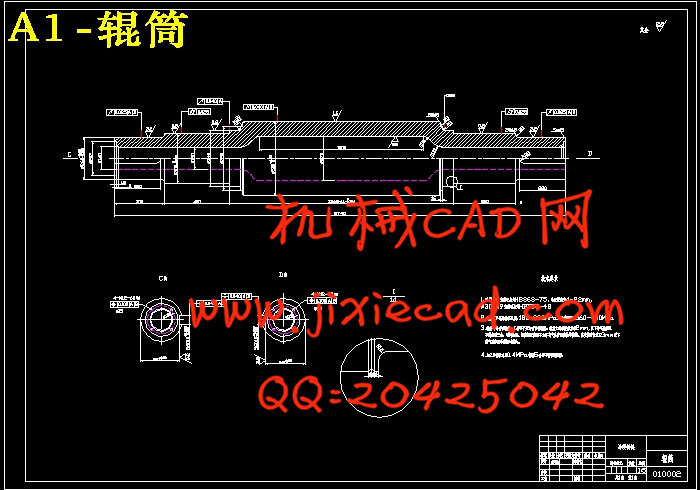

开炼机主要使用于对于天然橡胶的塑炼,配合剂和生胶的混炼。或者当作胶料的压片之用和胶料的热炼。开炼机构成由机座、机架、电动机、辊筒、辊温调节装置、传动齿轮、润滑装置、加热和冷却装置、安全制动装置和减速器等主要零件组成。开炼机辊筒使用冷硬铸铁制造而成,表面经过磨削形成的表面比较光滑。辊筒的内部是空心结构,根据开炼机使用要求,通入冷却水或者使用蒸汽进行冷却处理。

炼胶过程中为了调节辊筒的温度,可以通过进水管将水导入辊筒的内腔,溢流将会从辊筒某一端的喇叭孔进入溢流槽然后再排出去。为了使操作相对安全,在开炼机的上端安装了安全拉杆,在拉动拉杆之后,开炼机将自动切断电源,电磁抱闸从而可以自动停车。为了阻止胶料会从辊筒两端挤入辊筒,轴承部分一般会装有挡胶板。

关键词:机座;开炼机;辊筒;辊筒轴承;加热与冷却装置;安全制动装置;

Abstract

Mixing equipment is the rubber industry general equipment, in all rubber products processing must be to go through the mixing process. So, the most important in rubber machinery equipment in one of the mixing equipment. The mixing equipment mainly open smelting machine, dense mixer - batch production, (current), continuous mixing extruding machine - continuous production, (rubber under study, plastics have all been industrialized).In the rubber industry, mixing workshop is the core of the whole industry, is the most important department of rubber factory, is also a major energy consumption, accounting for 40% of the whole plant, is currently one of the key energy saving department or processes. It includes oven, rubber cutting machine, open mill, internal mixer and auxiliary. In recent years, foreign rubber industry has developed rapidly, not only in terms of the various processing technology has considerable progress and equipment have great development, widely application computer management and control the mixing operation, greatly improved the level of automation to mixing system, also caused the change of mixing system.

Over the years, foreign of compound system technical reform practice proof: first reform rubber mixing machine and its device, and the modernization, in order to obtain a higher labor productivity, higher efficiency and the mixing operation optimization, can we truly achieve the compound system of technological innovation. After years of reform, the contemporary compound system especially tire plant, rubber mixing system has developed into a higher level of automation engineering systems.

Open smelting machine is referred to as the open rubber mixing machine, in the rubber industry open smelting machine is one of use has a long history of processing equipment, accompanied by rubber and plastics industry emerged, along with the development of rubber industry and the gradual development. Is one of the most commonly used equipment for processing rubber and plastic rubber industry, as one of the basic equipment also. According to preliminary statistics, the number of China's current annual production of mills is 5000. Every year, there are a certain number of open refining machine exports to Southeast Asia and other countries.

Mixing machine is mainly used for natural rubber mixing, compounding agent and rubber mixing. Or used as a rubber sheet and a rubber compound. Open smelting machine composition comprising a machine base, a machine frame, a motor, a roller, a roller temperature adjusting device, a transmission gear, a lubricating device, heating and cooling device, safety braking device and reducer main parts. Mill roller using chilled cast iron manufacturing, surface after grinding formed relatively smooth. The interior is a hollow structure, according to the requirements of the mills, pass into the cooling water or steam cooling.

Refining process for adjusting the roller temperature, can be through the water inlet pipe to the inner cavity of the water into the bowl, the overflow will from one end of the roller horn hole into the overflow tank and then drain out. In order to make the operation is relatively safe, open smelting machine is installed on the upper end of the pull rod safety, after pulling, open smelting machine will automatically cut off the power, electromagnetic brake which can automatic parking. In order to prevent the rubber roller from both ends into the roller bearing part, usually with the glue.

Key words:Frame; Mill; Roller; Roller Bearings; Heating and Cooling Device; Safety Braking Device;

目 录

第一章 绪论 1

1.1 开炼机的工作原理 1

1.2 开炼机的结构形式 2

1.3 控制方式智能化 3

1.4 开炼机结构形式的历史发展与现状 4

第二章 主要参数的选取与计算 5

2.1 主要参数确定 5

2.2电动机和减速器的选择 5

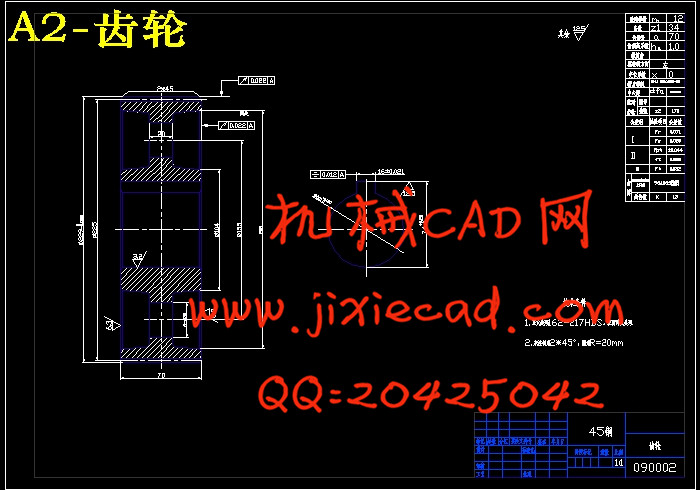

2.2.1速比齿轮的参数确定 6

2.2.2 强度校核 7

2.3 传动齿轮的设计计算 9

2.3.1 强度校核 9

第三章 主要零部件的设计 12

3.1 辊筒的设计 12

3.1.1 辊筒的主要结构 12

3.1.2 横压力计算 12

3.1.3 辊筒计算 14

3.1.4 辊筒与轴承间隙的确定 18

3.2 横梁和机架 19

3.2.1 机架的强度计算 19

3.2.2 压盖的强度计算 24

3.2.3 安全系数与许用应力 25

3.3 润滑系统 25

3.4 制动装置 25

第四章 调距装置 26

4.1 调距螺杆的计算 26

4.2 螺杆螺纹的自锁条件 27

4.3 螺母计算 27

第五章 辊温调节装置 31

5.1 辊筒冷却计算 31

5.2 实际冷却水消耗的确定 31

5.3 冷却水管进水管直径的计算 31

第六章 总结 33

参考文献 34

致谢 35