设计简介

摘要

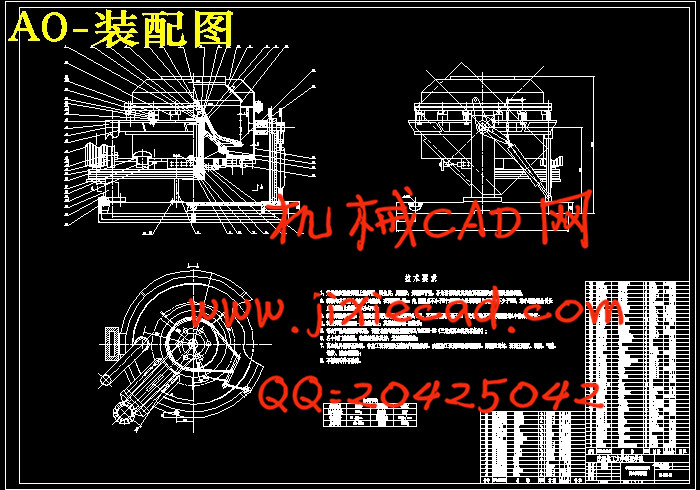

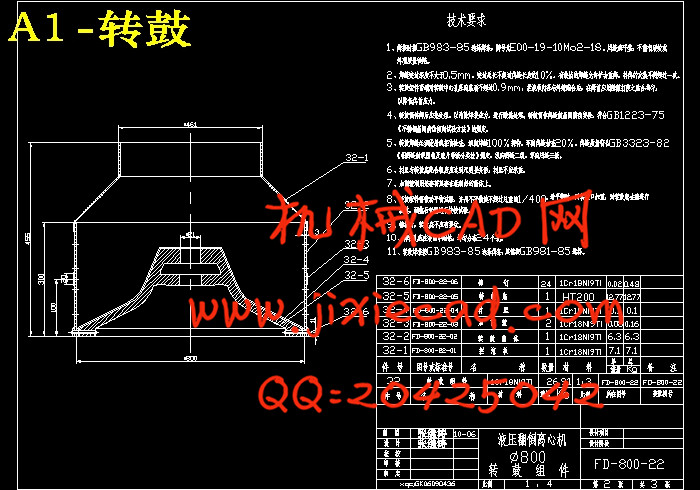

该设计题目是Φ800液压翻倒卸料离心机的设计。进行了转鼓强度计算与校核,转鼓壁的厚度计算,拦液板的计算,转鼓底的设计,功率计算和电动机的选择,所有回转件质量,质心及转动惯量计算,传动皮带的设计校核及选择,主轴的设计和强度校核,主轴的结构设计,受力分析以及主轴的临界转速计算,轴承的选择,翻到架的设计和强度计算,一些固定件的质量,质心计算,右轴的结构设计及键的校核,刹车的结构设计和强度计算,制动系统的选择,带式制动器的强度校核,翻倒传动部分的设计计算,液压缸的选择,液压缸壁厚计算,和其它的一些设计计算。

在设计中,首先要了解到离心机的工作原理:先由控制电路接通带动转鼓转动的电动机,通过皮带的传动使转鼓转动,转鼓转动使物料固液分离,液体通过离心机底部的排液管流出,固体留在转鼓壁上,然后再由控制电路接通翻倒电动机使离心机翻转倒出固体,这样就完成了分离的整个过程,这也是我们设计必须明白的。然后使了解离心机的各个零部件的构造和它们的材料工艺要求。最后对离心机进行整体的评定。

关键词: 离心机;转鼓壁;转鼓底;刹车

该设计题目是Φ800液压翻倒卸料离心机的设计。进行了转鼓强度计算与校核,转鼓壁的厚度计算,拦液板的计算,转鼓底的设计,功率计算和电动机的选择,所有回转件质量,质心及转动惯量计算,传动皮带的设计校核及选择,主轴的设计和强度校核,主轴的结构设计,受力分析以及主轴的临界转速计算,轴承的选择,翻到架的设计和强度计算,一些固定件的质量,质心计算,右轴的结构设计及键的校核,刹车的结构设计和强度计算,制动系统的选择,带式制动器的强度校核,翻倒传动部分的设计计算,液压缸的选择,液压缸壁厚计算,和其它的一些设计计算。

在设计中,首先要了解到离心机的工作原理:先由控制电路接通带动转鼓转动的电动机,通过皮带的传动使转鼓转动,转鼓转动使物料固液分离,液体通过离心机底部的排液管流出,固体留在转鼓壁上,然后再由控制电路接通翻倒电动机使离心机翻转倒出固体,这样就完成了分离的整个过程,这也是我们设计必须明白的。然后使了解离心机的各个零部件的构造和它们的材料工艺要求。最后对离心机进行整体的评定。

关键词: 离心机;转鼓壁;转鼓底;刹车

Abstract

The graduation project topic is φ 800 hydraulic tipping over of centrifuge design. For has turned drum strength calculation and check, turned drum wall of thickness calculation, stopped liquid Board of calculation, turned drum end of of design, power calculation and motor of select, all Rotary pieces quality, mass and the inertia calculation, drive belt of design check and the select, spindle of design and strength check, spindle of structure design, by force analysis and spindle of critical speed calculation, bearing of select, turned to frame of design and strength calculation, some fixed pieces of quality, mass calculation, right axis of structure design and the key of check, Structure design and strength calculation of the brake, and selection of brake system, brake strength, overturned part of the design, selection of hydraulic cylinder, hydraulic cylinder wall thickness calculation, and other design.

In design in the, first to understand to centrifugal machine of work principle: first by control circuit connected led turned drum turned of motor, through belt of drive makes turned drum turned, turned drum turned makes material solid liquid separation, liquid through centrifugal machine bottom of row liquid tube outflow, solid left in turned drum wall Shang, then again by control circuit connected overturned motor makes centrifugal machine flip pour out solid, such on completed has separation of whole process, this is we design must understand of. Then learn all parts of centrifuges construction materials and their processing requirements. Final overall evaluation of centrifuge.

Key words: Centrifuges; Drum wall; Brake

原始数据

转鼓直径: 800mm

工作转速: 1200r/min

物料密度: 1.05 10

10 kg/m

kg/m

启动时间: 60~120s

固液比 : 1:1

The graduation project topic is φ 800 hydraulic tipping over of centrifuge design. For has turned drum strength calculation and check, turned drum wall of thickness calculation, stopped liquid Board of calculation, turned drum end of of design, power calculation and motor of select, all Rotary pieces quality, mass and the inertia calculation, drive belt of design check and the select, spindle of design and strength check, spindle of structure design, by force analysis and spindle of critical speed calculation, bearing of select, turned to frame of design and strength calculation, some fixed pieces of quality, mass calculation, right axis of structure design and the key of check, Structure design and strength calculation of the brake, and selection of brake system, brake strength, overturned part of the design, selection of hydraulic cylinder, hydraulic cylinder wall thickness calculation, and other design.

In design in the, first to understand to centrifugal machine of work principle: first by control circuit connected led turned drum turned of motor, through belt of drive makes turned drum turned, turned drum turned makes material solid liquid separation, liquid through centrifugal machine bottom of row liquid tube outflow, solid left in turned drum wall Shang, then again by control circuit connected overturned motor makes centrifugal machine flip pour out solid, such on completed has separation of whole process, this is we design must understand of. Then learn all parts of centrifuges construction materials and their processing requirements. Final overall evaluation of centrifuge.

Key words: Centrifuges; Drum wall; Brake

原始数据

转鼓直径: 800mm

工作转速: 1200r/min

物料密度: 1.05

启动时间: 60~120s

固液比 : 1:1

目 录

第一章 绪论 1

1.1 离心机的应用及其发展 1

1.2 离心机的分类 2

1.3 离心沉降 3

1.3.1 离心沉降分离技术的基本原理 3

1.3.2 离心沉降分离机的种类 4

第二章 离心机转鼓的强度计算 6

2.1 转鼓强度计算与校核 6

第三章 功率计算 8

3.1 所有回转件质量、质心及转动惯量计算 8

3.2 功率的计算与电机的选择 10

第四章 皮带传动的设计与校核 13

4.1 皮带及皮带轮的设计计算 13

4.1.1 材料的选择 13

4.1.2 设计步骤 13

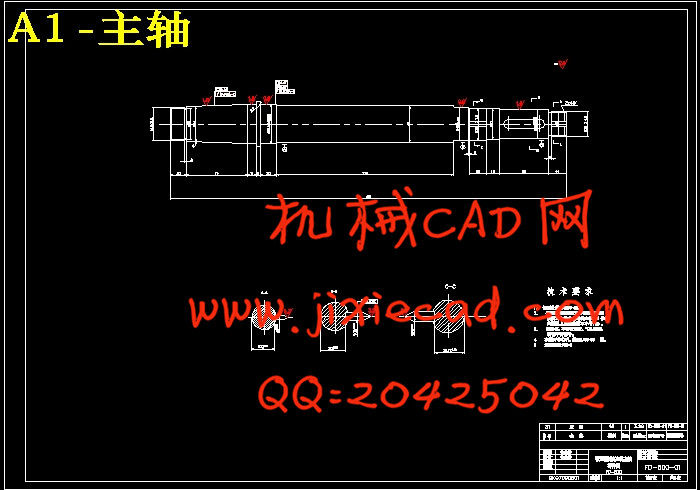

第五章 主轴的设计计算 16

5.1 主轴的结构设计 16

5.2 主轴的受力分析 16

5.3 轴承的选择、设计及寿命校核 18

5.4 主轴临界转速计算 20

第六章 翻倒架的设计计算 21

6.1 一些固定件的质量、质心计算 21

6.2 翻倒架的强度计算 23

6.3 右轴的结构设计与强度计算 24

6.4 键的校核 26

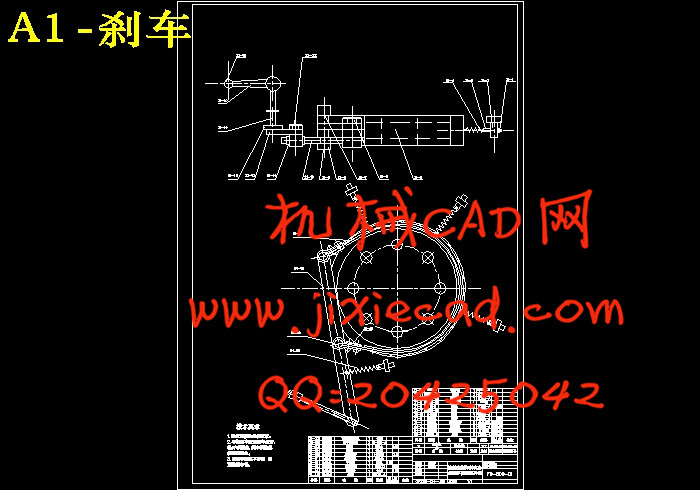

第七章 刹车的结构设计与强度计算 28

7.1 制动系统的选择 28

7.2 带式制动器的强度校核 28

第八章 翻倒传动部分的设计与计算 30

8.1 液压缸的选择 30

8.2 液压缸壁厚计算 30

结论与展望 33

参考文献 34

致谢 35