设计简介

针对液压阻尼器的特性,设计同时满足其静态性能和动态性能测试的试验台,要求最大输出动态力为200KN,频率范围0.01~33Hz。设计液压系统的原理图;选择液压元件,主要包括电动机、液压泵、伺服阀、比例阀、电磁换向阀、单向阀等;对系统进行性能验算。

目 录

绪论 1

第一章 液压振动试验台的现状和发展趋势分析 2

1.1 国外液压振动试验台的发展现状 2

1.2阻尼器性能检测方法 4

第二章 液压振动试验台的功能分析 7

1.1 液压振动试验台研制方案的提出 7

1.2 本文的主要研究内容 8

1.3 论文组织架构 9

1.4液压振动试验台的设计 9

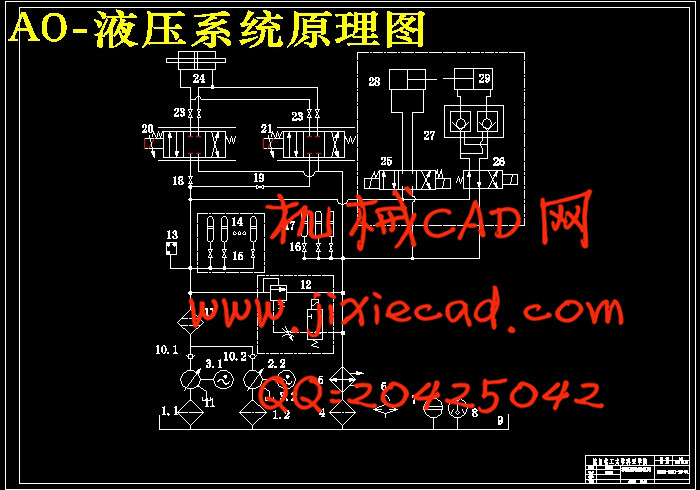

第三章 拟定动静态液压试验台的液压原理图 10

3.1 试验台架功能和组成 10

3.2 液压系统 10

3.3 效率问题 10

3.4 动静态试验问题 11

第四章 选择液压元件 13

4.1分类 15

4.2 用途 17

4.3分类功能 17

第五章 液压系统性能的验算 19

5.1 系统冲击问题 19

5.2 主机设计 20

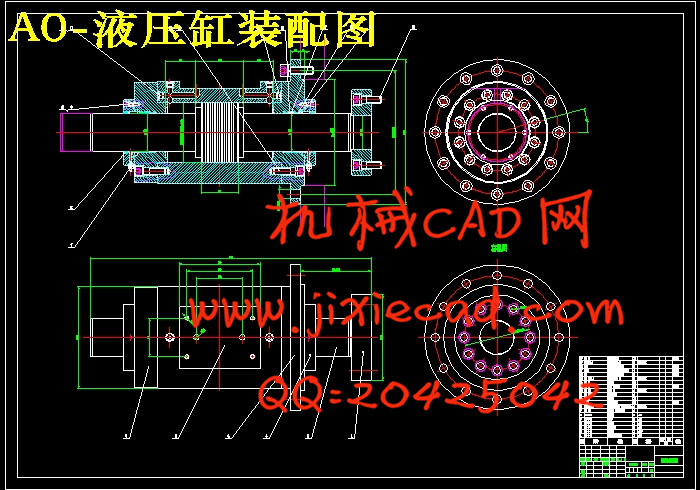

第六章 伺服液压缸机械部分设计 23

6.1 试验台的技术指标 23

6.2 供油压力的选择 23

6.3 机架的设计说明 27

总结 28

参考文献 29

致谢 30

摘要

阻尼器是一种能够吸收、衰减冲击与振动的控制装置,随着设计和制造技术的不断提高,其应用越来越广泛.鉴于阻尼器如此广泛的使用,且其对系统的安全性起着至关重要的作用,必须确保阻尼器具备合格的性能指标和制造质量。因此,研制阻尼器振动试验台对测试阻尼器性能,保证产品质量具有重要意义。

本文调研了阻尼器振动试验台的发展现状,在分析了各类振动试验台性能特点的基础上,提出使用液压振动试验台检测阻尼器的方法,并针对国内外液压振动试验台研究中存在的不足,研究开发了一套具备高精度、大载荷、宽频响等特点的百吨级液压振动试验台系统,并完成了系统具体设计。

对液压振动试验台的系统原理进行阐述,根据试验台的技术指标,对试验台 液压系统主要元件和试验台机架进行设计,并针对试验台设计中的技术难点进行 分析。

关键词:阻尼器;液压试验台;性能检测;伺服控制

阻尼器是一种能够吸收、衰减冲击与振动的控制装置,随着设计和制造技术的不断提高,其应用越来越广泛.鉴于阻尼器如此广泛的使用,且其对系统的安全性起着至关重要的作用,必须确保阻尼器具备合格的性能指标和制造质量。因此,研制阻尼器振动试验台对测试阻尼器性能,保证产品质量具有重要意义。

本文调研了阻尼器振动试验台的发展现状,在分析了各类振动试验台性能特点的基础上,提出使用液压振动试验台检测阻尼器的方法,并针对国内外液压振动试验台研究中存在的不足,研究开发了一套具备高精度、大载荷、宽频响等特点的百吨级液压振动试验台系统,并完成了系统具体设计。

对液压振动试验台的系统原理进行阐述,根据试验台的技术指标,对试验台 液压系统主要元件和试验台机架进行设计,并针对试验台设计中的技术难点进行 分析。

关键词:阻尼器;液压试验台;性能检测;伺服控制

Abstract

Damper as an absorption and attenuation of shock and vibration control device, as the design and manufacturing technology The continuous improvement of operation, its application is more and more widely. In view of the damper is so widely used, and the system Security plays an important role, must ensure that the damping apparatus for manufacturing quality and qualified performance indicators. Therefore, the development to test the tester damper vibration damper performance, ensure the quality of products is of great significance. In this paper, the research of vibration damper test bench development present situation, the analysis of the various characteristics of vibration table Based on the analysis of using hydraulic method to detect damper vibration test rig, and in view of the hydraulic vibration test at home and abroad Test platform of the insufficiency in research, the research developed a high precision, large load, bandwidth, etc The tonnage hydraulic vibration test system, and completed the system design. On the system principle of hydraulic vibration test bench, according to the technical index of the test bench, main components and hydraulic system on test bench test bed frame design, and in view of the technical difficulties in the design of test bed are analyzed. Based on the above research results, the tonnage hydraulic vibration damper test rig is developed, and in jiangsu electric power Run the installation for co., LTD The damper test showed that this paper developed test rig, Load control accurate, reliable test data, fully meet the needs of enterprises on the damper performance test.

Key words: damper; Hydraulic test bench; Performance testing; Servo control

Damper as an absorption and attenuation of shock and vibration control device, as the design and manufacturing technology The continuous improvement of operation, its application is more and more widely. In view of the damper is so widely used, and the system Security plays an important role, must ensure that the damping apparatus for manufacturing quality and qualified performance indicators. Therefore, the development to test the tester damper vibration damper performance, ensure the quality of products is of great significance. In this paper, the research of vibration damper test bench development present situation, the analysis of the various characteristics of vibration table Based on the analysis of using hydraulic method to detect damper vibration test rig, and in view of the hydraulic vibration test at home and abroad Test platform of the insufficiency in research, the research developed a high precision, large load, bandwidth, etc The tonnage hydraulic vibration test system, and completed the system design. On the system principle of hydraulic vibration test bench, according to the technical index of the test bench, main components and hydraulic system on test bench test bed frame design, and in view of the technical difficulties in the design of test bed are analyzed. Based on the above research results, the tonnage hydraulic vibration damper test rig is developed, and in jiangsu electric power Run the installation for co., LTD The damper test showed that this paper developed test rig, Load control accurate, reliable test data, fully meet the needs of enterprises on the damper performance test.

Key words: damper; Hydraulic test bench; Performance testing; Servo control

目 录

绪论 1

第一章 液压振动试验台的现状和发展趋势分析 2

1.1 国外液压振动试验台的发展现状 2

1.2阻尼器性能检测方法 4

第二章 液压振动试验台的功能分析 7

1.1 液压振动试验台研制方案的提出 7

1.2 本文的主要研究内容 8

1.3 论文组织架构 9

1.4液压振动试验台的设计 9

第三章 拟定动静态液压试验台的液压原理图 10

3.1 试验台架功能和组成 10

3.2 液压系统 10

3.3 效率问题 10

3.4 动静态试验问题 11

第四章 选择液压元件 13

4.1分类 15

4.2 用途 17

4.3分类功能 17

第五章 液压系统性能的验算 19

5.1 系统冲击问题 19

5.2 主机设计 20

第六章 伺服液压缸机械部分设计 23

6.1 试验台的技术指标 23

6.2 供油压力的选择 23

6.3 机架的设计说明 27

总结 28

参考文献 29

致谢 30