设计简介

摘要

从20世纪中叶机器人伺服滑台机械系统出现以来,机器人伺服滑台机械系统给机械制造业带来了革命性的变化。机器人伺服滑台机械系统具有如下特点:方便快捷的实现了产品的运输,提高了工作效率,减轻操作者劳动强度、改善劳动条件,有利于生产管理的现代化以及经济效益的提高。机器人伺服滑台机械系统是一种高度机电一体化的产品,适用于高效的运输产品的功能,能在短生产周期的急需零件的运送。

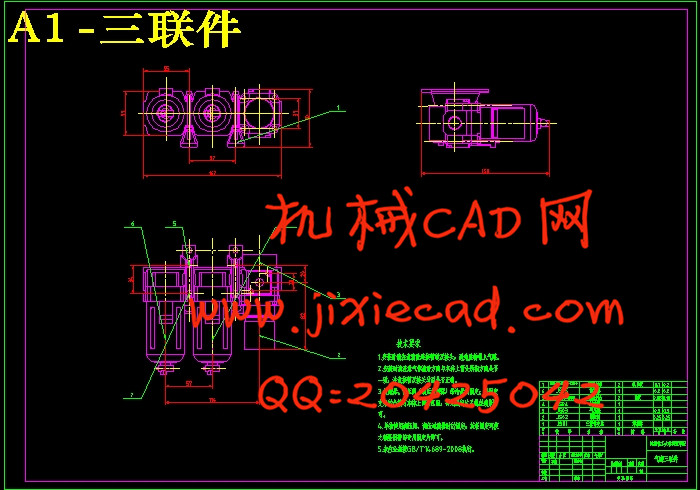

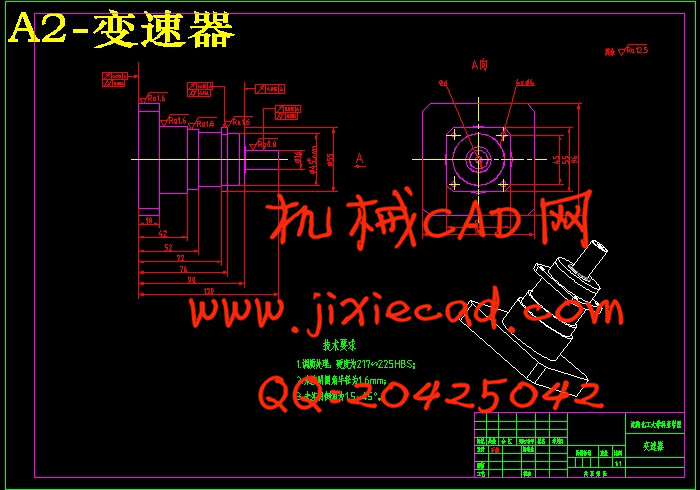

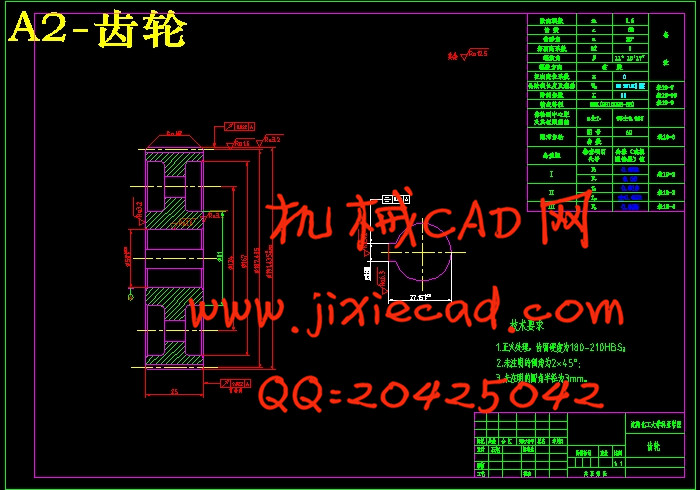

本文重点介绍了机器人伺服滑台的整体机构,对整个系统的动力结构进行了分析,主要是齿轮齿条的传动机构,首先对齿轮齿条进行了材料的选定,接着对齿轮进行了精度的选取,并对齿轮齿条的啮合进行了尺寸上的以及强度方面的校核,依据系统机构的要求设计出了相应的尺寸结构。还主要介绍的直线导轨结构,对直线导轨的特点进行了详细的说明,对直线到的寿命进行了分析,对其中的硬度系数,温度系数,负荷系数,接触系数并进行了相关的计算。接着利用solidworks对整个系统进行了建模分析,熟练地掌握了三维软件的相关操作,零件图的绘画,以及进行零件图的装配,最后对整个的装配体进行了渲染。

本设计对机器人伺服滑台机械系统的滑台部分进行了研究,利用机器人的优势,配合伺服电机,再加上直线导轨一,使得整个机构便于操作,运行方便,可以可靠地满足工业上的要求,保质保量的完成相关的工作。使得该设计显得相当的有效。另外,对车间的生产加工的效率得到了很大的提高。与此同时,对我国的现代工业具有极大的驱动作用。

关键词: 机器人; 伺服滑台; 机械系统;

从20世纪中叶机器人伺服滑台机械系统出现以来,机器人伺服滑台机械系统给机械制造业带来了革命性的变化。机器人伺服滑台机械系统具有如下特点:方便快捷的实现了产品的运输,提高了工作效率,减轻操作者劳动强度、改善劳动条件,有利于生产管理的现代化以及经济效益的提高。机器人伺服滑台机械系统是一种高度机电一体化的产品,适用于高效的运输产品的功能,能在短生产周期的急需零件的运送。

本文重点介绍了机器人伺服滑台的整体机构,对整个系统的动力结构进行了分析,主要是齿轮齿条的传动机构,首先对齿轮齿条进行了材料的选定,接着对齿轮进行了精度的选取,并对齿轮齿条的啮合进行了尺寸上的以及强度方面的校核,依据系统机构的要求设计出了相应的尺寸结构。还主要介绍的直线导轨结构,对直线导轨的特点进行了详细的说明,对直线到的寿命进行了分析,对其中的硬度系数,温度系数,负荷系数,接触系数并进行了相关的计算。接着利用solidworks对整个系统进行了建模分析,熟练地掌握了三维软件的相关操作,零件图的绘画,以及进行零件图的装配,最后对整个的装配体进行了渲染。

本设计对机器人伺服滑台机械系统的滑台部分进行了研究,利用机器人的优势,配合伺服电机,再加上直线导轨一,使得整个机构便于操作,运行方便,可以可靠地满足工业上的要求,保质保量的完成相关的工作。使得该设计显得相当的有效。另外,对车间的生产加工的效率得到了很大的提高。与此同时,对我国的现代工业具有极大的驱动作用。

关键词: 机器人; 伺服滑台; 机械系统;

Abstract

From the middle of the 20th century robot servo sliding table of mechanical system, the robot servo sliding table of mechanical system for mechanical manufacturing industry has brought the revolutionary change.Robot servo sliding table of mechanical system has the following characteristics: quick and easy to realize the transportation of products, improve the work efficiency, reduce the operator labor intensity, improve working conditions, conducive to the modernization of production management and improving economic benefit.Robot servo sliding table of mechanical system is a highly mechanical and electrical integration products, the function of the product is suitable for the efficient transport, can in a short production cycle need parts delivery.The characteristics of the robot servo sliding table of mechanical system and its application range makes it important equipment of the development of national economy and national defense construction.

This paper mainly introduces the robot servo sliding table overall organization, analyses the dynamic structure of the whole system, mainly is the gear rack transmission mechanism, the first gear and rack for the material selected, then to the selection of the precision of gear, and the meshing of gear and rack on the size and strength check, according to the requirements of system institutions designed the corresponding size structure.Also introduces the structure of linear guide, has carried on the detailed instructions to the characteristics of linear guide, to the life of a straight line to the analysis, the hardness of them coefficient, temperature coefficient, load factor and coefficient of contact and the relevant calculation.Then use solidworks modeling analysis, to the whole system skillfully mastered the related

operations of 3 d software, parts figure painting, detail drawing and assembly, and finally to the whole assembly of rendering.In the process, but also to the whole body parts to carry on the material selection, the coefficient of determination.And analyses the important first close parts, for the whole system have a more comprehensive understanding of the individual.

The design of the robot servo slider sliding table part of mechanical system are studied, for the whole sliding table Body part has carried on the detailed design, the use of the advantages of robots with servo motor, combined with a linear guide, make whole body is convenient for operation, the operation is convenient, can reliably meet the requirements of industry, the related work to be accomplished both in quality and quantity.Make the design appears quite effective.In addition, the efficiency of production and processing of workshop has been greatly improved.At the same time, the role of modern industry of our country has a great driver.

Key words: The robots; Servo sliding table; Mechanical systems

The design of the robot servo slider sliding table part of mechanical system are studied, for the whole sliding table Body part has carried on the detailed design, the use of the advantages of robots with servo motor, combined with a linear guide, make whole body is convenient for operation, the operation is convenient, can reliably meet the requirements of industry, the related work to be accomplished both in quality and quantity.Make the design appears quite effective.In addition, the efficiency of production and processing of workshop has been greatly improved.At the same time, the role of modern industry of our country has a great driver.

Key words: The robots; Servo sliding table; Mechanical systems

目 录

引言 1

第一章 机器人的发展背景 2

1.1国际机器人发展态势 2

1.2我国机器人发展现状 3

1.3我国发展机器人技术与产业的对策建议 4

第二章 机器人伺服滑台机械系统设计 7

2.1机器人伺服滑台机械系统设计的关键参数 7

2.2机器人伺服滑台传动工作原理 7

2.3电机的选择 7

第三章 齿轮齿条传动设计 9

3.1 选取齿轮的材料、热处理及精度 9

3.2 初步设计齿轮传动的主要尺寸 9

3.3 按照齿根弯曲强度设计齿轮主要尺寸 12

3.4 几何尺寸计算 13

3.5 齿轮结构设计 14

第四章 直线滚动导轨的特点及选用 16

4.1直线滚动导轨的特点 16

4.2 直线滚动导轨的寿命 17

第五章 基于solidworks软件进行的建模及装配 21

5.1 solidworks软件建模与装配概述 21

5.2 运用SolidWorks软件进行零件设计 21

5.3运用SolidWorks软件进行零件装配 24

结论 26

参考文献 27

致谢 28

附 录 29