设计简介

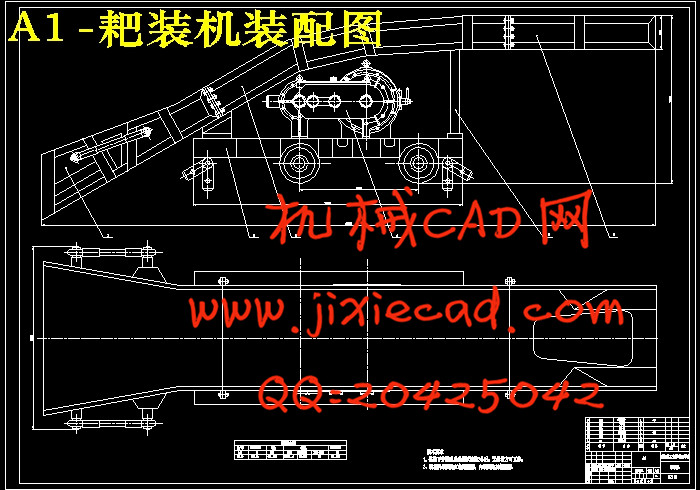

通过查阅资料及调研,要求设计一个耙斗装岩机传动部分设计。生产率为60m³/h。牵引力为20KN。耙斗容积为0.6m³。所选电动机线数度为0.97m/s。一般制造条件。

摘 要

采矿工业,是生产资源中的基础性工业,在国民经济中具有重要位置,我国的矿产资源储量可观,种类丰富,以煤炭资源最为突出,随着中国特色社会主义建设的发展和社会主义市场经济的一步步深化,我国的能源消耗比例正进一步向更加理想化的方向发展,但是煤炭资源仍就是以后一段时间内的主要能源物质。

对于金属矿山开采,可以分为露天开采和地下开采两类。我国露天开采采出的矿石比重约为 ,但是从事地下开采的人员远比露天开采的人员多。主要是因为地下开采的条件复杂,使用的设备种类繁多,在产量相同的情况下,对地下矿投资的人力和物力远大于露天矿。

,但是从事地下开采的人员远比露天开采的人员多。主要是因为地下开采的条件复杂,使用的设备种类繁多,在产量相同的情况下,对地下矿投资的人力和物力远大于露天矿。

保护自然环境,合理利用和开采矿产资源,是发展社会主义经济中的必要条件。随着浅埋矿床的耗尽,而越来越向深部开发,或当露天开采的深度很大而让地表遭受大面积的破坏的时候,就必须改用地下开采。

不论是露天矿开采还是地下矿开采,对矿体和围岩的金属矿山,都是经凿岩爆破将崩落的松散矿石或岩石,经装运作业运至下步工序的作业地点。装载作业式矿山,整个生产过程,既繁重又费时的作业。所以努力提高装载机械的作业能力,对实现矿山生产的高效率低消耗起着重要作用。

由于装载作业的工作环境条件恶劣,机器的有效利用程度较低,任务量繁重,生产率不高,还有很大一部分的繁重人工劳动,所以,20世纪初,美,英等国开始使用装载机械替代手工作业。50年代,装载机已大量的推广,并发展成若干品种与型号,其中使用最多的是后卸式装载机,扒爪装载机。70年代后,随着巷道断面的增大,侧卸式装载机快速发展。国外发展的比较早,种类也很多,大概有17种基本类型,近5000多型号及规格。现在广泛被使用的有15种,大致有蟹爪式、铲斗式、耙斗式、星轮式、滚筒式等等。近年来大都集中在发展铲斗后卸式、耙斗式、侧卸式及星轮式。

中国50年代初使用后卸式装载机和扒爪装载机,于60年代研制耙斗装载机,70年代研制成功侧卸式装载机与凿岩台车配套使用。装载机械的发展与掘进断面的大小以及被装物料的特性密切相关。随着掘进断面的增大,在大断面巷道中多采用侧卸式铲斗装载机,且向大功率,大容量的方向发展。对用于中小断面掘进的装载机,则着眼于提高其机械性能和工作可靠性,并使其更方便灵活。此外,正探索装载机械向一机多能方面发展,如在装载机上增加钻臂等,铲斗臂上增设可卸载的工作平台。解决煤矿的机械化程度低是首要问题,但在煤矿施工中最重要、最核心的是安全。现在的煤矿作业的特点是多工种,战线长,多电作业,没有保护措施是不行的,未来的煤矿机械应具有便于维护操作,高可靠性的特点。

耙斗装载机,属于矿井巷道掘进的装岩设备,是耙装机和转载机“合二为一”的机型,可称之为转载式耙斗装岩机。在巷道掘进中,作为装载设备的装岩机有多种,主要有耙斗式、铲斗式装岩机两种。耙斗装载机是一种利用绞车牵引耙斗把岩石装入矿车的机械设备。

关键词: 耙斗装岩机;绞车设计; 滚筒;行星齿轮

Abstract

Mining industry is the basic industry of the production resources, occupies an important position in the national economy, the rich variety of China's mineral resources, substantial reserves, to the most outstanding coal resources, with the construction of socialism with Chinese characteristics and development of the socialist market economy deepen step by step, China's energy consumption proportion is further to the more perfect the direction of development, but the coal resources in the later period of time is still the main energy.

Metal mining, can be divided into two types of open-pit mining and underground mining. China's open pit mined ore proportion is about, but engaged in underground mining personnel than open-pit mining personnel. Mainly because of underground mining condition is complex, the use of variety of the equipment, in the production of the same, of underground mining investment of manpower and material is much greater than in open pit mine.

To protect the natural environment, the rational utilization of mineral resources, is a necessary condition for the development of the socialist economy. With the depletion of shallow deposits, and more and more to the deep development, or when the open-pit mining depth and large surface to a large area of damage, you must switch to underground mining.

Both open-pit and underground mining, to the ore body and surrounding rock of metal mines are by drilling and blasting the caving of loose ore and rock, the loading operation of transport to the job site next working procedure. Work is arduous and time-consuming loading operation type mines in the whole production process. To improve the work ability of mechanical loading, it plays an important role in the realization of low consumption high efficiency of mine production.

Due to loading working conditions bad, machine effective utilization rate is low, heavy workload, the productivity is not high and a large part of the heavy manual labor, so at the beginning of the 20th century, beauty, Britain and other countries began using the loading machinery instead of manual operation. In 50, the loader has been extended and developed into several varieties, which is the most used loader and jaw loader. After 70 years, with the increase of cross section, the side loader rapid development. The foreign development early, there are many types, there are about 17 basic types, more than 5000 models and specifications. Now there are 15 most widely used forms, generally have a crab claw type scraper bucket type bucket type, drum type, star wheel and so on. In recent years, mostly concentrated in the development after unloading, the bucket scraper type, side dump and star wheel.

China in the early 1950s, after use dump loaders and grilled claw loaders, 60 years development and rake bucket loading machine and in the 1970s developed successful side dump loader and jumbo supporting the use of. The size and characteristics of the development of mechanical and material loading is closely related to the excavation section. With increase of the excavated section, in Roadway with large cross section in the side dump bucket loader and to high power and large capacity. For the small and medium section of the loader loader, it is aimed at improving the mechanical performance and reliability of the work, and make it more convenient and flexible. In addition, is exploring loading machine to a machine to development, such as loaders to increase drilling arm, arm and bucket additional unloading platform. Improve the degree of mechanization of coal mine is the primary problem, but in coal mine construction, the most important is safe, but now coal mine operational characteristics is multi-disciplinary, long front, the more electric operation, there is no protection is not, the future of coal mine machinery should has the advantages of convenient operation and maintenance, and high reliability.

Rake bucket loading machine, which belongs to the mine roadway excavation of rock loading equipment is rake loading machines and reproduced the "combined" models, and can be referred for conveyor scraper bucket to pack the rock machine. In tunneling, as rock loading machine loading equipment has a variety of main cent scraper type bucket type pack rock machine two. The scraper bucket loader is a winch traction scraper bucket to pack the rock into mine machinery.

Key words: Rake Bucket Loader; Winch Design; Roller; Planetary Gear

目 录

引言 ......................................................1

第一章 方案论证 ...........................................2

1.1 耙斗装岩机的结构及工作原理 ............................2

1.2 耙斗装岩机主要部件结构.................................3

1.2.1 耙斗.............................................. 3

1.2.2 主轴部件 ..........................................5

1.2.3 带式制动闸 ........................................6

1.2.4 辅助闸 ............................................7

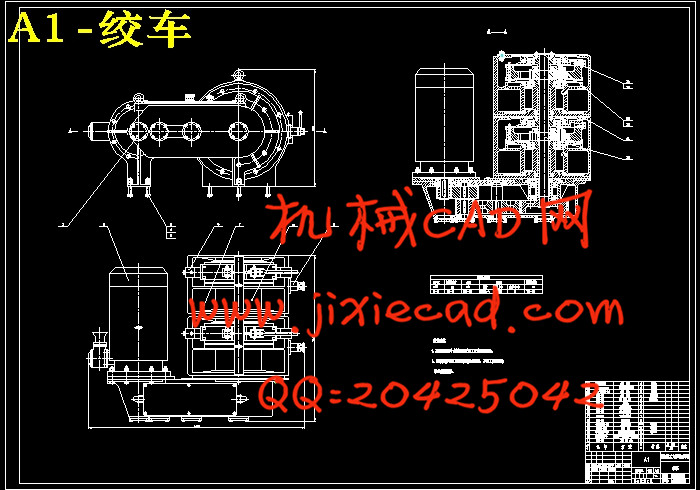

1.2.5 传动系统 ..........................................8

1.3 牵引钢丝绳 ...........................................11

第二章 耙斗装岩机主要部件设计及选择.......................13

2.1 总体设计方案选择 .....................................13

2.2 电动机选型 ...........................................13

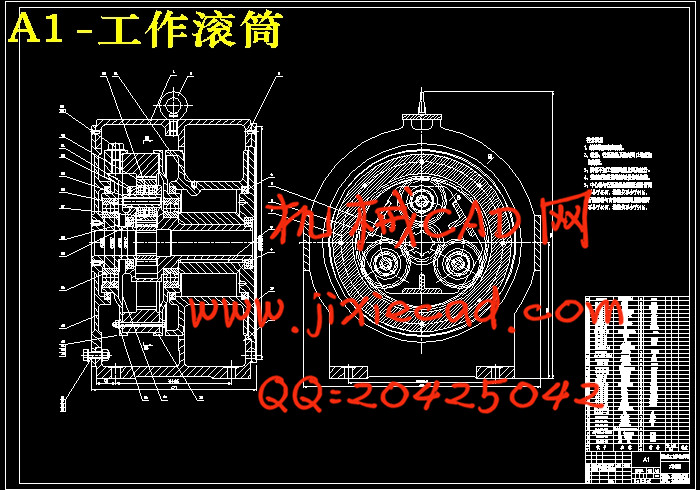

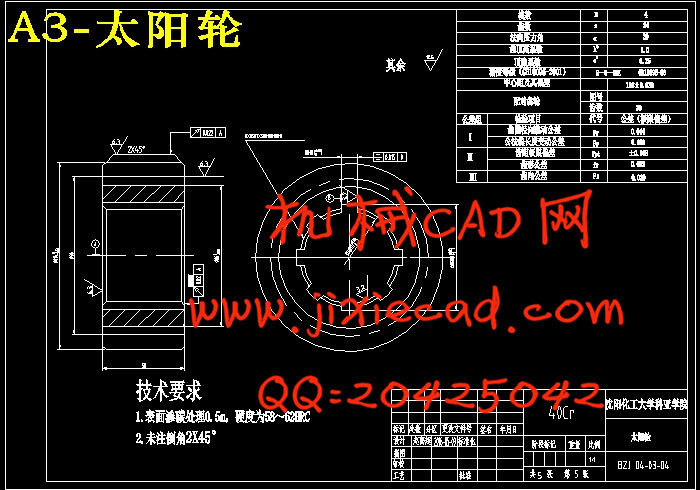

2.3 工作滚筒中行星齿轮传动部分设计计算 ...................14

2.3.1 设计绘制工作滚筒的装配草图 .......................14

2.3.2 确定行星减速器各构件转速 .........................15

2.3.3 确定减速器的效率和各轴上的扭矩 ...................16

2.3.4 齿轮强度计算 .....................................16

2.3.5 传动的几何尺寸计算 ...............................19

2.3.6 啮合力计算 .......................................20

2.3.7 行星齿轮传动的主要零件设计 .......................20

2.3.8 选择轴承 .........................................22

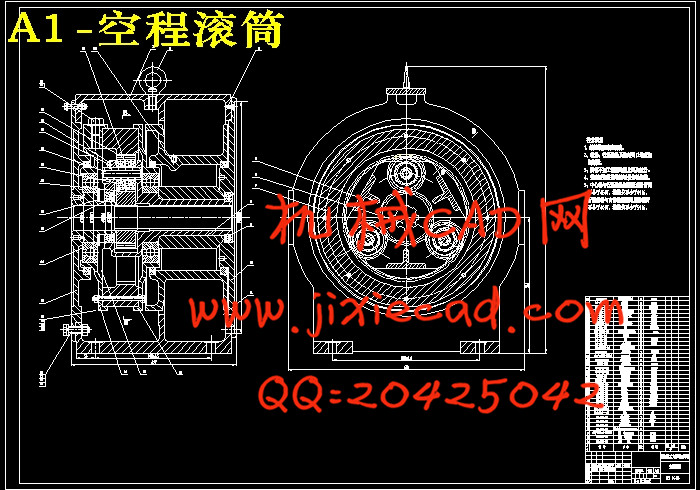

2.4 空程滚筒中行星齿轮传动部分设计计算 ...................23

2.4.1 设计、绘制空程滚筒的装配草图 .....................23

2.4.2 确定行星减速器各构件转速 .........................24

2.4.3 确定减速器的效率和各轴上的扭矩 ...................25

2.4.4 齿轮强度计算 .....................................26

2.4.5 传动的几何尺寸计算 ...............................38

2.4.6 啮合力计算 .......................................29

2.4.7 行星齿轮传动的主要零件设计 .......................29

2.4.8 选择轴承 .........................................31

2.5 台车及操作机构设计 ...................................32

2.6 料槽设计 .............................................33

2.7 辅助设备介绍 .........................................36

2.7.1 固定装置 .........................................36

2.7.2 导向轮 ...........................................38

2.7.3 撑脚 .............................................40

第三章 耙装机的操作和维护 ................................41

3.1 耙装机的操作 .........................................41

3.1.1 尾轮的悬挂 .......................................41

3.2 耙装机的位置及移动 ...................................42

结 论 ...................................................43

参考文献 .................................................45

致 谢 ...................................................45

摘 要

采矿工业,是生产资源中的基础性工业,在国民经济中具有重要位置,我国的矿产资源储量可观,种类丰富,以煤炭资源最为突出,随着中国特色社会主义建设的发展和社会主义市场经济的一步步深化,我国的能源消耗比例正进一步向更加理想化的方向发展,但是煤炭资源仍就是以后一段时间内的主要能源物质。

对于金属矿山开采,可以分为露天开采和地下开采两类。我国露天开采采出的矿石比重约为

保护自然环境,合理利用和开采矿产资源,是发展社会主义经济中的必要条件。随着浅埋矿床的耗尽,而越来越向深部开发,或当露天开采的深度很大而让地表遭受大面积的破坏的时候,就必须改用地下开采。

不论是露天矿开采还是地下矿开采,对矿体和围岩的金属矿山,都是经凿岩爆破将崩落的松散矿石或岩石,经装运作业运至下步工序的作业地点。装载作业式矿山,整个生产过程,既繁重又费时的作业。所以努力提高装载机械的作业能力,对实现矿山生产的高效率低消耗起着重要作用。

由于装载作业的工作环境条件恶劣,机器的有效利用程度较低,任务量繁重,生产率不高,还有很大一部分的繁重人工劳动,所以,20世纪初,美,英等国开始使用装载机械替代手工作业。50年代,装载机已大量的推广,并发展成若干品种与型号,其中使用最多的是后卸式装载机,扒爪装载机。70年代后,随着巷道断面的增大,侧卸式装载机快速发展。国外发展的比较早,种类也很多,大概有17种基本类型,近5000多型号及规格。现在广泛被使用的有15种,大致有蟹爪式、铲斗式、耙斗式、星轮式、滚筒式等等。近年来大都集中在发展铲斗后卸式、耙斗式、侧卸式及星轮式。

中国50年代初使用后卸式装载机和扒爪装载机,于60年代研制耙斗装载机,70年代研制成功侧卸式装载机与凿岩台车配套使用。装载机械的发展与掘进断面的大小以及被装物料的特性密切相关。随着掘进断面的增大,在大断面巷道中多采用侧卸式铲斗装载机,且向大功率,大容量的方向发展。对用于中小断面掘进的装载机,则着眼于提高其机械性能和工作可靠性,并使其更方便灵活。此外,正探索装载机械向一机多能方面发展,如在装载机上增加钻臂等,铲斗臂上增设可卸载的工作平台。解决煤矿的机械化程度低是首要问题,但在煤矿施工中最重要、最核心的是安全。现在的煤矿作业的特点是多工种,战线长,多电作业,没有保护措施是不行的,未来的煤矿机械应具有便于维护操作,高可靠性的特点。

耙斗装载机,属于矿井巷道掘进的装岩设备,是耙装机和转载机“合二为一”的机型,可称之为转载式耙斗装岩机。在巷道掘进中,作为装载设备的装岩机有多种,主要有耙斗式、铲斗式装岩机两种。耙斗装载机是一种利用绞车牵引耙斗把岩石装入矿车的机械设备。

关键词: 耙斗装岩机;绞车设计; 滚筒;行星齿轮

Abstract

Mining industry is the basic industry of the production resources, occupies an important position in the national economy, the rich variety of China's mineral resources, substantial reserves, to the most outstanding coal resources, with the construction of socialism with Chinese characteristics and development of the socialist market economy deepen step by step, China's energy consumption proportion is further to the more perfect the direction of development, but the coal resources in the later period of time is still the main energy.

Metal mining, can be divided into two types of open-pit mining and underground mining. China's open pit mined ore proportion is about, but engaged in underground mining personnel than open-pit mining personnel. Mainly because of underground mining condition is complex, the use of variety of the equipment, in the production of the same, of underground mining investment of manpower and material is much greater than in open pit mine.

To protect the natural environment, the rational utilization of mineral resources, is a necessary condition for the development of the socialist economy. With the depletion of shallow deposits, and more and more to the deep development, or when the open-pit mining depth and large surface to a large area of damage, you must switch to underground mining.

Both open-pit and underground mining, to the ore body and surrounding rock of metal mines are by drilling and blasting the caving of loose ore and rock, the loading operation of transport to the job site next working procedure. Work is arduous and time-consuming loading operation type mines in the whole production process. To improve the work ability of mechanical loading, it plays an important role in the realization of low consumption high efficiency of mine production.

Due to loading working conditions bad, machine effective utilization rate is low, heavy workload, the productivity is not high and a large part of the heavy manual labor, so at the beginning of the 20th century, beauty, Britain and other countries began using the loading machinery instead of manual operation. In 50, the loader has been extended and developed into several varieties, which is the most used loader and jaw loader. After 70 years, with the increase of cross section, the side loader rapid development. The foreign development early, there are many types, there are about 17 basic types, more than 5000 models and specifications. Now there are 15 most widely used forms, generally have a crab claw type scraper bucket type bucket type, drum type, star wheel and so on. In recent years, mostly concentrated in the development after unloading, the bucket scraper type, side dump and star wheel.

China in the early 1950s, after use dump loaders and grilled claw loaders, 60 years development and rake bucket loading machine and in the 1970s developed successful side dump loader and jumbo supporting the use of. The size and characteristics of the development of mechanical and material loading is closely related to the excavation section. With increase of the excavated section, in Roadway with large cross section in the side dump bucket loader and to high power and large capacity. For the small and medium section of the loader loader, it is aimed at improving the mechanical performance and reliability of the work, and make it more convenient and flexible. In addition, is exploring loading machine to a machine to development, such as loaders to increase drilling arm, arm and bucket additional unloading platform. Improve the degree of mechanization of coal mine is the primary problem, but in coal mine construction, the most important is safe, but now coal mine operational characteristics is multi-disciplinary, long front, the more electric operation, there is no protection is not, the future of coal mine machinery should has the advantages of convenient operation and maintenance, and high reliability.

Rake bucket loading machine, which belongs to the mine roadway excavation of rock loading equipment is rake loading machines and reproduced the "combined" models, and can be referred for conveyor scraper bucket to pack the rock machine. In tunneling, as rock loading machine loading equipment has a variety of main cent scraper type bucket type pack rock machine two. The scraper bucket loader is a winch traction scraper bucket to pack the rock into mine machinery.

Key words: Rake Bucket Loader; Winch Design; Roller; Planetary Gear

目 录

引言 ......................................................1

第一章 方案论证 ...........................................2

1.1 耙斗装岩机的结构及工作原理 ............................2

1.2 耙斗装岩机主要部件结构.................................3

1.2.1 耙斗.............................................. 3

1.2.2 主轴部件 ..........................................5

1.2.3 带式制动闸 ........................................6

1.2.4 辅助闸 ............................................7

1.2.5 传动系统 ..........................................8

1.3 牵引钢丝绳 ...........................................11

第二章 耙斗装岩机主要部件设计及选择.......................13

2.1 总体设计方案选择 .....................................13

2.2 电动机选型 ...........................................13

2.3 工作滚筒中行星齿轮传动部分设计计算 ...................14

2.3.1 设计绘制工作滚筒的装配草图 .......................14

2.3.2 确定行星减速器各构件转速 .........................15

2.3.3 确定减速器的效率和各轴上的扭矩 ...................16

2.3.4 齿轮强度计算 .....................................16

2.3.5 传动的几何尺寸计算 ...............................19

2.3.6 啮合力计算 .......................................20

2.3.7 行星齿轮传动的主要零件设计 .......................20

2.3.8 选择轴承 .........................................22

2.4 空程滚筒中行星齿轮传动部分设计计算 ...................23

2.4.1 设计、绘制空程滚筒的装配草图 .....................23

2.4.2 确定行星减速器各构件转速 .........................24

2.4.3 确定减速器的效率和各轴上的扭矩 ...................25

2.4.4 齿轮强度计算 .....................................26

2.4.5 传动的几何尺寸计算 ...............................38

2.4.6 啮合力计算 .......................................29

2.4.7 行星齿轮传动的主要零件设计 .......................29

2.4.8 选择轴承 .........................................31

2.5 台车及操作机构设计 ...................................32

2.6 料槽设计 .............................................33

2.7 辅助设备介绍 .........................................36

2.7.1 固定装置 .........................................36

2.7.2 导向轮 ...........................................38

2.7.3 撑脚 .............................................40

第三章 耙装机的操作和维护 ................................41

3.1 耙装机的操作 .........................................41

3.1.1 尾轮的悬挂 .......................................41

3.2 耙装机的位置及移动 ...................................42

结 论 ...................................................43

参考文献 .................................................45

致 谢 ...................................................45