设计简介

工程陶瓷材料珩磨加工珩磨头的设计

摘 要

本设计是对珩磨头的结构设计,首先通过相关资料的查询认识了解珩磨机的工作原理,清楚其结构组成;然后重点观察现有珩磨头的结构,对特定型号的珩磨机掌握其运动参数的选择原则、油石个数的选择及分布原理、涨锥的设计技术要求以及进给机构的运动装置等;最后了解现有珩磨头结构的缺点,确定对大孔加工所用珩磨头的总体方案。

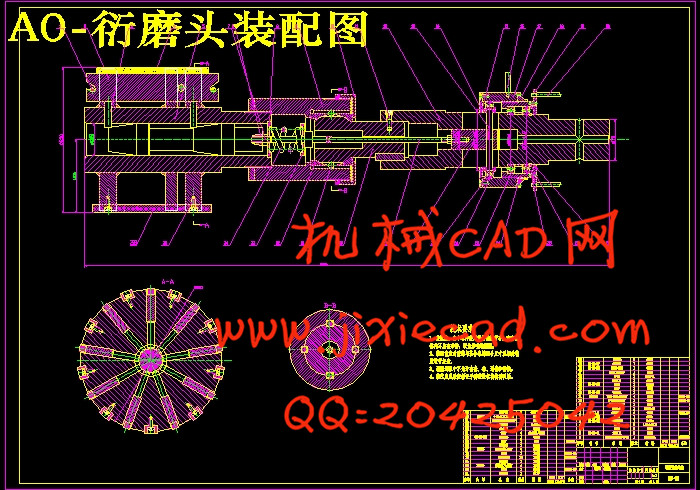

其次利用设珩磨头结构的设计原理对各个具体零件进行详细的设计,然后对个别零件进行校核,使设计出的结构可确保磨削可靠运行,在此基础上完成了本毕业论文的写作。最后绘制整套的装珩磨头结构的装配图和零件图。

通过对本课题珩磨头的结构设计,使书本知识和理论与实际生产相结合,加强了对机械零件、机械制造工艺学以及现代磨削技术等相关专业知识的理解,使自己能运用书本知识设计出基本符合生产要求的零部件。在论文中我充分地运用了大学期间所学到的知识。进行了研究,巩固和深化,达到了预期的设计意图。

关键词:珩磨头;涨锥;进给机构;油石;

THE STRUCTURE DESIGN OF THE HEAD OF A MACHINE HONING

ABSTRACT

This design is the structure design of head honing,first, through internships understanding the working principle of honing, clear machine and its structure is composed; Then the key observe the structure of the existing honing,and master the models of the motion parameters selection for head of honing machines principle in particular, the selection and oil-stone number distribution principle, the design technology requirements up cone and the movement to institutions into devices; Finally understand the shortcomings of existing honing , determine the head of structure of large hole processing the overall scheme of honing head used.

Secondly using the design principle of the head detailed design each structure of specific parts. Then, checking the individual parts of designed structure can ensure grinding reliable operation. Based on this completed this graduation thesis writing. Finally draw full sets of outfit honing the head structure of spare parts and assembly drawing.

Through this project structure design of honing head, make text-book knowledge and theory combining with practical production, Strengthening the understanding of the mechanical parts, mechanical manufacturing technology and modern grinding technology and related professional knowledge understanding. Make me to use the book knowledge designed with production requirements of the basic components Make me to use the book knowledge to design the basic components with production requirements. In the paper, I fully using university period the knowledge I have learned,then Studied, strengthening and deepening, to achieve the expected design intent.

KEY WORDS: Honing head; feeding institutions; Rise cone; oil-ston;

目录摘 要

本设计是对珩磨头的结构设计,首先通过相关资料的查询认识了解珩磨机的工作原理,清楚其结构组成;然后重点观察现有珩磨头的结构,对特定型号的珩磨机掌握其运动参数的选择原则、油石个数的选择及分布原理、涨锥的设计技术要求以及进给机构的运动装置等;最后了解现有珩磨头结构的缺点,确定对大孔加工所用珩磨头的总体方案。

其次利用设珩磨头结构的设计原理对各个具体零件进行详细的设计,然后对个别零件进行校核,使设计出的结构可确保磨削可靠运行,在此基础上完成了本毕业论文的写作。最后绘制整套的装珩磨头结构的装配图和零件图。

通过对本课题珩磨头的结构设计,使书本知识和理论与实际生产相结合,加强了对机械零件、机械制造工艺学以及现代磨削技术等相关专业知识的理解,使自己能运用书本知识设计出基本符合生产要求的零部件。在论文中我充分地运用了大学期间所学到的知识。进行了研究,巩固和深化,达到了预期的设计意图。

关键词:珩磨头;涨锥;进给机构;油石;

THE STRUCTURE DESIGN OF THE HEAD OF A MACHINE HONING

ABSTRACT

This design is the structure design of head honing,first, through internships understanding the working principle of honing, clear machine and its structure is composed; Then the key observe the structure of the existing honing,and master the models of the motion parameters selection for head of honing machines principle in particular, the selection and oil-stone number distribution principle, the design technology requirements up cone and the movement to institutions into devices; Finally understand the shortcomings of existing honing , determine the head of structure of large hole processing the overall scheme of honing head used.

Secondly using the design principle of the head detailed design each structure of specific parts. Then, checking the individual parts of designed structure can ensure grinding reliable operation. Based on this completed this graduation thesis writing. Finally draw full sets of outfit honing the head structure of spare parts and assembly drawing.

Through this project structure design of honing head, make text-book knowledge and theory combining with practical production, Strengthening the understanding of the mechanical parts, mechanical manufacturing technology and modern grinding technology and related professional knowledge understanding. Make me to use the book knowledge designed with production requirements of the basic components Make me to use the book knowledge to design the basic components with production requirements. In the paper, I fully using university period the knowledge I have learned,then Studied, strengthening and deepening, to achieve the expected design intent.

KEY WORDS: Honing head; feeding institutions; Rise cone; oil-ston;

前言 I

1 课题研究的目的及意义 I

2 国内外研究状况 I

3 课题研究基本设计思路和研究手段 II

第一章 精整加工技术 1

1.1 精整加工的范畴和特点 1

1.2 精整加工机理 1

第二章 普通珩磨 3

2.1 珩磨加工原理 3

2.2 珩磨加工的特点 6

2.3 珩磨的切削过程 7

2.4 珩磨头的结构形式 8

第三章 珩磨头结构的设计 13

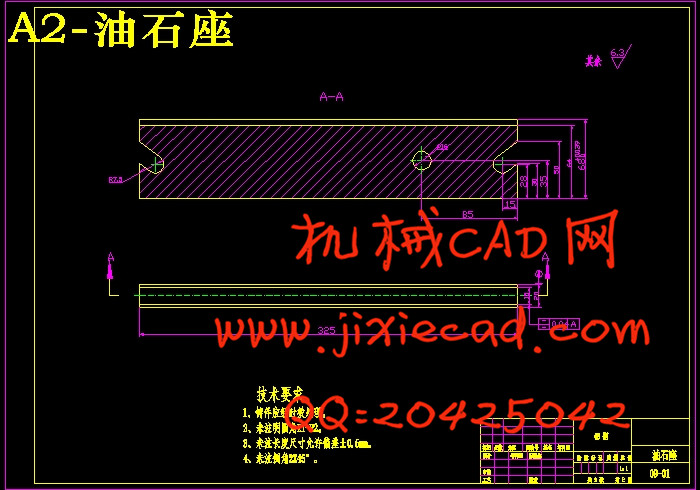

3.1 珩磨油石的选择 13

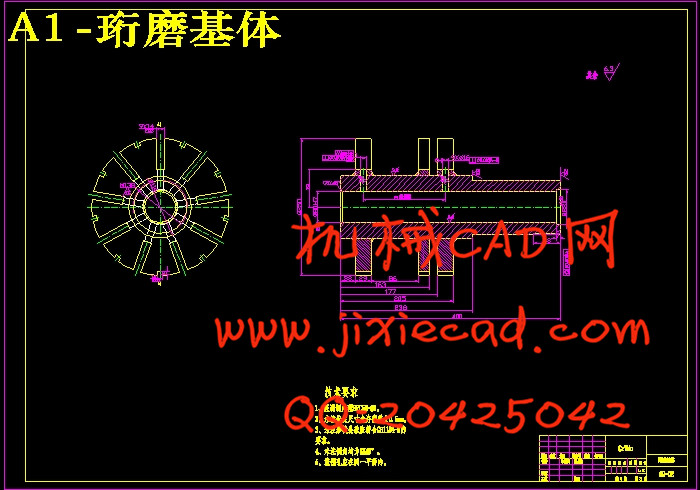

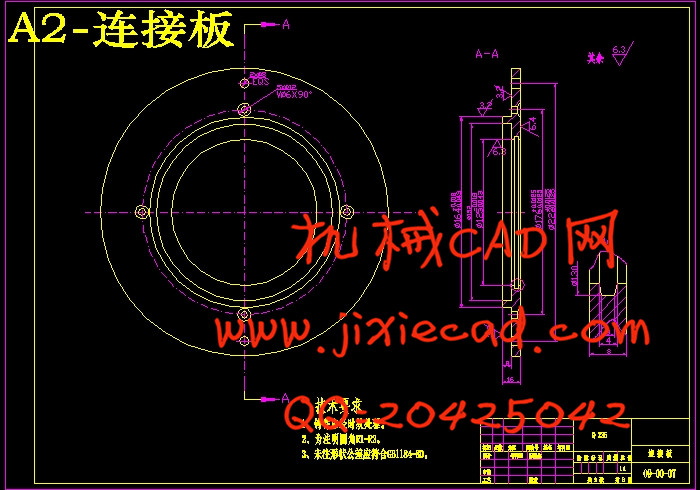

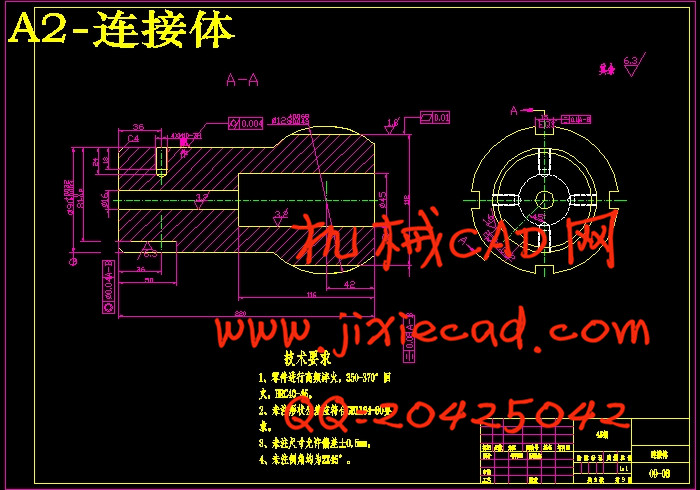

3.2 珩磨头基体结构设计 20

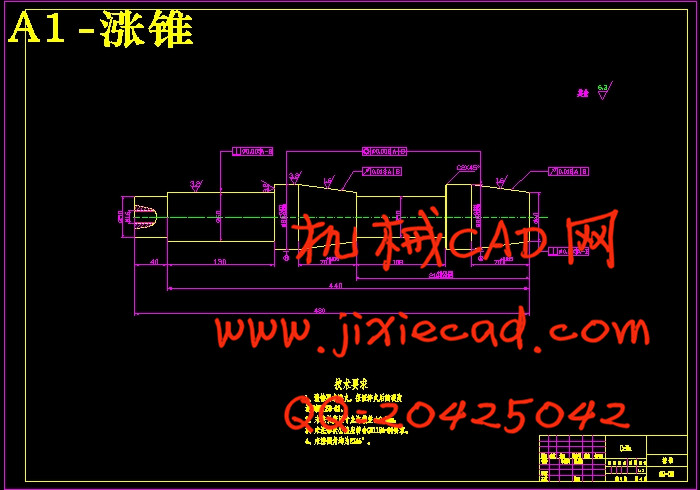

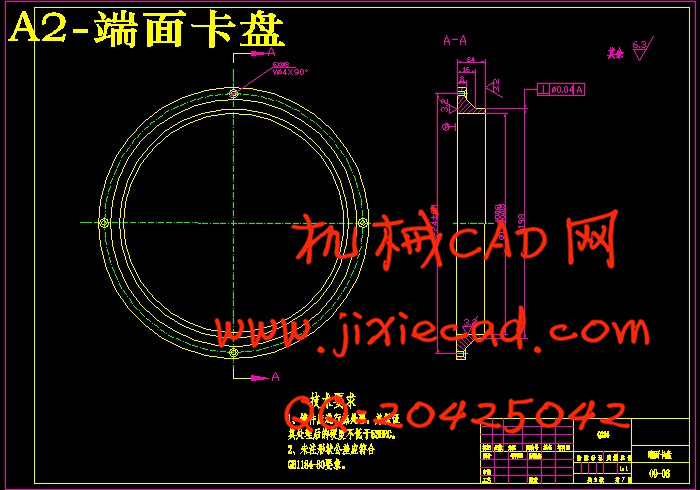

3.3涨锥(微调锥芯)设计 23

3.4导向装置设计 25

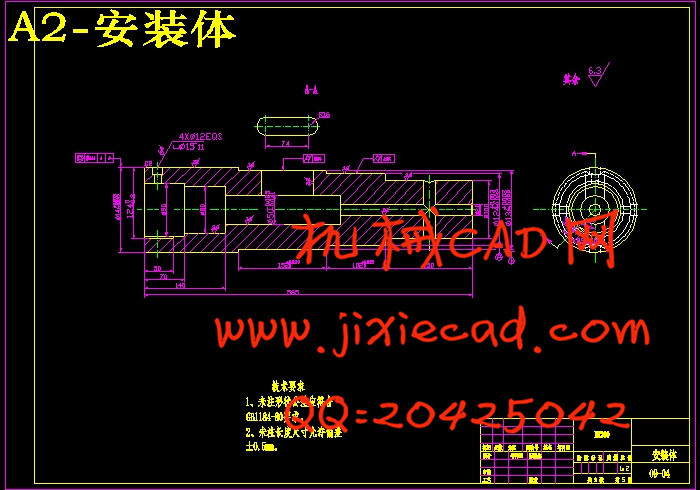

3.5手动进给装置的设计 25

第四章 珩磨用量的选择 28

4.1 切削速度与网纹交叉角 28

4.2 珩磨油石压力 30

4.3扩涨进给速度的选择 32

4.4 工作行程的计算与调整 32

4.6珩磨前工序要求 34

4.7珩磨液的选择 34

第五章 珩磨头结构薄弱零件的校核 37

5.1 零件3圆柱销扭转强度的校核 37

5.2零件11六角头沉头螺钉强度的校核 38

结束语 41

致谢 42

参考文献 43