设计简介

摘 要

数控机床上下料机械手是工业机器人机械手的一种,机械手在工业生产中能代替人手做某些单调、频繁和重复的长时间作业,或是危险、恶劣环境下的作业,例如在冲压、压力铸造、热处理、焊接、涂装、塑料制品成形、 机械加工和简单装配等工序上,以及在原子能工业等部门中,完成对人体有害物料的搬运或工艺操作【1】。

数控机床上下料机械手主要由手部和运动机构组成。手部是用来抓持工件(或工具)的部件,根据被抓持物件的形状、尺寸、重量、材料和作业要求而有多种结构形式,如夹持型、托持型和吸附型等。运动机构,使手部完成各种转动(摆动)、移动或复合运动来实现规定的动作,改变被抓持物件的位置和姿势。运动机构的升降、伸缩、旋转等独立运动方式,称为机械手的自由度 。为了抓取空间中任意位置和方位的物体,需有6个自由度。自由度是机 械手设计的关 键参数。自由 度越多,机械手的灵活性越大,通用性越广,其结构也越复杂。一般专用机械手有2~3个自由度。

机械手的种类,按驱动方式可分为液压式、气动式、电动式、机械式机械手;按适用范围可分为专用机械手和通用机械手两种;按运动轨迹控制方式可分为点位控制和连续轨迹控制机械手等。【2】

数控机床上下料机械手是近几十年发展起来的一种高科技自动化生产设备。数控机床上下料机械手的是工业机器人的一个重要分支。它的特点是可通过编程来完成各种预期的作业任务,在构造和性能上兼有人和机器各自的优点,尤其体现了人的智能和适应性。机械手作业的准确性和各种环境中完成作业的能力,在国民经济各领域有着广阔的发展前景。

在工业上,自动控制系统有着广泛的应用,如工业自动化机床控制,计算机系统,机器人等。而工业机器人是相对较新的电子设备,它正开始改变现代化工业面貌。实际的机器人由带有腕(或称为手臂)的主机身和机身端部的工具(通常是某些类型的夹持器)组成,同时也包括一个辅助动力系统。本文是对整个设计工作较全面的介绍和总 机械手技术涉及到力学、机械学、电气液压技术、自动控制技术、传感器技术和计算机技术等科学领域,是一门跨学科综合技术。

关键词:手臂 夹持器 工业机器人

Abstract

Industrial machine hand in industrial production can replace hand to do some drab, frequent and repeat the long operation, or danger, harsh environment, such as the homework in pressing, welding, casting, heat stress, coating, plastic forming, machining and assembling process such as simple, and in the atomic energy industry departments, complete harmful material handling or process operation. Manipulator hand and movement mainly by institutions. Hand is used to catch the workpiece (or tools), according to the parts of the object was caught the shape, size, weight, materials and operational requirements and has a variety of structural forms, such as the type of clamping, and adsorption type, etc. Sports organizations and finish all kinds of rotating (hand), moving or composite swing motion to realize, change the position of the object was caught and posture. The lifting mechanism, and the independence movement of the manipulator, called freedom. In order to grab arbitrary position and orientation of the object, need to have six degrees. Freedom is the design of hand machine armed key parameters. The freedom of the manipulator, the degree of flexibility, the greater the universality and broader, its structure is more complex. General special manipulator has 2-3 degrees.

According to the types of the manipulator, driving mode can be divided into hydraulic, pneumatic, electric type, mechanical manipulator, According to the scope and special manipulator can be divided into two manipulators, According to the trajectory control mode can be divided into position control and continuous trajectory control manipulator, etc.

Robots are usually used or other machine tools, such as additional device in automatic machine or automatic production line, loading and unloading workpieces relay in machining center, the replacement of tools is not independent control device. Some operations to direct manipulation by device, such as atomic energy sector also dangerous goods masterslave gunner also often called the manipulator.

Industrial robot developed in recent years is a high-tech automation production

equipment. Industrial robots is an important branch of industrial robots. Its characteristic is accomplished by programming task, various expected in the structure and performance of the respective advantages of both human beings and machines, particularly reflected people's intelligence and adaptability. Manipulator and the accuracy of all sorts of homework assignments in the environment of national economy, in the field has broad prospects for development. In industry, the automatic control system in a wide range of applications, such as industrial automation control, computer systems, machine, etc. Industrial robot is a relatively new electronic equipment, it is beginning to change the face of modern industry. The actual robot with a wrist (or called by the host body and arms) at the end of the fuselage of tool (usually a certain types of grippers), also include an auxiliary power system. This is the design of the whole work is introduced and the total manipulator technology involves mechanics, mechanical, electrical and hydraulic technology, automatic control technology, the sensor technology and computer technology, science, is an interdisciplinary comprehensive technology.

Key words:arm grippers industrial robots

目 录

摘 要 I

Astract II

1.绪论 1

1.1 选题背景 1

1.2 设计目的 1

1.3 国内外研究现状和趋势业 2

2.工业机器人机械手的总体设计 3

2.1 工业机器人的组成及各部分的关系概述 3

2.2工业机器人机械手设计分析 3

3.工业机器人机械手的运动系统分析 6

3.1工业机器人的运动自由度 6

3.2机器人的运动空间和机械结构类型 6

4.工业机器人机械手的执行机构设计 8

4.1末端执行机构设计 8

4.2手臂机构的设计 11

4.3腰部和基座设计 14

总 结 20

参考文献 21

致 谢 22

附 录 23

数控机床上下料机械手是工业机器人机械手的一种,机械手在工业生产中能代替人手做某些单调、频繁和重复的长时间作业,或是危险、恶劣环境下的作业,例如在冲压、压力铸造、热处理、焊接、涂装、塑料制品成形、 机械加工和简单装配等工序上,以及在原子能工业等部门中,完成对人体有害物料的搬运或工艺操作【1】。

数控机床上下料机械手主要由手部和运动机构组成。手部是用来抓持工件(或工具)的部件,根据被抓持物件的形状、尺寸、重量、材料和作业要求而有多种结构形式,如夹持型、托持型和吸附型等。运动机构,使手部完成各种转动(摆动)、移动或复合运动来实现规定的动作,改变被抓持物件的位置和姿势。运动机构的升降、伸缩、旋转等独立运动方式,称为机械手的自由度 。为了抓取空间中任意位置和方位的物体,需有6个自由度。自由度是机 械手设计的关 键参数。自由 度越多,机械手的灵活性越大,通用性越广,其结构也越复杂。一般专用机械手有2~3个自由度。

机械手的种类,按驱动方式可分为液压式、气动式、电动式、机械式机械手;按适用范围可分为专用机械手和通用机械手两种;按运动轨迹控制方式可分为点位控制和连续轨迹控制机械手等。【2】

数控机床上下料机械手是近几十年发展起来的一种高科技自动化生产设备。数控机床上下料机械手的是工业机器人的一个重要分支。它的特点是可通过编程来完成各种预期的作业任务,在构造和性能上兼有人和机器各自的优点,尤其体现了人的智能和适应性。机械手作业的准确性和各种环境中完成作业的能力,在国民经济各领域有着广阔的发展前景。

在工业上,自动控制系统有着广泛的应用,如工业自动化机床控制,计算机系统,机器人等。而工业机器人是相对较新的电子设备,它正开始改变现代化工业面貌。实际的机器人由带有腕(或称为手臂)的主机身和机身端部的工具(通常是某些类型的夹持器)组成,同时也包括一个辅助动力系统。本文是对整个设计工作较全面的介绍和总 机械手技术涉及到力学、机械学、电气液压技术、自动控制技术、传感器技术和计算机技术等科学领域,是一门跨学科综合技术。

关键词:手臂 夹持器 工业机器人

Abstract

Industrial machine hand in industrial production can replace hand to do some drab, frequent and repeat the long operation, or danger, harsh environment, such as the homework in pressing, welding, casting, heat stress, coating, plastic forming, machining and assembling process such as simple, and in the atomic energy industry departments, complete harmful material handling or process operation. Manipulator hand and movement mainly by institutions. Hand is used to catch the workpiece (or tools), according to the parts of the object was caught the shape, size, weight, materials and operational requirements and has a variety of structural forms, such as the type of clamping, and adsorption type, etc. Sports organizations and finish all kinds of rotating (hand), moving or composite swing motion to realize, change the position of the object was caught and posture. The lifting mechanism, and the independence movement of the manipulator, called freedom. In order to grab arbitrary position and orientation of the object, need to have six degrees. Freedom is the design of hand machine armed key parameters. The freedom of the manipulator, the degree of flexibility, the greater the universality and broader, its structure is more complex. General special manipulator has 2-3 degrees.

According to the types of the manipulator, driving mode can be divided into hydraulic, pneumatic, electric type, mechanical manipulator, According to the scope and special manipulator can be divided into two manipulators, According to the trajectory control mode can be divided into position control and continuous trajectory control manipulator, etc.

Robots are usually used or other machine tools, such as additional device in automatic machine or automatic production line, loading and unloading workpieces relay in machining center, the replacement of tools is not independent control device. Some operations to direct manipulation by device, such as atomic energy sector also dangerous goods masterslave gunner also often called the manipulator.

Industrial robot developed in recent years is a high-tech automation production

equipment. Industrial robots is an important branch of industrial robots. Its characteristic is accomplished by programming task, various expected in the structure and performance of the respective advantages of both human beings and machines, particularly reflected people's intelligence and adaptability. Manipulator and the accuracy of all sorts of homework assignments in the environment of national economy, in the field has broad prospects for development. In industry, the automatic control system in a wide range of applications, such as industrial automation control, computer systems, machine, etc. Industrial robot is a relatively new electronic equipment, it is beginning to change the face of modern industry. The actual robot with a wrist (or called by the host body and arms) at the end of the fuselage of tool (usually a certain types of grippers), also include an auxiliary power system. This is the design of the whole work is introduced and the total manipulator technology involves mechanics, mechanical, electrical and hydraulic technology, automatic control technology, the sensor technology and computer technology, science, is an interdisciplinary comprehensive technology.

Key words:arm grippers industrial robots

目 录

摘 要 I

Astract II

1.绪论 1

1.1 选题背景 1

1.2 设计目的 1

1.3 国内外研究现状和趋势业 2

2.工业机器人机械手的总体设计 3

2.1 工业机器人的组成及各部分的关系概述 3

2.2工业机器人机械手设计分析 3

3.工业机器人机械手的运动系统分析 6

3.1工业机器人的运动自由度 6

3.2机器人的运动空间和机械结构类型 6

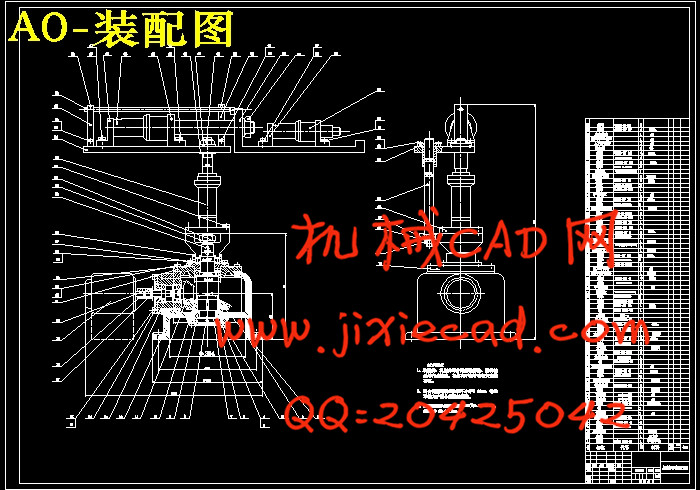

4.工业机器人机械手的执行机构设计 8

4.1末端执行机构设计 8

4.2手臂机构的设计 11

4.3腰部和基座设计 14

总 结 20

参考文献 21

致 谢 22

附 录 23