设计简介

摘 要

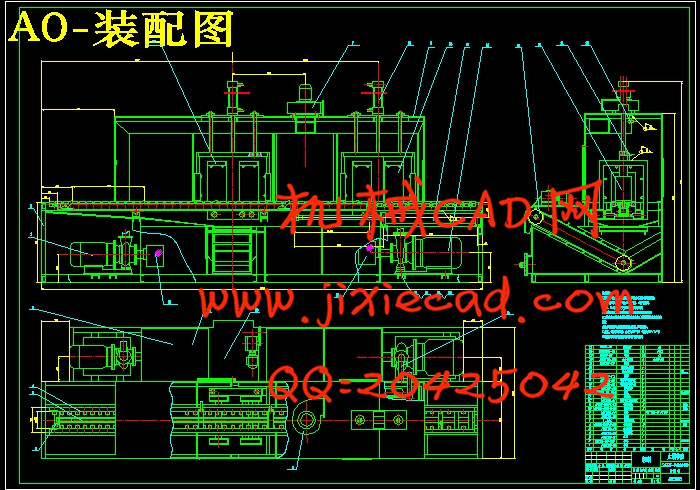

S195G-01006机体清洗机是用于S195G-01006机体的专用清洗设备。适用于生产流水线上批量生产的已完成机加工的机体在入库前的常温清洗。S195G柴油机机体专用清洗机床采用高压喷射清洗方式。本机床为液压步进、连续型、多工位清洗机。机床主要由机架、输送机构、水箱、清洗液输送系统、喷水清洗系统、喷气吹干系统、液压系统、电气控制系统组成。采用液压步进式连续型工作生产方式:机体从上料端上料后,由步进式输送机构在PLC程序控制系统控制下按程序先后送入清洗、吹干工位,完成定点对位清洗及吹干以后输出。从机体上料后能自动完成机体的清洗、吹干等工序,直至自动输出。由于采用流水线清洗,清洗效率高;由于采用定点,对位清洗清洗效果特别好,清洗质量高;控制系统采用PC控制,操作完全实现自动化。因此,清洗任务能安全高效的完成,并且操作、维护十分方便。

关键词:S195G柴油机机体;清洗;高压喷射清洗;液压步进式输送机构

Abstract

S195G -01006 cleaning equipment is a special cleaning machine for the mass-produced diesel engine bodies of S 195G -01006 at room temperature before they are sent into stock after they come out of the production lines with the machining finished. High-pressure spraying cleaning method is applied in this hydraulic stepping, continuous-working and multiple-step cleaning machine tool. It is composed of tool rack, conveying mechanism, water tank, washing liquid delivery system, water spray cleaning system, gas-ejecting drying system, hydraulic system and electrical control system. After the diesel engine body is placed into the cleaning machine from the input port, the diesel engine body will be sent along the stepping conveying mechanism to be cleaned and dried step by step as programmed by PLC program control system. After the fixed-point and aligned cleaning and drying are finished, the engine body will be sent out automatically. The whole procedures of input, cleaning,drying and output are complete automatization. As production-line cleaning mode is made use of, the cleaning efficiency of this cleaning machine is great; And because the cleaning is done at fixed points and is aligned with the engine body, the cleaning quality is high and the cleaning effect is good. With the PC control system applied, the whole operation realizes automatization. Hence, the cleaning task is accomplished safely and highly efficiently. Besides, the operation and maintenance of this cleaning machine are very convenient.

Key words: S195G engine block;washing machines;high pressure water cleaning;hydraulic Step-by-step transfer agencies

目 录

摘 要 III

Abstract.IV

目 录 V

1 绪论 1

1.1 清洗机技术现状和发展趋势 1

1.3 课题的主要内容 2

2 清洗机设计方案论证 3

2.1 机体零件的清洗特点 3

2.2 机床总方案 3

2.4 液压系统方案确定 5

2.5 控制系统方案确定 6

3 清洗机主要参数的分析与计算 7

3.1 设计技术参数 7

3.2 机械系统主要计算 7

4 清洗机床的设计 11

4.1 机械系统的设计 11

4.1.1 清洗机床的总体设计 11

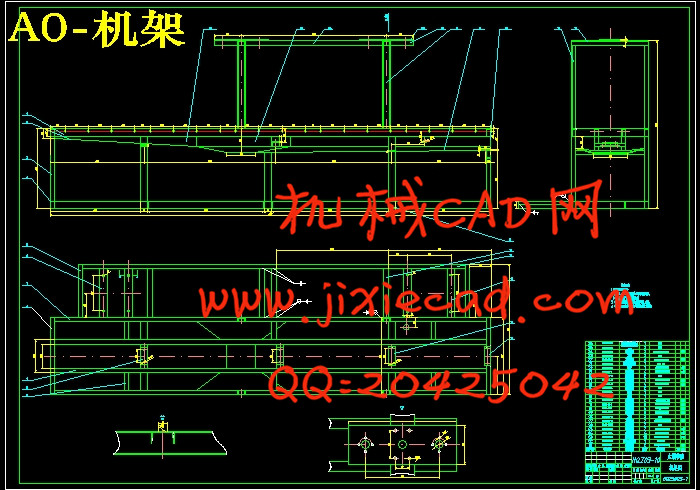

4.1.2 机架的设计 15

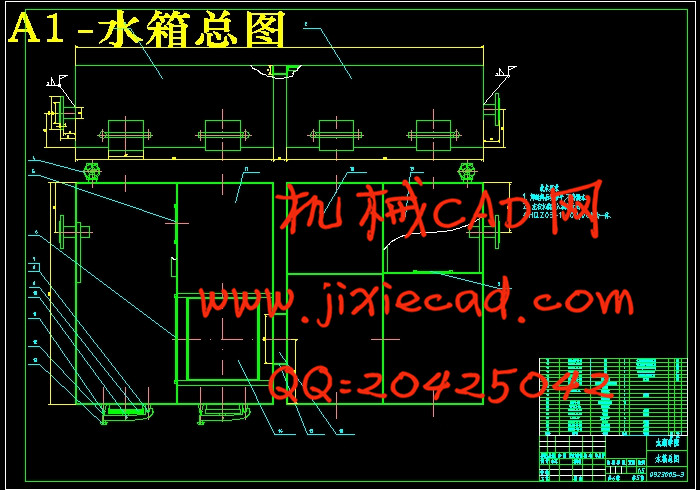

4.1.3 水箱的设计 16

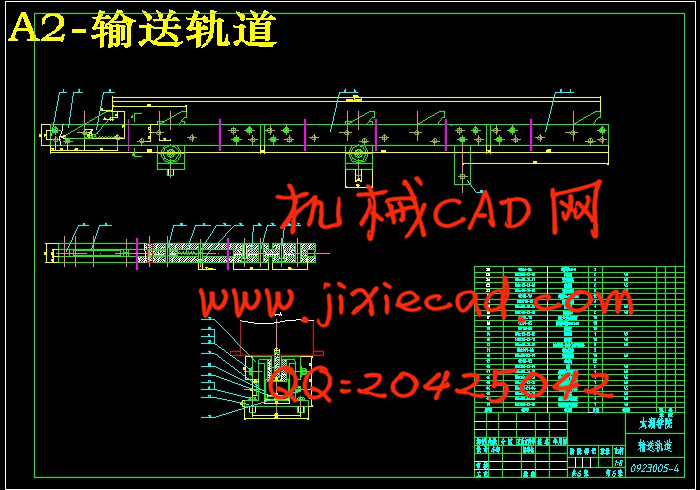

4.1.4 输送滚道与机构的设计 19

4.1.5 升降喷水吹风系统的设计 21

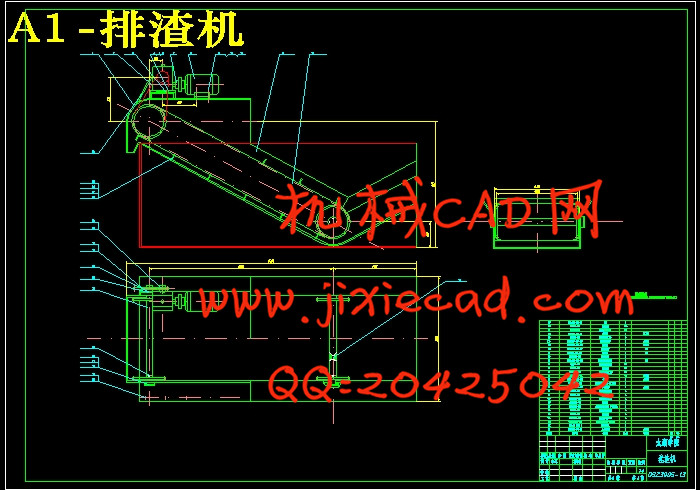

4.1.6 排渣机的设计 25

4.2 液压系统的设计 26

4.2.1 液压系统原理图设计 27

4.2.2 液压系统管道图设计 27

4.3 控制系统的设计 28

5 结论与展望 29

5.1结论 29

5.2不足之处及未来展望 29

致谢 30

参考文献 31