设计简介

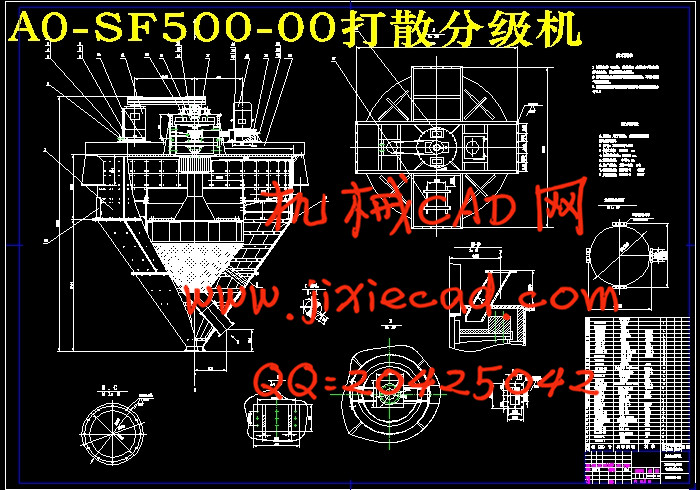

SF500/100打散分级机内外筒体及原设计改进探讨

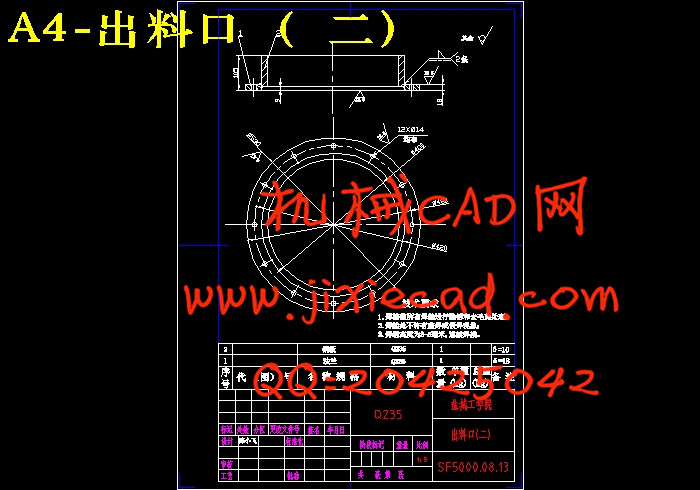

摘要:本课题是进行打散分级机的内外筒体及对原设计的改进,在筒体设计中我们先确定筒体的尺寸参数,然后对关键地方进行受力分析,在改进部分,我们对原设计进行了仔细的分析,指出了原设计的不足之处,然后对其进行合理的改进。打散分级机是九十年代初问世的新型料饼打散分选设备,集料饼打散与颗粒分级于一体,与挤压机配套使用,可以消除挤压粉碎机边缘漏斗和开停机过程中及正常工作时未被充分挤压的大颗粒对后续球磨系统产生不利的影响,以获得大幅度增产节能的效果。因为辊压机操作规程规定:设备启动时液压系统应处于卸压状态。所以,在辊压机启动过程中将有大量未经有效挤压的物料通过辊压机。这也是在打散分级机介入挤压粉磨工艺系统前的挤压预粉磨系统产量提高幅度不大且存在较大波动的重要原因。打散分级机利用离心冲击破碎原理对物料进行打散,利用惯性及空气动力学原理对散状物了实现分级。在挤压联合粉磨工艺系统中应用,可取得增产100%-200%,节约用电30%以上,研磨体消耗降低60%以上的效果。

关键词:辊压机;挤压粉磨工艺系统;打散分级机;

The design of the outer shell of SF500/100 Scatter grading device and the original improvement discussion

Abstract:This topic carries on the design of the outer shell of scatter grading device and the original improvement, in the shell design we have determined first the shell’s size parameter, then carries on the stress analysis to the essential place, in the improvement part, we have carried on the careful analysis to the original design, pointed out the original design deficiency, then makes the reasonable improvement to it.Scatter grading device is the new blank cake which is published at the beginning of the 90's hits the divergence to choose the equipment, the aggregate cake to scatter with the size grading in a body, with the extruder necessary use, it may eliminate the disadvantageous influence extrusion grinder edge funnel and opens in when the engine off process and the normal work the big pellet which fully extrudes to the following grinding system has not been produced, which obtains the effect of the large scale production increase energy conservation. Because the rolling machine working instruction has stipulated: when the equipment starts the hydraulic system should be at the release of pressure condition. Therefore, when the rolling machine start process there will have massively material through roller press which have not after the effective extrusion. This is also the important reason that in scatter grading device involvement to push the press powder to be grinded in front of the craft system the extrusion pre- powder to rub the system output to enhance the scope not to be big also the existence big undulation. Scatter grading device carry on using the centrifugal impact crash principle to the material scatters, to disperse the shape realization graduation using the inertia and the aerodynamics principle.The gringing in the craft system in the extrusion union powder may obtain increases production 100% to 200%, frugal uses electricity above 30%, grinds the body consumption reduce above 60%.

Key words: Roller press; Compressed grinding system; Scatter grading device

目录

1 前言 1

1.1本课题的来源、基本前提条件和技术要求 1

1.2本课题要解决的主要问题和设计总体思路 1

1.3预期的成果及其理论意义 1

2 总体方案论证 2

2.1 国内(外)发展概况及现状的介绍 2

2.2 打散分级机的工作原理 2

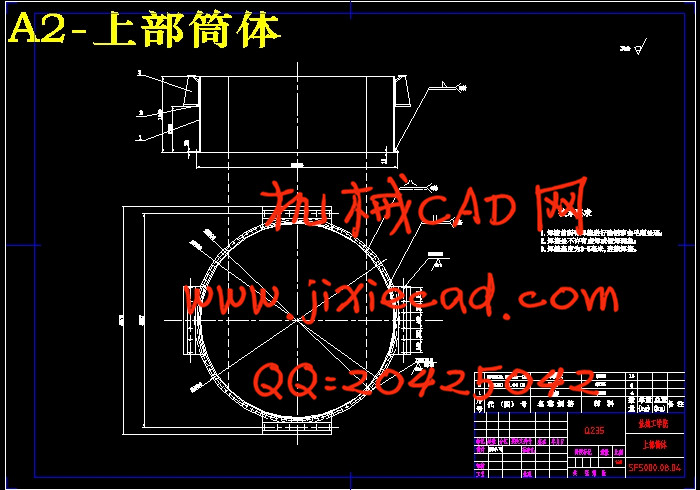

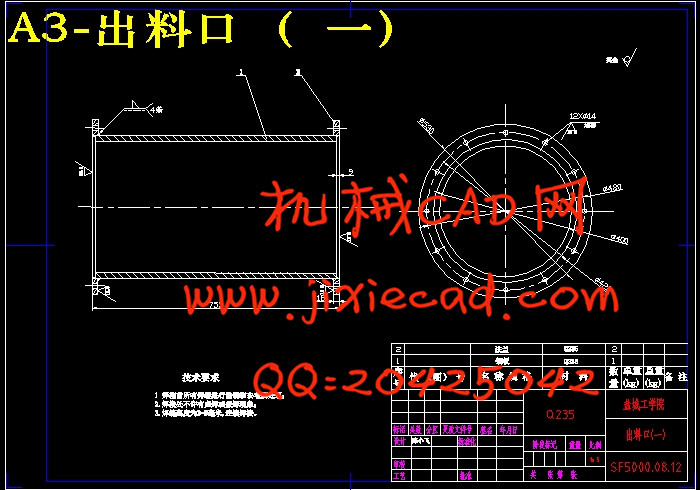

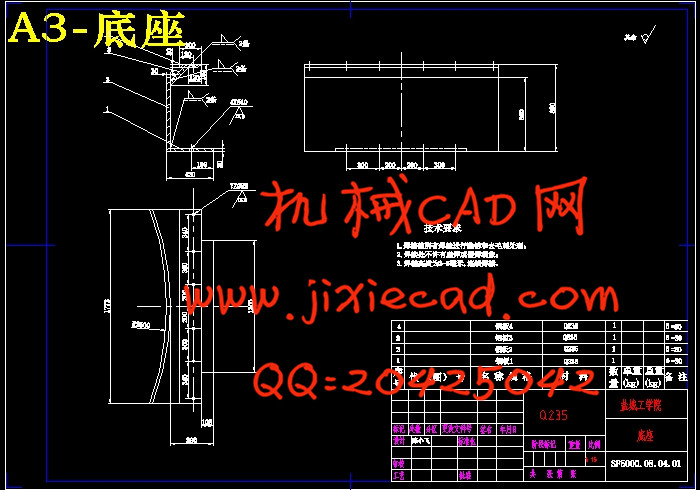

2.3 主要结构介绍 3

3 具体设计说明 4

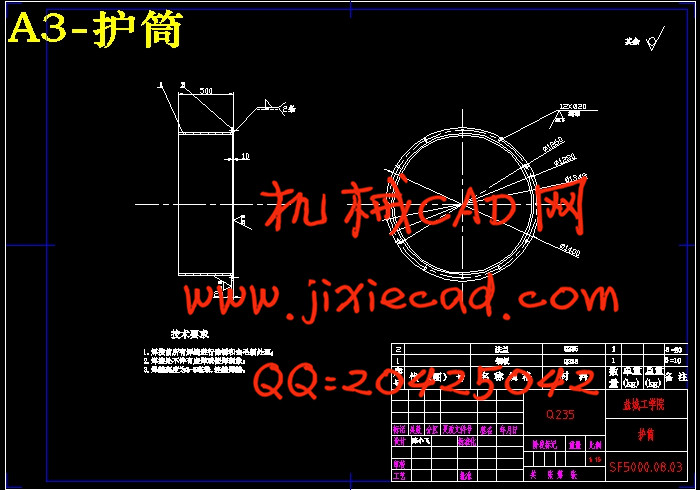

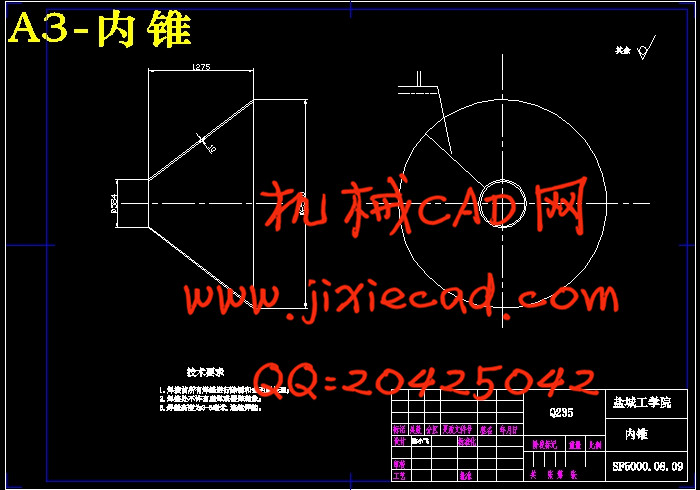

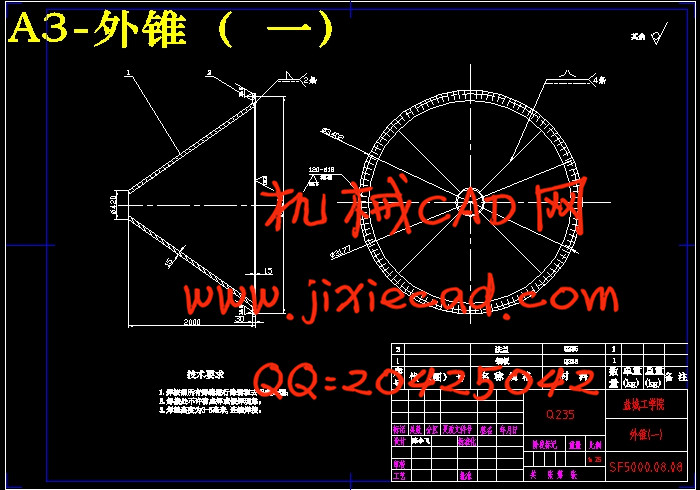

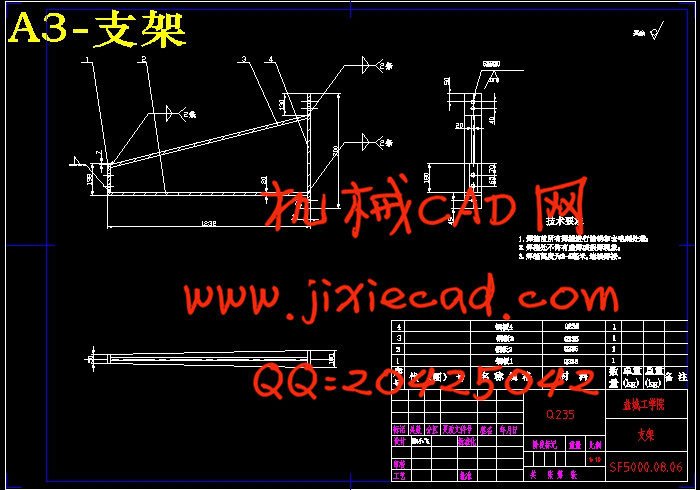

3.1 原方案的筒体结构参数的设计 4

3.2 螺栓组联接的结构设计 5

3.3 螺栓联接的强度校核 6

3.4 钢板焊接方面的处理 8

3.5 原设计改进部分 9

3.5.1 方案的提出 9

3.5.2 改进的打散分级机主要尺寸的确定 10

3.5.3 风轮电机的选型 10

3.5.4 打散电机的选型 14

3.6 设备的安装要求 16

3.7 预期效果 17

4 结论 18

参考文献 19

致谢 20

附录 21

摘要:本课题是进行打散分级机的内外筒体及对原设计的改进,在筒体设计中我们先确定筒体的尺寸参数,然后对关键地方进行受力分析,在改进部分,我们对原设计进行了仔细的分析,指出了原设计的不足之处,然后对其进行合理的改进。打散分级机是九十年代初问世的新型料饼打散分选设备,集料饼打散与颗粒分级于一体,与挤压机配套使用,可以消除挤压粉碎机边缘漏斗和开停机过程中及正常工作时未被充分挤压的大颗粒对后续球磨系统产生不利的影响,以获得大幅度增产节能的效果。因为辊压机操作规程规定:设备启动时液压系统应处于卸压状态。所以,在辊压机启动过程中将有大量未经有效挤压的物料通过辊压机。这也是在打散分级机介入挤压粉磨工艺系统前的挤压预粉磨系统产量提高幅度不大且存在较大波动的重要原因。打散分级机利用离心冲击破碎原理对物料进行打散,利用惯性及空气动力学原理对散状物了实现分级。在挤压联合粉磨工艺系统中应用,可取得增产100%-200%,节约用电30%以上,研磨体消耗降低60%以上的效果。

关键词:辊压机;挤压粉磨工艺系统;打散分级机;

The design of the outer shell of SF500/100 Scatter grading device and the original improvement discussion

Abstract:This topic carries on the design of the outer shell of scatter grading device and the original improvement, in the shell design we have determined first the shell’s size parameter, then carries on the stress analysis to the essential place, in the improvement part, we have carried on the careful analysis to the original design, pointed out the original design deficiency, then makes the reasonable improvement to it.Scatter grading device is the new blank cake which is published at the beginning of the 90's hits the divergence to choose the equipment, the aggregate cake to scatter with the size grading in a body, with the extruder necessary use, it may eliminate the disadvantageous influence extrusion grinder edge funnel and opens in when the engine off process and the normal work the big pellet which fully extrudes to the following grinding system has not been produced, which obtains the effect of the large scale production increase energy conservation. Because the rolling machine working instruction has stipulated: when the equipment starts the hydraulic system should be at the release of pressure condition. Therefore, when the rolling machine start process there will have massively material through roller press which have not after the effective extrusion. This is also the important reason that in scatter grading device involvement to push the press powder to be grinded in front of the craft system the extrusion pre- powder to rub the system output to enhance the scope not to be big also the existence big undulation. Scatter grading device carry on using the centrifugal impact crash principle to the material scatters, to disperse the shape realization graduation using the inertia and the aerodynamics principle.The gringing in the craft system in the extrusion union powder may obtain increases production 100% to 200%, frugal uses electricity above 30%, grinds the body consumption reduce above 60%.

Key words: Roller press; Compressed grinding system; Scatter grading device

目录

1 前言 1

1.1本课题的来源、基本前提条件和技术要求 1

1.2本课题要解决的主要问题和设计总体思路 1

1.3预期的成果及其理论意义 1

2 总体方案论证 2

2.1 国内(外)发展概况及现状的介绍 2

2.2 打散分级机的工作原理 2

2.3 主要结构介绍 3

3 具体设计说明 4

3.1 原方案的筒体结构参数的设计 4

3.2 螺栓组联接的结构设计 5

3.3 螺栓联接的强度校核 6

3.4 钢板焊接方面的处理 8

3.5 原设计改进部分 9

3.5.1 方案的提出 9

3.5.2 改进的打散分级机主要尺寸的确定 10

3.5.3 风轮电机的选型 10

3.5.4 打散电机的选型 14

3.6 设备的安装要求 16

3.7 预期效果 17

4 结论 18

参考文献 19

致谢 20

附录 21