设计简介

摘 要

随着社会的进步,制造业的发展越来越迅速,数控技术和数控装备是制造工业现代化的重要基础。这个基础是否牢固直接影响到一个国家的经济发展和综合国力,关系到一个国家的战略地位。因此,世界上各工业发达国家均采取重大措施来发展自己的数控技术及其产业。在我国,数控技术与装备的发展亦得到了高度重视,近年来取得了相当大的进步。数控机床发展很快,作为数控机床的重要部分,主轴箱的设计更新也越来越快。

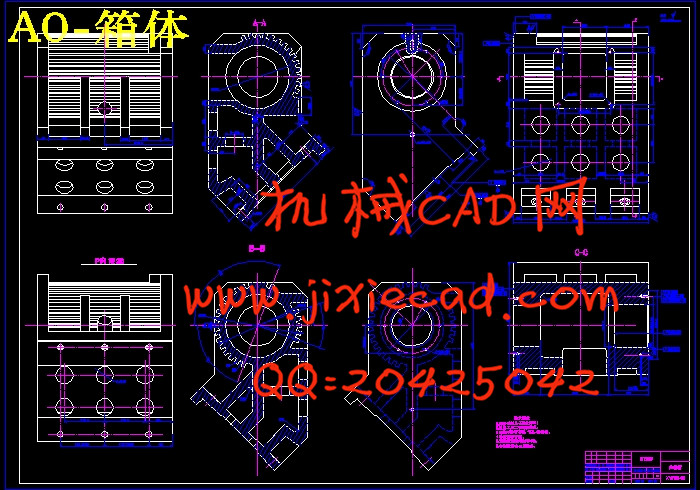

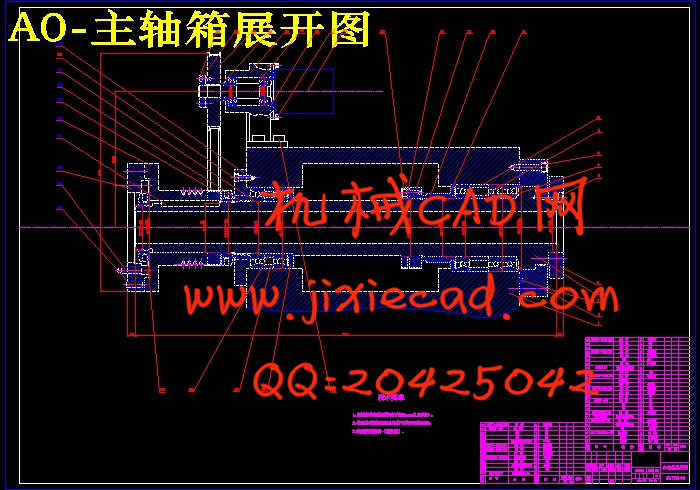

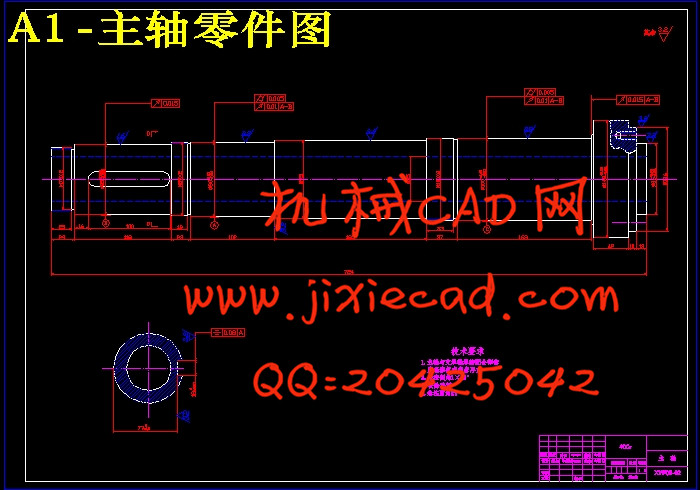

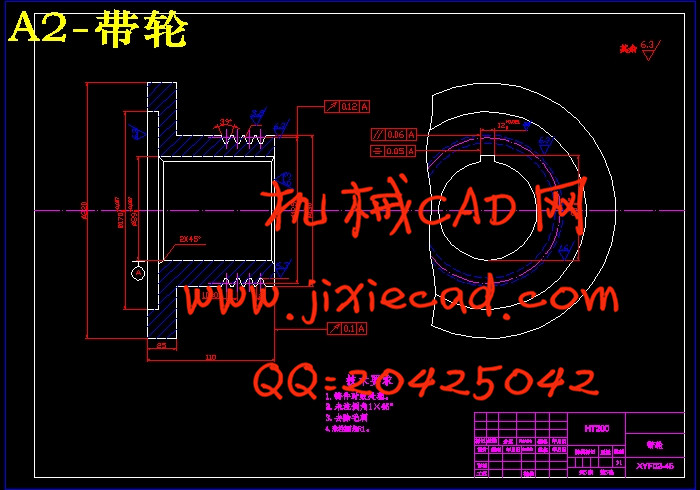

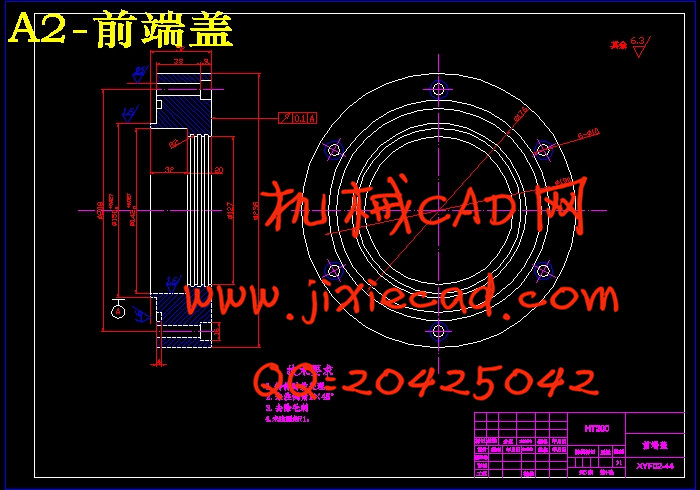

我设计的是SSCK20A数控机床主轴和主轴箱箱体加工工艺以及数控编程,其中涉及了主轴和箱体加工中刀具、量具、毛坯、定位基准等的选择。设计图为两张零号图纸,一张一号图纸,两张二号图纸。

关键词:数控加工工艺 、数控编程、定位基准、主轴箱、工艺编程。

Abstract

Ore and Along with the advance of society, the development of manufacturing industry is mmore quick, the technical equipment of numerical control of numerical control is to make industrial modern important foundation. Whether directly affect a economy of country strongly develop this foundation with the country's comprehensive power, concern a strategic position of country. Therefore on world, each industrial developed countries adopts significant measure to develop the own technical and its estate of numerical control. in recent years, have gotten fairly big advance. The development of numerical control of machine tool is very rapid , is the important part of the machine tool of numerical control, the design of the case of main shaft update also more and more rapid.

What I design is that the case casing processing technology as well as programming of numerical control of machine tool of main shaft have in which been concerned with the option of cutting tool, measuring tool, blank and location standard etc. in casing processing. Design drawing is the two blueprints No. 0 and a blueprint No. 1 and two blueprints No. 2 .

Keyword: Number control to process the craft、count to control to weave the distance、fixed position basis、 principal axis box、craft plait distance。

目 录

摘要:···························································1

Abstract·······················································2

第一章 绪论····················································5

第二章 数控加工概念··········································6

2.1高速、高效、高精度、高可靠性···························8

第三章 数控车床···············································9

3.1数控车床的组成········································9

3.2数控车床的特点 ·····································11

3.3数控车床的适用范围及工作原理························12

第四章 数控加工工艺分析·····································15

4.1 毛坯的选择···········································18

4.2确定数控加工内容·····································18

4.3数控加工零件的工艺性分析····························18

4.4定位基准的选择·······································19

4.4.1精基准的选择····································19

4.4.2粗基准的选择····································19

4.5加工方法的选择·······································20

4.6刀具的选择············································21

4.6.1数控车刀的类型与刀片选择·······················21

4.7夹具的选择···········································21

4.8量具的选择············································22

4.9数控加工工艺路线设计································22

4.9.1外圆表面的加工方法的选择······················22

第五章 工序的划分············································24

5.1加工顺序的安排·······································25

5.1.1切削加工工序安排································25

5.1.2热处理工序安排···································25

5.1.3辅助工序安排·····································26

5.2数控加工工序设计····································26

5.3走刀路线和工步顺序的确定····························26

5.4主轴机械加工工艺规程卡片····························27

5.5主轴的工艺分析·······································27

5.6箱体机械加工工艺规程卡片····························27

5.7箱体的工艺分析·······································28

第六章 数控加工程序··········································29

6.1主轴数控加工程序·····································29

6.2箱体数控加工部分的程序······························31

6.2.1安装面的数控加工································31

6.2.2主轴孔的数控加工程序····························33

第七章 毕业设计总结··········································37

7.1成本分析··············································37

7.2经济效益分析·········································37

7.3前景预测·············································37

结论··························································38

参考文献······················································39

致谢···························································40

随着社会的进步,制造业的发展越来越迅速,数控技术和数控装备是制造工业现代化的重要基础。这个基础是否牢固直接影响到一个国家的经济发展和综合国力,关系到一个国家的战略地位。因此,世界上各工业发达国家均采取重大措施来发展自己的数控技术及其产业。在我国,数控技术与装备的发展亦得到了高度重视,近年来取得了相当大的进步。数控机床发展很快,作为数控机床的重要部分,主轴箱的设计更新也越来越快。

我设计的是SSCK20A数控机床主轴和主轴箱箱体加工工艺以及数控编程,其中涉及了主轴和箱体加工中刀具、量具、毛坯、定位基准等的选择。设计图为两张零号图纸,一张一号图纸,两张二号图纸。

关键词:数控加工工艺 、数控编程、定位基准、主轴箱、工艺编程。

Abstract

Ore and Along with the advance of society, the development of manufacturing industry is mmore quick, the technical equipment of numerical control of numerical control is to make industrial modern important foundation. Whether directly affect a economy of country strongly develop this foundation with the country's comprehensive power, concern a strategic position of country. Therefore on world, each industrial developed countries adopts significant measure to develop the own technical and its estate of numerical control. in recent years, have gotten fairly big advance. The development of numerical control of machine tool is very rapid , is the important part of the machine tool of numerical control, the design of the case of main shaft update also more and more rapid.

What I design is that the case casing processing technology as well as programming of numerical control of machine tool of main shaft have in which been concerned with the option of cutting tool, measuring tool, blank and location standard etc. in casing processing. Design drawing is the two blueprints No. 0 and a blueprint No. 1 and two blueprints No. 2 .

Keyword: Number control to process the craft、count to control to weave the distance、fixed position basis、 principal axis box、craft plait distance。

目 录

摘要:···························································1

Abstract·······················································2

第一章 绪论····················································5

第二章 数控加工概念··········································6

2.1高速、高效、高精度、高可靠性···························8

第三章 数控车床···············································9

3.1数控车床的组成········································9

3.2数控车床的特点 ·····································11

3.3数控车床的适用范围及工作原理························12

第四章 数控加工工艺分析·····································15

4.1 毛坯的选择···········································18

4.2确定数控加工内容·····································18

4.3数控加工零件的工艺性分析····························18

4.4定位基准的选择·······································19

4.4.1精基准的选择····································19

4.4.2粗基准的选择····································19

4.5加工方法的选择·······································20

4.6刀具的选择············································21

4.6.1数控车刀的类型与刀片选择·······················21

4.7夹具的选择···········································21

4.8量具的选择············································22

4.9数控加工工艺路线设计································22

4.9.1外圆表面的加工方法的选择······················22

第五章 工序的划分············································24

5.1加工顺序的安排·······································25

5.1.1切削加工工序安排································25

5.1.2热处理工序安排···································25

5.1.3辅助工序安排·····································26

5.2数控加工工序设计····································26

5.3走刀路线和工步顺序的确定····························26

5.4主轴机械加工工艺规程卡片····························27

5.5主轴的工艺分析·······································27

5.6箱体机械加工工艺规程卡片····························27

5.7箱体的工艺分析·······································28

第六章 数控加工程序··········································29

6.1主轴数控加工程序·····································29

6.2箱体数控加工部分的程序······························31

6.2.1安装面的数控加工································31

6.2.2主轴孔的数控加工程序····························33

第七章 毕业设计总结··········································37

7.1成本分析··············································37

7.2经济效益分析·········································37

7.3前景预测·············································37

结论··························································38

参考文献······················································39

致谢···························································40