设计简介

摘要

目前,在面对国民生活水平快速提高的形势下对肉和馅制品的需求量不断加大,肉

制品加工机械发展也越来越快。肉和馅制品加工过程中,首先碰到的是根据工艺要求将

原料进行预处理,包括切片、切丝和绞馅等。本文论述了肉类加工机械绞肉机的工作原

理、主要技术参数、传动系统、典型零件的结构设计及生产能力分析。绞肉机的种类尽

管繁多,但是它们的基术结构和工作原理是相同的。工作过程,主要靠旋转的工作螺杆

(绞笼),将料斗提供的肉料通过工作圆筒推挤到筛网和切刀处,利用转动的切刀刃和

筛网孔口形成约剪切和研磨作用将肉切碎,并在螺杆挤压力作用下将肉粒排出筛网。

关键词肉类工业;绞肉机;挤肉样板;绞刀

ABSTRACT

Atpresent,inthefaceoftherapidincreaseinthelevelofnationallife

situationthedemandformeatandfillingproductscontinuetoincrease,meat

processingmachinerydevelopmentisalsogrowingfast。Meatandstuffingproduct

processingprocess,thefirstencounterisaccordingtothetechnical

requirementofthepretreatmentofrawmaterials,includingslicingand

shreddingandwringstuffingandsoon.Thispaperdealswiththemeatprocessing

machinerymincingmachineworkingprinciple,maintechnicalparameters,

transmissionsystemoftypicalparts,structuredesignandproductioncapacity

analysis.Althoughmanykindsofmeatgrinder,buttheirbasicstructureand

workingprincipleisthesame.Workingprocess,mainlybytherotationofthe

screwworking(strandingcage),thehopperofthemeatmaterialthroughthe

workingcylinderpushestothescreenandthecuttingknifeat,therotation

ofthecuttingedgeandthescreenholeformaboutcuttingandgrindingwill

bechoppedmeat,andscrewextrusionpressureunderthemeatparticlesdischarge

screen.

Keywords:meatchopperCrowdedmeatmodereamerCage

II

目录

目录....................................................................................................................................................................2

摘要.....................................................................................................................................................................I

Abstract.............................................................................................................................................................II

第一章引言.................................................................................................................................................- 1 -

第二章结构与工作原理............................................................................................................................ - 2 -

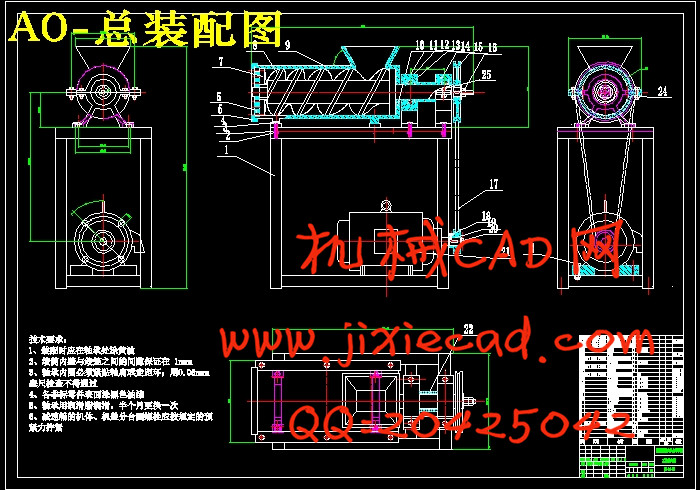

2.1绞肉机的结构................................................................................................................................- 2 -

2.1.1送料机构............................................................................................................................ - 2 -

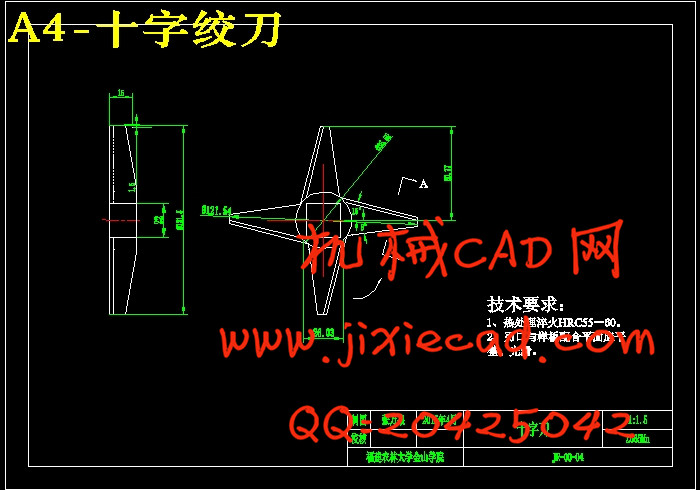

2.1.2切割机构............................................................................................................................ - 2 -

2.1.3驱动机构............................................................................................................................ - 3 -

2.2工业绞肉机的工作原理........................................................................................................- 3 -

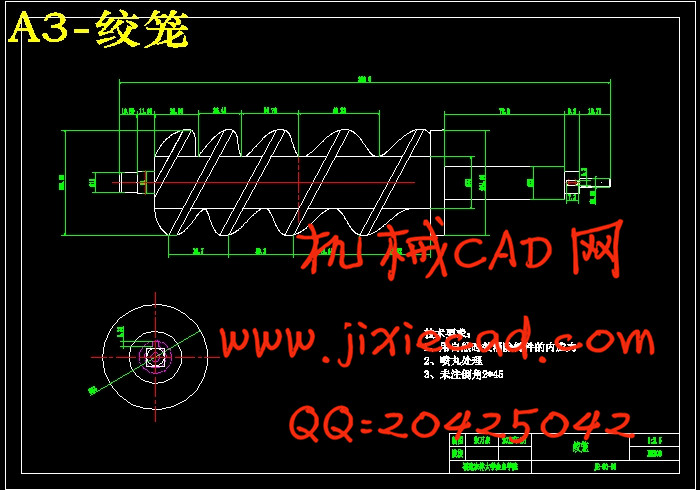

第三章螺旋供料器的设计........................................................................................................................ - 4 -

3.1轴的设计........................................................................................................................................- 4 -

3.1.1绞笼的材料........................................................................................................................ - 4 -

3.1.2螺旋直径 ......................................................................................................................... - 5 -

3.1.3额定绞笼的转速................................................................................................................ - 5 -

3.1.4螺旋节距............................................................................................................................ - 5 -

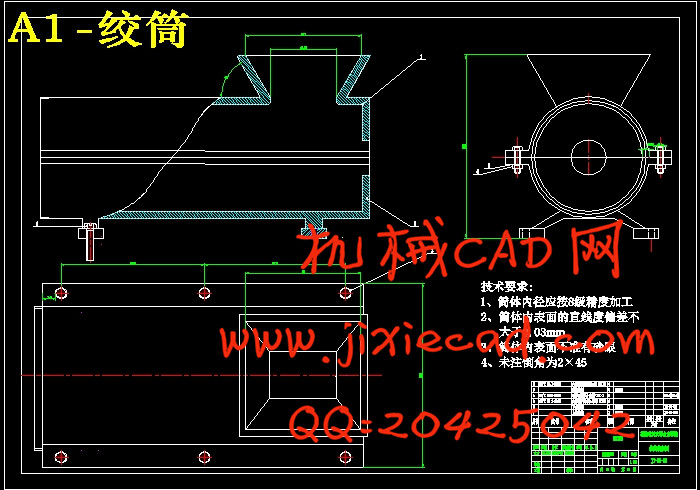

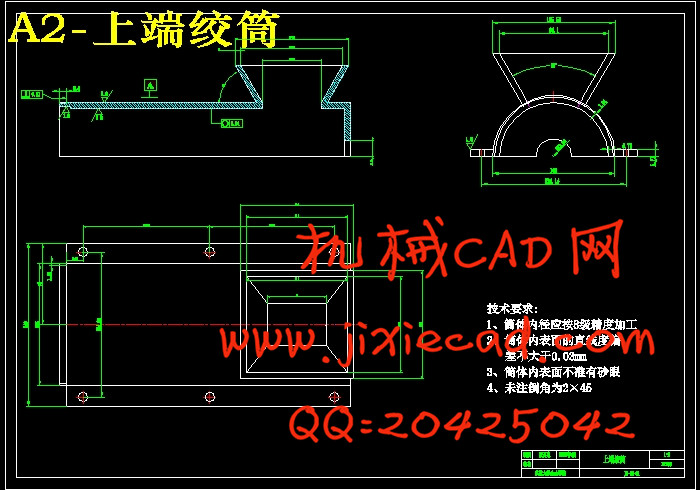

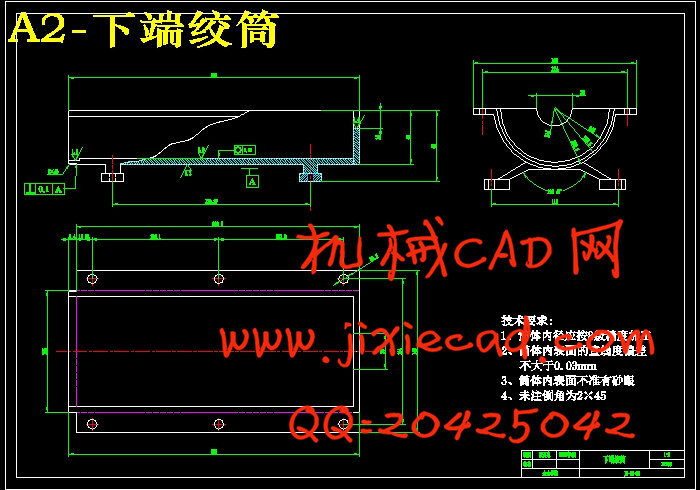

3.2绞筒的设计....................................................................................................................................- 5 -

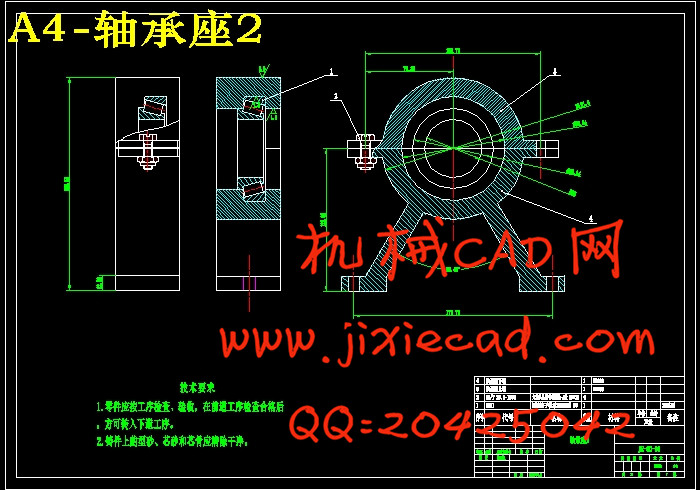

3.3止推轴承座的设计........................................................................................................................- 6 -

第四章传动系统的设计............................................................................................................................ - 8 -

4.1电机的选择....................................................................................................................................- 8 -

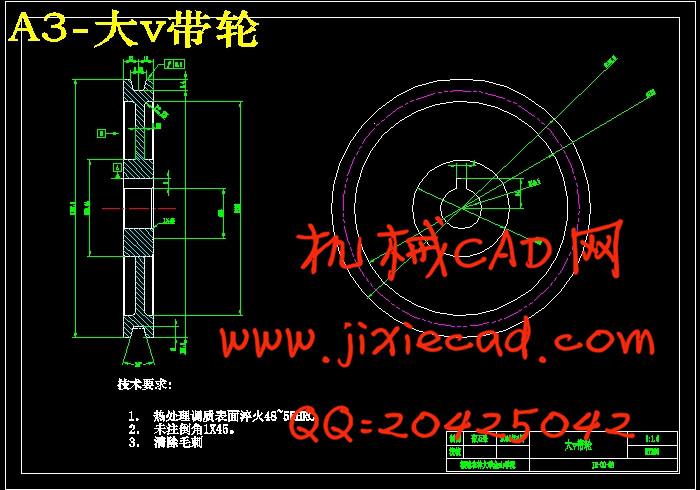

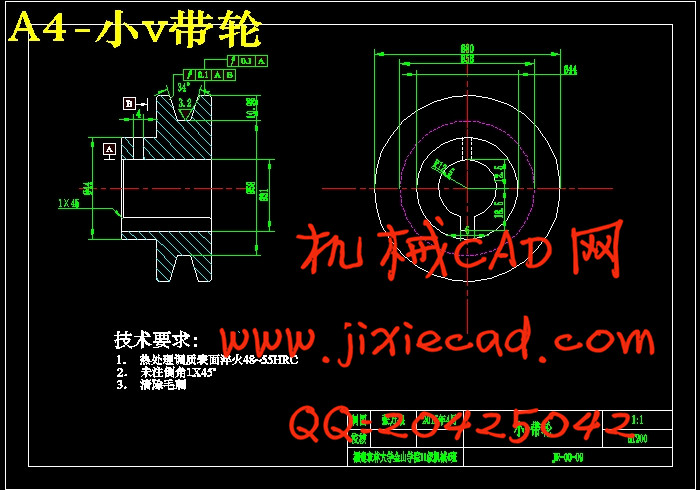

4.2带传动的设计................................................................................................................................- 9 -

4.2.1设计功率 Pd .......................................................................................................................- 9 -

4.2.1大带轮基准直径d

d2(mm)...........................................................................................- 9 -

4.2.2初定轴间距a0(mm).....................................................................................................- 10 -

4.2.3小带轮包角¶1.................................................................................................................- 10 -

4.2.4 V带的根数Z....................................................................................................................- 11 -

4.3皮带的选择、及计算..................................................................................................................- 11 -

4.3.1单根 V带的预紧力..........................................................................................................- 11 -

4.3.2作用在轴上的力.............................................................................................................- 12 -

4.3.3带轮的结构和尺寸.........................................................................................................- 12 -

第五章绞刀的设计..................................................................................................................................- 13 -

5.1绞刀的设计..................................................................................................................................- 13 -

5.1.1刀刃的起讫位置..............................................................................................................- 14 -

5.1.2刀刃的前角......................................................................................................................- 15 -

5.1.3刀刃的后角......................................................................................................................- 16 -

5.1.4刀刃的刃倾角..................................................................................................................- 17 -

5.1.5刀刃上任一点位量上绞肉速度......................................................................................- 19 -

5.1.6刀片的结构.....................................................................................................................- 20 -

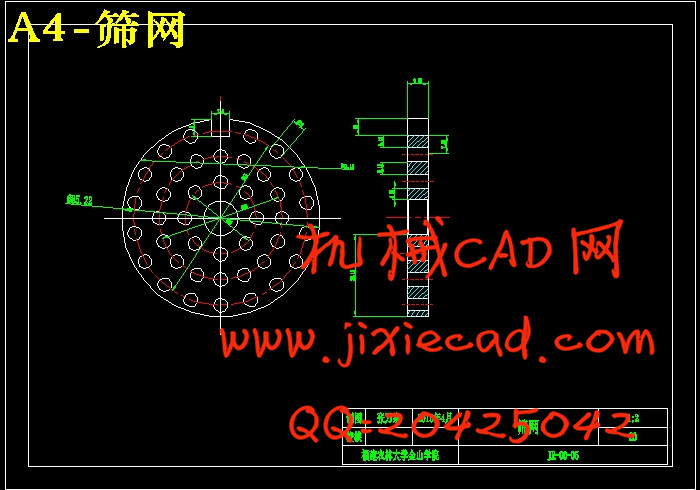

5.2筛网的设计..................................................................................................................................- 21 -

第六章生产能力分析..............................................................................................................................- 22 -

6.1影响生产能力的主要因素......................................................................................................... - 22 -

6.2绞刀的切割能力..........................................................................................................................- 22 -

6.3绞肉机的生产能力......................................................................................................................- 22 -

6.4功率消耗......................................................................................................................................- 23 -

结束语........................................................................................................................................................ - 24 -

参考文献.................................................................................................................................................... - 24 -

致谢............................................................................................................................................................ - 25 -

目前,在面对国民生活水平快速提高的形势下对肉和馅制品的需求量不断加大,肉

制品加工机械发展也越来越快。肉和馅制品加工过程中,首先碰到的是根据工艺要求将

原料进行预处理,包括切片、切丝和绞馅等。本文论述了肉类加工机械绞肉机的工作原

理、主要技术参数、传动系统、典型零件的结构设计及生产能力分析。绞肉机的种类尽

管繁多,但是它们的基术结构和工作原理是相同的。工作过程,主要靠旋转的工作螺杆

(绞笼),将料斗提供的肉料通过工作圆筒推挤到筛网和切刀处,利用转动的切刀刃和

筛网孔口形成约剪切和研磨作用将肉切碎,并在螺杆挤压力作用下将肉粒排出筛网。

关键词肉类工业;绞肉机;挤肉样板;绞刀

ABSTRACT

Atpresent,inthefaceoftherapidincreaseinthelevelofnationallife

situationthedemandformeatandfillingproductscontinuetoincrease,meat

processingmachinerydevelopmentisalsogrowingfast。Meatandstuffingproduct

processingprocess,thefirstencounterisaccordingtothetechnical

requirementofthepretreatmentofrawmaterials,includingslicingand

shreddingandwringstuffingandsoon.Thispaperdealswiththemeatprocessing

machinerymincingmachineworkingprinciple,maintechnicalparameters,

transmissionsystemoftypicalparts,structuredesignandproductioncapacity

analysis.Althoughmanykindsofmeatgrinder,buttheirbasicstructureand

workingprincipleisthesame.Workingprocess,mainlybytherotationofthe

screwworking(strandingcage),thehopperofthemeatmaterialthroughthe

workingcylinderpushestothescreenandthecuttingknifeat,therotation

ofthecuttingedgeandthescreenholeformaboutcuttingandgrindingwill

bechoppedmeat,andscrewextrusionpressureunderthemeatparticlesdischarge

screen.

Keywords:meatchopperCrowdedmeatmodereamerCage

II

目录

目录....................................................................................................................................................................2

摘要.....................................................................................................................................................................I

Abstract.............................................................................................................................................................II

第一章引言.................................................................................................................................................- 1 -

第二章结构与工作原理............................................................................................................................ - 2 -

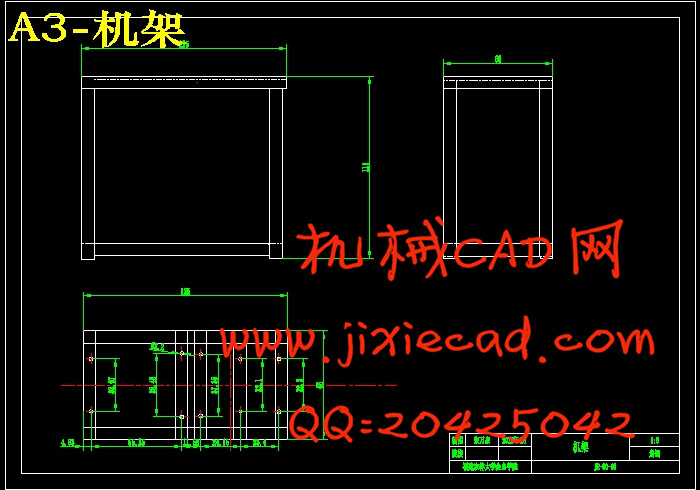

2.1绞肉机的结构................................................................................................................................- 2 -

2.1.1送料机构............................................................................................................................ - 2 -

2.1.2切割机构............................................................................................................................ - 2 -

2.1.3驱动机构............................................................................................................................ - 3 -

2.2工业绞肉机的工作原理........................................................................................................- 3 -

第三章螺旋供料器的设计........................................................................................................................ - 4 -

3.1轴的设计........................................................................................................................................- 4 -

3.1.1绞笼的材料........................................................................................................................ - 4 -

3.1.2螺旋直径 ......................................................................................................................... - 5 -

3.1.3额定绞笼的转速................................................................................................................ - 5 -

3.1.4螺旋节距............................................................................................................................ - 5 -

3.2绞筒的设计....................................................................................................................................- 5 -

3.3止推轴承座的设计........................................................................................................................- 6 -

第四章传动系统的设计............................................................................................................................ - 8 -

4.1电机的选择....................................................................................................................................- 8 -

4.2带传动的设计................................................................................................................................- 9 -

4.2.1设计功率 Pd .......................................................................................................................- 9 -

4.2.1大带轮基准直径d

d2(mm)...........................................................................................- 9 -

4.2.2初定轴间距a0(mm).....................................................................................................- 10 -

4.2.3小带轮包角¶1.................................................................................................................- 10 -

4.2.4 V带的根数Z....................................................................................................................- 11 -

4.3皮带的选择、及计算..................................................................................................................- 11 -

4.3.1单根 V带的预紧力..........................................................................................................- 11 -

4.3.2作用在轴上的力.............................................................................................................- 12 -

4.3.3带轮的结构和尺寸.........................................................................................................- 12 -

第五章绞刀的设计..................................................................................................................................- 13 -

5.1绞刀的设计..................................................................................................................................- 13 -

5.1.1刀刃的起讫位置..............................................................................................................- 14 -

5.1.2刀刃的前角......................................................................................................................- 15 -

5.1.3刀刃的后角......................................................................................................................- 16 -

5.1.4刀刃的刃倾角..................................................................................................................- 17 -

5.1.5刀刃上任一点位量上绞肉速度......................................................................................- 19 -

5.1.6刀片的结构.....................................................................................................................- 20 -

5.2筛网的设计..................................................................................................................................- 21 -

第六章生产能力分析..............................................................................................................................- 22 -

6.1影响生产能力的主要因素......................................................................................................... - 22 -

6.2绞刀的切割能力..........................................................................................................................- 22 -

6.3绞肉机的生产能力......................................................................................................................- 22 -

6.4功率消耗......................................................................................................................................- 23 -

结束语........................................................................................................................................................ - 24 -

参考文献.................................................................................................................................................... - 24 -

致谢............................................................................................................................................................ - 25 -