设计简介

摘要

数控机床在现代制造业中扮演着一个重要的角色。本论文介绍了THY5940型立式加工中心设计思想和设计过程。主要叙述了数控进给系统的传动设计及主要传动件滚珠丝杠及其支承的设计计算。并对进给系统进行了校验,取得了预期的效果。该机床适用于摩托车、汽车、轻工机械等行业提高生产率。不仅对刀具的位置或轨迹进行控制,而且还具有自动换刀和补偿功能,具有很高的强度,刚度和抗震性。以前采用的专用机床加工零件,虽然效率较高,但制约被加工零件的改进。而加工中心具有柔性,从而能适应产品在最短时间内达到商品化。本加工中心的设计拟采用主机,数控系统(包括伺服和驱动系统)及相关配套件三部分组成。在对以前研究成果分析总结的基础上,按照技术要求指标,对初步拟订的方案进行细化,论证,完善和总结。

加工中心的进给系统承担加工中心各直线坐标轴的定位和切削进给,进给系统的好坏将直接影响整机的运行状态和精度指标。设计过程中应使进给稳定性和快速响应的特性。同时,要求有合理的控制系统,而且要求对驱动元件和机械传动装置的参数进行合理的选择,使整个进给系统工作时的动态特性相匹配。

THY5940型立式加工中心机床解决了单件,小批量,特别是复杂型面的零件的加工自动化问题。对于提高企业的生产率,提高工件的加工精度以及提高机床的使用寿命都具有十分重要的意义。

经过研究,本论文基本取得了预期效果,完成了进给系统的设计计算。同时,对数控机床的进给系统设计方法的研究也取得一定的效果。

关键词:数控技术;数控机床;进给系统;滚珠丝杠

Abstract

Numerical control machine tools play an important role in nowadays manufacturing. This article integrate the design method and design process of the entering system of NC machining center of type of THY 5940.It specifies the driving design and important driving accessory –ball bearing and it,s bearing of the entering system of NC machining center .In the same way ,checkout the entering system . We have achieved the method of intelligent design.This machine applies to car/motorcycle and light industry of engine in order to improve their production ratio. It is not only control the position and track of the falchion, but also has the function of change the falchion automatically and compensates; have high intension/Steelton and non-shake. In the old days, people often use special machine to product accessories. Although have a high production ratio, hobble the improving of producing accessories. But NC machining center is flexible, so it can adopt the changed production and organize production and shorten regulate period of production possibly. The NC machine center design adopt main –frame\NC machining center system and correlative accessories, on the base of the former study progeny.

The entering system of NC machining bears NC machining all line coordinate ordination and cutting entering. The advantage and disadvantage of entering system will influence the driving station of the whole machine and precision guideline. In the process of design, we should make sure that the interring system meets the stability and response quickly. Contemporary, require reasonable control system. Furthermore, have a logical choose for the parameter of driving settings. So the whole entering system can match the machine when it is working.

The entering system of NC machining center of type of THY 5940 settle the problems of the product automatically of one accessory small production and complex accessories. This machine has an important role in improving the production of enterprise to improve the product precision and advance the longevity of machine.

After this study, we have realized the anticipate purpose. We have completed the antitype of the intelligent design system, and we have achieved the method of intelligent design.

Key words: Numerical control technology; Numerical control machine tool;Feed system;Ball bearing guide screw

摘 要 I

Abstract II

第1章 引言 1

第2章 THY5940简介 4

2.1 机床的设计参数 4

2.2 机床坐标与进给传动机构 5

第3章 进给系统的设计计算 6

3.1 数控机床进给传动系统机械结构 6

3.1.1 进给传动系统的机械结构 6

3.1.2 设计传动系统时应注意的问题 7

3.1.3 传动过程中的关键元件 8

3.2 滚珠丝杠的选择 9

3.3 丝杠拖动电机的确定 9

3.3.1 丝杠的转动惯量J 9

3.3.2 电机的选择 10

3.4 刚度计算 11

第4章 滚珠丝杠副的校验与进给系统误差分析 13

4.1 机床定位精度与丝杠精度 13

4.2 滚珠丝杠的疲劳强度 13

4.3 死区误差的分析 14

4.4 由传动刚度的变化引起的定位误差 14

第5章 机床的总体设计思路 16

5.1 主轴箱平衡和主轴箱拖动 16

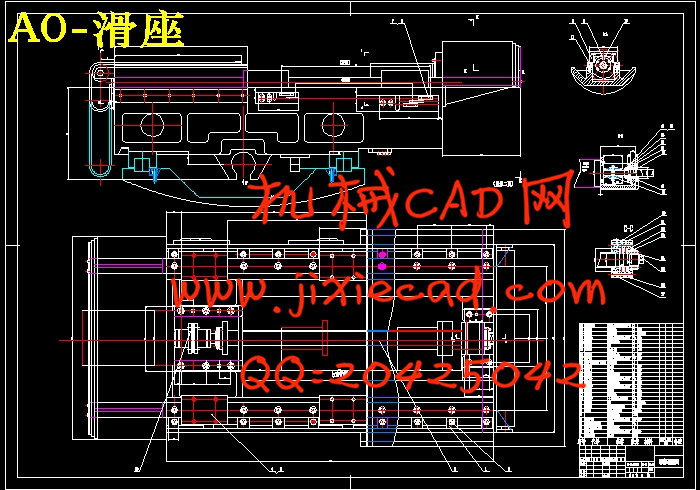

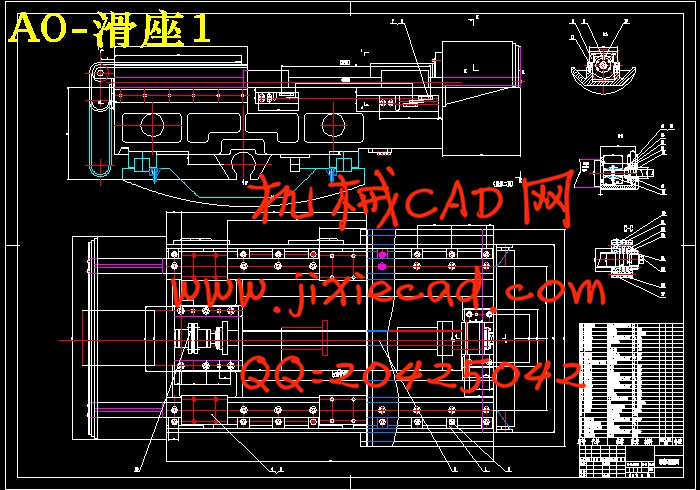

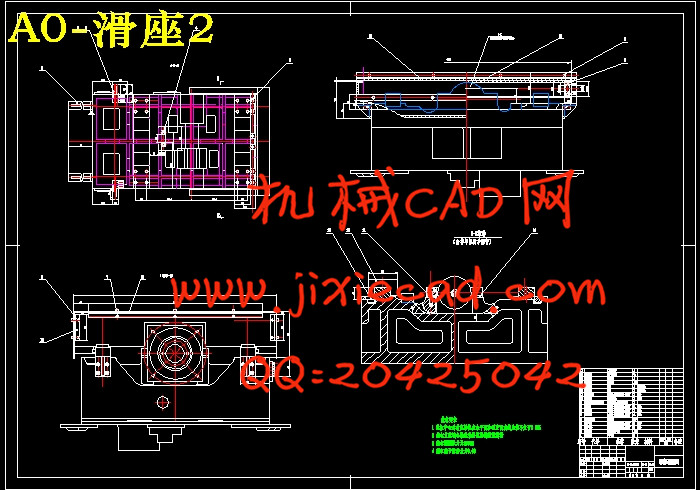

5.2 滑座及立柱拖动 16

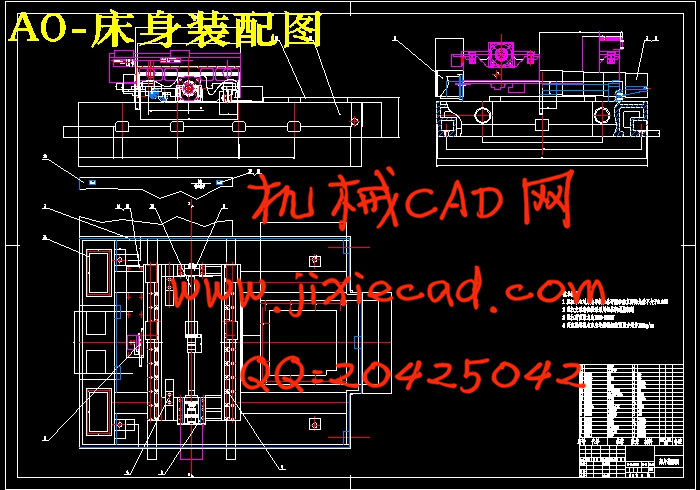

5.3 床身及滑座拖动 16

5.4 机床的防护系统 17

结 论 18

参 考 文 献 19

致 谢 21