设计简介

TK型弹簧开关的自动贴胶机设计

摘 要

当前,电子产品随着新技术、新材料、新工艺的不断出现和应用,有着向微小型化和高精度化发展的趋势。现在,国外微电路的制造已普遍采用了0.8~1.0纳米技术,国内也已经达到2~3纳米水平。在电子工业日趋激烈的竞争中,谁的产品质量稳定、供货及时,谁就能在竞争中脱颖而出。

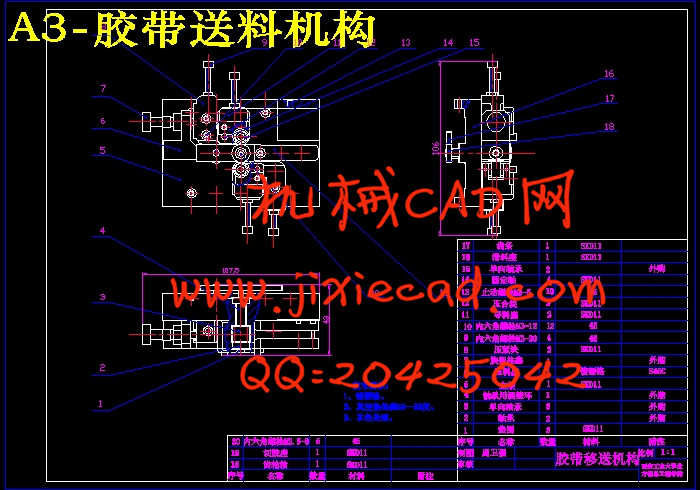

自动贴胶机的设计就是为了提高产量,并保证质量要求而提出的。该套设备主要应用于自动生产线上,主要动作是通过可编程控制器配合几种传感器来控制一系列气缸来完成动作的。该设备就是气压传动的在实际应用中的一个典型范例。整个自动生产线的设备由放料机、贴胶机、测试机、成型包装机组成,其中贴胶机正是整条自动线的核心,而贴胶机构则是贴胶机的核心部件。整个贴胶机构是由一个步进电机通过皮带传动来带动滚珠丝杠螺母副拨动齿条,使齿轮轴转动。齿轮轴上装有一个单向轴承,通过单向轴承来限定齿轮轴只能向一个方向转动,再与其它的两个单向轴承配合实现单向定长送料。

关键词:步进电机;滚珠丝杠螺母副;单向轴承;可编程控制器

The automatic adhesive machine design of TK Spring switch

Abstract

At present, electronic products with new technologies, new materials, new technology and emerging applications, have to micro and small and the development trend of high-precision. Now, foreign micro-circuit manufacturing has generally been used by 0.8 to 1.0 nanometer technology, China has already reached 2 to 3 nanometer level. In the electronics industry increasingly fierce competition, whose product quality and timely supply, who will be able to come to the fore in the competition.

The design of automatic adhesive is to increase production and quality assurance requirements by copies of the major equipment moves through the PLC with several sensors to control a series of moves to complete the cylinder. The device is the pressure in the transmission of practical applications in a typical example. The equipment from discharge machines, plastic stickers machines, test machines, packaging machines molding, composed of gum paste the entire machine is the core of the automatic line, and paste the plastic body is affixed plastic components of the core. Gum paste the entire body by a stepper motor to drive through the belt driven ball screw nut Vice Boding rack so that the gear shaft rotation. Gear shaft equipped with a one-way bearing, through one-way gear shaft bearings to qualify only one direction to the rotation, with the other two one-way bearing with one-way to achieve the long feed.

Key Words:Stepper motor;Vice ball screw nut; One-way bearing;PLC

目 录

1 绪论 1

1.1前言 1

1.2课题背景 6

1.3主要研究内容 7

2 产品简介 8

3 设计方案的拟定 9

3.1本文主要研究内容 9

3.2对机器功能的分析 9

3.3方案的提出 9

3.4对方案的评价、决策 11

3.4.1技术分析 11

3.4.2经济分析 12

3.4.3劳动保护和环境保护分析 12

3.4.4可靠性分析 12

3.4.5方案决策 12

4 技术设计 14

4.1传动部分的设计 14

4.1.1步进电机的选择 14

4.1.2步进电机的一些基本参数 15

4.1.3步进电机的一些特点 16

4.1.4步进电机动态指标及术语 16

4.1.5滚珠丝杠螺母副的选择 17

4.1.6齿轮齿条的设计 18

4.2机械手的设计 19

4.3胶带剥离机构的设计 20

4.4气缸的选用 20

4.5控制部件的选用 21

5 对设计结果的分析和评价 23

5.1功能分析 23

5.2经济分析 23

5.3劳动保护和环境保护 24

6 结束语 25

致 谢 26

参考文献 27

摘 要

当前,电子产品随着新技术、新材料、新工艺的不断出现和应用,有着向微小型化和高精度化发展的趋势。现在,国外微电路的制造已普遍采用了0.8~1.0纳米技术,国内也已经达到2~3纳米水平。在电子工业日趋激烈的竞争中,谁的产品质量稳定、供货及时,谁就能在竞争中脱颖而出。

自动贴胶机的设计就是为了提高产量,并保证质量要求而提出的。该套设备主要应用于自动生产线上,主要动作是通过可编程控制器配合几种传感器来控制一系列气缸来完成动作的。该设备就是气压传动的在实际应用中的一个典型范例。整个自动生产线的设备由放料机、贴胶机、测试机、成型包装机组成,其中贴胶机正是整条自动线的核心,而贴胶机构则是贴胶机的核心部件。整个贴胶机构是由一个步进电机通过皮带传动来带动滚珠丝杠螺母副拨动齿条,使齿轮轴转动。齿轮轴上装有一个单向轴承,通过单向轴承来限定齿轮轴只能向一个方向转动,再与其它的两个单向轴承配合实现单向定长送料。

关键词:步进电机;滚珠丝杠螺母副;单向轴承;可编程控制器

The automatic adhesive machine design of TK Spring switch

Abstract

At present, electronic products with new technologies, new materials, new technology and emerging applications, have to micro and small and the development trend of high-precision. Now, foreign micro-circuit manufacturing has generally been used by 0.8 to 1.0 nanometer technology, China has already reached 2 to 3 nanometer level. In the electronics industry increasingly fierce competition, whose product quality and timely supply, who will be able to come to the fore in the competition.

The design of automatic adhesive is to increase production and quality assurance requirements by copies of the major equipment moves through the PLC with several sensors to control a series of moves to complete the cylinder. The device is the pressure in the transmission of practical applications in a typical example. The equipment from discharge machines, plastic stickers machines, test machines, packaging machines molding, composed of gum paste the entire machine is the core of the automatic line, and paste the plastic body is affixed plastic components of the core. Gum paste the entire body by a stepper motor to drive through the belt driven ball screw nut Vice Boding rack so that the gear shaft rotation. Gear shaft equipped with a one-way bearing, through one-way gear shaft bearings to qualify only one direction to the rotation, with the other two one-way bearing with one-way to achieve the long feed.

Key Words:Stepper motor;Vice ball screw nut; One-way bearing;PLC

目 录

1 绪论 1

1.1前言 1

1.2课题背景 6

1.3主要研究内容 7

2 产品简介 8

3 设计方案的拟定 9

3.1本文主要研究内容 9

3.2对机器功能的分析 9

3.3方案的提出 9

3.4对方案的评价、决策 11

3.4.1技术分析 11

3.4.2经济分析 12

3.4.3劳动保护和环境保护分析 12

3.4.4可靠性分析 12

3.4.5方案决策 12

4 技术设计 14

4.1传动部分的设计 14

4.1.1步进电机的选择 14

4.1.2步进电机的一些基本参数 15

4.1.3步进电机的一些特点 16

4.1.4步进电机动态指标及术语 16

4.1.5滚珠丝杠螺母副的选择 17

4.1.6齿轮齿条的设计 18

4.2机械手的设计 19

4.3胶带剥离机构的设计 20

4.4气缸的选用 20

4.5控制部件的选用 21

5 对设计结果的分析和评价 23

5.1功能分析 23

5.2经济分析 23

5.3劳动保护和环境保护 24

6 结束语 25

致 谢 26

参考文献 27