设计简介

TY2100柴油机机体缸孔粗镗组合机床总体及刀具设计

摘要:组合机床是根据工件加工需要,以大量通用部件为基础,配以少量专用部件组成的一种高效专用机床。组合机床的研制和推广,是加速机械工业技术革命的有效途径之一,是机械工业,特别是汽车、拖拉机、电机、仪表等生产部门进行机床革新,推动生产发展的重要设备。柴油机缸体是需要大量生产的零件,为了提高加工精度和生产效率,需要设计一台组合机床来改善柴油机机体缸孔的的加工情况。

设计出的组合机床结构简单,操作方便,加工精度高,减轻了劳动强度,提高了加工效率,具有较好的经济性。在此设计中大量使用了机械设计方面的知识,并且参考了许多资料。

关键词:组合机床;柴油机缸体;刀具

overall and tool design for rough boring TY2100- Block of Diesel Engine of combination machine

Abstract:Combination Machine is an efficient machine which based on common ents, supported by a small number of parts. The development and promotion of the Combination Machine is one of the effective way for the development of the Machinery Industry technological revolution.It is the important device to impove mechanical industry especialy in the field on automotive、tractor、motor、instrument and so on. A large numble parts have been used in diesel engine block. In order to imrove the accuracy of processing and production efficiency, a new combination machine is needed to improve the processing situation to the block of the cylinder engine .

The structure of combination machine is simple ,easy to operate, high-precision machining.It can also reduc the labor intensity, and improve processing efficiency with a better economy. A large-scale use of the mechanical design of knowledge and information and a lot of information have been used in this design.

Keywords:Combination Machine Block of Diesel Engine Tool

目 录

1前言 1

2组合机床总体设计 3

2.1 总体方案的确定 3

2.1.1 工艺方案的拟订 3

2.1.2 定位基准的选择 4

2.1.3 机床配置型式的选择 4

2.1.4 滑台型式的选择 4

2.2 切削用量及选择刀具的确定 5

2.2.1 切削用量的选择 5

2.2.2 切削力、切削扭矩及切削功率的计算 6

2.2.3 刀具结构的选择 8

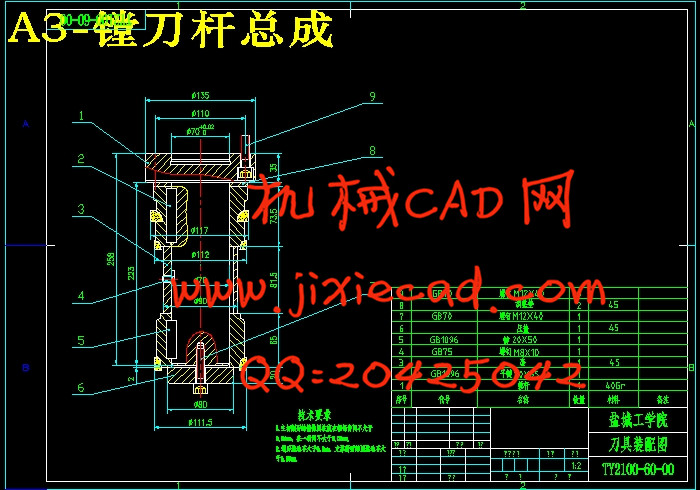

2.3 组合机床总体设计—“三图一卡” 8

2.3.1 被加工零件工序图 8

2.3.2 加工示意图 9

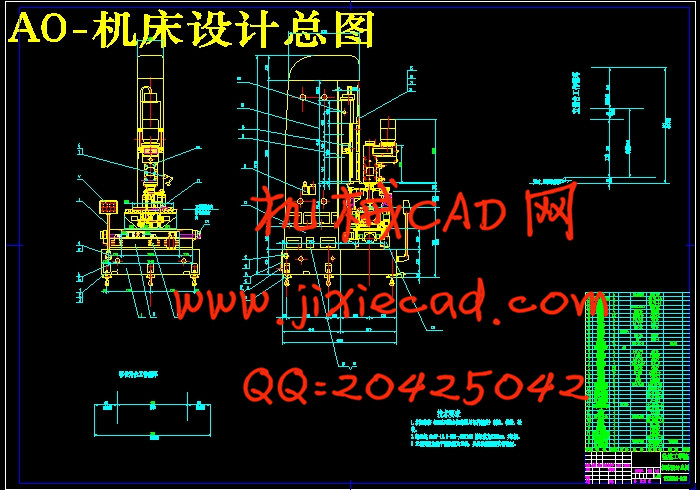

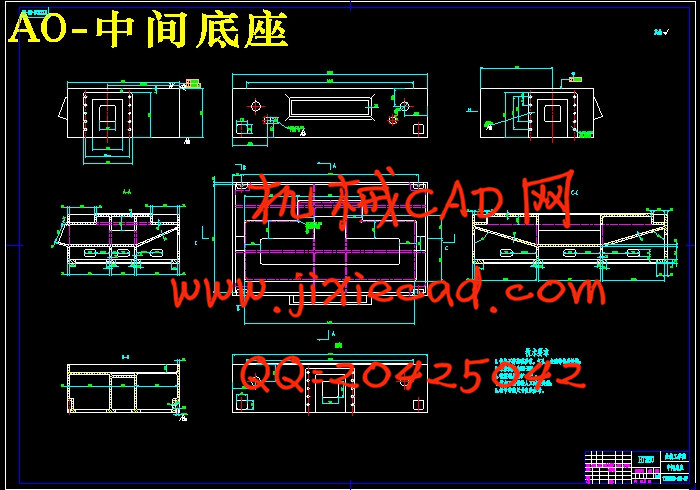

2.3.3 机床联系尺寸总图 10

2.3.4 生产率计算卡 11

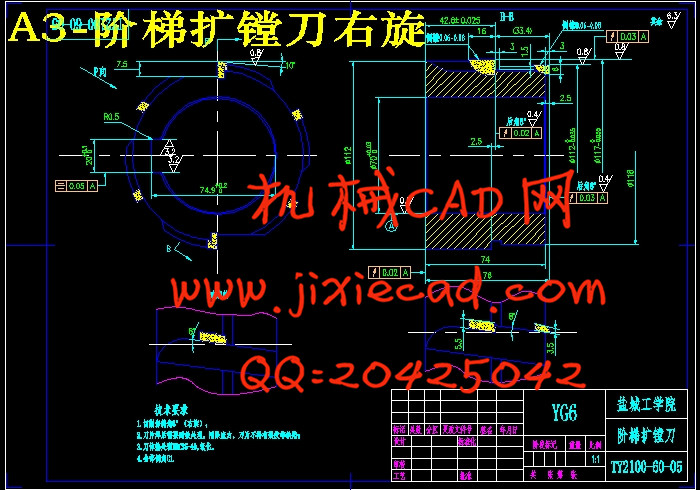

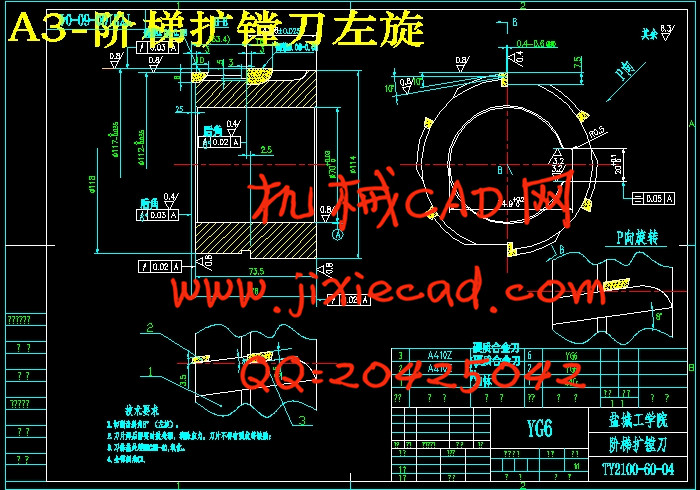

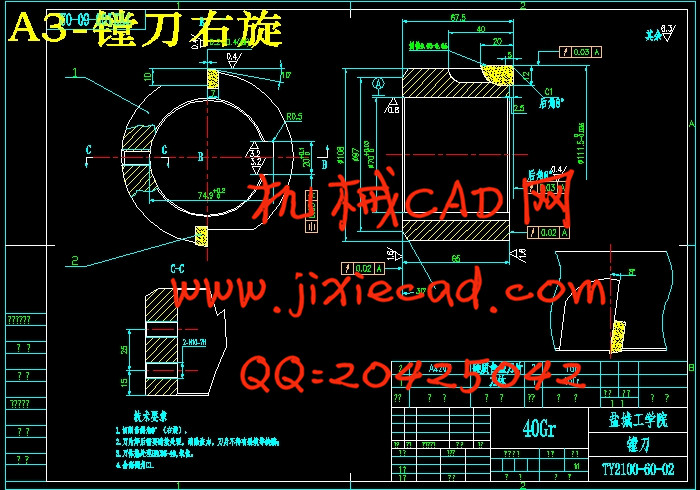

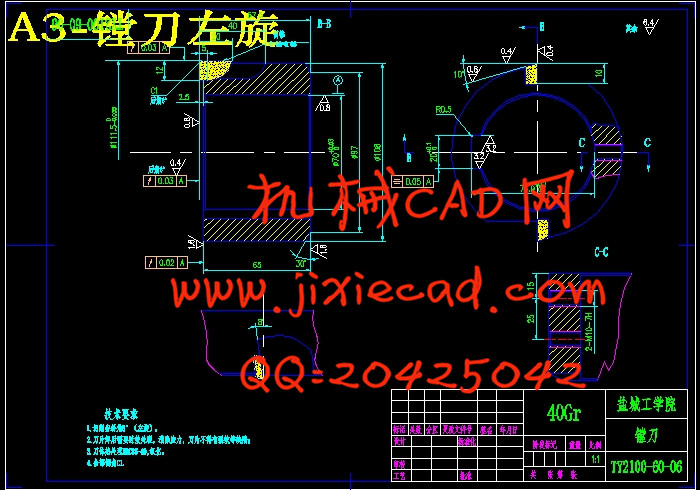

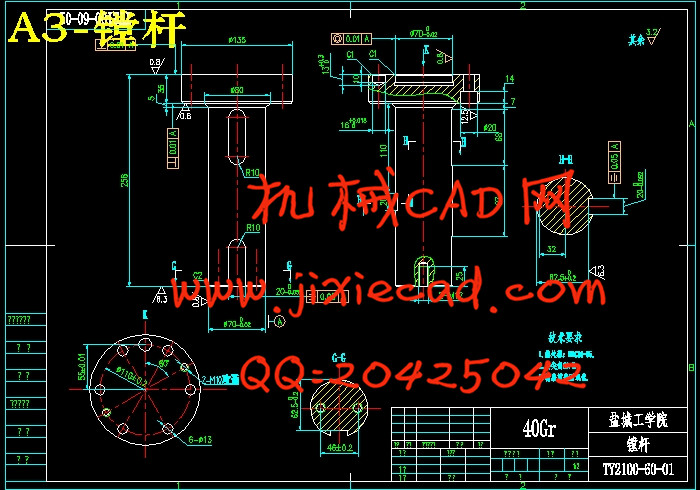

3 镗刀设计 14

3.1 刀具设计概述 14

3.2 组合镗刀工作原理 14

3.3 镗刀设计 17

4 结论 21

文 献 资 料 22

致 谢 23

附 录 24

摘要:组合机床是根据工件加工需要,以大量通用部件为基础,配以少量专用部件组成的一种高效专用机床。组合机床的研制和推广,是加速机械工业技术革命的有效途径之一,是机械工业,特别是汽车、拖拉机、电机、仪表等生产部门进行机床革新,推动生产发展的重要设备。柴油机缸体是需要大量生产的零件,为了提高加工精度和生产效率,需要设计一台组合机床来改善柴油机机体缸孔的的加工情况。

设计出的组合机床结构简单,操作方便,加工精度高,减轻了劳动强度,提高了加工效率,具有较好的经济性。在此设计中大量使用了机械设计方面的知识,并且参考了许多资料。

关键词:组合机床;柴油机缸体;刀具

overall and tool design for rough boring TY2100- Block of Diesel Engine of combination machine

Abstract:Combination Machine is an efficient machine which based on common ents, supported by a small number of parts. The development and promotion of the Combination Machine is one of the effective way for the development of the Machinery Industry technological revolution.It is the important device to impove mechanical industry especialy in the field on automotive、tractor、motor、instrument and so on. A large numble parts have been used in diesel engine block. In order to imrove the accuracy of processing and production efficiency, a new combination machine is needed to improve the processing situation to the block of the cylinder engine .

The structure of combination machine is simple ,easy to operate, high-precision machining.It can also reduc the labor intensity, and improve processing efficiency with a better economy. A large-scale use of the mechanical design of knowledge and information and a lot of information have been used in this design.

Keywords:Combination Machine Block of Diesel Engine Tool

目 录

1前言 1

2组合机床总体设计 3

2.1 总体方案的确定 3

2.1.1 工艺方案的拟订 3

2.1.2 定位基准的选择 4

2.1.3 机床配置型式的选择 4

2.1.4 滑台型式的选择 4

2.2 切削用量及选择刀具的确定 5

2.2.1 切削用量的选择 5

2.2.2 切削力、切削扭矩及切削功率的计算 6

2.2.3 刀具结构的选择 8

2.3 组合机床总体设计—“三图一卡” 8

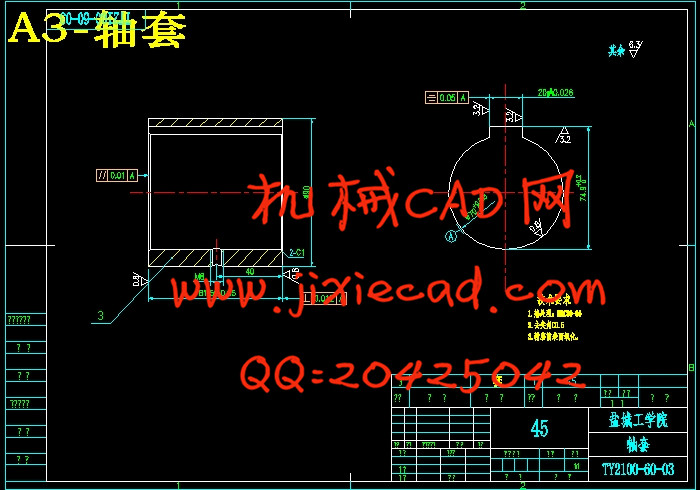

2.3.1 被加工零件工序图 8

2.3.2 加工示意图 9

2.3.3 机床联系尺寸总图 10

2.3.4 生产率计算卡 11

3 镗刀设计 14

3.1 刀具设计概述 14

3.2 组合镗刀工作原理 14

3.3 镗刀设计 17

4 结论 21

文 献 资 料 22

致 谢 23

附 录 24