设计简介

摘要:铣床是一种应用广泛的机床,铣床除能铣削平面、沟槽、轮齿、螺纹和花键轴外,还能加工比较复杂的型面,效率较刨床高,在机械制造和修理部门得到广泛应用。本课题设计的是一台实现三轴联动的铣床,并利用UG软件进行运动仿真。机床运动仿真分析已成为机床设计过程中重要的辅助手段,利用仿真可以及时发现存在的运动干涉、设计不合理等问题,这样可以在机床制造前及时解决,避免产生巨大的成本花费。

首先,简单介绍课题来源,铣床的分类及发展历程。

其次,对三轴铣床进行总体设计,确定各个零件的尺寸和定位关系并进行校核。使用UG软件,建立铣床运动模型并进行简单的运动仿真。

最后,总结全文,并展望了计算机仿真技术在机床设计方面的前景。本课题是涉及机械和计算机技术的研究型项目。文中对UGNX软件的应用、铣床总体结构进行了一些探究,为机床设计与研制方面累积了一些经验。

关键词:三轴铣床;UG;运动仿真

首先,简单介绍课题来源,铣床的分类及发展历程。

其次,对三轴铣床进行总体设计,确定各个零件的尺寸和定位关系并进行校核。使用UG软件,建立铣床运动模型并进行简单的运动仿真。

最后,总结全文,并展望了计算机仿真技术在机床设计方面的前景。本课题是涉及机械和计算机技术的研究型项目。文中对UGNX软件的应用、铣床总体结构进行了一些探究,为机床设计与研制方面累积了一些经验。

关键词:三轴铣床;UG;运动仿真

Motion simulation of three-axis milling machine based on UG

Abstract:Milling machine is a widely used machine, Milling machine can mill plane, groove, teeth, thread, spline axis, and more complex surface machining . Its higher efficiency than the planer , it has been widely used in the machinery manufacturing and repair sector . The project is designed to achieve a linkage axis milling machine, and using motion simulation by UG. Analysis of machine tool motion simulation has become an important adjunct in theMachine tool design process.This simulation can be used to detect the existence of the movement interference, design issues such as unreasonable. This can be resolved in time for the machine tool manufacturers, to avoid spending huge cost.

Firstly,in this paper,it introduces a brief subject sources, classification and development process of milling.

Secondly, it makes the overall design of three-axis milling machine, determines the size and location of each part and checks them between.,Confirm a simple motion model and motion simulation by UG software.

Finally, it concluds remarks and prospects of the computer simulation in the design of future machines.This issue is related to mechanical and computer technology research projects, In this paper, application of UGNX software and the overall structure of milling machines has be explored,it accumulats some experience in design and development of machine tools .

Key words:Three-axis milling machine;UG; Motion simulation

目录

1.绪论 1Abstract:Milling machine is a widely used machine, Milling machine can mill plane, groove, teeth, thread, spline axis, and more complex surface machining . Its higher efficiency than the planer , it has been widely used in the machinery manufacturing and repair sector . The project is designed to achieve a linkage axis milling machine, and using motion simulation by UG. Analysis of machine tool motion simulation has become an important adjunct in theMachine tool design process.This simulation can be used to detect the existence of the movement interference, design issues such as unreasonable. This can be resolved in time for the machine tool manufacturers, to avoid spending huge cost.

Firstly,in this paper,it introduces a brief subject sources, classification and development process of milling.

Secondly, it makes the overall design of three-axis milling machine, determines the size and location of each part and checks them between.,Confirm a simple motion model and motion simulation by UG software.

Finally, it concluds remarks and prospects of the computer simulation in the design of future machines.This issue is related to mechanical and computer technology research projects, In this paper, application of UGNX software and the overall structure of milling machines has be explored,it accumulats some experience in design and development of machine tools .

Key words:Three-axis milling machine;UG; Motion simulation

目录

1.1简介: 1

1.2发展历程: 1

1.3国内外现状综述: 1

1.4主要分类: 2

2.铣床机械部分设计 4

2.1 总体设计要求 4

2.2 运动轴的布置 4

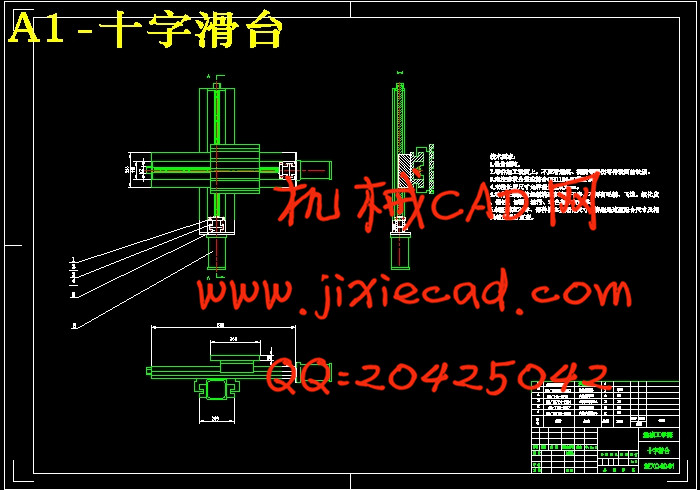

2.3 运动部件的行程范围 4

2.4导轨的选择 4

2.5联轴器的选择 5

2.6铣削力的计算 5

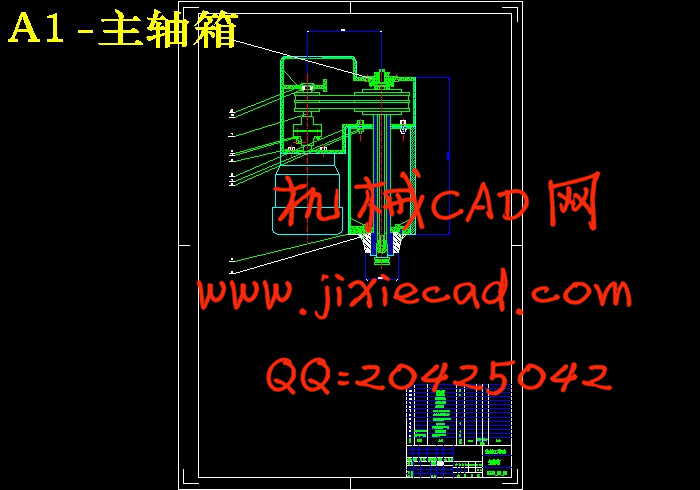

2.6.1主轴电机的选择 6

2.6.2X、Y轴铣削力的计算 6

2.7步进电机的选择 7

2.7.1步进电机应用中的注意事项 7

2.7.2步进电机三因素的选择 7

2.7.3步进电机参数的计算选择 8

2.8滚珠丝杠的选择 8

2.8.1滚珠丝杠的选择计算 9

2.8.2滚珠丝杠的校核 10

2.9轴承的选择 11

3.运动仿真 16

3.1建模 16

3.2装配 16

3.3创建机床运动模型 18

3.3.1定义机床基础部件 18

3.3.2定义机床运动组件和分类 18

3.3.3创建联接坐标系和分类 18

3.4机床入库 21

4.结论 25

参考文献 26

致 谢 27