设计简介

2DS(Y)—10/5型电动往复泵

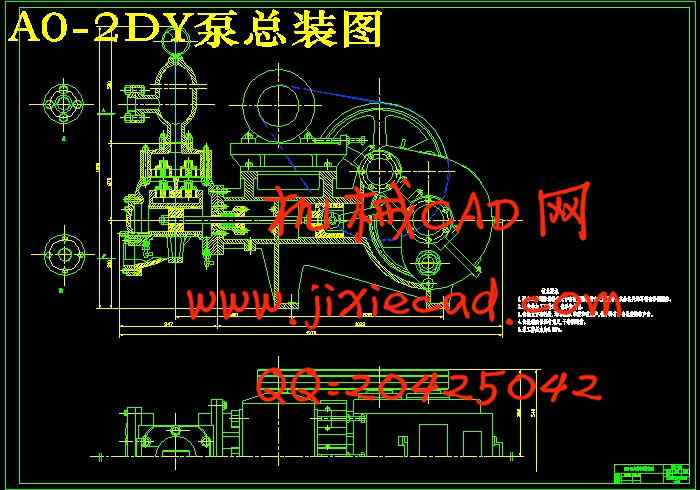

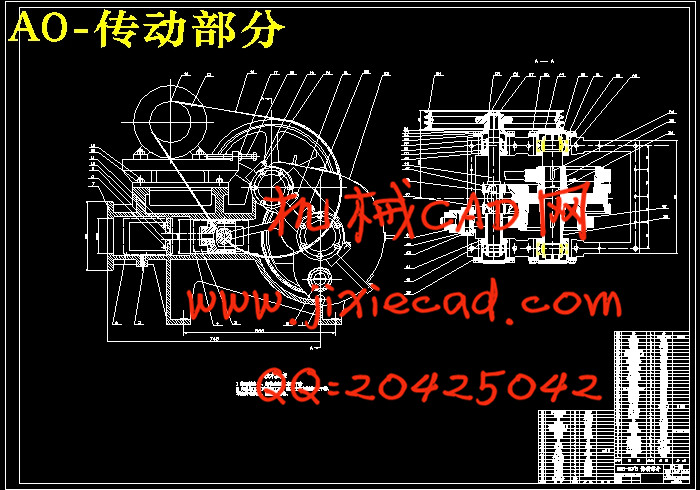

摘 要该设计是对2DS(Y)—10/5型电动往复泵的设计。往复泵是借助于活塞在液缸工作腔内的往复运动,使工作腔容积产生周期性变化来达到输送液体的目的,它是把机械能转化为压力能的装置。此种泵的流量只取决于工作腔容积变化值及在单位时间内的变化次数(频率),而在理论上与排出压力无关。本次设计通过对已知数据的分析以及参考相关资料完成的,该系列电动往复泵系双缸双作用泵,主要由液缸体和传动部分组成。对其活塞、泵阀等零部件进行具体的分析和计算,完成了本次设计的任务。

关键词:电动往复泵;泵阀;活塞;设计

The design of 2DS (Y) -10 / 5 electric reciprocating pump

Abstract

This graduation project is to the 2DS(Y) - 10/5 electrically operated reciprocating pump design. The reciprocating pump is drawssupport the piston in fluid cylinder work cavity reciprocal motion,causes the work cavity volume to have the periodic variation toachieve the transportation liquid the goal, it is transforms themechanical energy as the fluid pressure energy installment. This kindpumps the current capacity is only decided by the work cavity volumechange value and in the unit time change number of times (frequency),but in theoretically has nothing to do with with the deliverypressure. This design through completes to the known data analysis aswell as the reference correlation data, this series electricallyoperated reciprocating pump is the two-cylinder double-acting pump,mainly partially is composed by the fluid cylinder body and thetransmission. To its spare part and so on piston, pump valve carrieson the concrete analysis and the computation, has completed thisdesign task.

Key word :Electrically operated reciprocating pump;Pump valve;Piston;design

目 录

Abstract ii

绪 论 1

第一章 概 述 2

第一节 往复泵的结构和工作原理 2

第二节 往复泵的特点和分类 4

第三节 往复泵的应用与发展 7

第二章 往复泵的总体设计 10

第一节 泵型及总体结构形式选择 10

第二节 液力端结构形式的选择 11

第三章 2DS(Y)-10/5型电动往复泵的设计 14

第一节 主要结构参数的选择与确定 14

第二节 原动机的选择 19

第四章 液力端主要零部件设计 22

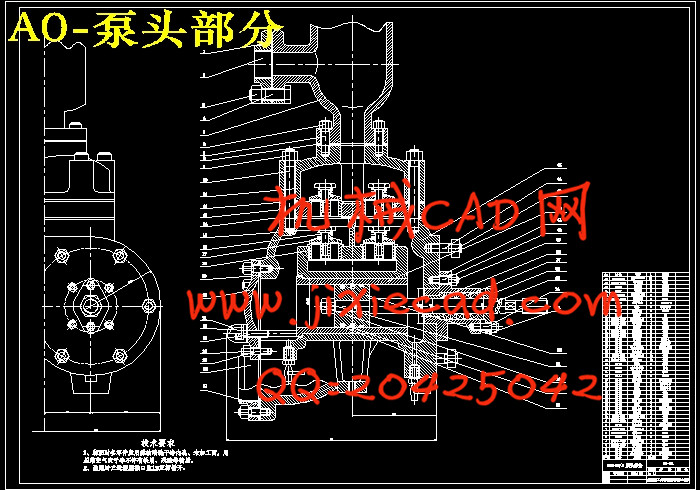

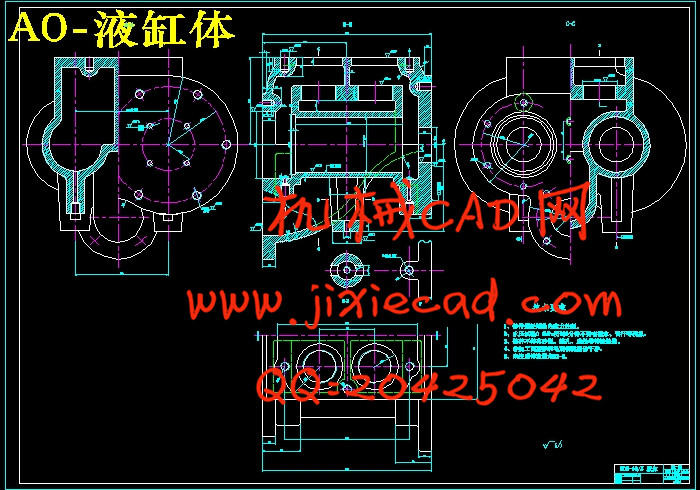

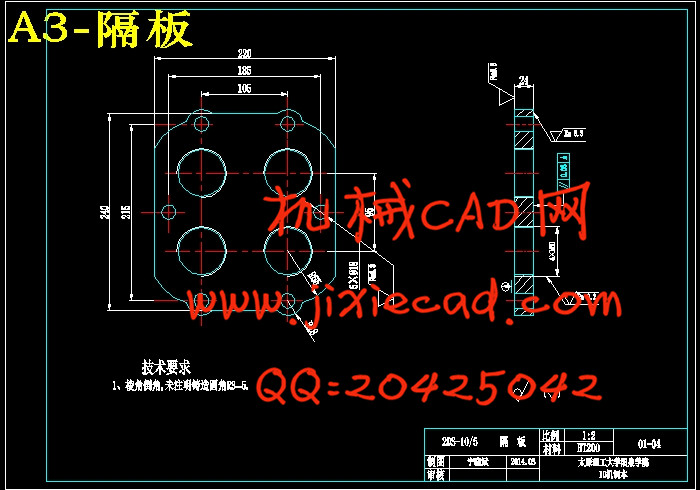

第一节 液 缸 体 22

第二节 泵 阀 设 计 23

第三节 活塞、活塞杆、活塞环 27

总 结 40

参考文献 41