设计简介

X62铣床数控改造

摘 要

本文在X62铣床数控改造设计时主要从经济性、方便性、实用性、可靠性四方面因素出发,对X62 型铣床进行了铣床数控机械系统设计,硬件及电路设计。使改造后的机床的机械传动部分具有高静态、动态刚度;运动副之间的摩擦因数小,传动无间隙;功率大;便于操作和维修。

X62铣床数控机械系统设计包括伺服驱动系统的设计计算,滚珠丝杠螺母副的设计计算。进给传动系统设计中,拆除纵向、横向、垂向进给箱齿轮,在该处将手轮轴通过一对减速齿轮和纵向、横向及垂向步进电机相连。丝杠拆去,换上滚珠丝杠,并由齿轮箱与滚珠丝杠连接,改造后的X62铣床的定位精度为士0.01㎜,重复定位精度为士0.005㎜。X、Y电机能够拖动工作台以6~2300r/min的切削进给速度进行X向、Y向运动。

数控系统是一个基于8031单片机的数字型控制系统。采用较小体积的单片机来实现一般的逻辑功能, 对进给系统的两个轴进行控制。

关键词 铣床;数控改造;步进电机;滚珠丝杠

X62 CNC milling machine transformation

Abstract

Based on the aspects of the improvement on X62 milling machine as follows: the economy,convenience , function and reliability. This dissertation conducts the systematic design and hardware circuit design . These work improve the functions of milling machine on some aspects as follows: the large static and dynamic stiffness of the mechanical drive parts, the little friction factor of the motion pairs,no clearance in driving,the large power and the convenient operation and maintenance.

The system designs of X62 numerical machine’s mechanical include the design and the calculation of the design and the calculation of the servo drive system, of the lead screw nut pair. In the design of he feed motion’s drive system,it should be removed that the longitudinal and the traverse and the vertical feed change gears. Joint the handle wheel axel with the vertical stepping motor through a pair of reduction gear there, the ball screw is used instead of the leads crew, which is connected with the gearbox. Accuracy of position of the improved X62 milling machine is士0.01mm, its precision of repeatability is士 0.005mm. The motors for X and Y directions in the speed of 6-2300r/min.

The numerical system is a data control system designed by model block based on single chip microcomputer of 8031. The single chip microcomputer of smaller volume is adopted to realize the ordinary function., command the locomotion of the X and Y.

Keywords Milling machine, NC innovation, Stepping motor,Ball bearing thread stick

目 录

摘 要 I摘 要

本文在X62铣床数控改造设计时主要从经济性、方便性、实用性、可靠性四方面因素出发,对X62 型铣床进行了铣床数控机械系统设计,硬件及电路设计。使改造后的机床的机械传动部分具有高静态、动态刚度;运动副之间的摩擦因数小,传动无间隙;功率大;便于操作和维修。

X62铣床数控机械系统设计包括伺服驱动系统的设计计算,滚珠丝杠螺母副的设计计算。进给传动系统设计中,拆除纵向、横向、垂向进给箱齿轮,在该处将手轮轴通过一对减速齿轮和纵向、横向及垂向步进电机相连。丝杠拆去,换上滚珠丝杠,并由齿轮箱与滚珠丝杠连接,改造后的X62铣床的定位精度为士0.01㎜,重复定位精度为士0.005㎜。X、Y电机能够拖动工作台以6~2300r/min的切削进给速度进行X向、Y向运动。

数控系统是一个基于8031单片机的数字型控制系统。采用较小体积的单片机来实现一般的逻辑功能, 对进给系统的两个轴进行控制。

关键词 铣床;数控改造;步进电机;滚珠丝杠

X62 CNC milling machine transformation

Abstract

Based on the aspects of the improvement on X62 milling machine as follows: the economy,convenience , function and reliability. This dissertation conducts the systematic design and hardware circuit design . These work improve the functions of milling machine on some aspects as follows: the large static and dynamic stiffness of the mechanical drive parts, the little friction factor of the motion pairs,no clearance in driving,the large power and the convenient operation and maintenance.

The system designs of X62 numerical machine’s mechanical include the design and the calculation of the design and the calculation of the servo drive system, of the lead screw nut pair. In the design of he feed motion’s drive system,it should be removed that the longitudinal and the traverse and the vertical feed change gears. Joint the handle wheel axel with the vertical stepping motor through a pair of reduction gear there, the ball screw is used instead of the leads crew, which is connected with the gearbox. Accuracy of position of the improved X62 milling machine is士0.01mm, its precision of repeatability is士 0.005mm. The motors for X and Y directions in the speed of 6-2300r/min.

The numerical system is a data control system designed by model block based on single chip microcomputer of 8031. The single chip microcomputer of smaller volume is adopted to realize the ordinary function., command the locomotion of the X and Y.

Keywords Milling machine, NC innovation, Stepping motor,Ball bearing thread stick

目 录

Abstract II

第1章 绪论 1

1.1 课题背景 1

1.2 X62 铣床数控改造设计总体要求和内容 3

第2章 X62 铣床数控机械系统设计 6

2.1 概述 6

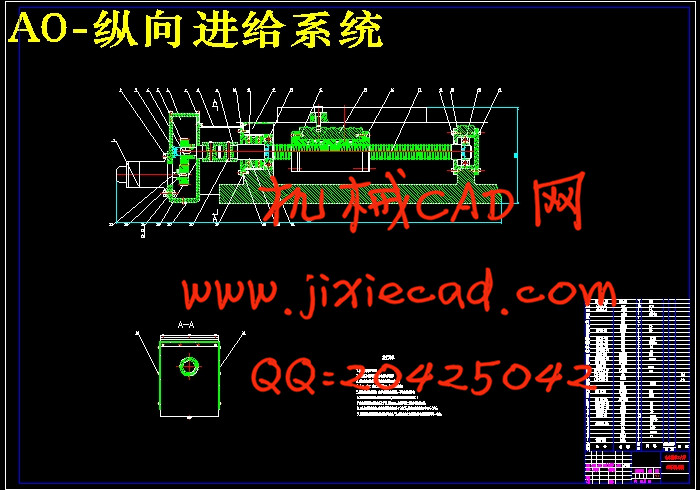

2.2 纵向进给系统的设计计算 7

2.2.1 滚珠丝杠螺母副的设计计算 7

2.2.2 伺服驱动系统的设计计算 9

2.3 横向进给系统的设计计算 11

2.3.1 滚珠丝杠螺母副的设计计算 11

2.3.2 伺服驱动系统的设计计算 12

2.4 垂直进给系统的设计计算 13

2.4.1 滚珠丝杠螺母副的设计计算 13

第3章 X62 数控系统设计 16

3.1 X62 铣床数控控制系统方案 16

3.2 CPU分析选用 16

3.2.1 单片机引脚及其功能 16

3.2.2 3.2.2 I/O口及其功能 16

3.2.3 控制线 17

3.3 存储器I/O的扩展 18

3.3.1 存储器的选用、扩展及连接 18

3.3.2 键盘与显示接口电路 19

3.3.3 8255与8031的连接 27

结论 38

致谢 39

参考文献 40

附录 42