设计简介

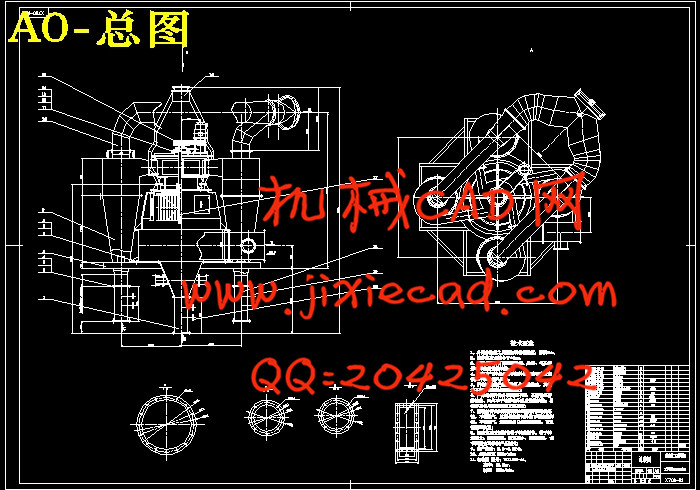

X700涡旋式选粉机(壳体及传动部件)设计

摘 要:选粉机是水泥粉磨系统中不可缺少的一种分级设备,也是提高粉磨系统中水泥产量的主要途径。而传统的离心式、旋风式选粉机已经不适应现代水泥工业发展的需要,必须开发新型高效选粉机。为了满足现代水泥企业越来越高的生产要求,本课题设计了X700 涡旋式选粉机。本次设计采用理论设计和经验设计相结合的方法,通过类比法设计了壳体和旋风筒。首先对其传动系统进行改进。由于原本所用的减速器价格比较高,易损件多,油耗大,更换麻烦且停产时间长,对水泥企业的正常生产造成极大的影响。因此用故障率较低,维修及更换零件方便的皮带传动取代。然后参考了实践生产中的一些改进经验进行总体方案的论证,计算了主轴转速和功率,来确定电机的型号。同时改进选粉机的内部结构,提高选粉力场。改进措施包括采用笼型转子,导流叶片,耐磨陶瓷,从而提高了选粉效率。经过改造后的选粉机大大减少了运行成本,提高了生产效率。

关键词:涡旋式;改进;传动;皮带;选粉力场;选粉机

The design of X700 Eddy type powder selecting machine

(shell and transmission parts)

Abstract : Powder selecting machine is an indispensable equipment of cement grinding system .It is also the main way to increase output in the grinding powder system .Because the traditional centrifugal type and the tornado type of the powder selecting machine is already unsuitable to the modern cement industry development ,so it is necessary to develop new high efficiency the powder selecting machine . In order to meet more and more high production demand , the technological improvement is carried out for X700 Gubernatorial powder selecting machine in this subject. This design adopts the methods which combines theories design and experience design. The shell and the cyclone of canister are optimized based on that the strengths of chassis and support are assured with analogy design .First, its transmission system has been improved. Because the price of the decelerator is high, there are many quick-wear parts, the oil consumption is great, the time of changing the part and non-production is long, it causes bad influence on the normal production of cement enterprises. The transmission fault rate of the belt is relatively low, it is convenient to maintain and change the part. So we take the belt transmission device instead of decelerator. Then referring to some improvement experience in the practice production .And we has calculated the axle rotational speed and the power, and determined the type of electrical machinery the model. At the same time, change the inside structure of the powder selecting machine, improve the selecting force. It includes making Cage-shaped rotors, diversion leaves and Wear-resisting ceramics to improve its powder selecting force field. It reduces the operating cost greatly after transformation, and the production efficiency has been raised.

Key words: eddy; improvement; transmission; belt; powder selecting force field.; powder selecting machine

目录

1前言…………………………………………………………………………………1

1.1 本课题的来源和技术要求………………………………………………………1

1.2 本课题要解决的主要问题和设计总体思路……………………………………1

1.3 预期的成果及其理论意义………………………………………………………2

2 目前市场上有几种不同应用形式的高效选粉机………………………………3

2.1旋风组合式选粉机………………………………………………………………3

2.2高效动态选粉机…………………………………………………………………3

3总体方案论证………………………………………………………………………4

3.1动力——调速电机………………………………………………………………4

3.2 立轴——双支撑系统……………………………………………………………4

3.3喂料口……………………………………………………………………………5

3.4进风——导向叶片………………………………………………………………5

3.5旋风筒……………………………………………………………………………5

3.6内衬的处理——耐磨瓷砖………………………………………………………5

3.7 工作原理…………………………………………………………………………5

3.8改进后的效果……………………………………………………………………6

4具体设计说明………………………………………………………………………7

4.1循环负荷和选粉效率………………………………………………………7

4.2 选粉效率E和循环负荷C的关系………………………………………8

4.3 工艺参数…………………………………………………………………………9

4.3.1主要工艺尺寸…………………………………………………………………9

4.3.2合宜转速…………………………………………………………………10

4.3.3生产能力……………………………………………………………………10

4.4 传动部分设计………………………………………………………10

4.5 螺栓组联接的结构设计……………………………………………………13

4.6 螺栓联接的强度校核………………………………………………14

5焊接工艺……………………………………………………………………17

5.1 焊接接头及坡口型式…………………………………………………………17

5.2 焊接坡口边缘的加工………………………………………………………17

5.2.1法兰的气割…………………………………………………………………17

5.2.2 坡口的气割………………………………………………………………18

5.2.3 气焊规范的选择…………………………………………………………18

5.3壳体焊接加工的技术要求…………………………………………………18

6结语……………………………………………………………………………19

参考文献……………………………………………………………………………20

致谢…………………………………………………………………………………21

摘 要:选粉机是水泥粉磨系统中不可缺少的一种分级设备,也是提高粉磨系统中水泥产量的主要途径。而传统的离心式、旋风式选粉机已经不适应现代水泥工业发展的需要,必须开发新型高效选粉机。为了满足现代水泥企业越来越高的生产要求,本课题设计了X700 涡旋式选粉机。本次设计采用理论设计和经验设计相结合的方法,通过类比法设计了壳体和旋风筒。首先对其传动系统进行改进。由于原本所用的减速器价格比较高,易损件多,油耗大,更换麻烦且停产时间长,对水泥企业的正常生产造成极大的影响。因此用故障率较低,维修及更换零件方便的皮带传动取代。然后参考了实践生产中的一些改进经验进行总体方案的论证,计算了主轴转速和功率,来确定电机的型号。同时改进选粉机的内部结构,提高选粉力场。改进措施包括采用笼型转子,导流叶片,耐磨陶瓷,从而提高了选粉效率。经过改造后的选粉机大大减少了运行成本,提高了生产效率。

关键词:涡旋式;改进;传动;皮带;选粉力场;选粉机

The design of X700 Eddy type powder selecting machine

(shell and transmission parts)

Abstract : Powder selecting machine is an indispensable equipment of cement grinding system .It is also the main way to increase output in the grinding powder system .Because the traditional centrifugal type and the tornado type of the powder selecting machine is already unsuitable to the modern cement industry development ,so it is necessary to develop new high efficiency the powder selecting machine . In order to meet more and more high production demand , the technological improvement is carried out for X700 Gubernatorial powder selecting machine in this subject. This design adopts the methods which combines theories design and experience design. The shell and the cyclone of canister are optimized based on that the strengths of chassis and support are assured with analogy design .First, its transmission system has been improved. Because the price of the decelerator is high, there are many quick-wear parts, the oil consumption is great, the time of changing the part and non-production is long, it causes bad influence on the normal production of cement enterprises. The transmission fault rate of the belt is relatively low, it is convenient to maintain and change the part. So we take the belt transmission device instead of decelerator. Then referring to some improvement experience in the practice production .And we has calculated the axle rotational speed and the power, and determined the type of electrical machinery the model. At the same time, change the inside structure of the powder selecting machine, improve the selecting force. It includes making Cage-shaped rotors, diversion leaves and Wear-resisting ceramics to improve its powder selecting force field. It reduces the operating cost greatly after transformation, and the production efficiency has been raised.

Key words: eddy; improvement; transmission; belt; powder selecting force field.; powder selecting machine

目录

1前言…………………………………………………………………………………1

1.1 本课题的来源和技术要求………………………………………………………1

1.2 本课题要解决的主要问题和设计总体思路……………………………………1

1.3 预期的成果及其理论意义………………………………………………………2

2 目前市场上有几种不同应用形式的高效选粉机………………………………3

2.1旋风组合式选粉机………………………………………………………………3

2.2高效动态选粉机…………………………………………………………………3

3总体方案论证………………………………………………………………………4

3.1动力——调速电机………………………………………………………………4

3.2 立轴——双支撑系统……………………………………………………………4

3.3喂料口……………………………………………………………………………5

3.4进风——导向叶片………………………………………………………………5

3.5旋风筒……………………………………………………………………………5

3.6内衬的处理——耐磨瓷砖………………………………………………………5

3.7 工作原理…………………………………………………………………………5

3.8改进后的效果……………………………………………………………………6

4具体设计说明………………………………………………………………………7

4.1循环负荷和选粉效率………………………………………………………7

4.2 选粉效率E和循环负荷C的关系………………………………………8

4.3 工艺参数…………………………………………………………………………9

4.3.1主要工艺尺寸…………………………………………………………………9

4.3.2合宜转速…………………………………………………………………10

4.3.3生产能力……………………………………………………………………10

4.4 传动部分设计………………………………………………………10

4.5 螺栓组联接的结构设计……………………………………………………13

4.6 螺栓联接的强度校核………………………………………………14

5焊接工艺……………………………………………………………………17

5.1 焊接接头及坡口型式…………………………………………………………17

5.2 焊接坡口边缘的加工………………………………………………………17

5.2.1法兰的气割…………………………………………………………………17

5.2.2 坡口的气割………………………………………………………………18

5.2.3 气焊规范的选择…………………………………………………………18

5.3壳体焊接加工的技术要求…………………………………………………18

6结语……………………………………………………………………………19

参考文献……………………………………………………………………………20

致谢…………………………………………………………………………………21