设计简介

目录

【摘 要】随着石油天然气资源的不断开采利用,尾管固井工艺成了提高深井和特殊井固井质量最常用的一种方法。尾管固井具有较好的经济和社会价值,正日益广泛地被采用。尾管悬挂器是实施尾管固井技术的关键装置,尾管悬挂器以尾管悬挂器的力学分析作为其设计和研制的理论依据,以便使尾管悬挂器的性能更好的满足现场的各项要求。基于这种背景,本文首先回顾了国内外尾管悬挂器技术进展:先叙述了常规的尾管悬挂器的技术进展,又介绍了目前具有特殊功能的新型尾管悬挂器研究现状。在充分掌握尾管悬挂器的分类、结构原理和现场对尾管悬挂器的性能要求的基础上,先用数学工具对卡瓦、悬挂部位套管及悬挂器本体进行力学分析和强度校核,并应用简化的数学模型,通过对现场实例的计算结果来验证数学模型的正确性。计算并验证卡瓦的尺寸是否合理,以达到理论指导实践的目的。同时为尾管悬挂器的研制、改进和创新提供了重要的理论指导。

【关键词】尾管悬挂器;技术进展;工作原理;力学分析

[Abstract] With the continued exploitation and use of oil and natural gas, linercementing technics hasbecome one of the most commonly used methods toimprove the cementing quality of the deep and special wells. Liner cementing isincreasingly widely adopted with better economic and social value. Liner hangeris the critical device in the progress of implementing liner cementing technology.Liner hanger is designed and developed on the theoretical basis of itsmechanical analysis in order to make it better meet the requirements of thescene.Basis of this background, in this paper, at the beginning, the developmentprocess of liner hanger technology both at home and abroad is reviewed, firstly,the technical development of the conventional liner hanger is described, and then current research status quo of the liner hanger with special functions introduces is introduced.

Based on a full grasp of the classification, structure, principle and the performance requirements of the liner hanger by the scene, mechanical analysis and strength check of slip are made by useing mathematical tools for suspension parts of the casing hanger, hanger body, and a simplified mathematical model is established. Then the correctness of the mathematical model is verified by means of the alculation results of the scene examples. Calculates the size of the slip and estimate whether it is reasonable to achieve the purpose that theory guides practice. At the same time, an important theoretical guidance for the development, improvement and innovation of the liner hanger is provided.

[Keywords] liner hanger; technical progress; principle; mechanical analysis;finite element method

摘 要 X

前言 1

1选题背景 2

1.1 尾管固井的广泛应用 2

1.2 尾管悬挂器的重要作用 2

1.3 课题研究的目的及意义 3

2国内外尾管悬挂器的发展现状及趋势 4

2.1 国外尾管悬挂器技术进展 4

2.2 国内尾管悬挂器技术进展 10

2.3 尾管悬挂器的发展趋势 11

3 尾管悬挂器的结构和工作原理 12

3.1 机械式尾管悬挂器 12

3.2 液压式尾管悬挂器 12

3.3特殊尾管悬挂器 13

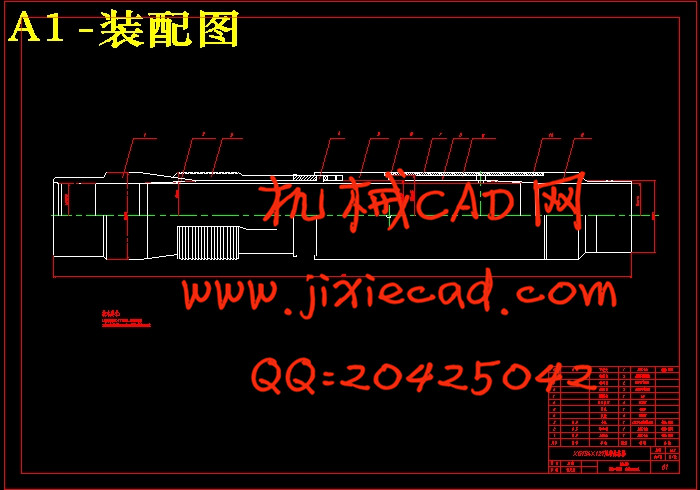

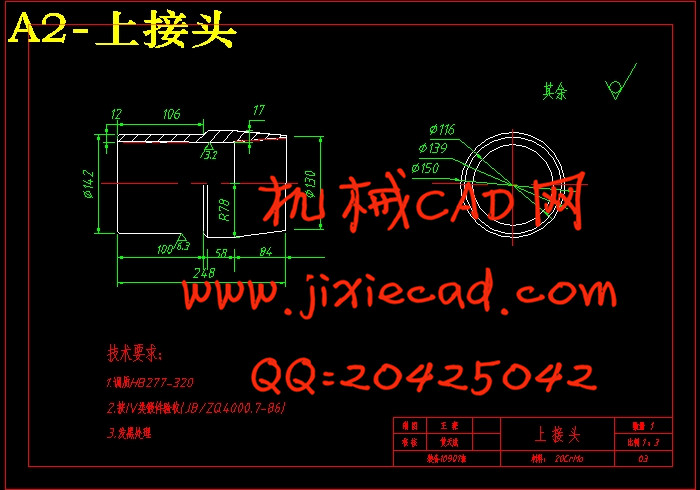

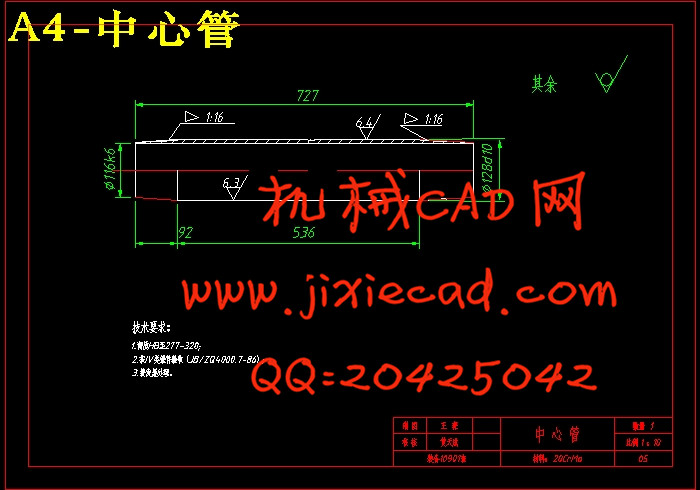

3.4 XG194×127尾管悬挂器 13

4尾管悬挂器力学分析的数学模型 14

4.1 悬挂部分套管受力分析 14

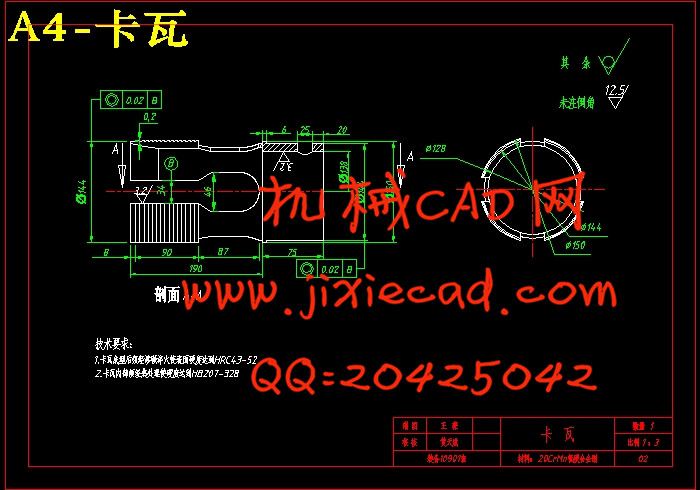

4.2 卡瓦的力学分析与合理设计 17

4.3 悬挂器本体受力分析 22

4.4 悬挂器坐挂失效的简要分析 26

5参考文献 27

致 谢 30