设计简介

摘 要

Y38滚齿机是齿轮加工机床中应用广泛的一种机床,在其上可切削直齿、斜齿圆柱齿轮,还可加工蜗轮、链轮等。其工作台由工作台壳体、蜗轮、蜗杆、储油匣等组成。按照加工原理,齿面加工可以分为成形法和展成法两大类。Y38滚齿机选择范成法加工齿轮的优点是,只要模数和压力角相同,一把刀具可以加工任意齿数的齿轮。生产率和加工精度都比较高。所以在齿轮加工中,范成法应用最为广泛。齿轮是工业生产中的重要基础零件,其加工技术和加工能力反映一个国家的工业水平。作为机械制造业的基础装备的金属切削机床,在国民经济中占有重要地位,而齿轮作为机械传动中最常见,最重要的传动零件,被广泛地应用于机械设备的传动系统中。滚齿是应用最广的切齿方法,滚齿加工大多都是在滚齿机上进行的,因此滚齿机在金属切削机床之中占有举足轻重的作用。

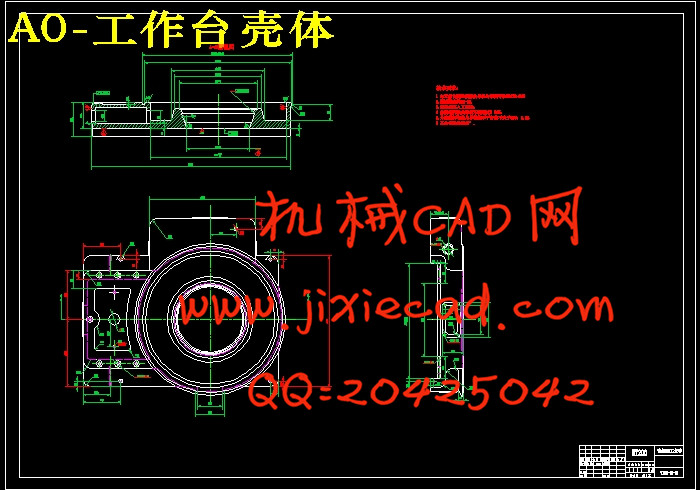

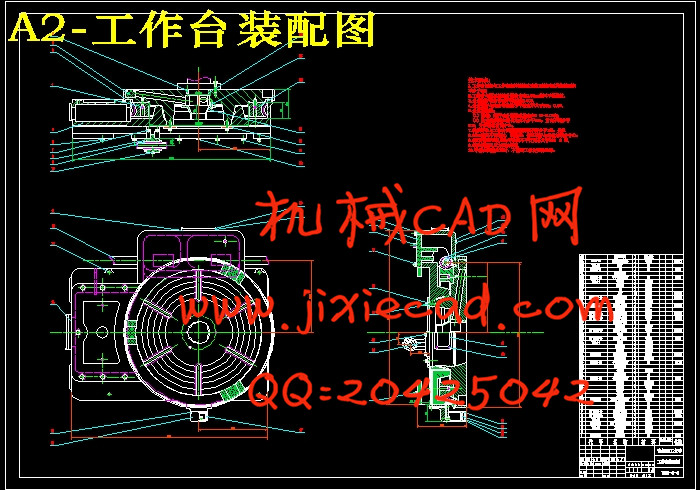

本次方案设计中最核心和最创新的是应用了功能分析法,其实质是用科学来解决问题的方法,通过黑箱法,找到输入输出间的关系,分析确定要设计的功能,来达成我们要实现的目的。我主要设计的部分是:分齿挂轮系统和机床工作台的,分齿挂轮主要是通过不同的挂轮来实现两末端件的复杂的关系。工作台为箱型结构,装在床身的矩形轨道上,工作台壳体以其环形表面支撑工作台圆盘,并以其锥孔来定工作台中心,分度蜗轮与工作台壳体连在一起,分度蜗杆与工作台座连接在一起,壳体内油室是供给装置润滑油的。具体外形尺寸,见工作装配 (图Y38-4-6)。

关键词:滚齿机;Y38;分齿挂轮

Abstract

Y38 is a gear hobbing machine tools in a wide range of machine tools, which can cut straight-tooth gear, helical gears, and worm gear as well as sprocket can also be processed, The table of Y38 is composed of its shell of the table, worm, and reservoir tray. According to the principles of tooth surface forming process, processing can be divided into major categories and exhibition into law. As long as the modulus and the pressure angle of the same, the advantage of choosing Y38 hobbing method to process gear is processing any number of teeth of the gear, as well as higher productivity and machining accuracy. Therefore, processing gear is most widely used in gear processing method.Industrial production gear is an important foundation for Parts,and its processing technology and capacity reflect the level of a country's industry. As the basis for machinery and equipment manufacturing, the metal cutting machine tools occupies an important position in the national economy, however, as the most common mechanical transmission and important mechanical parts, gear is most widely used in cutting method of hobbing process. Hobbing process are often carried out in the fobbing machine, therefore, gear hobbing machine plays an important role in possession of metal-cutting machine tools.

The design of the core and the most innovative feature is the application of the analysis, which is the essence of scientific method to solve the problem, using the black box to find the relationship between input and output, analyzing and deciding the content of design, and achieving what we aim to. The part of the main design of mine is sub-system and the gear teeth of the machine tool table. Sub-tooth gear achieves the two main pieces of the end of the transmission chain. The box structure of table is mounted on a rectangular bed track, with its circular table and surface of the shell plate supporting the table, and its cone center hole sets the table, and table indexing worm shell is together with the table indexing. Block worm connected to the shell inside the chamber is the device of storing oil lubricants. Specific dimensions see the work of the assembly (Figure Y38-4-6).

Key words: gear hobbing machine; y38; sub-tooth gear

目录

摘要 I

Abstract II

目录 IV

第1章 绪论 1

1.1 滚齿机研究的意义及发展现状 1

1.2 滚齿技术的未来发展方向 3

1.3 论文主要研究内容 4

第 2 章 Y38滚齿机方案设计 5

2.1 用功能分析法(黑箱法)明确总功能: 5

2.2 功能原理选择 6

2.3 针对机械传动的滚齿机作功能元分解 8

2.3.1 功能分解图 8

2.3.2功能元求解 8

2.3.3 功能元求解方案分析 9

2.4 最佳方案分析及确定 15

2.4.1加权系数分析 16

2.4.2最佳方案选择 16

2.5 计算滚刀速度和功率并选择电动机 19

2.5.1 计算滚刀(单头)速度: 19

2.5.2 滚刀的切削功率计算: 20

2.5.3 选择电动机 21

第 3 章 Y38滚齿机分齿设计及其计算 23

3.1 分齿功能原理分析 23

3. 2 分齿挂轮的计算 25

3. 3 分齿挂轮搭配表 26

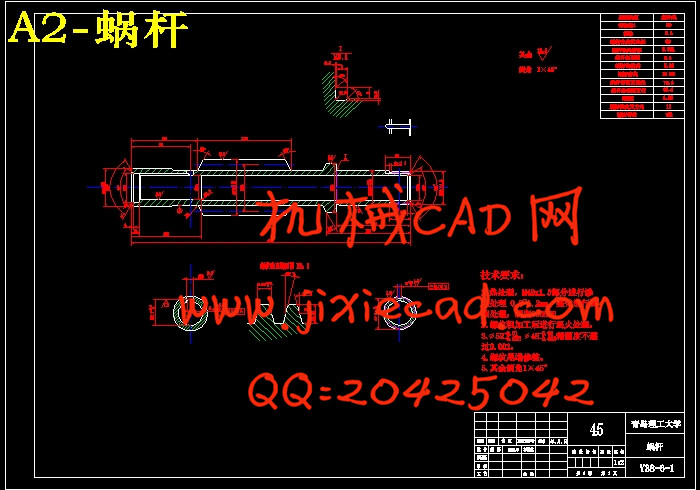

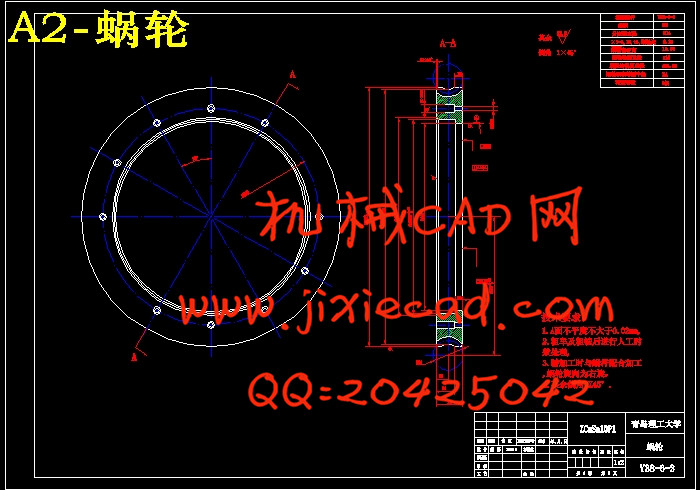

第4章 蜗轮、蜗杆设计计算及校核 36

4.1蜗轮、蜗杆的选择 36

4.1.1蜗杆的输入转矩及输入功率: 36

4.1.2蜗杆的选取 36

4.1.3 蜗杆与蜗轮的主要参数与几何尺寸 38

4.1.4 校核齿根弯曲疲劳强度 40

4.1.5 传动的热平衡计算 40

结论 42

参 考 文 献 43

致谢 44