设计简介

摘要

滚齿机是使用最广泛的齿轮加工机床,其数量约占整个齿轮加工机床的45%左右。多数情况下,滚齿机用来加工渐开线齿形的直齿、斜齿、和人字齿轮。只要滚刀与工件齿形共轭,就可以加工相应齿形的工件,如圆弧齿轮、棘轮、链轮等。滚齿机既适合于高效率的齿形粗加工,又适合于高精度齿形精加工。由于适应范围大、调整简易、操作方便,因此这种机床不论对于大量生产和成批生产的工厂,或者是小量生产和单件生产的工厂,都是一种比较经济的齿形加工设备。

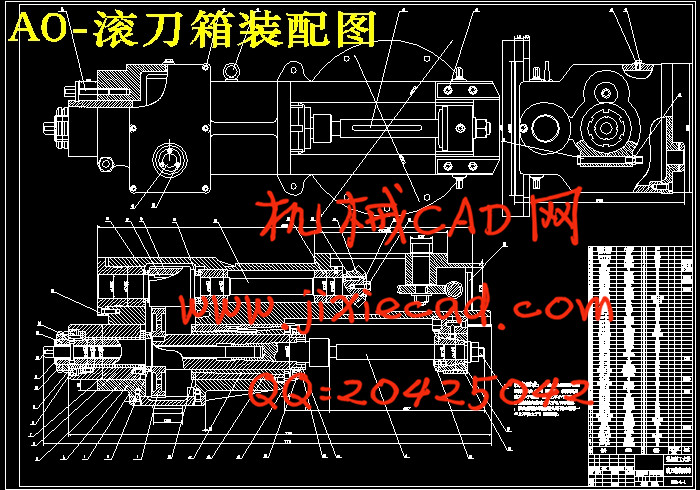

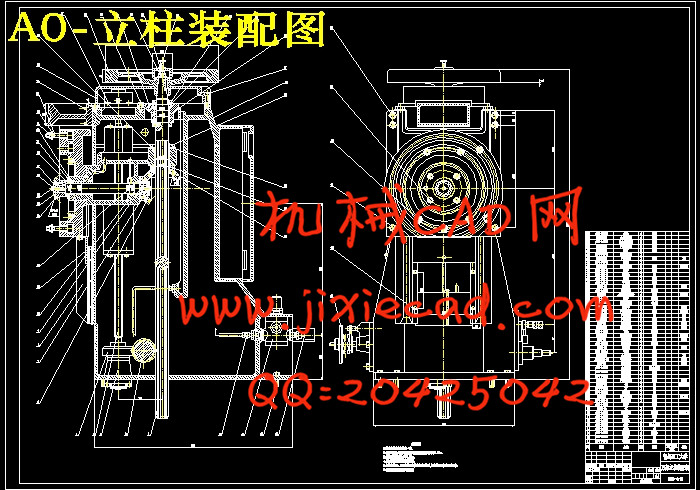

滚刀箱是一个二级减速机构,其主轴上装有滚刀心轴,主轴的旋转运动带动滚刀心轴旋转,从而带动滚刀做旋转切削运动。滚刀箱装配在滚齿机的立柱上,可以在立柱内丝杠的带动下沿立柱导轨做垂直运动,从而满足被加工齿轮导线的形成;它也可以在垂直面内围绕其装配中心旋转,从而满足加工斜齿轮时所需要的刀具不同安装角的影响。

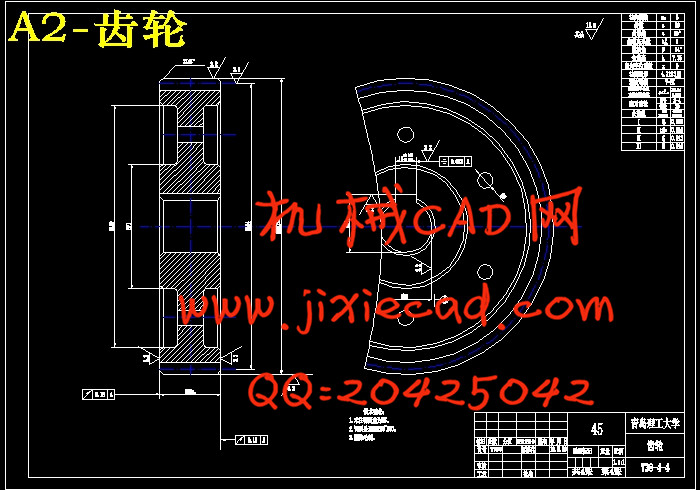

本说明书包含绪论,方案设计,计算说明三个主要部分。绪论就滚齿机的重要地位、发展历史和发展现状做了分析;方案设计对能实现滚齿机各运动的几种方案做了详细的比较选择;滚刀箱的第一级减速是由一轴端的锥齿轮实现,二级减速是由一对啮合的斜齿轮实现,本说明书的计算说明部分对各齿轮的类型、齿数、模数、材料等进行了设计计算;滚刀箱的内部有两根轴,其中轴VII转化为简支梁后为超静定结构,先按扭转强度估算出轴的最小直径,然后按弯扭合成强度对轴VII进行了校核,因为其为超静定结构,所以计算轴上的弯矩时要用到力法。轴VIII是一个截面形状连续变化的空心轴,只对其按扭转强度进行了校核。

关键词:滚齿机、滚刀牙箱、设计、校核、斜齿圆柱齿轮、锥齿轮、立柱。

Abstract

Hobbing is the most widely used gear machine tools, the number of gears about the whole machine around 45%. In most cases, hobbing machine for processing involute profile of the straight-tooth, Teeth, and herringbone gear. As long as the hob tooth profile conjugate with the workpiece can be processed corresponding profile of the workpiece, such as circular-arc gear, ratchet, sprocket and so on. Hobbing machine is suitable for high-efficiency roughing the tooth, but also suitable for high-precision finishing profile. Due to the scope of adaptation, and adjustment simple and easy to operate, so the machine regardless of the mass production and mass production factories, or a small amount of production and single production plant, is a more economical processing equipment profile.

Hob speed box is a secondary body axis is equipped with hob spindle, spindle rotation hob drive spindle rotation, thus rotating hob-cutting campaign to do. Hob hobbing box assembly in the column, you can screw in the column within the column, led by guides along the vertical movement to do to meet was the formation of wire processing gear; It can also be within the vertical plane around its center rotating assembly, which helical gear to meet the processing required to install the tool in different angle.

Introduction of this manual contains the program design, calculation that three main sections. Introduction of an important position on the hobbing machine, the development of the history and development of an analysis of the status quo; program designed to achieve hobbing of several programs of the movement has done a detailed comparison between the options; hob me slow down the first level of the shaft by a bevel gear achieved by the two slow down a pair of meshing helical gear to achieve, the statement that part of the calculation of the gear type, number of teeth, module, materials such as calculation of the design; hob box there are two axes, which VII-axis into a simply supported beam after hyperstatic structure, according to their strength to reverse the estimated minimum diameter of shaft, and then by bending and torsional strength of the shaft VII Synthesis of a check, because it is statically indeterminate structure, the calculation of axis When the moment to use the force method. VIII is a cross-section axis for changing the shape of the hollow shaft, only to reverse its intensity according to the check.

Key words: gear hobbing machine, hob tooth box, design, verification, helical gears, bevel gears, column.

Abstract II

目录 IV

第1章 绪论 1

1.1 滚齿机在我国国民经济中的地位 1

1. 2 滚齿技术及滚齿机制造技术的发展历程 1

1.3 滚齿机的国内外现状分析 3

第2章 Y38滚齿机方案设计 5

2.1 明确总功能 5

2.2功能原理的选择 5

2.3功能分解图 6

2.4功能元求解 8

2.5 各功能元求解方案分析 8

2.6 最佳方案的分析和确定 15

2.7草绘整体示意图和传动示意图 19

2.8计算滚刀的速度和功率并选择电动机 21

第3章 滚刀箱主要零件设计校核 25

3.1轴VII上斜齿圆柱齿轮啮合设计计算与校核 25

3.2 滚刀箱轴VII的设计计算与校核 32

3.3轴VII上键的校核 43

3.4 轴VI和轴VII上啮合锥齿轮的校核 44

3.5 按扭转强度校核滚刀箱主轴 47

参考文献 49

致谢 50

滚齿机是使用最广泛的齿轮加工机床,其数量约占整个齿轮加工机床的45%左右。多数情况下,滚齿机用来加工渐开线齿形的直齿、斜齿、和人字齿轮。只要滚刀与工件齿形共轭,就可以加工相应齿形的工件,如圆弧齿轮、棘轮、链轮等。滚齿机既适合于高效率的齿形粗加工,又适合于高精度齿形精加工。由于适应范围大、调整简易、操作方便,因此这种机床不论对于大量生产和成批生产的工厂,或者是小量生产和单件生产的工厂,都是一种比较经济的齿形加工设备。

滚刀箱是一个二级减速机构,其主轴上装有滚刀心轴,主轴的旋转运动带动滚刀心轴旋转,从而带动滚刀做旋转切削运动。滚刀箱装配在滚齿机的立柱上,可以在立柱内丝杠的带动下沿立柱导轨做垂直运动,从而满足被加工齿轮导线的形成;它也可以在垂直面内围绕其装配中心旋转,从而满足加工斜齿轮时所需要的刀具不同安装角的影响。

本说明书包含绪论,方案设计,计算说明三个主要部分。绪论就滚齿机的重要地位、发展历史和发展现状做了分析;方案设计对能实现滚齿机各运动的几种方案做了详细的比较选择;滚刀箱的第一级减速是由一轴端的锥齿轮实现,二级减速是由一对啮合的斜齿轮实现,本说明书的计算说明部分对各齿轮的类型、齿数、模数、材料等进行了设计计算;滚刀箱的内部有两根轴,其中轴VII转化为简支梁后为超静定结构,先按扭转强度估算出轴的最小直径,然后按弯扭合成强度对轴VII进行了校核,因为其为超静定结构,所以计算轴上的弯矩时要用到力法。轴VIII是一个截面形状连续变化的空心轴,只对其按扭转强度进行了校核。

关键词:滚齿机、滚刀牙箱、设计、校核、斜齿圆柱齿轮、锥齿轮、立柱。

Abstract

Hobbing is the most widely used gear machine tools, the number of gears about the whole machine around 45%. In most cases, hobbing machine for processing involute profile of the straight-tooth, Teeth, and herringbone gear. As long as the hob tooth profile conjugate with the workpiece can be processed corresponding profile of the workpiece, such as circular-arc gear, ratchet, sprocket and so on. Hobbing machine is suitable for high-efficiency roughing the tooth, but also suitable for high-precision finishing profile. Due to the scope of adaptation, and adjustment simple and easy to operate, so the machine regardless of the mass production and mass production factories, or a small amount of production and single production plant, is a more economical processing equipment profile.

Hob speed box is a secondary body axis is equipped with hob spindle, spindle rotation hob drive spindle rotation, thus rotating hob-cutting campaign to do. Hob hobbing box assembly in the column, you can screw in the column within the column, led by guides along the vertical movement to do to meet was the formation of wire processing gear; It can also be within the vertical plane around its center rotating assembly, which helical gear to meet the processing required to install the tool in different angle.

Introduction of this manual contains the program design, calculation that three main sections. Introduction of an important position on the hobbing machine, the development of the history and development of an analysis of the status quo; program designed to achieve hobbing of several programs of the movement has done a detailed comparison between the options; hob me slow down the first level of the shaft by a bevel gear achieved by the two slow down a pair of meshing helical gear to achieve, the statement that part of the calculation of the gear type, number of teeth, module, materials such as calculation of the design; hob box there are two axes, which VII-axis into a simply supported beam after hyperstatic structure, according to their strength to reverse the estimated minimum diameter of shaft, and then by bending and torsional strength of the shaft VII Synthesis of a check, because it is statically indeterminate structure, the calculation of axis When the moment to use the force method. VIII is a cross-section axis for changing the shape of the hollow shaft, only to reverse its intensity according to the check.

Key words: gear hobbing machine, hob tooth box, design, verification, helical gears, bevel gears, column.

目录

摘要 IAbstract II

目录 IV

第1章 绪论 1

1.1 滚齿机在我国国民经济中的地位 1

1. 2 滚齿技术及滚齿机制造技术的发展历程 1

1.3 滚齿机的国内外现状分析 3

第2章 Y38滚齿机方案设计 5

2.1 明确总功能 5

2.2功能原理的选择 5

2.3功能分解图 6

2.4功能元求解 8

2.5 各功能元求解方案分析 8

2.6 最佳方案的分析和确定 15

2.7草绘整体示意图和传动示意图 19

2.8计算滚刀的速度和功率并选择电动机 21

第3章 滚刀箱主要零件设计校核 25

3.1轴VII上斜齿圆柱齿轮啮合设计计算与校核 25

3.2 滚刀箱轴VII的设计计算与校核 32

3.3轴VII上键的校核 43

3.4 轴VI和轴VII上啮合锥齿轮的校核 44

3.5 按扭转强度校核滚刀箱主轴 47

参考文献 49

致谢 50