设计简介

摘要

齿轮的地位被各个国家所认同是因为轮是工业生产中的重要基础零件,其加工技师和加工能力反映一个国家的工业水平。并且齿轮作为机械传动中最常见,最重要的传动零件,被广泛地应用于机械设备的传动系统中,因此也决定了在一个国家的工业中齿轮的加工的重要地位。实现齿轮加工数控自动化、加工和检测的一体化是目前齿轮加工的发展趋势。所以大多数国家都在努力向研究数控机床的方向发展。由于数控滚齿机的制造难度相当的大,因此目前并没有被广泛的采用。目前各个国家普遍采用的传统的滚齿机型。滚齿机是齿轮加工机床中应用广泛的一种机床,在其上可切削直齿、斜齿圆柱齿轮,还可加工蜗轮、链轮等。按照加工原理,齿面加工可以分为成形法和展成法两大类。Y38滚齿机选择范成法加工齿轮的优点是,只要模数和压力角相同,一把刀具可以加工任意齿数的齿轮。生产率和加工精度都比较高。所以在齿轮加工中,范成法应用最为广泛。

本文采用功能分析设计法对机构的功能分析,这是本次设计的一次创新,用黑箱实现功能作用然后通过功能原理的选择,作功能分解图,对功能元进行求解分析,排列组合方案系统解,最后采用有限价值法或技术经济评价法对参数作评价决策,最佳方案解的分析确定。

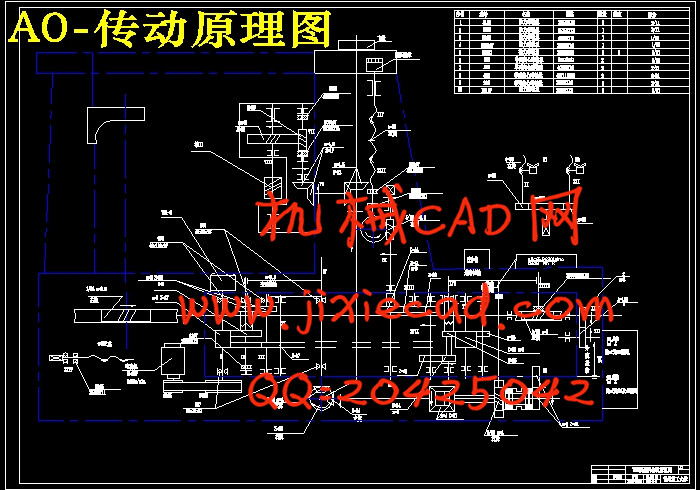

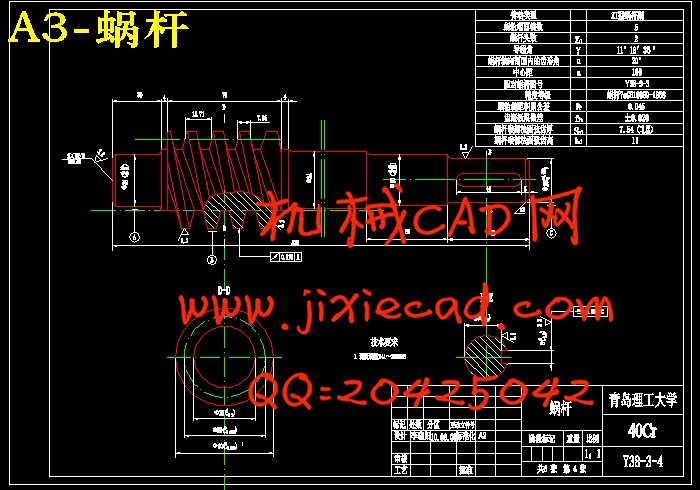

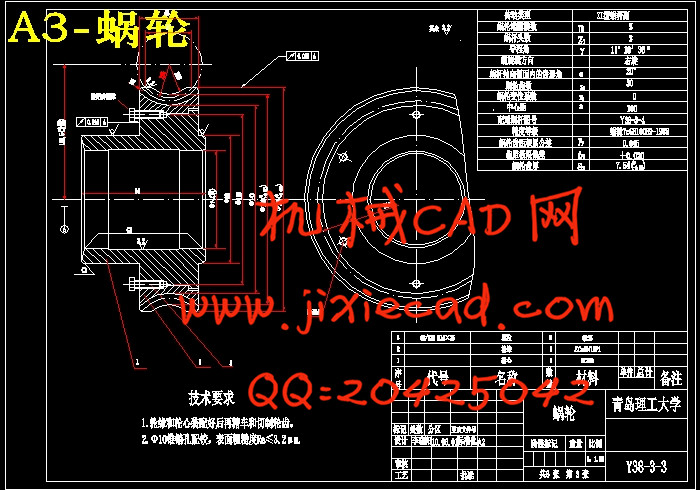

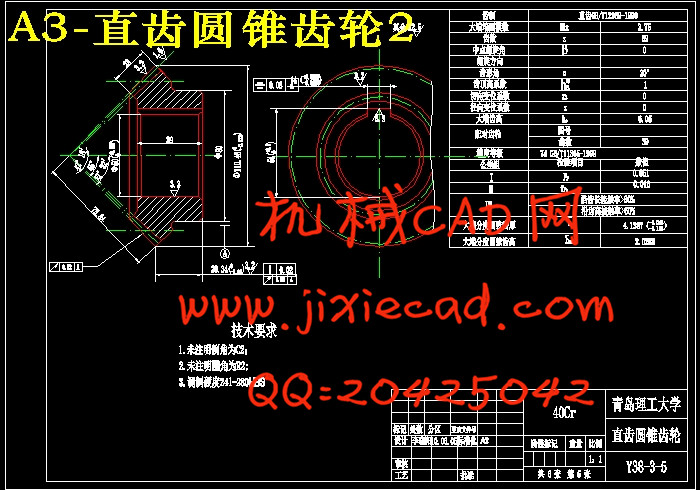

本说明书重点是介绍Y38滚齿机的进给的路线以及相关的计算及相关部件的选取和校核部分。其中有电机的选取,蜗轮蜗杆的计算校核,液压的计算校核以及丝杠的计算选择。对传动部分如大立柱等部分给予了作图说明。

关键词: 齿轮 滚齿机 黑箱 进给

Abstract

Gear are in industrial production base of the important parts of the process of technicians and processing ability to reflect a state of the industrial level. as a mechanical equipment manufacturing base metal cutting tools, and in the national economy occupies an important place, and the gear as a mechanical drive the most important parts of the transmission, is widely used in machinery equipment transmission. Implement the lean process Computer number control and automation, processing and detection of integration is currently one of the development trend.

Computer number control gear hobbing machine of the difficulty made considerable size, so there is not been widely adopted. at present, all countries of the widespread use of conventional models gear hobbing machine.Gear hobbing machine is widely used tools in the process of a kind of machine tools, on which may be cutting spur gear, helical-spur gear, and processing turbine, sprockets, etc. according to the process of principle, and spherical machining to the shaping and generating can be divided into two categories. Y38 gear hobbing maching of the options shaping processing gear advantage is that provided by number and the pressure of the same, one of the tool can work any of the gear . productivity and processing are comparatively high precision. in the processing, generation method is used most widely.

In the black box analysis of function design of the functional analysis, the function of the principle of choice, as a function is broken. the function of $solution for analysis, the arrangement. the system uses limited value of the law or technical and economic assessment of evaluation parameters for policy-making, best solution for analysis.

Manual emphasis is on the Y38 gear hobbing machine into the line and relevant terms and relevant components ‘s select and check.. The seleck of motor, the calculate of worm gear , and its check. The calculate of the hydraulic,and its check.. The seleck of the screw rod. Thers are also some graphs show the transmission part ,for column and so on..

Key words: Gear Gear hobbing machine Black box Feed

目录

摘要…………………………………………………………….………….I

Abstract…………………………………………………………….……Ⅱ

目录…………………………………………………….………….……..III

第1章 绪论…………………………………………………….……….1

1.1 齿轮的重要地位………………………………………………………….………1

1.2 滚齿机的发展…………………………………………………………….………5

1.3论文主要研究的内容………………………………………………………………..….…5

第2章 Y38滚齿机的设计方案…………………………………….……6

2.1 总功能分析………………………………………………………………..…...….6

2.2功能原理的选择…………………..…………………………………………….….………8

2.3功能元求解…………………………………………………………………...……...……..11

2.4方案初步筛选……………………………………………………………….………..……14

2.5方案的比较………………………………………………………………………...….……15

2.6最佳方案的分析和确定………………………………………………………...…....…..20

2.7算滚刀的速度切削功率并选择电动机…………………………………….………….25

第3章 进给部分的设计及其计算 30

3.1 蜗轮蜗杆的设计计算 31

3.2 丝杠的设计计算 42

3.3 液压系统的设计计算 47

结论 51

参考文献 52

致谢 53