设计简介

摘要

齿轮是现代机器和仪器中的重要零件,齿轮机构是在各种机构中应用最为广泛的一种传动机构。它依靠轮齿齿廓直接接触来传递空间任意两轴间的运动和动力,并具有传递功率范围大、传动效率高、传动比准确、使用寿命长、工作可靠等优点。因此,齿轮传动的应用极为广泛,齿轮的需要量也日益增加。用来加工齿轮轮齿表面的机床,称为齿轮加工机床。齿轮加工机床是机械制造工业中的一种重要技术装备。齿轮传动也是在各种传动机构中应用最为广泛的一种传动机构。传动比稳定往往是对传动性能的基本要求。正是由于其具有这一特点,齿轮传动获得广泛应用。于是,用来加工齿轮的滚齿机变的更为重要。

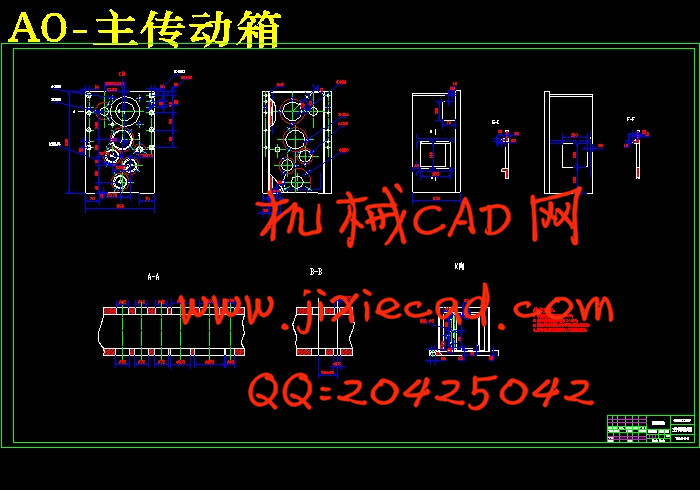

本说明书描述了滚齿机在齿轮加工领域的不可或缺的地位及发展趋势,重点介绍了Y315滚齿机主传动的设计计算。

本书从介绍课题研究的主要内容和滚齿机的的现状、未来的发展趋势入手,分析比较了滚齿机的多种方案设计,找出最佳方案,并对滚齿机主传动部分进行设计计算。

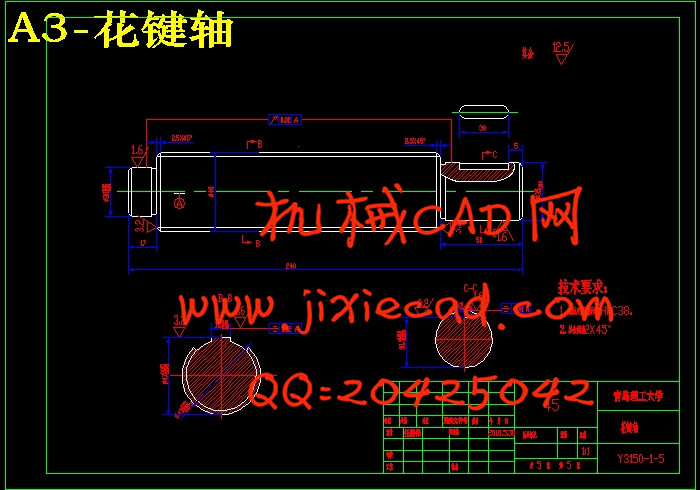

Y315:普通滚齿机,能加工直齿和斜齿圆柱齿轮、蜗轮及短花键轴,适于单件、小批或成批生产齿轮的工厂使用。机床结构优良,刚性强,热变形小,能承受较高速度的切削负荷,精度良好,操作方便,调整简单。加工齿轮时,机床可按顺铣或逆铣方式工作。机床带有自动停机机构、安全装置及自动润滑系统,可以根据用户要求配置进口液压元件或用于滚切蜗轮的切向刀架。

关键词: 齿轮、齿轮加工、滚齿机、主传动、轴

Abstract

Gear is an important part of modern machines and equipments and one of the most widely used transmission organization in a variety of organizations. It relies on direct contact of gear tooth profile to convey movement and power of arbitrary two-axis in the space, and has advantages of a wide range of transmission power, high ftransmission efficiency, accurate transmission ratio, long life, reliable and so on.. Therefore, the application of gear is wide and the demand of gears is also increasing. What is used to process gear tooth surface called Gear Processing Machine. Gear Processing Machine is an important technology equipment mechanical manufacture.Gear drive mechanism is also in a variety of most widely used in a transmission. The stability of the transmission ratio is often the basic requirements for transmission performance.It is precisely because it has the characteristics of gear drive is widely available. Thus, Gear hobbing machine for processing become even more important.

This book from the research introduced the main contents and status of the hobbing machine, start the trend of future development, analysis and comparison of the hobbing machine design of a variety of programs to find the best solution, and main drive gear-hobbing machine parts design and calculation.

Y315 :Ordinary hobbing machine can be processed straight tooth and helical gears, worm gear and the short spline shaft, suitable for one-piece, small batch or mass production of the factory gear. Excellent machine tool structure, rigidity, and thermal deformation small, can withstand higher cutting speed of the load, good accuracy, convenient operation, simple to adjust. Processing gear, the machine can be cis or milling milling inverse manner. Machine tool with automatic shutdown agencies, safety devices and automatic lubrication system can be configured according to user requirements for imports of hydraulic components or roll to the cutting knives to cut the worm.

Key words: Gears;gear machining; hobbing machine; main drive; shaft

目录

摘要 IAbstract II

目录 Ⅲ

第1章 绪论 1

1.1 滚齿机的研究意义及现状 1

1. 2 滚齿机的发展史及未来发展趋势 2

1.3 论文主要内容 4

第2章 Y315滚齿机方案设计 6

2.1 明确总功能 6

2.2功能原理 6

2.3功能分解图 8

2.4功能元求解 10

2.5 功能元求解方案分析 11

2.6 最佳方案的分析及确定 19

2.7草绘整体示意图和传动示意图 24

2.8计算滚刀的速度和功率并选择电动机 26

第3章 滚齿机传动部分相关计算 29

3.1机床传动系统分析 29

3.2 变速挂轮的计算 29

3.3带轮的设计计算 33

3.4 齿轮的材料选择和校核 35

3.5 轴的校核 41

参考文献 48

致谢 49