设计简介

摘 要

齿轮加工正朝着环保、高效、高精度及无屑加工方向发展,齿轮加工机床正朝着全数控、功能复合、柔性、自动化、安全性及网络化方向发展。传统机械式滚齿机传动结构异常复杂、传动效率低、传动精度差、磨损严重、切削速度低,在各方面都不能满足现代滚齿机的性能要求;普通全数控滚齿机虽然具有全数控化、柔性好、安全的特点,但是机械传动环节的存在始终限制其加工速度的提升,不能适应干式切削的需要。因此,国外的部分厂家从最近几年才开始研制“零传动”齿轮加工机床。零传动滚齿机突破了传统齿轮加工机床的结构设计原理,采用电主轴和内置力矩电机直接驱动滚刀旋转运动和工件轴旋转运动,是齿轮机床设计技术的重大变革。但国外零传动机床的售价很高(是一般数控机床的 2~3倍),设计原理和技术资料严格保密,形成了技术垄断的局面。为了打破国外的技术垄断,尽快提高我国齿轮加工机床的设计/制造水平,研究和开发高速、高精度零传动滚齿机是十分必要的。零传动滚齿机的研制基于零传动功能部件,由电主轴直接驱动的零传动刀架部件是研发的核心之一。

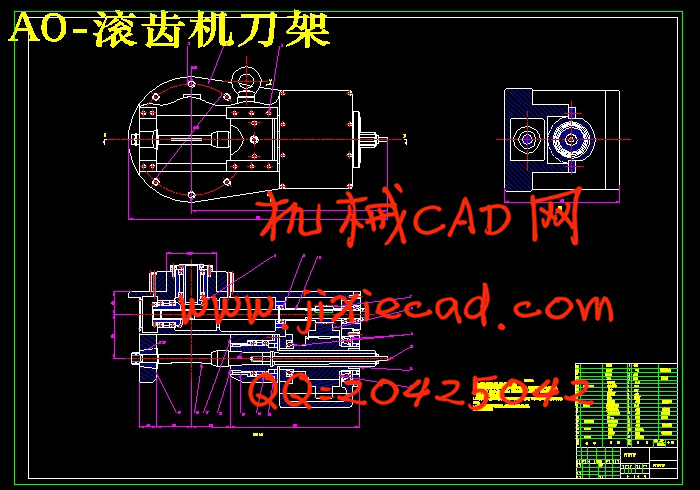

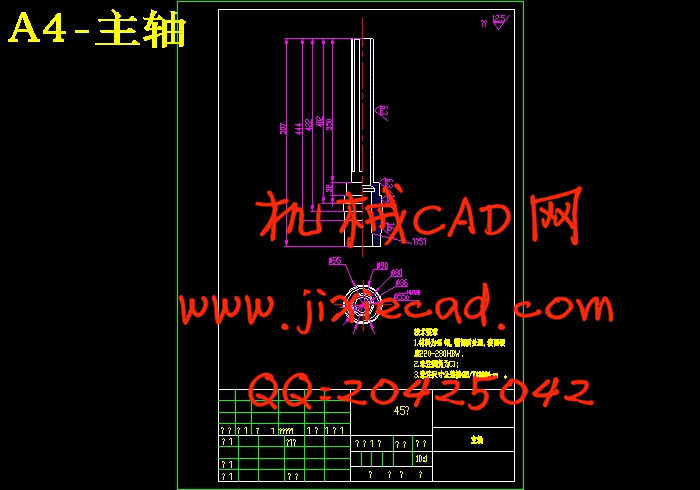

我的课题主要内容是滚齿机刀架系统设计。滚刀箱固定在刀架滑板上,滚刀心轴插入滚刀主轴并用拉紧螺栓固定在主轴上。为了保证主轴与前轴承的适当间隙,前轴承是做成外锥并开口。调整轴承上的两个螺母,可以使前轴承做轴向移动,使前轴承孔收缩便可消除主轴和轴承间过大的间隙。

关键词:滚齿机、刀架、动静态特性

ABSTRACT

The gear processing is developed an environment protecting, high-efficiency,high-precision and chipless machining mode, meanwhile the gear machine tools developed the completely-digital-control, function-complex, flexible, automatic, secure and network mode. Traditional gear hobbing machine can not satisfy performance demand of modern gear hobbing machine, because of its disadvantages, such as complex drive structure, low drive efficiency, low drive precision, bad abrasion, low cutting speed, and etc. normal NC gear hobbing machine has characteristics of CNC,good flexible and safety, but because the mechanical drive limit the cutting speed , it also can not fit for the demand of dry cutting.so ,some overseas companies have started to study zero-chain gear hobbing machine . zero-chain gear hobbing machine breaks through structure design principle of traditional gear cutting machine ,in which motorized spindle and built-in torque motor have been applied to realize rotary of hobbing cutter and workpiece-shaft.it is an important technological innovation of the design of gear machine tool. But the foreign Nought-Drive machine tools are expensive(2-3 times as much as the common digital-control machine tool), the design theory and the pertinent technical data are all kept absolutely secret that formed a situation of monopoly technology.

In order to break the technology monopoly and improve the level of designing/manufacturing rapidly in our country’s gear cutting machine, it's very necessary to study and develop high-speed and high-precision direct drive gear hobbing machine, one key of the research is the direct drive hobhead.

The topic main content of topic is hob-cutter frame design as well as the spindle assembly design. Rob cutter frame is fixed on the slide of cutter rack, the hob shaft is inserted into hob spindle and fixed with the draw-in bolt on the main axle. In order to guarantee the spindle and the suitable front bearing gap, the front bearing has the outer cone and the aperture. Adjusting on the bearing two nuts, it causes bearing movement along the front axle when motion and causes contraction of the front bearing hole then to be possible to eliminate the gap between the main axle and the bearing.

Key words : Direct-drive, Gear Hobbing Machine, hobhead, dynamic-static performance

第一章 绪论 1

1.1滚齿机国内外研究现状现状 1

1.2 滚齿机研制技术的发展趋势 2

第二章 滚齿机总体设计 4

2.1滚齿机总体方案设计 4

2.2 拟定传动方案设计 4

2.3 确定详细传动方案 6

2.4 滚齿机各部件方案设计 7

2.4.1 床身设计 7

2.4.2 主传动箱设计 7

2.4.3 刀架立柱设计 8

2..4.4 滚刀牙箱设计 8

2..4.5 工作台设计 8

2..4.6 外支架设计 8

第三章 滚刀箱结构设计 9

3.1滚刀箱的特性 9

3.2滚刀箱的结构设计 9

3.2.1 滚刀箱的功能结构分析 9

3.2.2 滚刀箱的壁厚 9

3.3 滚刀箱的设计计算 10

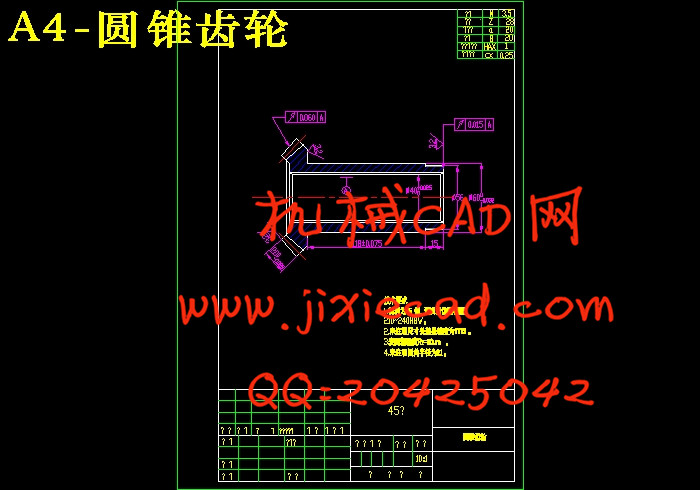

3.3.1 斜齿轮的设计 10

3.3.2 滚刀心轴的结构设计 14

第四章 刀架底座部件设计 17

4.1 工作要求 17

4.2窜刀运动与工件轴旋转的联动关系 17

4.3刀架底座部件的结构特点 18

4.4动力参数设计 18

4.4.1滚齿机切削力的关系及坐标变换 18

4.4.2 等效负载转矩计算 21

4.4.3 等效转动惯量的计算 23

4.4.4 加速度扭矩的计算 24

4.5滚柱丝杠副支承设计技术研究 26

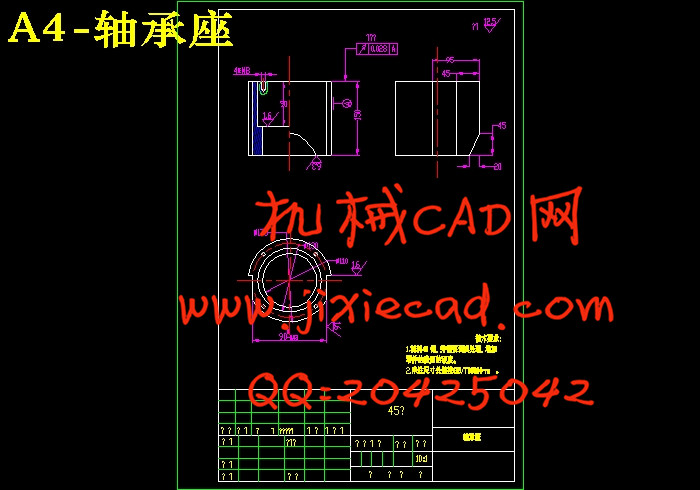

4.5.1 滚动轴承的选择 26

4.5.2 支承形式设计 26

4.5.3丝杠的预拉伸设计 27

4.6 滚刀轴部件锁紧的实现 29

第五章 滚刀箱形状和尺寸的确定 33

第六章 结束语 34

参考文献 35

致 谢 36