设计简介

YAG激光加工数控工作台设计

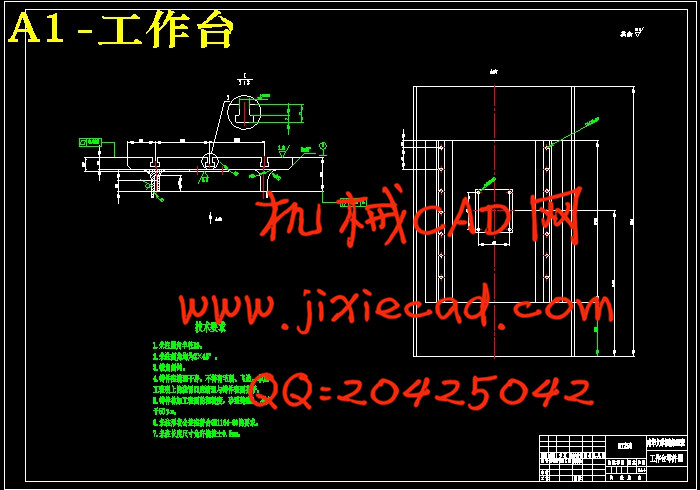

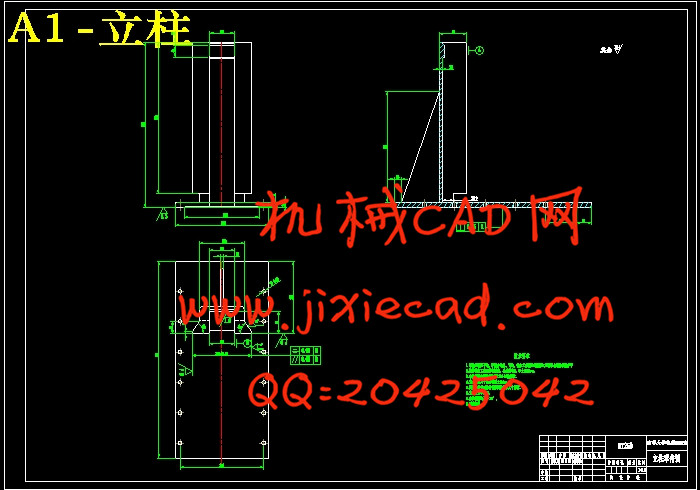

摘要:本次设计的课题是YAG激光加工数控工作台的设计。其中数控工作台是该YAG激光器的主要组成部分。它决定了激光器的加工精度,它的每个方向的行程要满足技术指标,传动系统应能满足在给定使用条件下具有良好的三坐标运动性和自锁性。传动系统应结构简单,制造、维修方便。总成及零、部件的设计应能满足零件标准化、部件通用化和产品系列化及机床变型的要求。在对数控传动系统的功能、工作原理进行分析后,根据任务书对该系统的要求及伺服电机与滚珠丝杆的设计,对传动系统采用何种结构形式进行了论证,并进行了结构优化设计和计算。

关键词:YAG;数控系统;三坐标

YAG laser processing CNC machine design

Abstract:The graduation design topic is YAG laser processing CNC Table design. Numerical control worktable is the main component of YAG laser. It determines the laser machining accuracy, its each direction of travel to meet the technical indicators, the transmission system should be able to meet at a given condition has a good three coordinates movement and self-locking. The transmission system has the advantages of simple structure, convenient manufacture, repair. Assembly and spare parts, the design should meet the standardization of parts, components and serialization of products and machine tool variant requirements. In the numerical control drive system function, working principle is analyzed, according to the task the system requirements and servo motor and ball screw design, the transmission system adopts the structural form of the argument, and the structure design and calculation of optimization.

Keywords: YAG ;numerical control;3coordinate

目 录

1 绪 论................................................ ...1

1.1本设计研究的目的和意义.....................................1

1.2本设计国内外研究历史与现状.....................................1

1.3目前存在的主要问题.............................................3

1.4本设计拟解决的关键问题和研究方法...............................4

2 总体方案设计....................................... .....5

2.1主要技术参数...................................................6

2.2运动形式.......................................................7

2.3导轨设计.......................................................7

3 传动系统设计......................................... ..10

3.1、X向传动机构设计..............................................12

3.2、Y向传动机构设计..............................................34

3.3、Z向传动机构设计..............................................34

4 Z方向平衡机构设计............................ .........49

5 机床总体布局的CAD......................................52

参考文献...................................................58

谢辞..................................... ....... ..........59

摘要:本次设计的课题是YAG激光加工数控工作台的设计。其中数控工作台是该YAG激光器的主要组成部分。它决定了激光器的加工精度,它的每个方向的行程要满足技术指标,传动系统应能满足在给定使用条件下具有良好的三坐标运动性和自锁性。传动系统应结构简单,制造、维修方便。总成及零、部件的设计应能满足零件标准化、部件通用化和产品系列化及机床变型的要求。在对数控传动系统的功能、工作原理进行分析后,根据任务书对该系统的要求及伺服电机与滚珠丝杆的设计,对传动系统采用何种结构形式进行了论证,并进行了结构优化设计和计算。

关键词:YAG;数控系统;三坐标

YAG laser processing CNC machine design

Abstract:The graduation design topic is YAG laser processing CNC Table design. Numerical control worktable is the main component of YAG laser. It determines the laser machining accuracy, its each direction of travel to meet the technical indicators, the transmission system should be able to meet at a given condition has a good three coordinates movement and self-locking. The transmission system has the advantages of simple structure, convenient manufacture, repair. Assembly and spare parts, the design should meet the standardization of parts, components and serialization of products and machine tool variant requirements. In the numerical control drive system function, working principle is analyzed, according to the task the system requirements and servo motor and ball screw design, the transmission system adopts the structural form of the argument, and the structure design and calculation of optimization.

Keywords: YAG ;numerical control;3coordinate

目 录

1 绪 论................................................ ...1

1.1本设计研究的目的和意义.....................................1

1.2本设计国内外研究历史与现状.....................................1

1.3目前存在的主要问题.............................................3

1.4本设计拟解决的关键问题和研究方法...............................4

2 总体方案设计....................................... .....5

2.1主要技术参数...................................................6

2.2运动形式.......................................................7

2.3导轨设计.......................................................7

3 传动系统设计......................................... ..10

3.1、X向传动机构设计..............................................12

3.2、Y向传动机构设计..............................................34

3.3、Z向传动机构设计..............................................34

4 Z方向平衡机构设计............................ .........49

5 机床总体布局的CAD......................................52

参考文献...................................................58

谢辞..................................... ....... ..........59