设计简介

中文摘要及关键词

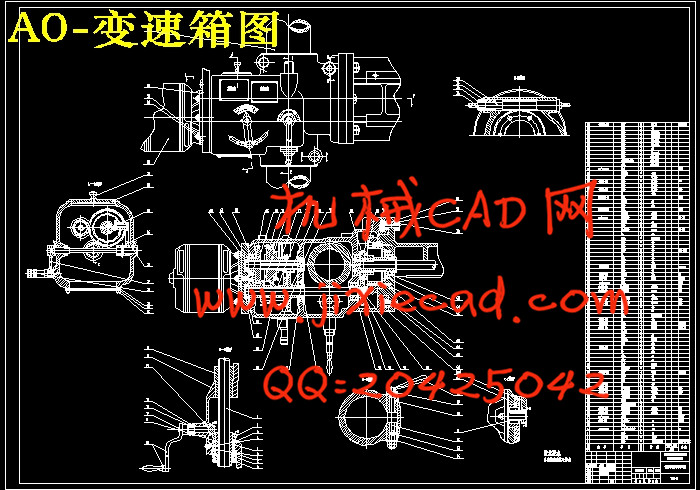

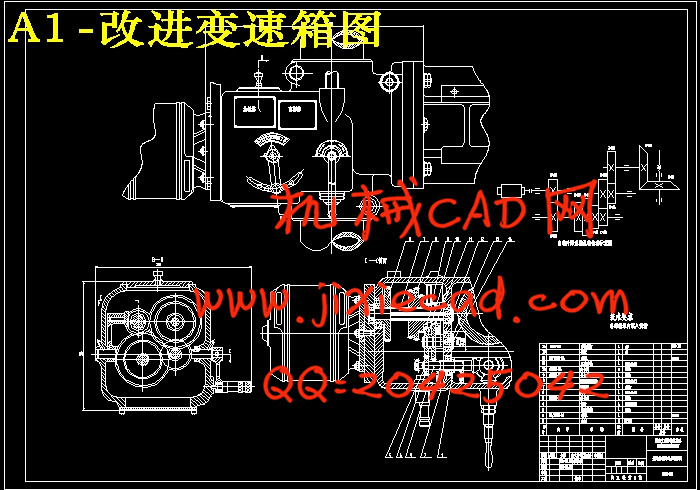

摘要:本次设计课题为“Z32K型摇臂钻床变速箱的改进设计”。主要是对Z32K型摇臂钻床的升降系统进行了改进、分析与设计,并对其主要传动零件进行设计及强度校核。了解和掌握Z32K型摇臂钻床在实际使用过程中出现的问题,在理论分析,计算的基础上,针对Z32K型摇臂钻床的升降系统是单手柄集中操作,操作起来比较麻烦,摇臂钻床体架太重,费力又费时,将其手动改进为自动升降,并提出了具体可行的解决方案。

关键词:摇臂钻床 手动、自动升降系统 电动机 齿轮 强度校核

英文摘要及关键词

Abstraction :This design topic is "the Z32K radial drill drilling machine gear box improvement design". Mainly was has made the improvement, the analysis and the design to the Z32K radial drill drilling machine jacking system, and carried on the design and the intensity examination to its main transmission components. Understood and grasps the Z32K radial drill drilling machine the question which appears in the actual use process, in the theoretical analysis, in the computation foundation, in view of the Z32K radial drill drilling machine jacking system is the single handle centralism operation, operates quite troublesomely, radial drill drilling machine body too is heavy, takes the trouble to take time, its manual improvement is the power elevation, and proposed specifically the feasible solution.

Keywords: universal raidial drilling machine manual operating and automatic fluctuation system electric motor gear strength cheeks.

目 录

中文摘要及关键词 ..................................................1

英文摘要及关键词 ..................................................2

第一章 概述 .......................................................3

1.1摇臂钻床的简介..................................................3

1.2摇臂钻床的国内发展动态及趋势 ...................................4

第二章 原动机的选择 ...............................................5

2.1常用原动机的运动形式 ...........................................5

2.2原动机的驱动形式 ...............................................5

2.3原动机选择应考虑的因素 .........................................5

2.4原动机的性能比较 ...............................................6

2.5确定原动机的选择 ...............................................7

第三章 机械传动设计方案的拟订与比较 ...............................8

3.1传动设计方案评价的目的 .........................................8

3.2传动设计方案评价的原则 .........................................8

3.3系统设计方案的比较与确定 .......................................8

第四章 绘制变速箱中升降系统的传动机构运动简图......................11

第五章 传动部分运动和动力分析 .....................................12

5.1部分传动连接设计 ..............................................12

5.2传动比、各轴转速、功率及转矩的计算 ............................12

5.3齿轮材料的选择 ................................................14

5.3.1齿轮材料的基本要求 ..........................................14

5.3.2常用材料及热处理 ............................................14

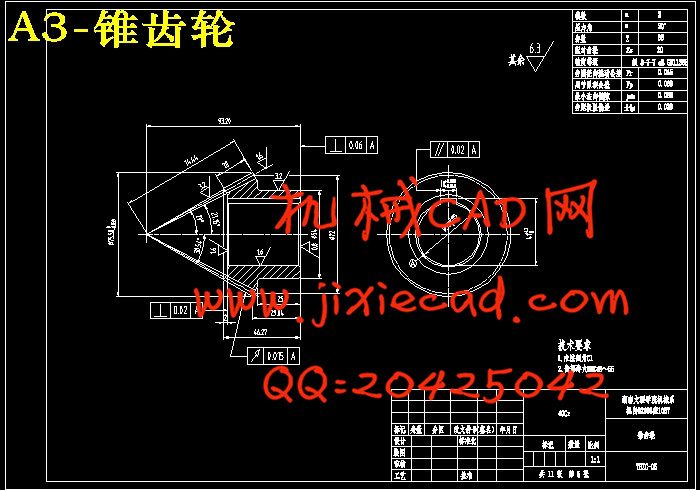

5.4直齿圆锥齿轮的尺寸设计计算及校核 ..............................17

5.4.1圆锥齿轮的各参数设计计算 ....................................17

5.4.2受力分析 ....................................................18

5.4.3结构设计 ....................................................18

5.4.4计算载荷 ....................................................19

5.4.5齿面接触疲劳强度的校核 ......................................20

5.4.6轮齿弯曲强度校核 ............................................21

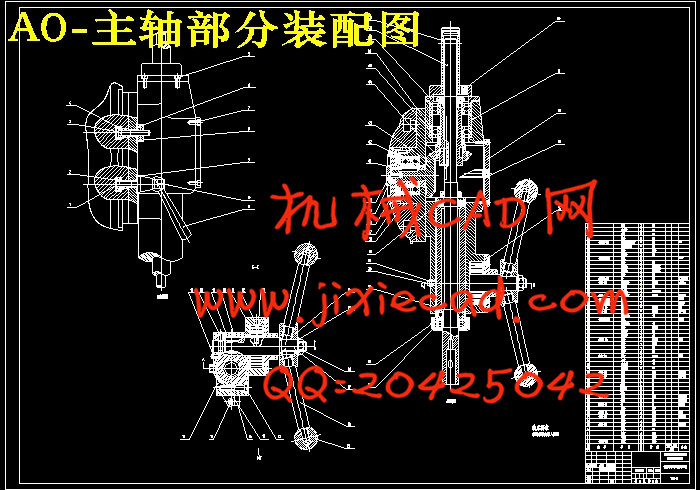

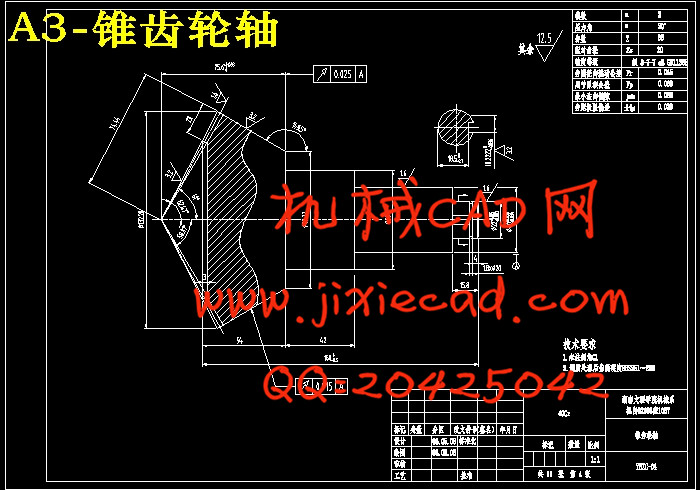

5.5锥齿轮轴的设计计算及校核 ......................................21

5.5.1锥齿轮部分主要参数设计计算 ..................................21

5.5.2轴端部分参数设计 ............................................23

5.5.3锥齿轮轴的固定 ..............................................23

5.6机-4齿轮设计计算及校核 .......................................24

5.6.1 尺寸设计计算 ...............................................24

5.6.2结构分析 ....................................................25

5.6.3受力分析 ....................................................25

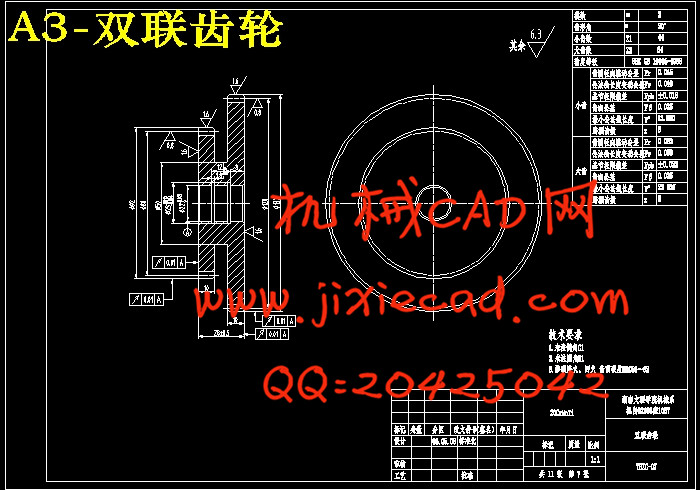

5.7双联齿轮的设计计算 ............................................26

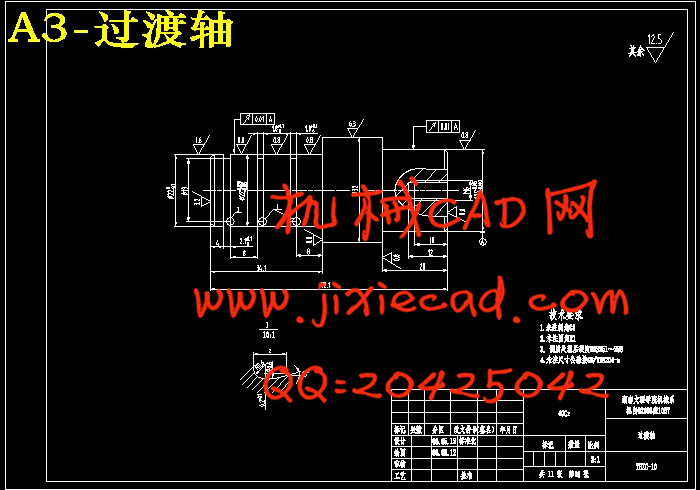

5.8 过渡轴的设计 .................................................27

5.8.1轴的失效形式 ................................................27

5.8.2轴的材料 ....................................................27

5.8.3过渡轴的强度校核 ............................................28

5.8.4过渡轴的固定 ................................................31

第六章 轴承的选择与校核 ........................................32

6.1轴承的分类 ....................................................32

6.2滚动轴承及类型 ................................................32

6.3 滚动轴承的失效形式 ...........................................32

6.4 轴承的选择计算 ...............................................33

第七章 键的选择和键联接强度计算 ..................................35

7.1 键的选择 .....................................................35

7.2 键联结强度计算 ...............................................35

第八章 设计小结 ..................................................37

参考文献 .........................................................38

致谢 .............................................................39

摘要:本次设计课题为“Z32K型摇臂钻床变速箱的改进设计”。主要是对Z32K型摇臂钻床的升降系统进行了改进、分析与设计,并对其主要传动零件进行设计及强度校核。了解和掌握Z32K型摇臂钻床在实际使用过程中出现的问题,在理论分析,计算的基础上,针对Z32K型摇臂钻床的升降系统是单手柄集中操作,操作起来比较麻烦,摇臂钻床体架太重,费力又费时,将其手动改进为自动升降,并提出了具体可行的解决方案。

关键词:摇臂钻床 手动、自动升降系统 电动机 齿轮 强度校核

英文摘要及关键词

Abstraction :This design topic is "the Z32K radial drill drilling machine gear box improvement design". Mainly was has made the improvement, the analysis and the design to the Z32K radial drill drilling machine jacking system, and carried on the design and the intensity examination to its main transmission components. Understood and grasps the Z32K radial drill drilling machine the question which appears in the actual use process, in the theoretical analysis, in the computation foundation, in view of the Z32K radial drill drilling machine jacking system is the single handle centralism operation, operates quite troublesomely, radial drill drilling machine body too is heavy, takes the trouble to take time, its manual improvement is the power elevation, and proposed specifically the feasible solution.

Keywords: universal raidial drilling machine manual operating and automatic fluctuation system electric motor gear strength cheeks.

目 录

中文摘要及关键词 ..................................................1

英文摘要及关键词 ..................................................2

第一章 概述 .......................................................3

1.1摇臂钻床的简介..................................................3

1.2摇臂钻床的国内发展动态及趋势 ...................................4

第二章 原动机的选择 ...............................................5

2.1常用原动机的运动形式 ...........................................5

2.2原动机的驱动形式 ...............................................5

2.3原动机选择应考虑的因素 .........................................5

2.4原动机的性能比较 ...............................................6

2.5确定原动机的选择 ...............................................7

第三章 机械传动设计方案的拟订与比较 ...............................8

3.1传动设计方案评价的目的 .........................................8

3.2传动设计方案评价的原则 .........................................8

3.3系统设计方案的比较与确定 .......................................8

第四章 绘制变速箱中升降系统的传动机构运动简图......................11

第五章 传动部分运动和动力分析 .....................................12

5.1部分传动连接设计 ..............................................12

5.2传动比、各轴转速、功率及转矩的计算 ............................12

5.3齿轮材料的选择 ................................................14

5.3.1齿轮材料的基本要求 ..........................................14

5.3.2常用材料及热处理 ............................................14

5.4直齿圆锥齿轮的尺寸设计计算及校核 ..............................17

5.4.1圆锥齿轮的各参数设计计算 ....................................17

5.4.2受力分析 ....................................................18

5.4.3结构设计 ....................................................18

5.4.4计算载荷 ....................................................19

5.4.5齿面接触疲劳强度的校核 ......................................20

5.4.6轮齿弯曲强度校核 ............................................21

5.5锥齿轮轴的设计计算及校核 ......................................21

5.5.1锥齿轮部分主要参数设计计算 ..................................21

5.5.2轴端部分参数设计 ............................................23

5.5.3锥齿轮轴的固定 ..............................................23

5.6机-4齿轮设计计算及校核 .......................................24

5.6.1 尺寸设计计算 ...............................................24

5.6.2结构分析 ....................................................25

5.6.3受力分析 ....................................................25

5.7双联齿轮的设计计算 ............................................26

5.8 过渡轴的设计 .................................................27

5.8.1轴的失效形式 ................................................27

5.8.2轴的材料 ....................................................27

5.8.3过渡轴的强度校核 ............................................28

5.8.4过渡轴的固定 ................................................31

第六章 轴承的选择与校核 ........................................32

6.1轴承的分类 ....................................................32

6.2滚动轴承及类型 ................................................32

6.3 滚动轴承的失效形式 ...........................................32

6.4 轴承的选择计算 ...............................................33

第七章 键的选择和键联接强度计算 ..................................35

7.1 键的选择 .....................................................35

7.2 键联结强度计算 ...............................................35

第八章 设计小结 ..................................................37

参考文献 .........................................................38

致谢 .............................................................39