设计简介

摘要

钻床是一种孔加工设备,可以用来钻孔、扩孔,铰孔。攻丝及修刮端面等多种形式的加工。在各类钻床中,摇臂钻床操作方便、灵活,适用范围广,具有典型性,特别适用于单件或批量生产带有多孔大型零件的孔加工,是一般机械加工车间常见的机床。

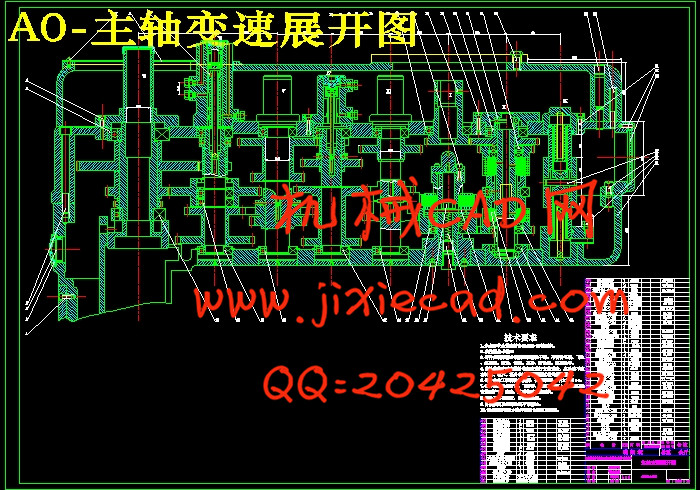

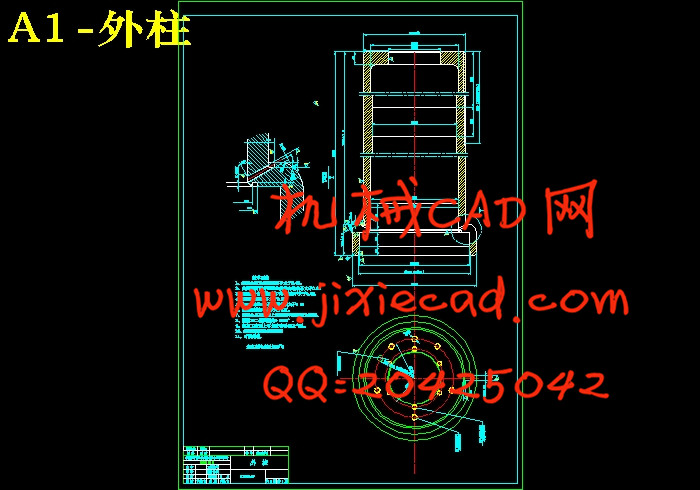

本设计通过对动力参数和运动参数的计算,转速范围的确定,以拟定传动系统图和转速图。重点是要考虑结构、尺寸、体积、等综合因素,设计出正确的结构分析式,绘制出正确的传动系统图,从而完成机床整体布局的设计,然后通过齿轮设计、键及轴承的选择、轴的设计以及其他一些附件设计,最后校核轴设计和键轴承选择的正确性与合理性,完成钻床主轴箱体传动系统的设计。

关键词:主轴的转速范围;齿轮模数设计;轴的设计;结构尺寸;机床功率;轴承设计

Abstract

Drilling is a hole processing equipment, can be used for drilling, reaming, reaming holes. Tapping and face a variety of forms such as scraping the processing. In all kinds of drilling radial drill, convenient operation, flexible, and wide application scope, typical, especially suitable for single or batch production with large parts of the pore porosity is general machinery processing workshop of common tools.

This design based on dynamic parameters and the movement parameters, speed limits, in transmission system and speed. Focus is to consider structure, size, volume, comprehensive factors, designed the correct structure analysis, draw out the correct transmission system, so as to complete the whole layout design of the machine, and then through the gears, bearings and design of the design, selection and other accessories, and finally checking shaft bearings choice of design and key correctness and rationality, complete drilling spindle box transmission system design.

Keywords: spindle speed range, Gear module design, Axis designs, Structure size, Machine power, Bearing design

目录

一 绪论 5

1.1 概述 5

1.2 钻床发展 5

二 钻床的设计 9

2.1 运动参数的确定 9

2.1.1 决定传动级数 9

2.1.2 选择转速数列 11

2.2 传动系统的设计 13

2.2.1主运动系的设计 13

2.2.2 传动系统的扩大顺序的安排 13

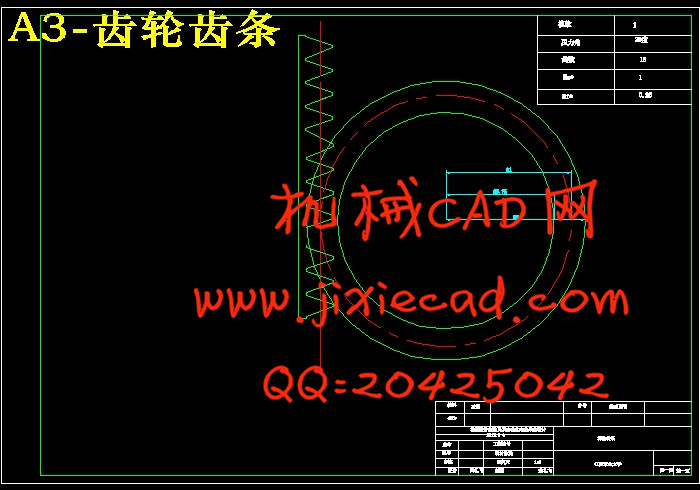

2.2.3 齿轮齿数的确定 14

2.2.4 转速图的确定 15

2.2.5 绘制传动系统图 20

2.3 动力设计 20

2.3.1 确定各轴转速 20

2.4 齿轮的设计及其校核 21

2.4.1 各传动组齿轮模数的确定 21

2.4.2 各传动组齿轮的校核 31

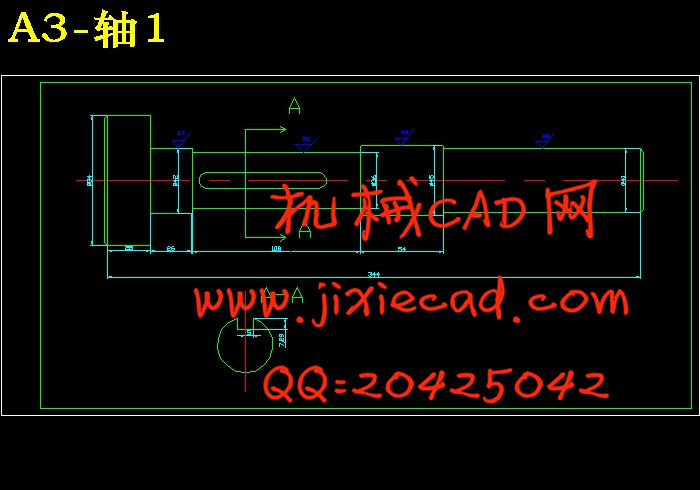

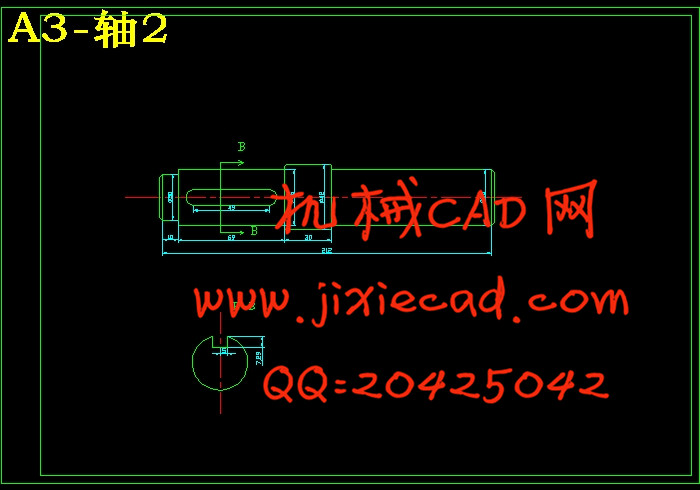

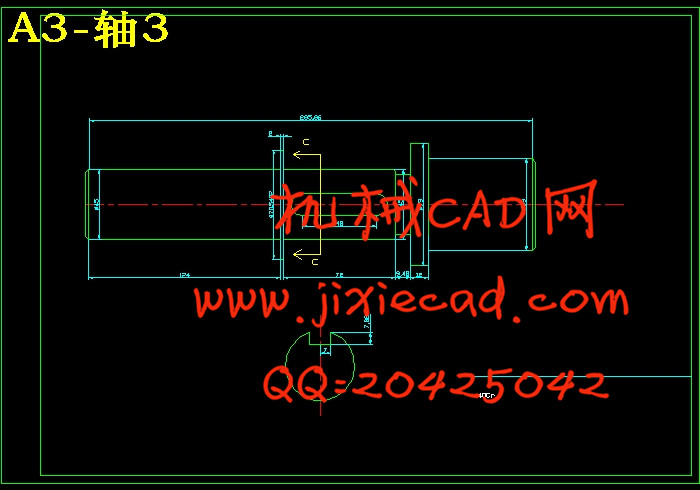

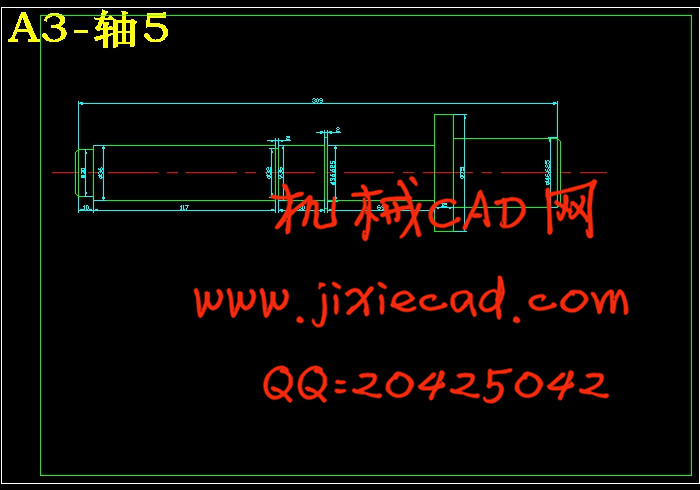

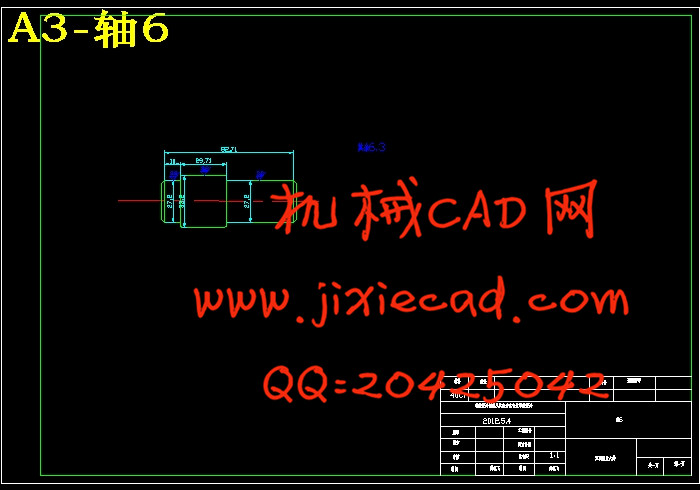

2.5 轴的设计及其校核 32

2.5.1 确定各轴的最小直径 33

2.5.2 Ⅰ轴的设计与校核 40

2.5.3 主轴的设计与校核 44

2.6 轴承的选择与校核 44

2.6.1 轴承的选择 45

2.6.2 轴承的校核 45

2.7 键的选择与校核 45

2.7.1 键的选择 46

2.7.2 键的校核 46

2.8 致谢 47

三 参考文献 48

钻床是一种孔加工设备,可以用来钻孔、扩孔,铰孔。攻丝及修刮端面等多种形式的加工。在各类钻床中,摇臂钻床操作方便、灵活,适用范围广,具有典型性,特别适用于单件或批量生产带有多孔大型零件的孔加工,是一般机械加工车间常见的机床。

本设计通过对动力参数和运动参数的计算,转速范围的确定,以拟定传动系统图和转速图。重点是要考虑结构、尺寸、体积、等综合因素,设计出正确的结构分析式,绘制出正确的传动系统图,从而完成机床整体布局的设计,然后通过齿轮设计、键及轴承的选择、轴的设计以及其他一些附件设计,最后校核轴设计和键轴承选择的正确性与合理性,完成钻床主轴箱体传动系统的设计。

关键词:主轴的转速范围;齿轮模数设计;轴的设计;结构尺寸;机床功率;轴承设计

Abstract

Drilling is a hole processing equipment, can be used for drilling, reaming, reaming holes. Tapping and face a variety of forms such as scraping the processing. In all kinds of drilling radial drill, convenient operation, flexible, and wide application scope, typical, especially suitable for single or batch production with large parts of the pore porosity is general machinery processing workshop of common tools.

This design based on dynamic parameters and the movement parameters, speed limits, in transmission system and speed. Focus is to consider structure, size, volume, comprehensive factors, designed the correct structure analysis, draw out the correct transmission system, so as to complete the whole layout design of the machine, and then through the gears, bearings and design of the design, selection and other accessories, and finally checking shaft bearings choice of design and key correctness and rationality, complete drilling spindle box transmission system design.

Keywords: spindle speed range, Gear module design, Axis designs, Structure size, Machine power, Bearing design

目录

一 绪论 5

1.1 概述 5

1.2 钻床发展 5

二 钻床的设计 9

2.1 运动参数的确定 9

2.1.1 决定传动级数 9

2.1.2 选择转速数列 11

2.2 传动系统的设计 13

2.2.1主运动系的设计 13

2.2.2 传动系统的扩大顺序的安排 13

2.2.3 齿轮齿数的确定 14

2.2.4 转速图的确定 15

2.2.5 绘制传动系统图 20

2.3 动力设计 20

2.3.1 确定各轴转速 20

2.4 齿轮的设计及其校核 21

2.4.1 各传动组齿轮模数的确定 21

2.4.2 各传动组齿轮的校核 31

2.5 轴的设计及其校核 32

2.5.1 确定各轴的最小直径 33

2.5.2 Ⅰ轴的设计与校核 40

2.5.3 主轴的设计与校核 44

2.6 轴承的选择与校核 44

2.6.1 轴承的选择 45

2.6.2 轴承的校核 45

2.7 键的选择与校核 45

2.7.1 键的选择 46

2.7.2 键的校核 46

2.8 致谢 47

三 参考文献 48