设计简介

ZFS液压支架的顶梁立柱的设计.

摘 要

在采煤综合机械化方面,放顶煤综采技术近年来在我国得到迅速的发展,放顶煤综采技术的推广使用,扩大了综合机械化开采的使用范围,简化了框架的采掘系统和生产组织,大幅度地提高了综采工作面的劳动生产率和产量,降低了煤炭的生产成本,在煤炭生产上取得了显著的技术经济效果。

在科研、设计和生产部门的共同努力下,放顶煤综采技术已逐步趋于成熟,放顶煤综采设备已经系列化。

在本次设计中,我设计的是ZFS4400/16/28型液压支架中的顶梁和立柱。

在设计过程中,首先是收集资料,可以从学校图书馆获得,也可以从其他方面得到。我是在学校图书馆中找了一些资料,对液压支架有了一个总体的认识和了解,对液压支架的结构有了进一步的认识。这对我做毕业课程设计有很大的帮助。

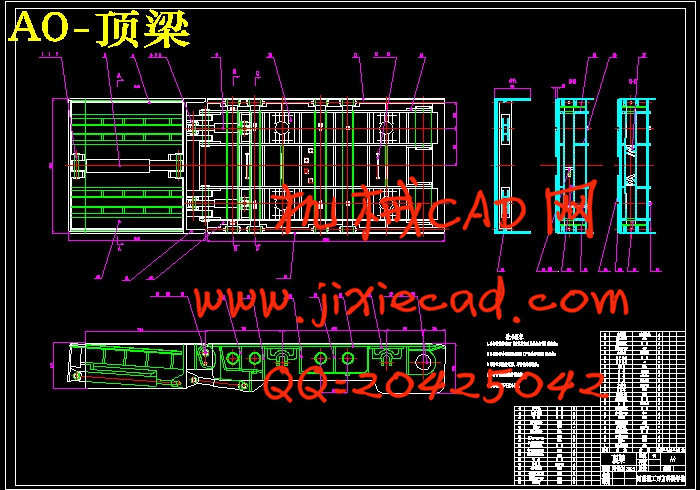

在设计顶梁时,首先对其受力分析;然后画出受力图、内力图和弯矩图,并找出最大危险截面;最后对最大危险截面进行受力分析,保证各个截面的安全。

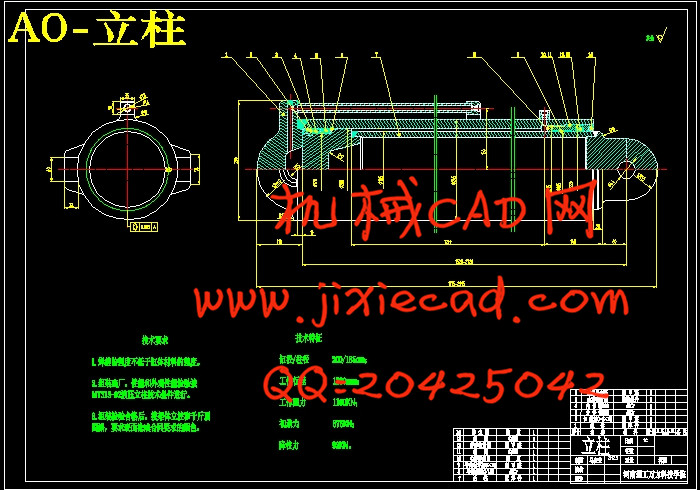

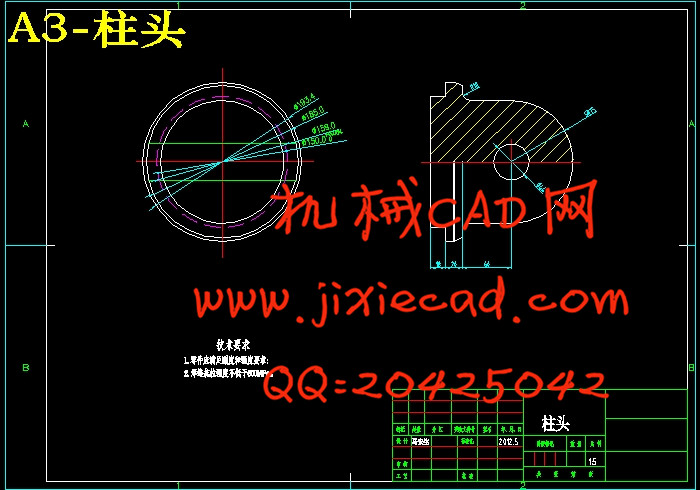

同样,对立柱设计时,应根据受力的大小来决定立柱缸径的大小,然后依次确定柱径、活塞、输油管等的尺寸和型号。

关键词:放顶煤、液压支架、顶梁、立柱。

Abstract

Integrated mechanized coal mining in the area, Research on top down to the coal integrated coal mining technology in recent years has been rapid development in China, Research on top down to the coal integrated coal mining technology to promote the use and expansion of the integrated use of mechanized mining scope of a framework to simplify the extraction systems and production organizations which substantially improved the Integrated Procurement located in labor productivity and output and reduced coal production costs, in coal production achieved remarkable technological and economic results.

In research, design and production departments work together, on top coal mining technology has gradually Integrated mature on top of coal mining equipment has serialization Research.

In this graduate course design, I design is the top ZFS4400/16/28 type hydraulic structures of on the top bar and Thursday.

In the design process, the first is to collect information that can be obtained from school libraries can receive from the other. I was in the school library to find some information. Then I follow the teacher to Zhengzhou Coal Mine Machinery Company do a graduate internship in hydraulic structures have a general knowledge and understanding of hydraulic structures better understanding of the structure. I do graduate courses designed to help a great deal.

In the design of the top bar, the first of its suffered an analysis of the power; Then painted by trying to, endogenous force, and moment, and to identify the greatest risk of cross-sectional; Finally its suffered an analysis of the power a cross-section of the greatest dangers to ensure the safety of all cross-sectional.

Likewise, the design of huge, the size should be based on the power to decide

Thursday And the diameter size, and then by identifying pillar Drive, piston, the size and type of pipeline.

Keywords : on top down to the coal, hydraulic structures ,on the top bar, Thursday.

目 录

摘 要 I

Abstract II

1绪 论 1

1.1国外主要产煤国家综采技术的发展趋势 1

1.2 放顶煤液压支架简介 3

1.3 方案确定 6

1.3.1 高位放顶煤液压支架的特点 6

1.3.2 中位放顶煤液压支架的特点 7

1.3.3 低位放顶煤液压支架的特点 8

1.4设计参数及要求 9

2 液压支架的工作原理 10

3 低位放顶煤液压支架受力分析 13

3.1 力学模型建立 13

3.2 支架的运动学分析 14

3.2.1立柱倾角计算 14

3.2.2前、后连杆及掩护梁与水平线的夹角计算 15

3.3 支架的受力分析 18

3.3.1顶梁 18

3.3.2掩护梁 19

3.3.4 支架前梁装置的受力分析与计算 21

4 顶梁的强度计算与校核 23

4.1 顶梁内力分析 23

4.2 顶梁的内力计算 23

4.3 各点处的剪力 24

5.4各点处弯矩和弯矩 25

4.5 集中载荷处断面强度 26

5 液压元件及系统的设计 29

5.1 拟定支架液压系统 29

5.1.1 ZFS 4400/16/28型支架液压系统 29

5.1.2 泵站 29

5.2工作机构 30

5.3控制系统 31

5.4电液控制系统 33

6 液压支架立柱的选择、计算与校核 35

6.1 立柱型式 35

6.1.1 单伸缩双作用立柱 35

6.1.2 单伸缩双作用带机械加长杆立柱 35

6.1.3 双伸缩双作用立柱 36

6.1.4 三伸缩双作用立柱 36

6.1.5 抗冲击立柱 36

6.2 立柱的主要组件、部件和零件的选取 37

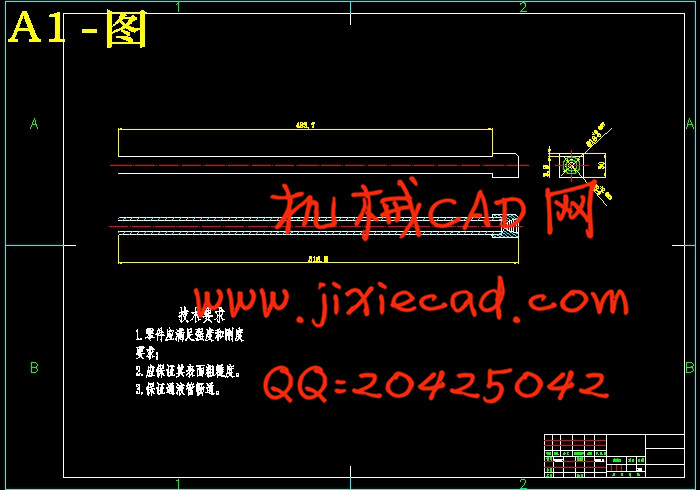

7.2.1 活柱组件 37

6.2.2 缸体部件 38

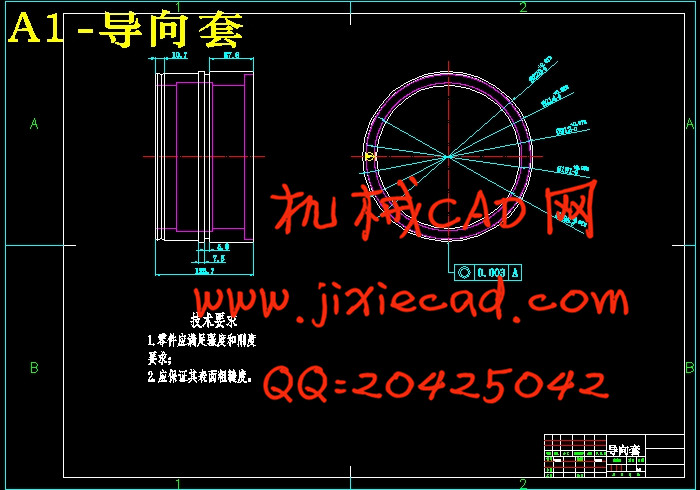

6.2.3 缸口导向套组 39

6.2.4 接长杆组件 40

6.2.5 底阀 40

6.3 液压支架立柱、活塞和活塞杆的密封型式、尺寸和公差 41

6.3.1 液压支架立柱、千斤顶密封结构的发展 41

6.3.2 液压支架立柱、千斤顶活塞和活塞杆 41

6.4 液压支架立柱、千斤顶结构合理化 44

6.4.1立柱和千斤顶在加工、使用和设计中存在的主要问题 44

6.4.2 立柱结构合理化 46

6.5液压支架立柱强度计算 51

6.5.1 立柱计算原则 51

6.5.2 立柱受力分析 51

7 低位放顶煤液压支架的使用与维护 57

致谢 60

参考文献 61

摘 要

在采煤综合机械化方面,放顶煤综采技术近年来在我国得到迅速的发展,放顶煤综采技术的推广使用,扩大了综合机械化开采的使用范围,简化了框架的采掘系统和生产组织,大幅度地提高了综采工作面的劳动生产率和产量,降低了煤炭的生产成本,在煤炭生产上取得了显著的技术经济效果。

在科研、设计和生产部门的共同努力下,放顶煤综采技术已逐步趋于成熟,放顶煤综采设备已经系列化。

在本次设计中,我设计的是ZFS4400/16/28型液压支架中的顶梁和立柱。

在设计过程中,首先是收集资料,可以从学校图书馆获得,也可以从其他方面得到。我是在学校图书馆中找了一些资料,对液压支架有了一个总体的认识和了解,对液压支架的结构有了进一步的认识。这对我做毕业课程设计有很大的帮助。

在设计顶梁时,首先对其受力分析;然后画出受力图、内力图和弯矩图,并找出最大危险截面;最后对最大危险截面进行受力分析,保证各个截面的安全。

同样,对立柱设计时,应根据受力的大小来决定立柱缸径的大小,然后依次确定柱径、活塞、输油管等的尺寸和型号。

关键词:放顶煤、液压支架、顶梁、立柱。

Abstract

Integrated mechanized coal mining in the area, Research on top down to the coal integrated coal mining technology in recent years has been rapid development in China, Research on top down to the coal integrated coal mining technology to promote the use and expansion of the integrated use of mechanized mining scope of a framework to simplify the extraction systems and production organizations which substantially improved the Integrated Procurement located in labor productivity and output and reduced coal production costs, in coal production achieved remarkable technological and economic results.

In research, design and production departments work together, on top coal mining technology has gradually Integrated mature on top of coal mining equipment has serialization Research.

In this graduate course design, I design is the top ZFS4400/16/28 type hydraulic structures of on the top bar and Thursday.

In the design process, the first is to collect information that can be obtained from school libraries can receive from the other. I was in the school library to find some information. Then I follow the teacher to Zhengzhou Coal Mine Machinery Company do a graduate internship in hydraulic structures have a general knowledge and understanding of hydraulic structures better understanding of the structure. I do graduate courses designed to help a great deal.

In the design of the top bar, the first of its suffered an analysis of the power; Then painted by trying to, endogenous force, and moment, and to identify the greatest risk of cross-sectional; Finally its suffered an analysis of the power a cross-section of the greatest dangers to ensure the safety of all cross-sectional.

Likewise, the design of huge, the size should be based on the power to decide

Thursday And the diameter size, and then by identifying pillar Drive, piston, the size and type of pipeline.

Keywords : on top down to the coal, hydraulic structures ,on the top bar, Thursday.

目 录

摘 要 I

Abstract II

1绪 论 1

1.1国外主要产煤国家综采技术的发展趋势 1

1.2 放顶煤液压支架简介 3

1.3 方案确定 6

1.3.1 高位放顶煤液压支架的特点 6

1.3.2 中位放顶煤液压支架的特点 7

1.3.3 低位放顶煤液压支架的特点 8

1.4设计参数及要求 9

2 液压支架的工作原理 10

3 低位放顶煤液压支架受力分析 13

3.1 力学模型建立 13

3.2 支架的运动学分析 14

3.2.1立柱倾角计算 14

3.2.2前、后连杆及掩护梁与水平线的夹角计算 15

3.3 支架的受力分析 18

3.3.1顶梁 18

3.3.2掩护梁 19

3.3.4 支架前梁装置的受力分析与计算 21

4 顶梁的强度计算与校核 23

4.1 顶梁内力分析 23

4.2 顶梁的内力计算 23

4.3 各点处的剪力 24

5.4各点处弯矩和弯矩 25

4.5 集中载荷处断面强度 26

5 液压元件及系统的设计 29

5.1 拟定支架液压系统 29

5.1.1 ZFS 4400/16/28型支架液压系统 29

5.1.2 泵站 29

5.2工作机构 30

5.3控制系统 31

5.4电液控制系统 33

6 液压支架立柱的选择、计算与校核 35

6.1 立柱型式 35

6.1.1 单伸缩双作用立柱 35

6.1.2 单伸缩双作用带机械加长杆立柱 35

6.1.3 双伸缩双作用立柱 36

6.1.4 三伸缩双作用立柱 36

6.1.5 抗冲击立柱 36

6.2 立柱的主要组件、部件和零件的选取 37

7.2.1 活柱组件 37

6.2.2 缸体部件 38

6.2.3 缸口导向套组 39

6.2.4 接长杆组件 40

6.2.5 底阀 40

6.3 液压支架立柱、活塞和活塞杆的密封型式、尺寸和公差 41

6.3.1 液压支架立柱、千斤顶密封结构的发展 41

6.3.2 液压支架立柱、千斤顶活塞和活塞杆 41

6.4 液压支架立柱、千斤顶结构合理化 44

6.4.1立柱和千斤顶在加工、使用和设计中存在的主要问题 44

6.4.2 立柱结构合理化 46

6.5液压支架立柱强度计算 51

6.5.1 立柱计算原则 51

6.5.2 立柱受力分析 51

7 低位放顶煤液压支架的使用与维护 57

致谢 60

参考文献 61