设计简介

ZH1105W柴油机机体钻孔钻机总体及夹具设计

摘 要:为保证ZH1105W柴油机气缸体孔加工及保证相应的位置精度,设计一台钻孔组合机床。在完成“三图一卡”的基础上,完成夹具设计。根据ZH1105W柴油机气缸体的工序图分析其精度、表面粗糙度、技术要求、加工部位尺寸、形状结构、材料硬度、工件刚性及零件的批量的大小不同,确定被加工零件工艺方法和工艺过程,确定该组合机床的总体设计方案;考虑该零件表面结构的不规则性但有较高精度的孔需要加工,定位基准选择“一面双孔”是最佳的方法。选择通用导套,保证零件上孔的位置精度。选用液压滑台来保证所需要的进给力。动力箱和机床底座都是经过严格的计算后再选择合适的标准件,减少机床设计周期和成本;在夹具设计方面采用“一面两销”的定位方案保证被加工孔的准确定位和尺寸精度。考虑到需要的夹紧力比较大和手动夹紧的局限性,选用了液压自动夹紧的方案,提供稳定的夹紧力,减少工人的操作时间并且满足中批量生产的要求。此次设计的组合机床,结构简单、维护方便,大量使用了通用部件来降低制造成本,达到了设计的要求。

关键词:气缸体;组合机床; 总体设计; 夹具;

The rigs overall and fixture design for ZH1105W engine block drilling machine

Abstract: In order to meet the hole processing and the corresponding position precision of the ZH1105W diesel engine cylinder, to drilling and the boring modular machine is designed. It mainly completes the jig design bases on “three charts and a card”.According to the working procedure chart of the ZH1105W diesel engine’s cylinder, analysis the work piece’s precision, the surface roughness, the specification, the processing spot size, the shape structure, material degree of hardness, the work piece rigidity and the different of the components batch size to definite technique and technological process, determine aggregate machine-tool’s overall plan. Consider to the irregularity components but have high accuracy holes to be processing. So, “two holes at a face” is the best localization plan. The general leads the wrap to Guarantee the hole of the components’ position precision. In order to guarantee the needs of the entering strength, we select hydraulic pressure sliding table. The power box and the engine bed are the standard parts base on our computation, so that we can greatly reduce the engine bed design cycle and the cost; In the jig aspect, we use the "two sells at the same surface for the localization plan. Only this way, we can guarantee the hole the accurate localization and the size precision. Considered to the strength of the manual clamps quite be small, selecting the hydraulic pressure clamps is the best way. It could provide stably clamps the strength, reduce worker's operating time and satisfy the volume production request greatly. Besides satisfying the processing request, the structure is simple, the maintenance is convenient. The general parts are massively used to reduce the production cost and meet the design requirements.

Key words: Cylinder body; Modular machine-tool; Overall design; Jig;

目 录

1前言 1

1.1课题内容 1

1.2课题来由 1

1.2.1课题背景 1

1.2.2 课题要求 1

1.2.3 组合机床国内外发展概况 1

1.2.4 本课题主要解决的问题和总体设计思路 2

2 组合机床总体设计 4

2.1 工艺方案的拟订 4

2.1.1 被加工零件特点 4

2.1.2 工艺路线的确定 4

2.1.3 影响机床工艺方案制定的主要因素 4

2.1.4 定位基准及夹压点的选择 5

2.2 三图一卡设计 6

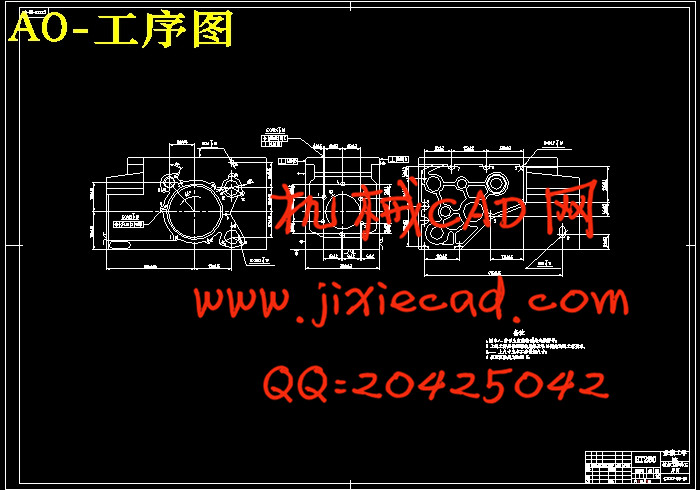

2.2.1 被加工零件工序图 6

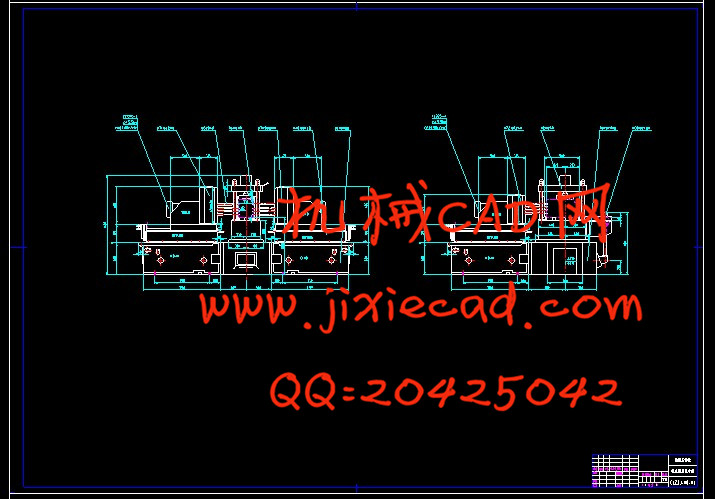

2.2.2 加工示意图 6

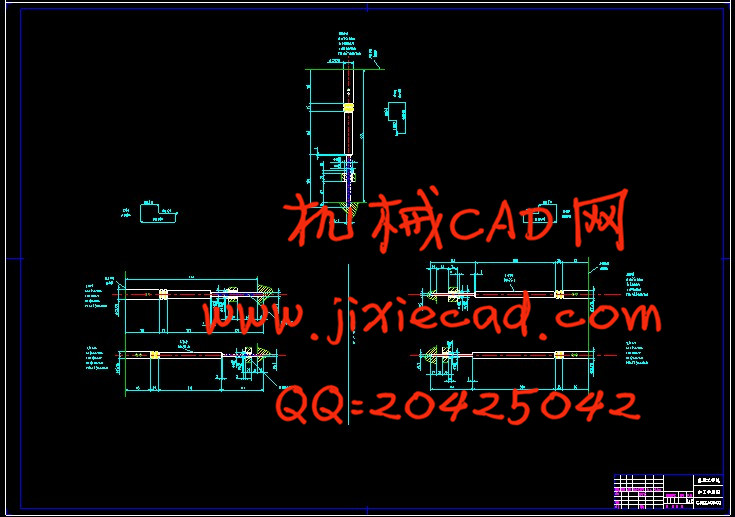

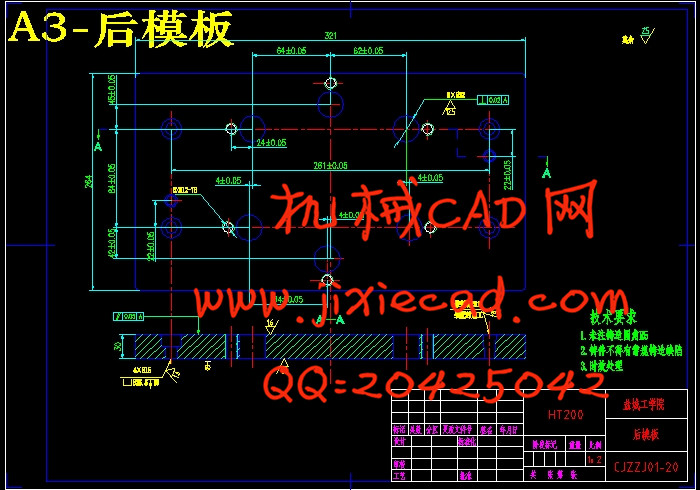

2.2.3 机床尺寸联系总图 9

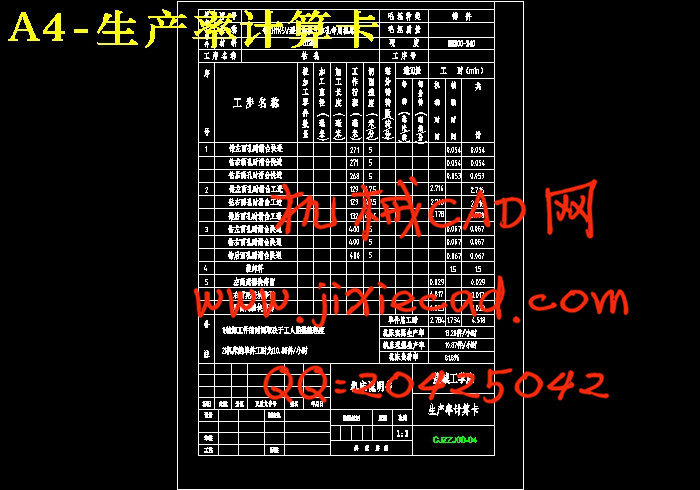

2.2.4 机床生产率计算卡 12

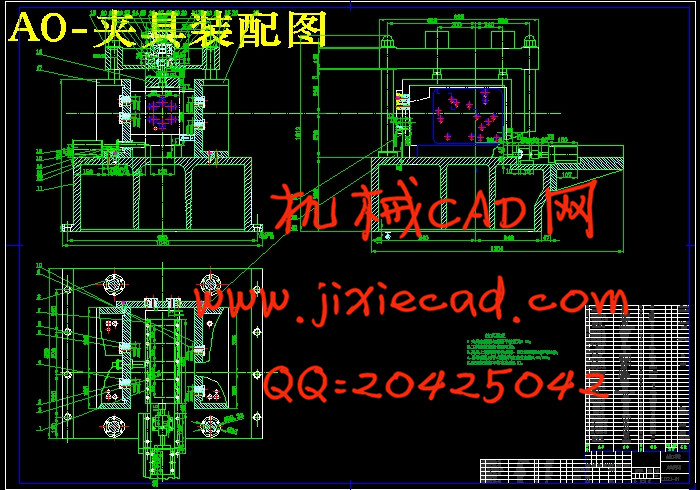

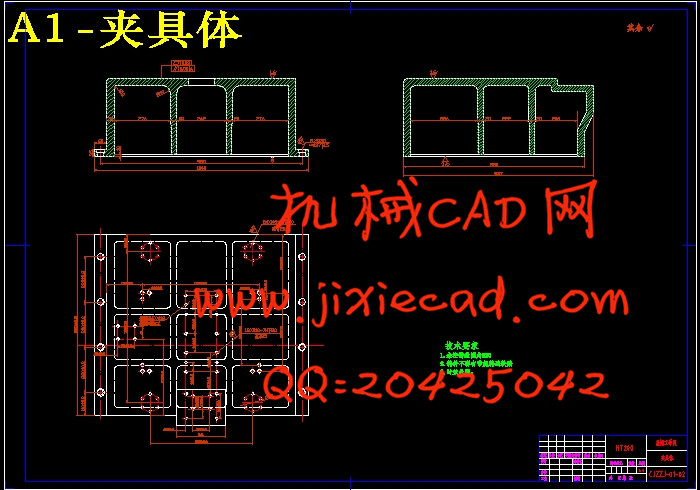

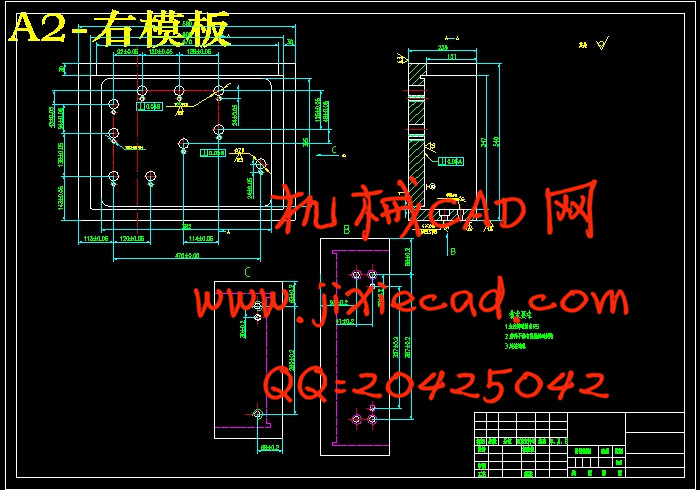

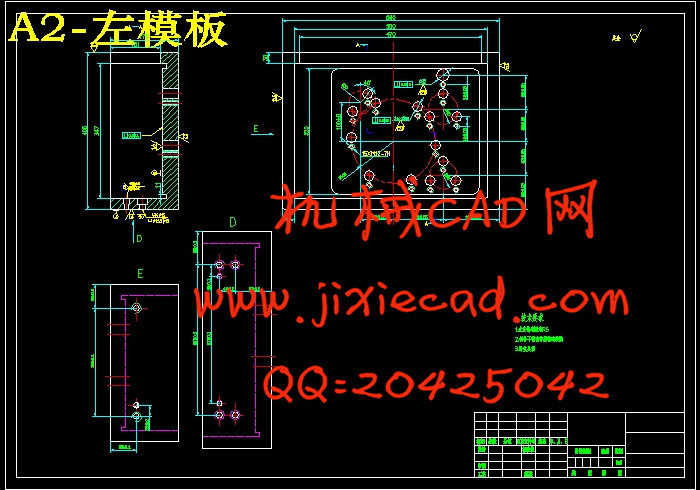

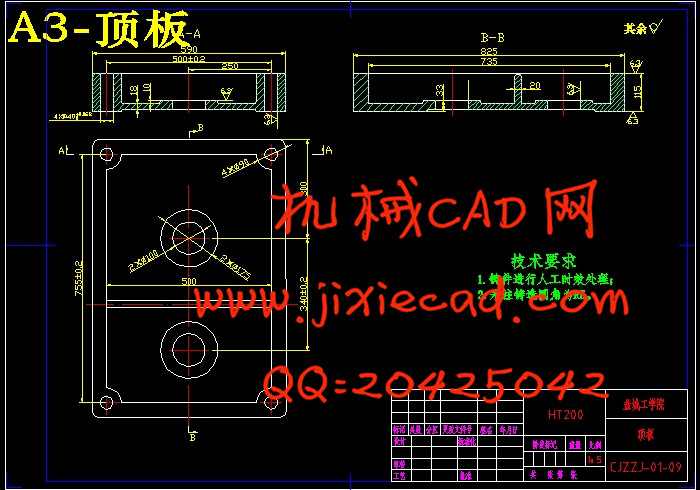

3 组合机床夹具设计 16

3.1 工件的定位基准及定位结构的设计 16

3.1.1 工件的定位基准选择 16

3.1.2 定位机构的设计 16

3.2 夹紧方案的选择及夹紧机构的设计 16

3.2.1 夹紧方案的选择 16

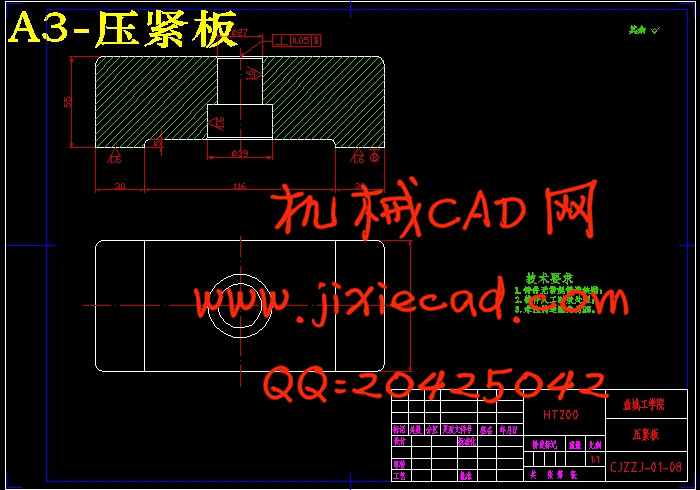

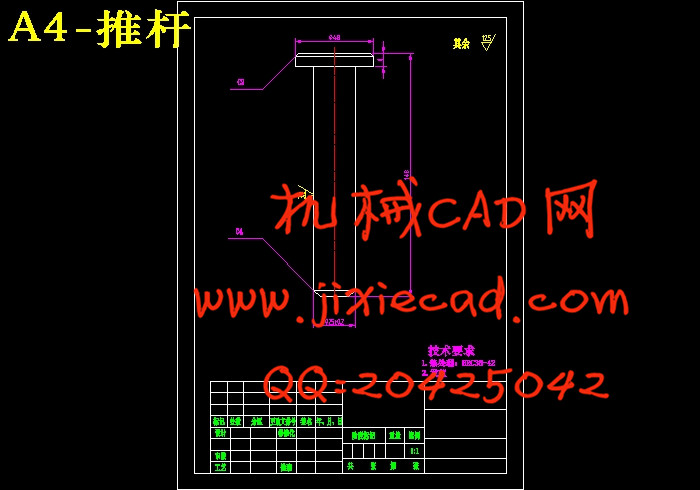

3.2.2 夹紧机构的设计 17

3.3 切削力及夹紧力的计算 17

3.3.1 切削力的计算 17

3.3.2 夹紧力的计算 17

3.3.3 液压缸的选择 19

3.4 定位误差的分析与计算 19

3.5 夹紧元件的强度校验 19

3.6 夹具体的设计及夹具的操作说明 19

3.6.1 夹具体的设计 19

3.6.2 夹具的操作说明 19

3.7 夹具的精度分析和计算 20

3.7.1 加工误差的来源 20

3.7.2 各项加工误差的计算 20

结论 22

参考文献 23

致谢 24

附录 25

摘 要:为保证ZH1105W柴油机气缸体孔加工及保证相应的位置精度,设计一台钻孔组合机床。在完成“三图一卡”的基础上,完成夹具设计。根据ZH1105W柴油机气缸体的工序图分析其精度、表面粗糙度、技术要求、加工部位尺寸、形状结构、材料硬度、工件刚性及零件的批量的大小不同,确定被加工零件工艺方法和工艺过程,确定该组合机床的总体设计方案;考虑该零件表面结构的不规则性但有较高精度的孔需要加工,定位基准选择“一面双孔”是最佳的方法。选择通用导套,保证零件上孔的位置精度。选用液压滑台来保证所需要的进给力。动力箱和机床底座都是经过严格的计算后再选择合适的标准件,减少机床设计周期和成本;在夹具设计方面采用“一面两销”的定位方案保证被加工孔的准确定位和尺寸精度。考虑到需要的夹紧力比较大和手动夹紧的局限性,选用了液压自动夹紧的方案,提供稳定的夹紧力,减少工人的操作时间并且满足中批量生产的要求。此次设计的组合机床,结构简单、维护方便,大量使用了通用部件来降低制造成本,达到了设计的要求。

关键词:气缸体;组合机床; 总体设计; 夹具;

The rigs overall and fixture design for ZH1105W engine block drilling machine

Abstract: In order to meet the hole processing and the corresponding position precision of the ZH1105W diesel engine cylinder, to drilling and the boring modular machine is designed. It mainly completes the jig design bases on “three charts and a card”.According to the working procedure chart of the ZH1105W diesel engine’s cylinder, analysis the work piece’s precision, the surface roughness, the specification, the processing spot size, the shape structure, material degree of hardness, the work piece rigidity and the different of the components batch size to definite technique and technological process, determine aggregate machine-tool’s overall plan. Consider to the irregularity components but have high accuracy holes to be processing. So, “two holes at a face” is the best localization plan. The general leads the wrap to Guarantee the hole of the components’ position precision. In order to guarantee the needs of the entering strength, we select hydraulic pressure sliding table. The power box and the engine bed are the standard parts base on our computation, so that we can greatly reduce the engine bed design cycle and the cost; In the jig aspect, we use the "two sells at the same surface for the localization plan. Only this way, we can guarantee the hole the accurate localization and the size precision. Considered to the strength of the manual clamps quite be small, selecting the hydraulic pressure clamps is the best way. It could provide stably clamps the strength, reduce worker's operating time and satisfy the volume production request greatly. Besides satisfying the processing request, the structure is simple, the maintenance is convenient. The general parts are massively used to reduce the production cost and meet the design requirements.

Key words: Cylinder body; Modular machine-tool; Overall design; Jig;

目 录

1前言 1

1.1课题内容 1

1.2课题来由 1

1.2.1课题背景 1

1.2.2 课题要求 1

1.2.3 组合机床国内外发展概况 1

1.2.4 本课题主要解决的问题和总体设计思路 2

2 组合机床总体设计 4

2.1 工艺方案的拟订 4

2.1.1 被加工零件特点 4

2.1.2 工艺路线的确定 4

2.1.3 影响机床工艺方案制定的主要因素 4

2.1.4 定位基准及夹压点的选择 5

2.2 三图一卡设计 6

2.2.1 被加工零件工序图 6

2.2.2 加工示意图 6

2.2.3 机床尺寸联系总图 9

2.2.4 机床生产率计算卡 12

3 组合机床夹具设计 16

3.1 工件的定位基准及定位结构的设计 16

3.1.1 工件的定位基准选择 16

3.1.2 定位机构的设计 16

3.2 夹紧方案的选择及夹紧机构的设计 16

3.2.1 夹紧方案的选择 16

3.2.2 夹紧机构的设计 17

3.3 切削力及夹紧力的计算 17

3.3.1 切削力的计算 17

3.3.2 夹紧力的计算 17

3.3.3 液压缸的选择 19

3.4 定位误差的分析与计算 19

3.5 夹紧元件的强度校验 19

3.6 夹具体的设计及夹具的操作说明 19

3.6.1 夹具体的设计 19

3.6.2 夹具的操作说明 19

3.7 夹具的精度分析和计算 20

3.7.1 加工误差的来源 20

3.7.2 各项加工误差的计算 20

结论 22

参考文献 23

致谢 24

附录 25