设计简介

ZH1105柴油机气缸体三面粗镗组合机床总体及夹具设计

摘 要:柴油机气缸体是大批量生产的零件。为了提高生产效率,满足被加工零件的精度要求,本课题设计了一台用于ZH1105柴油机气缸体三面粗镗孔的组合机床。本文介绍了该组合机床总体设计和夹具设计的思路,全文共分两个部分。首先是总体设计,采用单工位三面粗镗孔组合机床,考虑的因素有刀具、切削用量、切削力、切削扭矩及切削功率等,通过计算选择主轴直径、外伸尺寸、接杆型号、滑台、动力箱等通用部件,再确定动力部件的工作循环及工作行程,完成机床总体设计。其次是夹具设计,通过对被加工零件的全面分析,采用三面定位和固定镗模板可换导套导向;夹紧装置采用液压夹紧机构,直接夹紧与工件上;夹具体为框架式结构,有良好的刚性,使夹具能长期保持可靠的精度和稳定性。该组合机床不仅能保证加工精度,还能提高加工效率。整个机床布局合理,夹紧可靠,精度较高,使用操作方便,提高了工作效率,达到了设计要求。

关键词:气缸体;组合机床;粗镗;夹具

The design of the overall and jig of the modular machine-tool for drilling and boring in the body of ZH1105 diesel

Abstract: The cylinder body of diesel is made for large mass production. In order to enhance the production efficiency and meet the precision requested of the components processed, the topic is produced for designing a combined machine-tool, which is used to roughly bore the holes of the ZH1105 diesel engine cylinder .The design was introduced of the overall and jig of the combined machine-tool and the topic consists of two parts. The first part is overall design, adopting the combined machine-tool with single location three faces drilling and roughly bore the holes, considering such factors as tool, cutting parameter, cutting force, cutting torque and cutting power, and so on. Thus common parts such as sliding table, the power box and so on, were choused by calculating spindle diameter, and the extend sizes , the link-pole model. Then the operating cycle and the distance were determined. Thus the overall design was completed. Finally, the technological drawing was figured out of the part which need to be manufactured, the general drawing of modular machine tool, and drawing of cutter display and the efficiency card of manufacture. The second part is the jig design, having analyzed the work piece, the location plan adopted three-face location; the guiding equipment used the fixed bore plate with replaceable bore bush; the clamp uses the hydraulic pressure device, it directly presses on the work piece,the jig-body utilize the frame structure, possess fine rigidity, causes the jig to maintain good long-term precision. This combined machine-tool not only has guaranteed the drill hole precision efficiency. The laying out of the machine-tool is reasonable, the location of work piece is reliably, the accuracy is high, the operation is easy, enhanced the working efficiency, and meet with the design request well.

Key words:The cylinder body; Modular machine tool; Rough bore the holes; Jig

目 录

1前言 1

2 组合机床总体设计 3

2.1 组合机床工艺方案的制定 3

2.1.1工艺基准面的分析 3

2.1.2加工工艺的分析 3

2.1.3 确定机床完成工艺时的一些限制 3

2.2 组合机床配置型式的选择 3

2.2.1组合机床配置型式 3

2.2.2 选择机床配置型式和结构方案的一些问题 3

2.3确定切削用量及选择刀具 4

2.3.1选择切削用量 4

2.3.2 计算切削力、切削扭矩及切削功率 6

2.3.3选择刀具结构 10

2.4组合机床总体设计--三图一卡 10

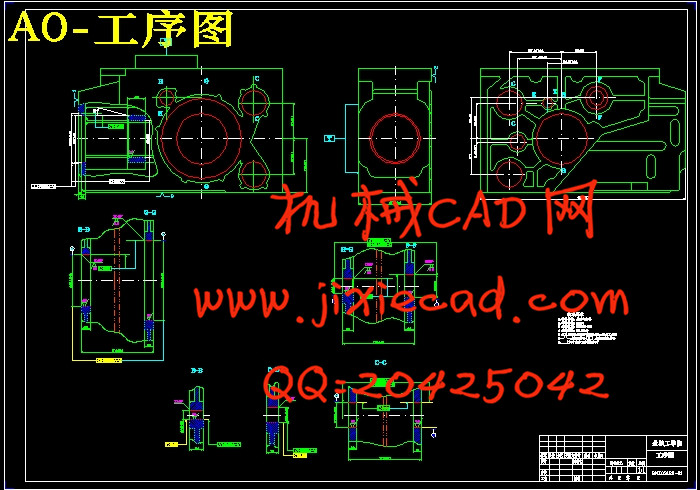

2.4.1被加工零件工序图 10

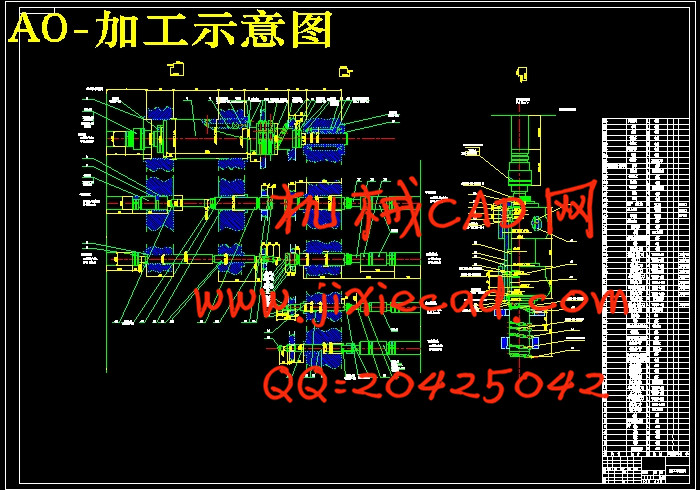

2.4.2 加工示意图 11

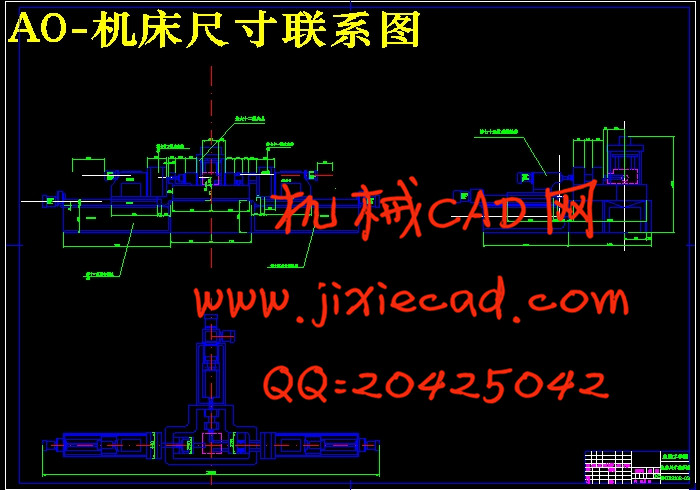

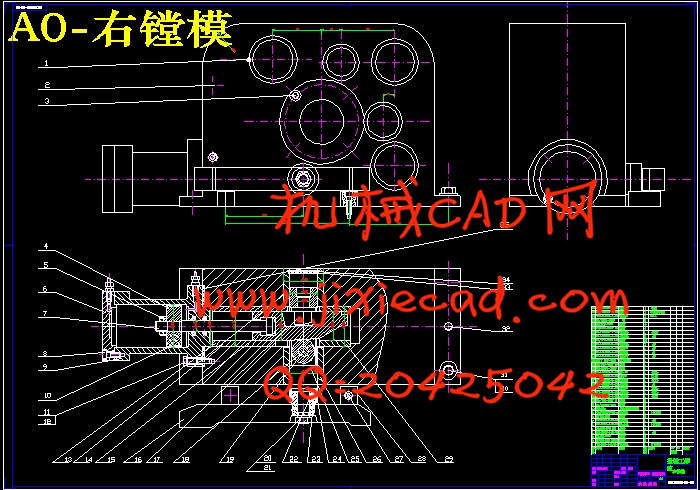

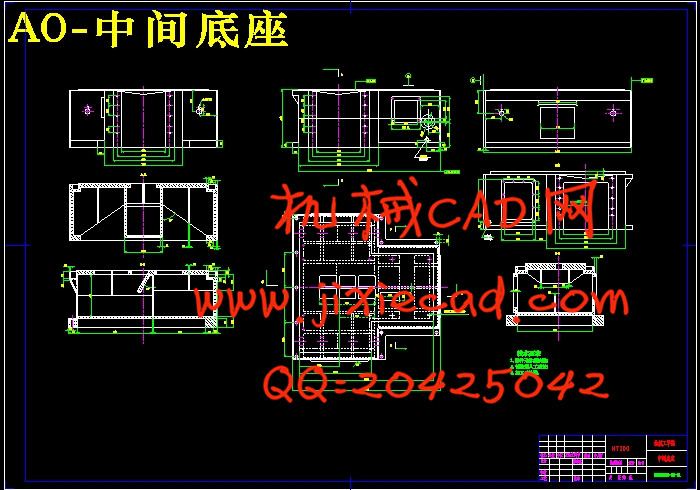

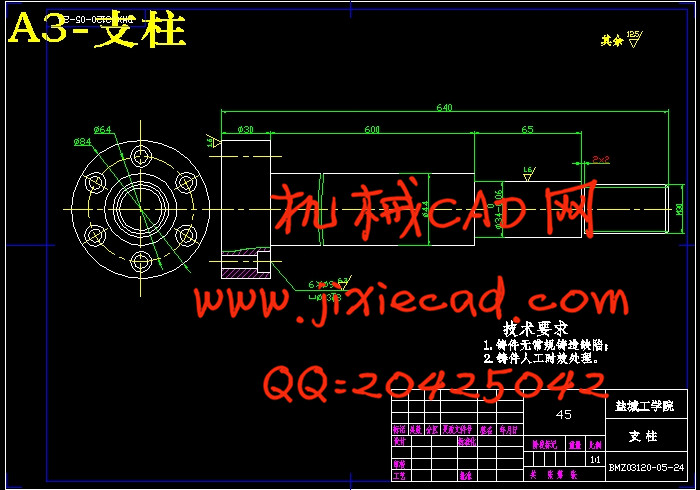

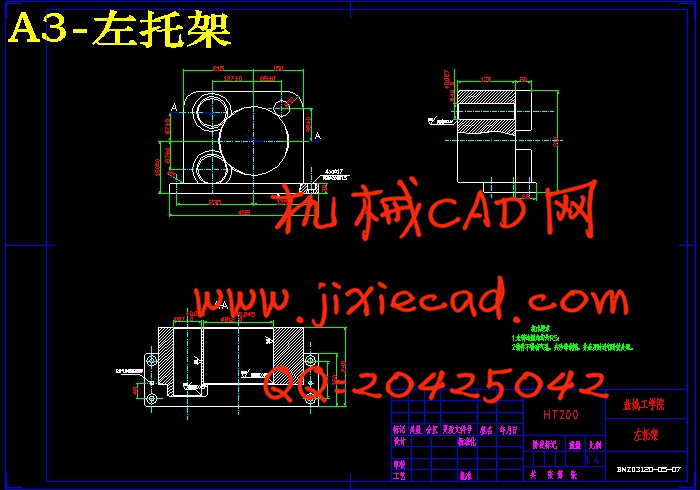

2.4.3机床尺寸联系图 13

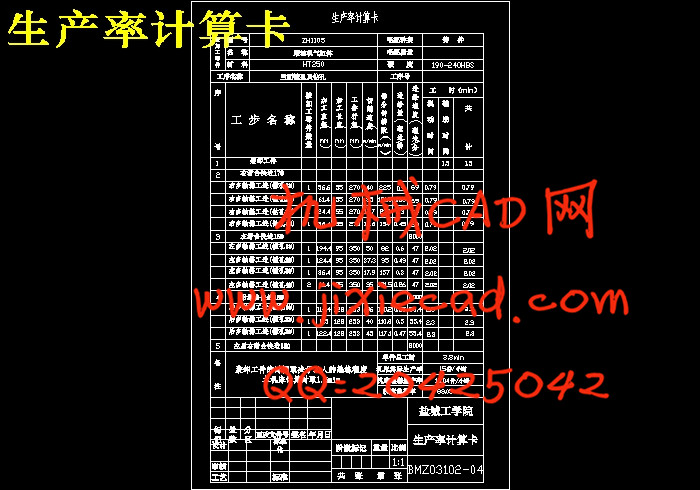

2.4.4机床生产率计算卡 16

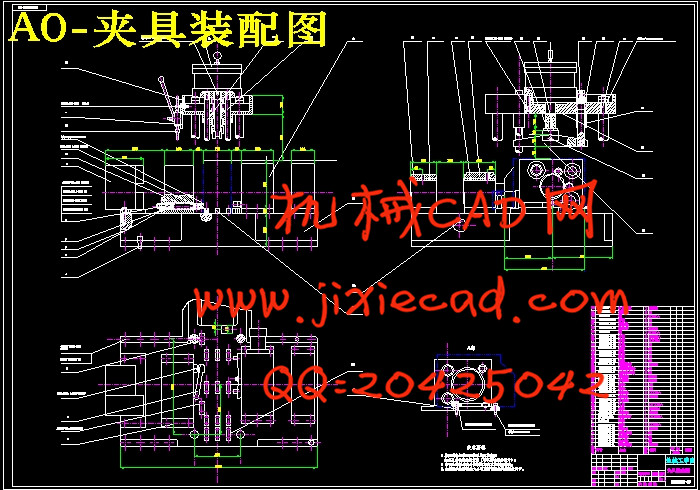

3 夹具设计 18

3.1夹具设计的基本要求和步骤 18

3.1.1夹具设计的基本要求 18

3.1.2夹具设计的步骤 18

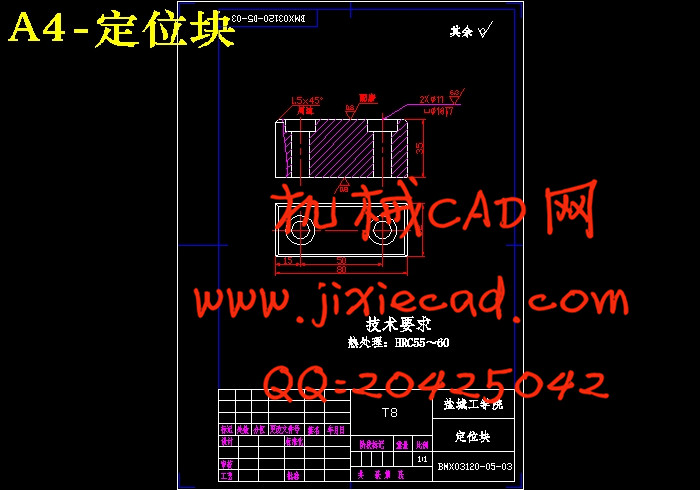

3.2定位方案的确定 19

3.2.1零件的工艺性分析 19

3.2.2定位方案的论证 19

3.2.3误差分析 20

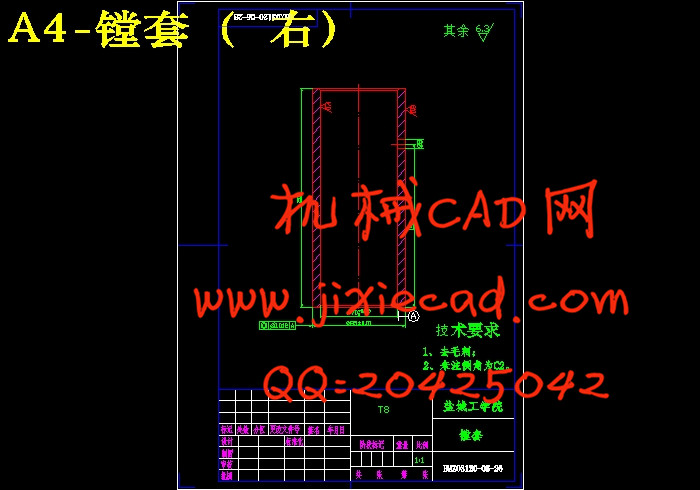

3.2.4导向装置 22

3.3夹紧方案的确定 22

3.3.1夹紧装置的确定 22

3.3.2夹紧力的确定 24

3.3.3 油缸的选择 25

3.4夹具体的设计 26

4结论 27

参考文献 28

致谢 29

摘 要:柴油机气缸体是大批量生产的零件。为了提高生产效率,满足被加工零件的精度要求,本课题设计了一台用于ZH1105柴油机气缸体三面粗镗孔的组合机床。本文介绍了该组合机床总体设计和夹具设计的思路,全文共分两个部分。首先是总体设计,采用单工位三面粗镗孔组合机床,考虑的因素有刀具、切削用量、切削力、切削扭矩及切削功率等,通过计算选择主轴直径、外伸尺寸、接杆型号、滑台、动力箱等通用部件,再确定动力部件的工作循环及工作行程,完成机床总体设计。其次是夹具设计,通过对被加工零件的全面分析,采用三面定位和固定镗模板可换导套导向;夹紧装置采用液压夹紧机构,直接夹紧与工件上;夹具体为框架式结构,有良好的刚性,使夹具能长期保持可靠的精度和稳定性。该组合机床不仅能保证加工精度,还能提高加工效率。整个机床布局合理,夹紧可靠,精度较高,使用操作方便,提高了工作效率,达到了设计要求。

关键词:气缸体;组合机床;粗镗;夹具

The design of the overall and jig of the modular machine-tool for drilling and boring in the body of ZH1105 diesel

Abstract: The cylinder body of diesel is made for large mass production. In order to enhance the production efficiency and meet the precision requested of the components processed, the topic is produced for designing a combined machine-tool, which is used to roughly bore the holes of the ZH1105 diesel engine cylinder .The design was introduced of the overall and jig of the combined machine-tool and the topic consists of two parts. The first part is overall design, adopting the combined machine-tool with single location three faces drilling and roughly bore the holes, considering such factors as tool, cutting parameter, cutting force, cutting torque and cutting power, and so on. Thus common parts such as sliding table, the power box and so on, were choused by calculating spindle diameter, and the extend sizes , the link-pole model. Then the operating cycle and the distance were determined. Thus the overall design was completed. Finally, the technological drawing was figured out of the part which need to be manufactured, the general drawing of modular machine tool, and drawing of cutter display and the efficiency card of manufacture. The second part is the jig design, having analyzed the work piece, the location plan adopted three-face location; the guiding equipment used the fixed bore plate with replaceable bore bush; the clamp uses the hydraulic pressure device, it directly presses on the work piece,the jig-body utilize the frame structure, possess fine rigidity, causes the jig to maintain good long-term precision. This combined machine-tool not only has guaranteed the drill hole precision efficiency. The laying out of the machine-tool is reasonable, the location of work piece is reliably, the accuracy is high, the operation is easy, enhanced the working efficiency, and meet with the design request well.

Key words:The cylinder body; Modular machine tool; Rough bore the holes; Jig

目 录

1前言 1

2 组合机床总体设计 3

2.1 组合机床工艺方案的制定 3

2.1.1工艺基准面的分析 3

2.1.2加工工艺的分析 3

2.1.3 确定机床完成工艺时的一些限制 3

2.2 组合机床配置型式的选择 3

2.2.1组合机床配置型式 3

2.2.2 选择机床配置型式和结构方案的一些问题 3

2.3确定切削用量及选择刀具 4

2.3.1选择切削用量 4

2.3.2 计算切削力、切削扭矩及切削功率 6

2.3.3选择刀具结构 10

2.4组合机床总体设计--三图一卡 10

2.4.1被加工零件工序图 10

2.4.2 加工示意图 11

2.4.3机床尺寸联系图 13

2.4.4机床生产率计算卡 16

3 夹具设计 18

3.1夹具设计的基本要求和步骤 18

3.1.1夹具设计的基本要求 18

3.1.2夹具设计的步骤 18

3.2定位方案的确定 19

3.2.1零件的工艺性分析 19

3.2.2定位方案的论证 19

3.2.3误差分析 20

3.2.4导向装置 22

3.3夹紧方案的确定 22

3.3.1夹紧装置的确定 22

3.3.2夹紧力的确定 24

3.3.3 油缸的选择 25

3.4夹具体的设计 26

4结论 27

参考文献 28

致谢 29