设计简介

摘 要

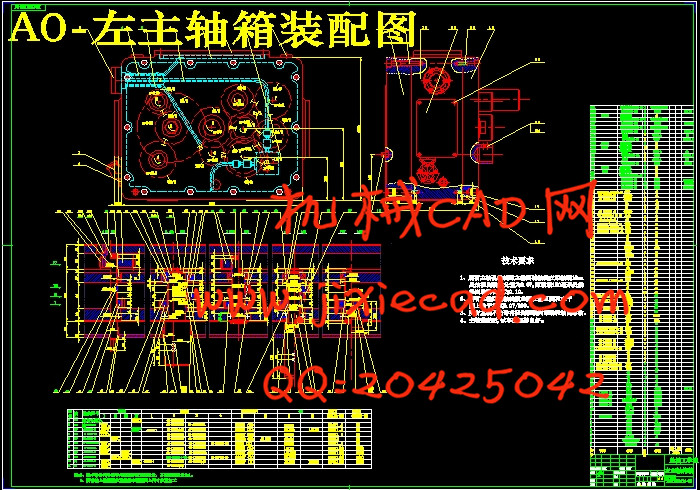

为了提高加工效率和质量以及保证ZH1105柴油机气缸体三面相应粗镗孔的尺寸精度及位置精度的要求,需要设计一台满足三面粗镗要求的卧式组合机床,本课题组设计了ZH1105柴油机气缸体三面粗镗机床及左主轴箱。在分析加工工件的特点的基础上,按组合机床的设计方法和步骤,进行了组合机床的总体设计,绘制了被加工零件的工序图、加工示意图、机床联系尺寸图和生产率计算卡,在此基础上,绘制了左主轴箱设计的原始依据图,拟订了主轴箱的传动路线,应用最优化方法布置齿轮。确定传动参数,绘制了主轴箱装配图、箱体坐标检查图、前盖及后盖的补充加工图,进行了轴、齿轮等零件的强度校核。该机较好地完成了设计要求,大大提高了工作效率。

关键词:柴油机;气缸体;三面粗镗;主轴箱;组合机床

Abstract

. To improve the efficiency of processing ,and quality assurance of ZH1105 engine casing ,and cylinder block three rough surface corresponding Boring, and the dimensional accuracy of location requirements for the design of a rough surface to satisfy the requirements of Horizontal Boring Machine portfolio, the discussion group has designed ZH1105 engine casing design of the cylinder block 3., Rough Boring Machine and left spindle box. On the base of the characteristics of the analysis’s process , the methods and steps of the design of the modular machine tool, the designing system was made. By the process of drawing ,the schematic diagram of machining ,the relationship of the machine size and the card of the productivity were drawn. Then the primitive chart for the design of the left-side spindle box was given out. The transmission route was confirmed and the transmission parameter was made. The assembly diagram of the spindle box was drawn. After arranging the gears ,we used the optimized design. The supplement processing diagram of the front side and behind side plate were also made. The intensity of the axises and gears was checked. The machine can satisfy the requirement of the design and the controlling precision was wholly improved.

Keywords:desel machine; cylinder body; three-side Rough Boring ; spindle box; modular machine tool.

目 录

1前言..............................................................1

1.1 总体设计.........................................................1

1.2 左主轴箱设计....................................................1

1.3 发展状况及涉及内容..............................................1

1.4 本课题拟解决的问题..............................................1

1.5 解决方案及预期效果..............................................2

1.5.1 解决方案......................................................2

1.5.2 预期效果.......................................................2

2方案论证..........................................................3

2.1组合机床工艺方案的制定..........................................3

2.1.1 确定机床完成工艺时的一些限制..................................3

2.2 确定切削用量及选择刀具..........................................3

2.2.1选择切削用量..............................................3

2.2.2 对左侧面上4个孔的切削用量的选择...............................4

2.2.3 对后面上1个孔的切削用量的选择..................................5

2.3 计算切削力、切削扭矩及切削功率...................................5

2.4选择刀具结构.....................................................9

3 组合机床总体设计—三图一卡.......................................10

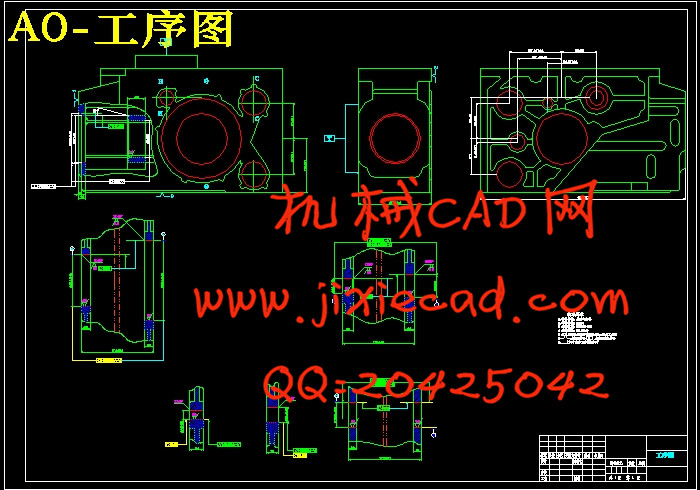

3.1被加工零件工序图................................................10

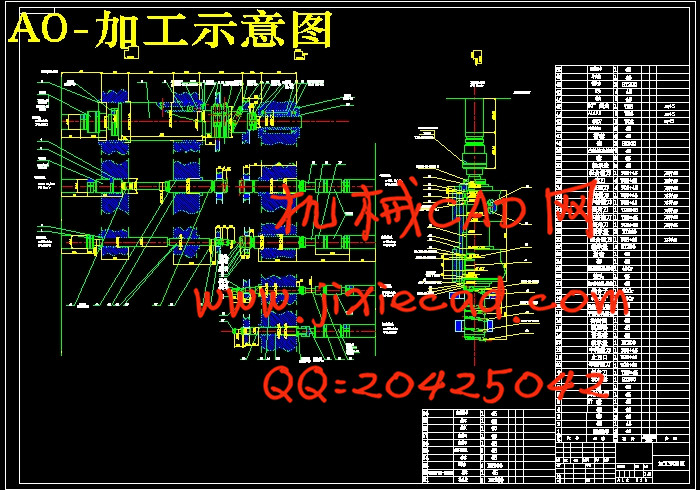

3.2 加工示意图...................................................10

3.2.1 导向结构的选择...............................................11

3.2.2 动力箱型号的选择...............................................11

3.2.3 动力部件工作循环及行程的确定..................................11

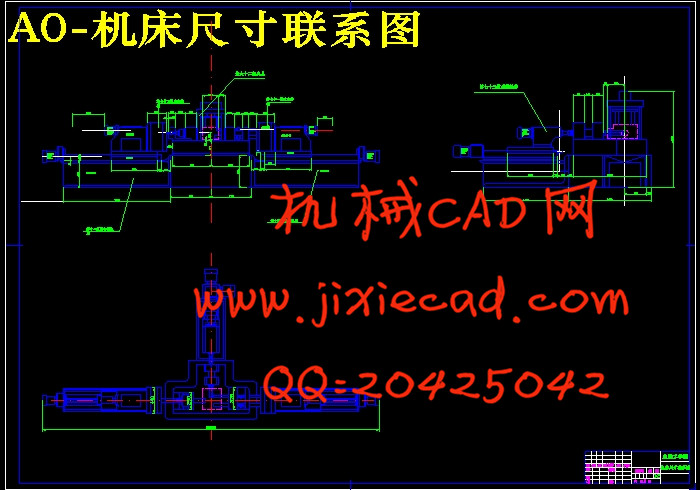

3.3机床尺寸联系总图...........................................12

3.3.1 选择动力部件...........................................12

3.3.2 动力箱型号的选择..............................................13

3.3.3 确定夹具轮廓尺寸.............................................13

3.3.4 确定中间底座尺寸..............................................14

3.3.5 确定主轴箱轮廓尺寸............................................14

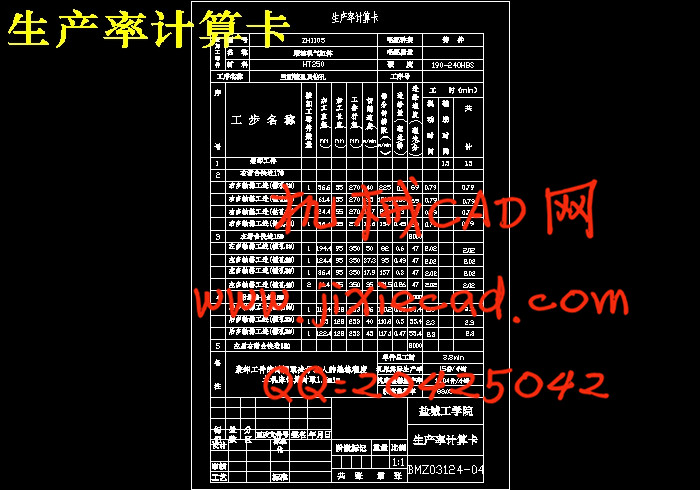

3.4机床生产率计算卡................................................15

4 左主轴箱设计....................................................17

4.1左主轴箱箱体零件的设计.........................................17

4.3坐标计算.......................................................19

4.4主轴等有关零件的设计...........................................22

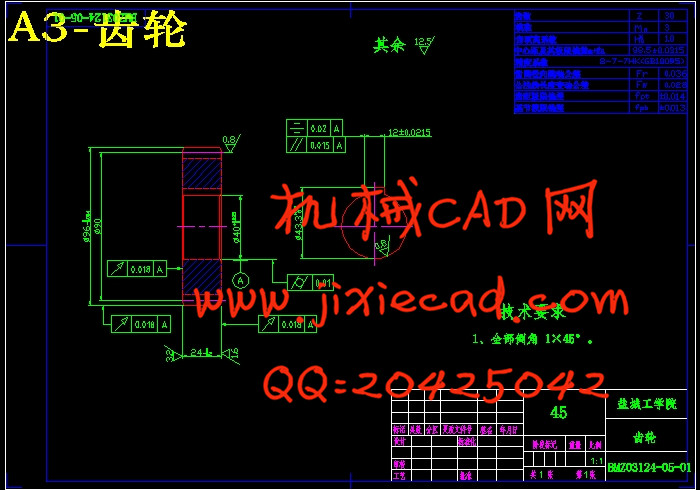

4.6.1 齿轮的校核...........................................25

4.6.1.1 齿轮的材料,精度和齿数的选择.................................25

4.6.1.2 设计计算....................................................25

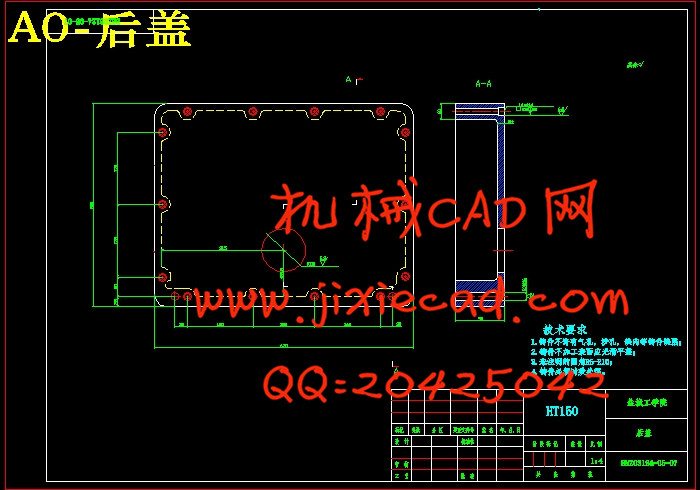

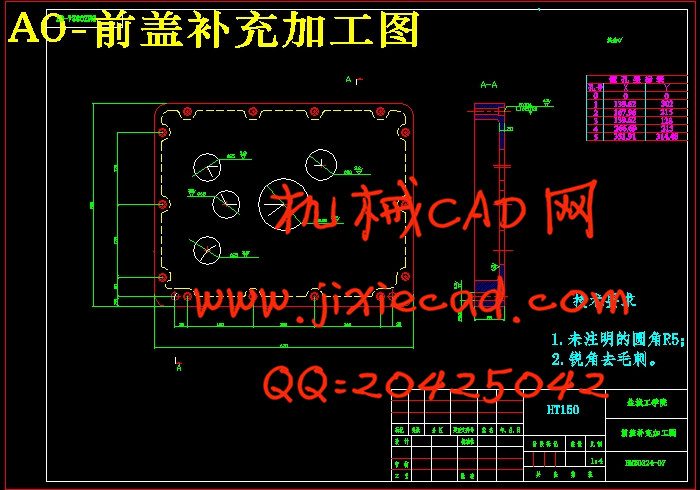

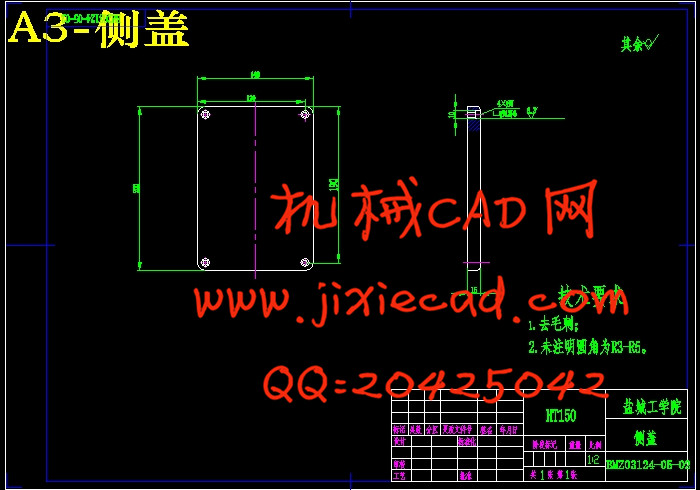

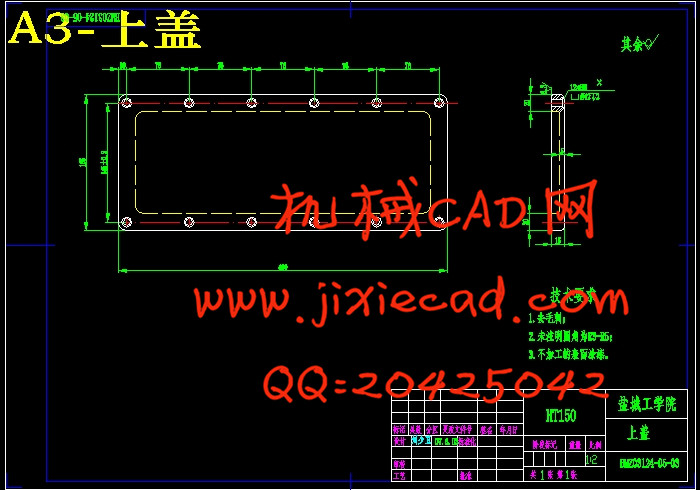

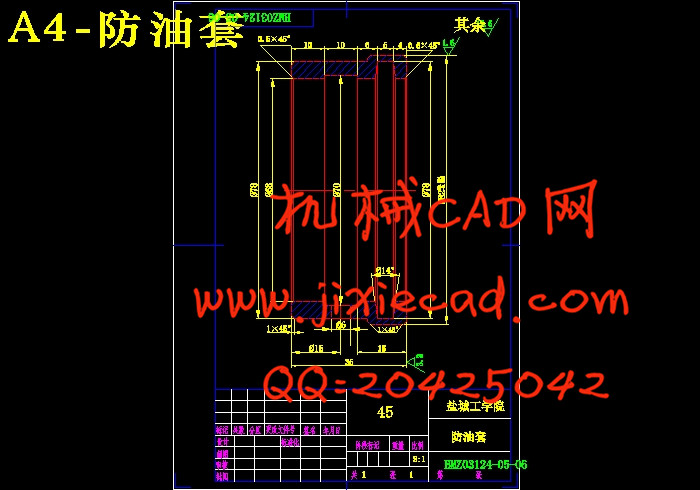

4.7箱体或前盖补充加工图...........................................27

5 设计总结.........................................................29

参考文献...........................................................30

致 谢...........................................................31

为了提高加工效率和质量以及保证ZH1105柴油机气缸体三面相应粗镗孔的尺寸精度及位置精度的要求,需要设计一台满足三面粗镗要求的卧式组合机床,本课题组设计了ZH1105柴油机气缸体三面粗镗机床及左主轴箱。在分析加工工件的特点的基础上,按组合机床的设计方法和步骤,进行了组合机床的总体设计,绘制了被加工零件的工序图、加工示意图、机床联系尺寸图和生产率计算卡,在此基础上,绘制了左主轴箱设计的原始依据图,拟订了主轴箱的传动路线,应用最优化方法布置齿轮。确定传动参数,绘制了主轴箱装配图、箱体坐标检查图、前盖及后盖的补充加工图,进行了轴、齿轮等零件的强度校核。该机较好地完成了设计要求,大大提高了工作效率。

关键词:柴油机;气缸体;三面粗镗;主轴箱;组合机床

Abstract

. To improve the efficiency of processing ,and quality assurance of ZH1105 engine casing ,and cylinder block three rough surface corresponding Boring, and the dimensional accuracy of location requirements for the design of a rough surface to satisfy the requirements of Horizontal Boring Machine portfolio, the discussion group has designed ZH1105 engine casing design of the cylinder block 3., Rough Boring Machine and left spindle box. On the base of the characteristics of the analysis’s process , the methods and steps of the design of the modular machine tool, the designing system was made. By the process of drawing ,the schematic diagram of machining ,the relationship of the machine size and the card of the productivity were drawn. Then the primitive chart for the design of the left-side spindle box was given out. The transmission route was confirmed and the transmission parameter was made. The assembly diagram of the spindle box was drawn. After arranging the gears ,we used the optimized design. The supplement processing diagram of the front side and behind side plate were also made. The intensity of the axises and gears was checked. The machine can satisfy the requirement of the design and the controlling precision was wholly improved.

Keywords:desel machine; cylinder body; three-side Rough Boring ; spindle box; modular machine tool.

目 录

1前言..............................................................1

1.1 总体设计.........................................................1

1.2 左主轴箱设计....................................................1

1.3 发展状况及涉及内容..............................................1

1.4 本课题拟解决的问题..............................................1

1.5 解决方案及预期效果..............................................2

1.5.1 解决方案......................................................2

1.5.2 预期效果.......................................................2

2方案论证..........................................................3

2.1组合机床工艺方案的制定..........................................3

2.1.1 确定机床完成工艺时的一些限制..................................3

2.2 确定切削用量及选择刀具..........................................3

2.2.1选择切削用量..............................................3

2.2.2 对左侧面上4个孔的切削用量的选择...............................4

2.2.3 对后面上1个孔的切削用量的选择..................................5

2.3 计算切削力、切削扭矩及切削功率...................................5

2.4选择刀具结构.....................................................9

3 组合机床总体设计—三图一卡.......................................10

3.1被加工零件工序图................................................10

3.2 加工示意图...................................................10

3.2.1 导向结构的选择...............................................11

3.2.2 动力箱型号的选择...............................................11

3.2.3 动力部件工作循环及行程的确定..................................11

3.3机床尺寸联系总图...........................................12

3.3.1 选择动力部件...........................................12

3.3.2 动力箱型号的选择..............................................13

3.3.3 确定夹具轮廓尺寸.............................................13

3.3.4 确定中间底座尺寸..............................................14

3.3.5 确定主轴箱轮廓尺寸............................................14

3.4机床生产率计算卡................................................15

4 左主轴箱设计....................................................17

4.1左主轴箱箱体零件的设计.........................................17

4.1.1 箱体的选用..........................................17

4.2确定传动轴的位置和齿轮齿数.....................................174.3坐标计算.......................................................19

4.4主轴等有关零件的设计...........................................22

4.4.1 主轴直径的确定................................................22

4.4.2 主轴结构的选定................................................22

4.4.3 传动轴的选定..........................................23

4.5主轴箱坐标计算、绘制坐标检查图.........................234.5.1 计算传动轴的坐标..............................................23

4.5.2 绘制坐标检查图.............................................24

4.6齿轮的校核及参数的确定.........................................254.6.1 齿轮的校核...........................................25

4.6.1.1 齿轮的材料,精度和齿数的选择.................................25

4.6.1.2 设计计算....................................................25

4.7箱体或前盖补充加工图...........................................27

5 设计总结.........................................................29

参考文献...........................................................30

致 谢...........................................................31