设计简介

摘要

刮板输送机是一种有扰性牵引机构的连续输送机。它的牵引机构是刮板链,承载装置是溜槽。在综采工作面,为了与采煤机、液压支架配合使用,在溜槽的采空区侧设有挡煤板,导向管(链牵引采煤机用)。

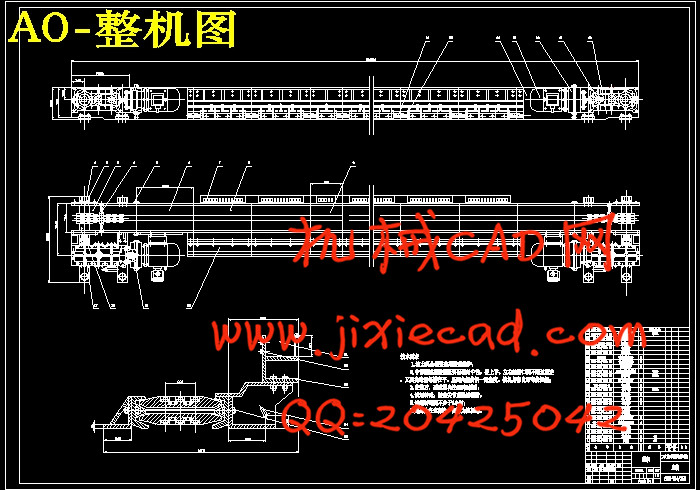

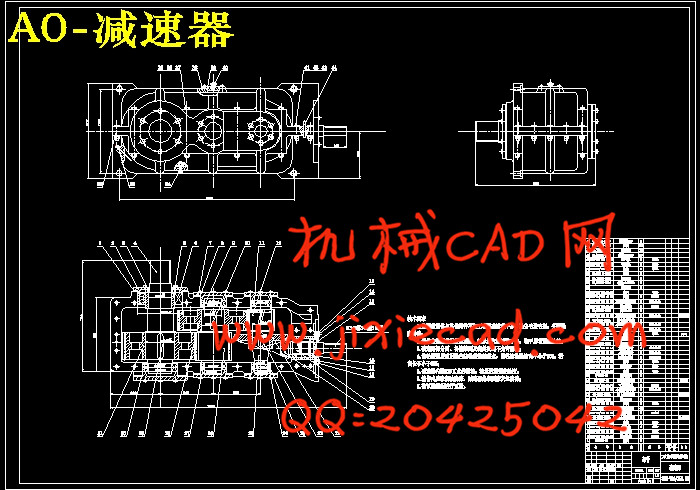

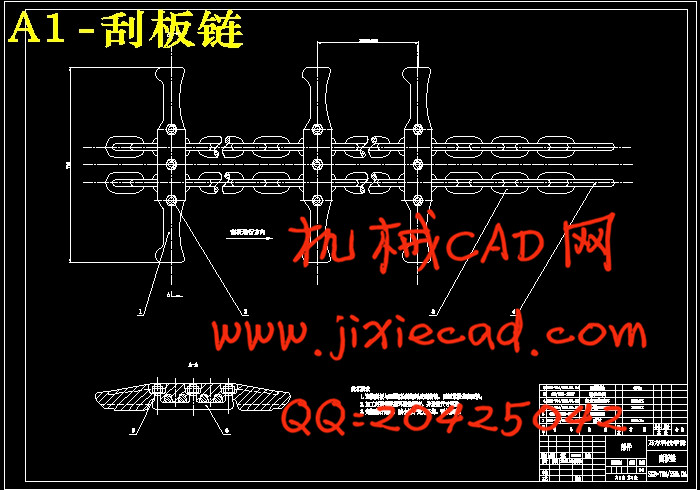

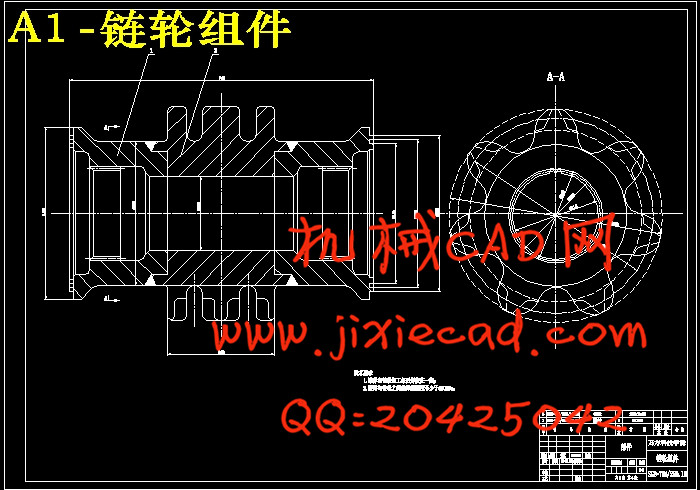

刮板输送机的动力装置采用防爆型异步电动机,按设计要求计算所需要功率后选择采用2台YB2-355M2-4型防爆异步电动机。电动机经过液力偶合器和减速器相连。根据功率和转速选择了YOX-600型液力偶合器。减速器是自行设计的三级圆锥——圆柱齿轮减速器,减速器与链轮相连,驱动绕过链轮的圆环链,圆环链绕过机头和机尾链轮进行无级闭合循环运行。圆环链和刮板相连,刮板将溜槽中的煤炭推移到机头处的卸载点卸载。溜槽是由中部槽、调节槽和过渡槽连接而成的,它们的连接方式我采用的是哑铃连接方式。

刮板输送机在综采工作面中起承载、运煤和采煤机导向以及液压支架推移支撑等作用,在整套综采设备中起着很重要的作用。

关键词:连续输送、刮板链、溜槽、闭合循环

ABSTRACT

The board conveyer is one kind of continuous conveyer which has disturbing nature draws the organization. The board chain is the organization to draw the board conveyer .The slip trough is the organization to bear the weight of device. On the working range of comprehensive complexion, use in order to cooperate with mining machine, hydraulic pressure support, slip trough complexion empty district side of trough is it block coal board, is it in charge of to lead to have (whether chain draw mining machine spend).

The motive equipment which blows the board conveyer adopts and separates the producing type asynchronous motor. I choose 2 YB2-355M2-4s and separate the asynchronous motor of explosion after the power of demand calculated by designing requirement. The motor links to decelerator through hydraulic coincidence device. I choose YOX-600 hydraulic coincidence derice after the calculating. The decelerator is a tertiary cone designed by myself-cylinder year wheel deceleration device. The decelerator and sprocket link to each other. The decelerator drives the rough ring chain which has wound the sprocket. The rough ring chain has wound the aircraft nose and aircraft tail sprocket and run by closed circulation. Round ring chain and the shaving board to link to each other. The shaving board slips away coal to the unloading point of the aircraft nose and to unload it. The trough is joined by the middle part trough, regulate the trough and transition. The connection way what I adopted is the dumbbell to sell the way of connecting.

The board conveyer use as the device of bearing the weight and the device of coal transportation and lending the device of mining machine and he pass and support the device of hydraulic pressure support. It plays a very important role in adopting the equipment a whole set of and comprehensivly.

Keywords: Send in succession; the Shave board chain; the slip trough; Close circulation

目录

1 绪论 6

1.1刮板输送机的发展史和发展趋势 6

1.1.1刮板输送机的发展史 6

1.1.2综采工作面刮板输送机的发展趋势 6

1.2刮板输送机的组成部分,工作原理和使用范围 8

1.3刮板输送机的主要类型和系列 10

1.4薄煤层综采工作面刮板输送机的结构特点 11

2 刮板输送机的设计 12

2.1总体设计要求 12

2.2总体方案的确定 12

2.3总体方案的设计 12

2.3.1运输能力的计算 12

2.3.2运行阻力和牵引力的计算 13

2.3.3电动机功率的计算与选型 15

2.3.4刮板链强度验算 17

2.4刮板输送机机头部及传动装置 19

2.4.1机头架 19

2.4.2减速器的传动设计 20

2.4.3液力耦合器 20

2.4.4链轮组件 23

2.4.5盲轴组件 23

2.5.2附件 26

2.6刮板链 26

2.6.1刮板链的结构形式 26

2.6.2刮板链的选型与技术要求 27

2.7紧链装置 28

2.8推移装置 29

3.1传动系统的确定 30

3.1.1总传动比及传动比分配 30

3.1.2传动装置运动参数的计算 31

3.2齿轮的设计 34

3.2.1弧齿圆锥齿轮的传动设计计算 34

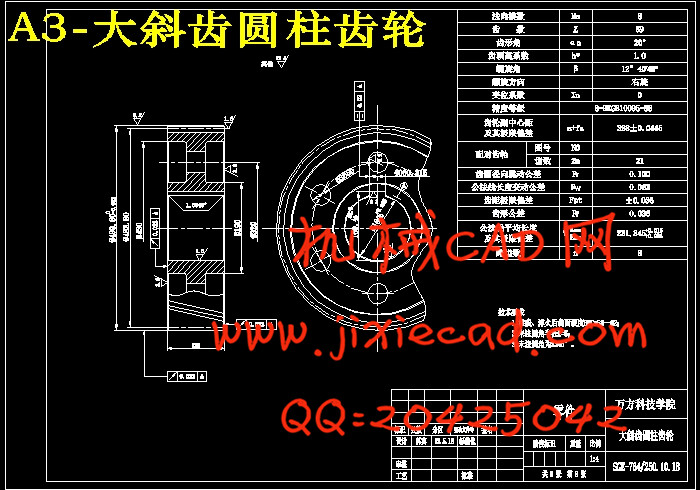

3.2.2斜齿圆柱齿轮的传动设计计算 45

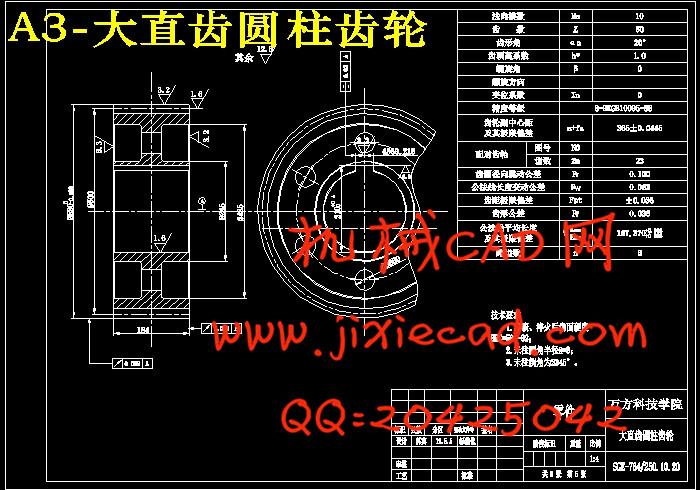

3.2.3直齿圆柱齿轮的传动设计计算 53

3.3减速器轴的设计与校核 59

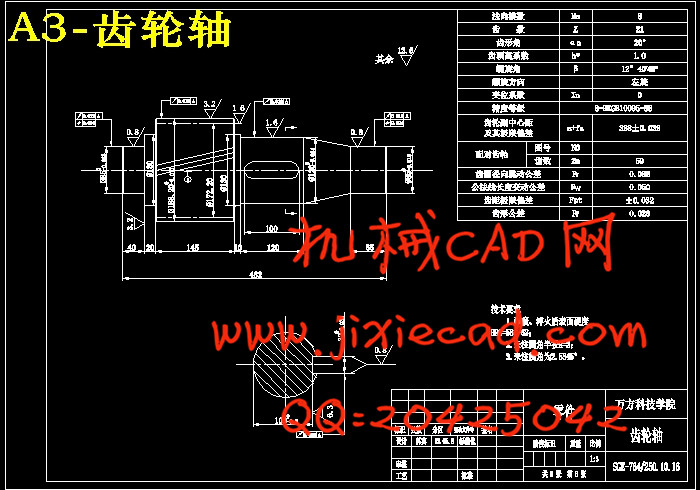

3.3.1高速轴(1轴)的设计 59

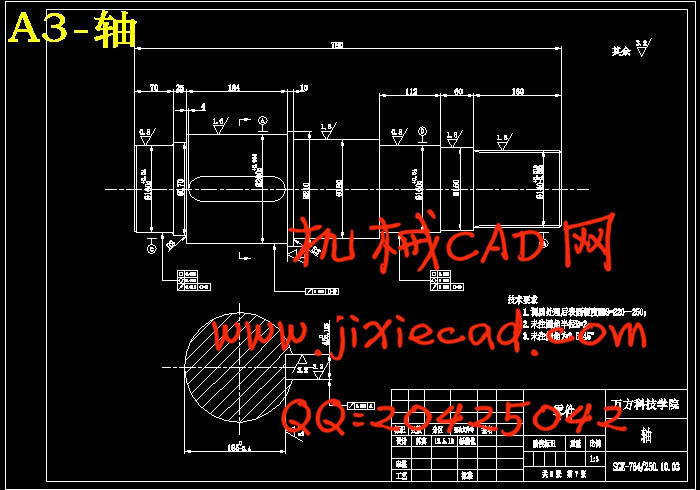

3.3.2轴2的设计与校核 67

3.3.3轴3的设计与校核 74

3.4轴承寿命的校核计算 80

3.4.1轴1处轴承寿命的校核 81

3.4.2轴2处轴承寿命的校核 83

3.5键的强度校核 84

3.5.1轴2上的键强度校核 84

3.5.2轴3上的键强度校核 85

3.5.3轴4上的键强度校核 85

4 刮板输送机的运转 87

4.1刮板输送机负载试运转 87

4.2刮板输送机的负载运转 87

4.3刮板输送机运转 87

5 刮板输送机的维护 89

总 结 91

参考文献 92

致 谢 93

刮板输送机是一种有扰性牵引机构的连续输送机。它的牵引机构是刮板链,承载装置是溜槽。在综采工作面,为了与采煤机、液压支架配合使用,在溜槽的采空区侧设有挡煤板,导向管(链牵引采煤机用)。

刮板输送机的动力装置采用防爆型异步电动机,按设计要求计算所需要功率后选择采用2台YB2-355M2-4型防爆异步电动机。电动机经过液力偶合器和减速器相连。根据功率和转速选择了YOX-600型液力偶合器。减速器是自行设计的三级圆锥——圆柱齿轮减速器,减速器与链轮相连,驱动绕过链轮的圆环链,圆环链绕过机头和机尾链轮进行无级闭合循环运行。圆环链和刮板相连,刮板将溜槽中的煤炭推移到机头处的卸载点卸载。溜槽是由中部槽、调节槽和过渡槽连接而成的,它们的连接方式我采用的是哑铃连接方式。

刮板输送机在综采工作面中起承载、运煤和采煤机导向以及液压支架推移支撑等作用,在整套综采设备中起着很重要的作用。

关键词:连续输送、刮板链、溜槽、闭合循环

ABSTRACT

The board conveyer is one kind of continuous conveyer which has disturbing nature draws the organization. The board chain is the organization to draw the board conveyer .The slip trough is the organization to bear the weight of device. On the working range of comprehensive complexion, use in order to cooperate with mining machine, hydraulic pressure support, slip trough complexion empty district side of trough is it block coal board, is it in charge of to lead to have (whether chain draw mining machine spend).

The motive equipment which blows the board conveyer adopts and separates the producing type asynchronous motor. I choose 2 YB2-355M2-4s and separate the asynchronous motor of explosion after the power of demand calculated by designing requirement. The motor links to decelerator through hydraulic coincidence device. I choose YOX-600 hydraulic coincidence derice after the calculating. The decelerator is a tertiary cone designed by myself-cylinder year wheel deceleration device. The decelerator and sprocket link to each other. The decelerator drives the rough ring chain which has wound the sprocket. The rough ring chain has wound the aircraft nose and aircraft tail sprocket and run by closed circulation. Round ring chain and the shaving board to link to each other. The shaving board slips away coal to the unloading point of the aircraft nose and to unload it. The trough is joined by the middle part trough, regulate the trough and transition. The connection way what I adopted is the dumbbell to sell the way of connecting.

The board conveyer use as the device of bearing the weight and the device of coal transportation and lending the device of mining machine and he pass and support the device of hydraulic pressure support. It plays a very important role in adopting the equipment a whole set of and comprehensivly.

Keywords: Send in succession; the Shave board chain; the slip trough; Close circulation

目录

1 绪论 6

1.1刮板输送机的发展史和发展趋势 6

1.1.1刮板输送机的发展史 6

1.1.2综采工作面刮板输送机的发展趋势 6

1.2刮板输送机的组成部分,工作原理和使用范围 8

1.3刮板输送机的主要类型和系列 10

1.4薄煤层综采工作面刮板输送机的结构特点 11

2 刮板输送机的设计 12

2.1总体设计要求 12

2.2总体方案的确定 12

2.3总体方案的设计 12

2.3.1运输能力的计算 12

2.3.2运行阻力和牵引力的计算 13

2.3.3电动机功率的计算与选型 15

2.3.4刮板链强度验算 17

2.4刮板输送机机头部及传动装置 19

2.4.1机头架 19

2.4.2减速器的传动设计 20

2.4.3液力耦合器 20

2.4.4链轮组件 23

2.4.5盲轴组件 23

2.5.2附件 26

2.6刮板链 26

2.6.1刮板链的结构形式 26

2.6.2刮板链的选型与技术要求 27

2.7紧链装置 28

2.8推移装置 29

3.1传动系统的确定 30

3.1.1总传动比及传动比分配 30

3.1.2传动装置运动参数的计算 31

3.2齿轮的设计 34

3.2.1弧齿圆锥齿轮的传动设计计算 34

3.2.2斜齿圆柱齿轮的传动设计计算 45

3.2.3直齿圆柱齿轮的传动设计计算 53

3.3减速器轴的设计与校核 59

3.3.1高速轴(1轴)的设计 59

3.3.2轴2的设计与校核 67

3.3.3轴3的设计与校核 74

3.4轴承寿命的校核计算 80

3.4.1轴1处轴承寿命的校核 81

3.4.2轴2处轴承寿命的校核 83

3.5键的强度校核 84

3.5.1轴2上的键强度校核 84

3.5.2轴3上的键强度校核 85

3.5.3轴4上的键强度校核 85

4 刮板输送机的运转 87

4.1刮板输送机负载试运转 87

4.2刮板输送机的负载运转 87

4.3刮板输送机运转 87

5 刮板输送机的维护 89

总 结 91

参考文献 92

致 谢 93