设计简介

摘 要

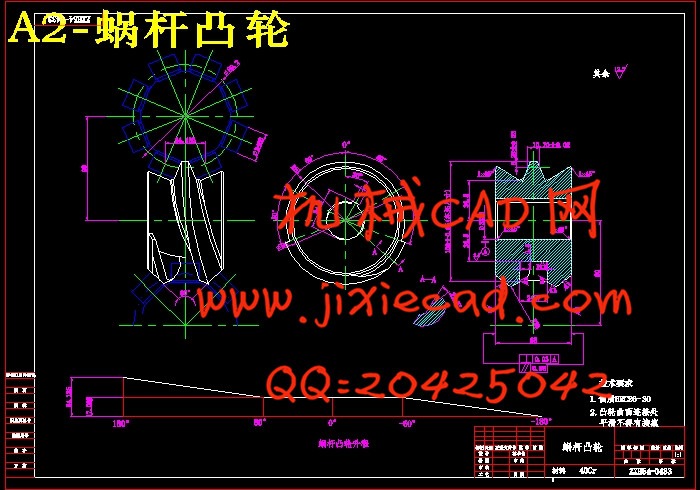

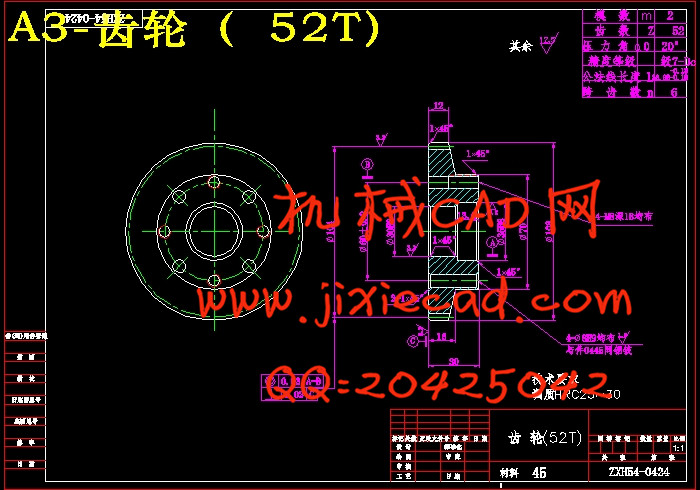

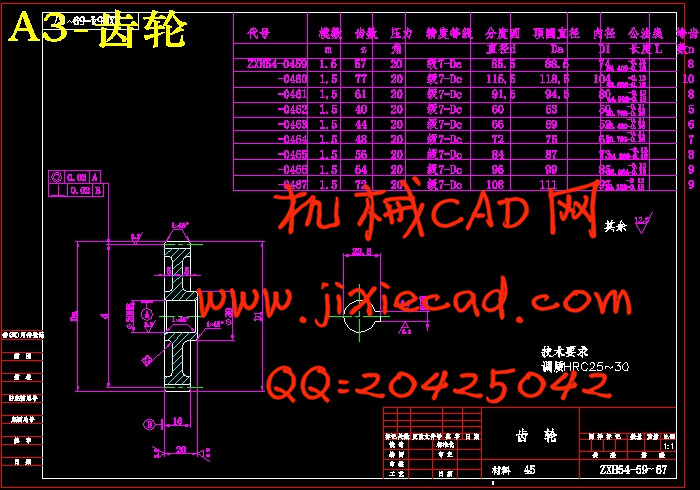

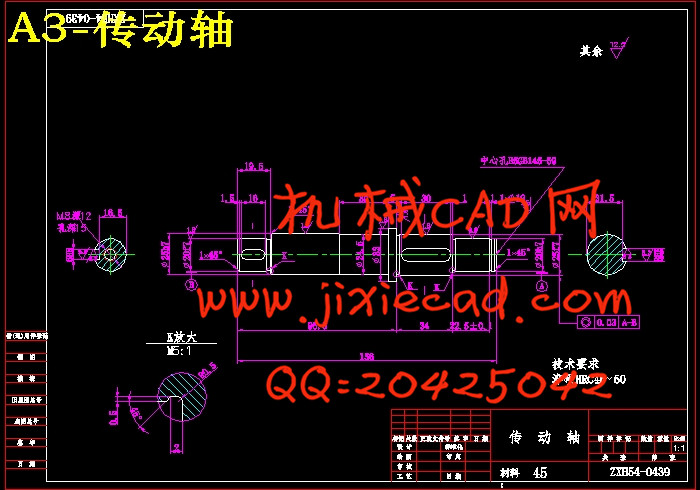

随着纺织业的不断发展,自动化在纺织业中的应用越来越广泛,其中“针板”(用于排放织针)就是实现自动化的一个重要部件。它的加工特殊,精度要求较高,需要有专门的机床加工,这就是我这次的毕业设计课题:ZXH54型铣槽机设计—立柱部件设计。

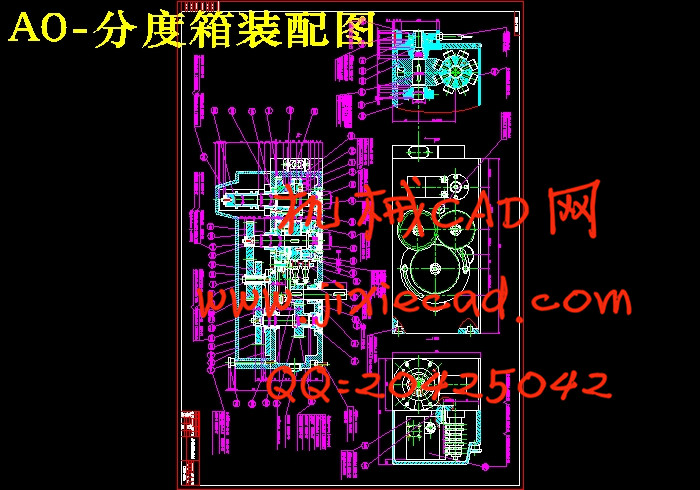

ZXH54型铣槽机是用于加工纺织业中“针板”的专用切削机床,属于典型的组合机床,该机床具有四工位、八铣头,能同时加工八个工件,具有较高的加工效率和加工精度,同时还能实现针槽与圆弧口槽同工位一次完成,克服了以前针板加工中加工工序复杂、加工效率低、加工精度不高的缺点,有较好的应用前景。

本次设计总共分为四大部分:第一部分组合机床的概述;第二部分ZXH54铣槽机的总体设计;第三部分铣槽机立柱部件的设计;第四部分结论与展望。其中第三部分的设计是本次设计的重点,设计从机械部件设计,液压部件设计,液压系统控制设计三个方面对ZXH54铣槽机立柱部件进行的整体细致的设计,不仅从机械和液压的角度对立柱的主要部件进行了校核计算,还从控制上提出了一套可行的控制方案,较好的完成了预期的设计要求。

Abstract

Along with the unceasing development of weaving trade, automation in the application in weaving trade is more and more extensive, " pin plate "(is used in put the needle) is a important parts in weaving trade of realization automation. It's processing is special, it is higher that precision is asked, and need to have the processing of special machine tool, this is me the graduated design program of this time: ZXH54 model milling groove machine design — pillar parts design.

ZXH54 model milling groove machine is used in processing weaving trade in " pin plate " use privately cut machine tool, belong to the modular machine tool, this machine tool have 4 works position and 8 milling heads, can at the same time process 8 workpieces, have higher processing efficiency and processing precision, and can at the same time still realize needle groove and circular arc groove same work position, it surmounted the shortcoming of that machining process complex, processing efficiency low and process precision do not be in height of the processing of pin plate beforetime, so it have better application prospect.

This design divide into 4 in all: the first part is the general state of machine tool; second part with the whole design of ZXH54 model milling groove machine; the part of 3rd is the design of milling groove machine pillar parts; conclusion and look ahead is the partial of 4th. In which, the design of the part of 3rd is the focal point of the design, design from mechanical parts design, hydraulic parts design, hydraulic systematic autocontrol design 3 aspects for ZXH54 model milling groove machine pillar parts to have a overall careful design, not only from machinery and the angle of hydraulic pressure check calculate for the major parts of pillar, but also have still made a set of feasible control scheme from autocontrol. It is better have completed the design requirement of expection.

目 录

前 言……………………………………………………………………1

第一章 组合机床概述……………………………………………………1

1-1组合机床及其特点………………………………………………………1

1-2组合机床的工艺范围……………………………………………………4

1-3组合机床通用部件及其选用……………………………………………4

1-3-1通用部件分类………………………………………………………4

1-3-2 通用部件的选用…………………………………………………5

1、通用部件选用的方法和原则……………………………………5

2、通用部件的选用…………………………………………………6

第二章 组合机床总体设计………………………………………………8

2-1组合机床的设计步骤……………………………………………………8

2-1-1调查研究……………………………………………………………8

2-1-2总体方案设计………………………………………………………9

2-1-3技术设计…………………………………………………………10

2-1-4工作设计…………………………………………………………10

2-2“三图一卡”……………………………………………………………10

2-2-1被加工零件工序图………………………………………………10

2-2-2加工示意图………………………………………………………11

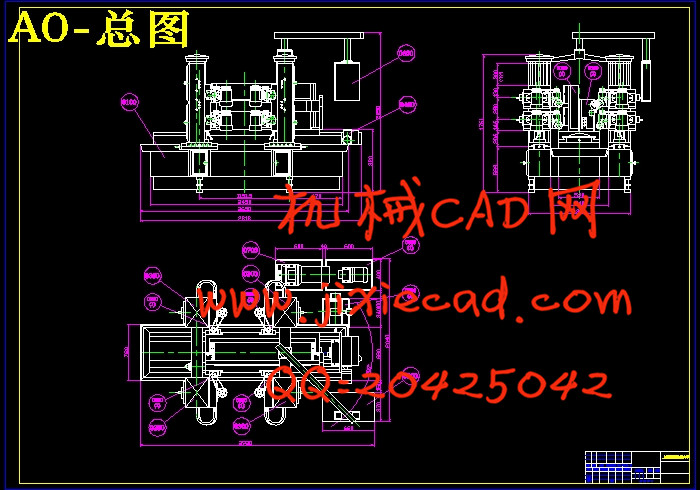

2-2-3机床联系尺寸总图………………………………………………11

2-2-4机床生产率计算卡………………………………………………12

2-3组合机床设计方案……………………………………………………13

2-4拟定方案“三图一卡”制作…………………………………………15

第三章 立柱部分设计…………………………………………………21

3-1整体设计………………………………………………………………21

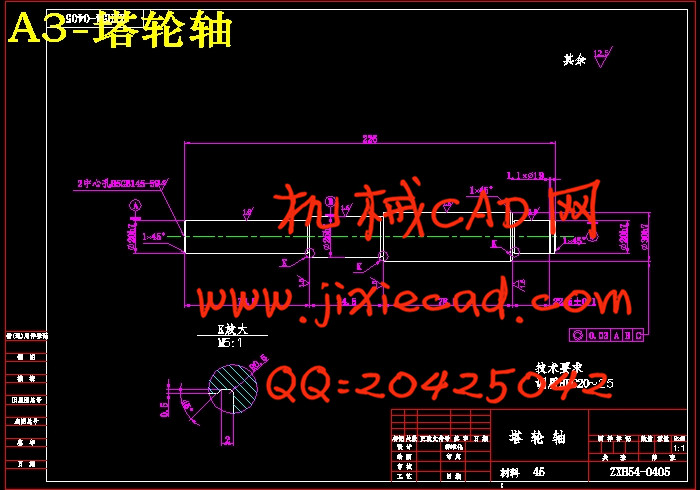

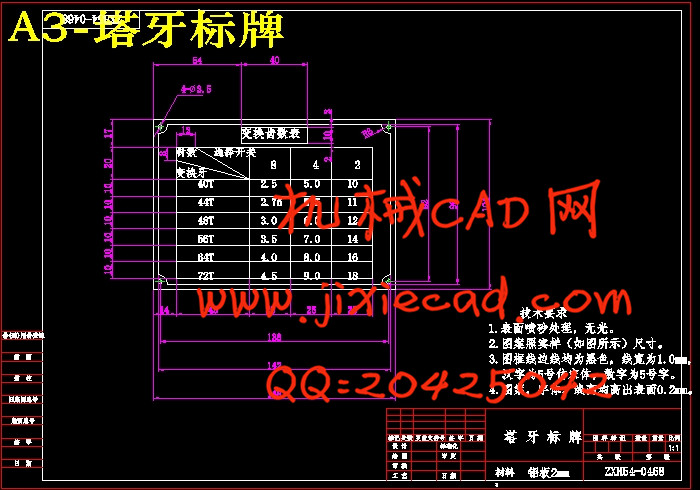

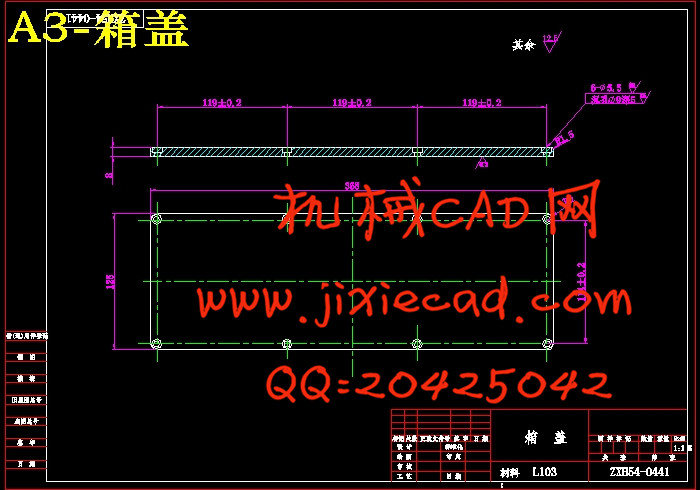

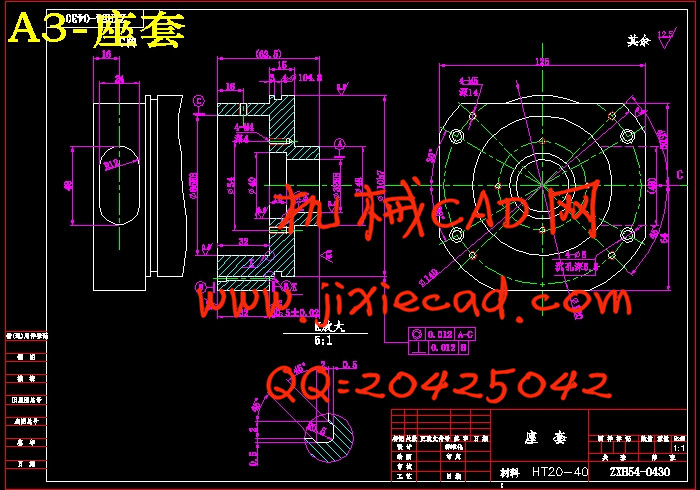

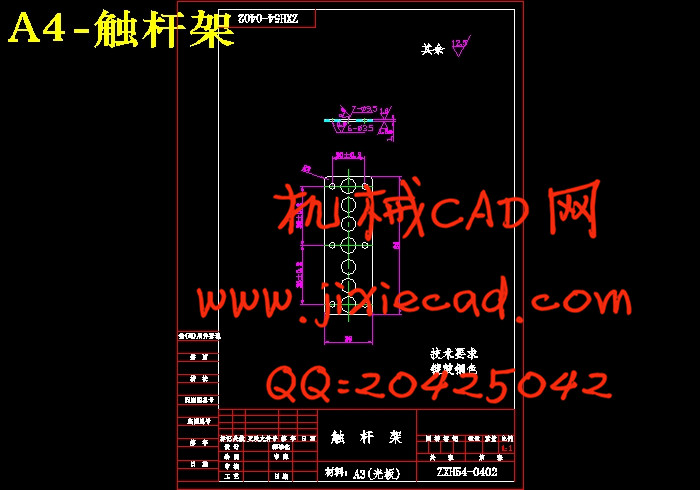

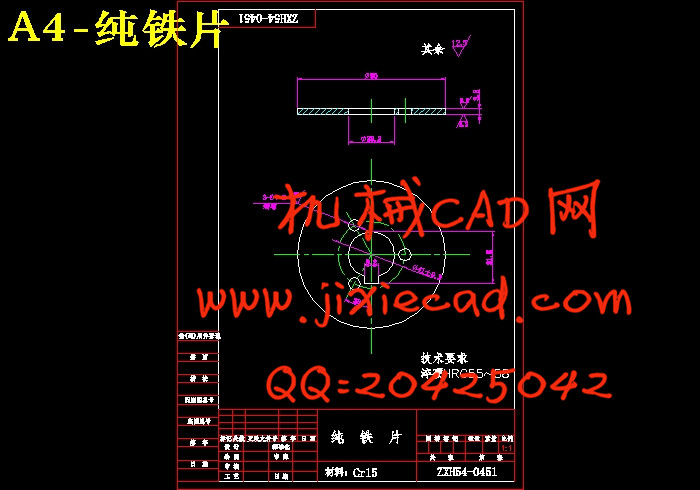

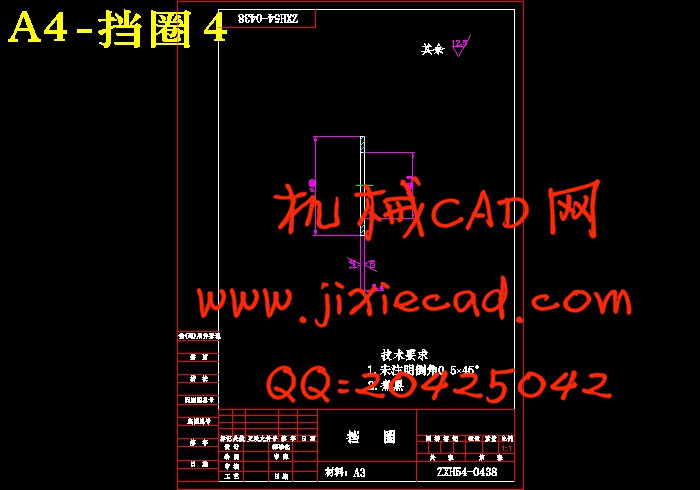

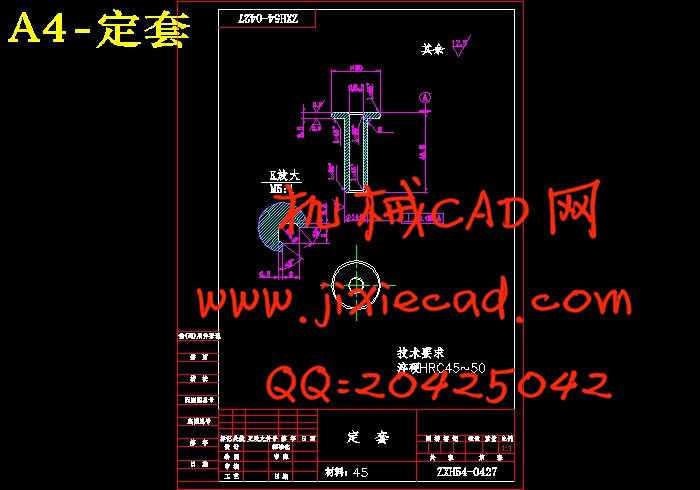

3-2机械部分设计…………………………………………………………21

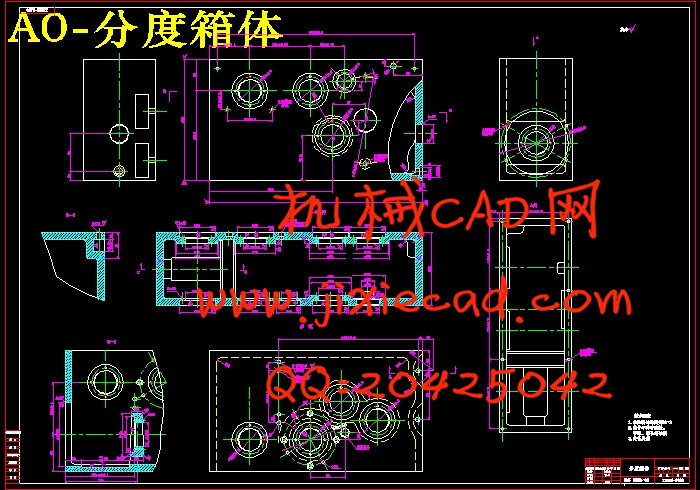

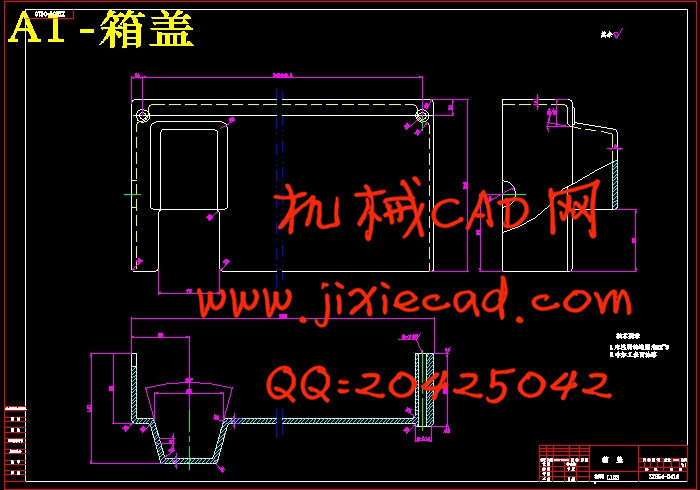

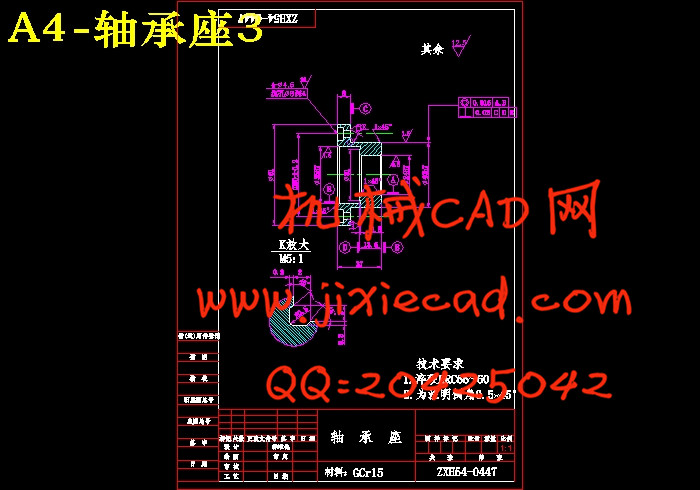

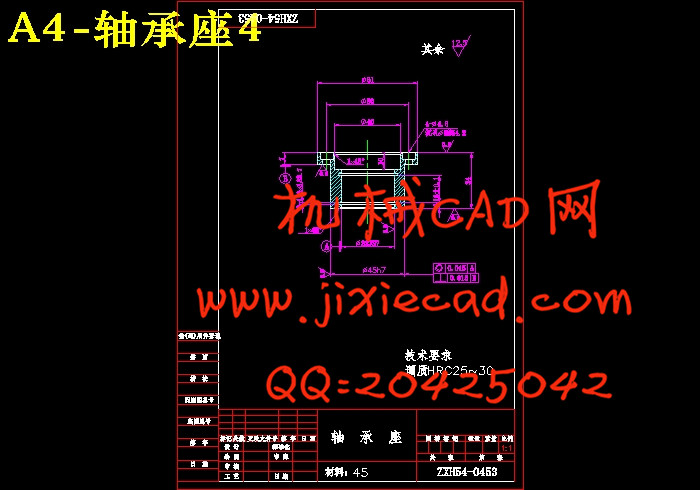

3-2-1支承件设计………………………………………………………21

3-2-2.导轨设计…………………………………………………………21

1、类型………………………………………………………………21

2、组合形式…………………………………………………………23

3、材料………………………………………………………………24

4、间隙调整…………………………………………………………24

5、润滑………………………………………………………………25

6、导轨验算…………………………………………………………25

7、爬行现象及消除措施……………………………………………30

3-3液压系统部分设计……………………………………………………30

3-3-1工况分析…………………………………………………………31

3-3-2拟定液压系统原理图……………………………………………33

3-3-3液压系统的计算和选择液压元件………………………………38

1、液压缸主要尺寸的确定…………………………………………38

2、计算在各工作阶段液压缸所需流量……………………………41

3、确定液压泵的流量、压力和选择泵的规格……………………41

4、液压阀的选择……………………………………………………43

5、确定管道尺寸……………………………………………………43

6、液压油箱容积的确定……………………………………………44

3-3-4液压缸的结构设计………………………………………………44

3-4系统自动控制设计……………………………………………………45

3-4-1控制方案拟定……………………………………………………45

3-4-2 ZXH54铣槽机自动控制的技术要求……………………………45

3-4-3程序流程图………………………………………………………46

3-4-4主程序……………………………………………………………48

3-4-5电器控制原理图…………………………………………………51

3-4-6控制元件选用……………………………………………………51

第四章 结论与展望……………………………………………………52

4-1结论……………………………………………………………………52

4-2展望……………………………………………………………………53

4-3致谢……………………………………………………………………53

参考文献…………………………………………………………………55

随着纺织业的不断发展,自动化在纺织业中的应用越来越广泛,其中“针板”(用于排放织针)就是实现自动化的一个重要部件。它的加工特殊,精度要求较高,需要有专门的机床加工,这就是我这次的毕业设计课题:ZXH54型铣槽机设计—立柱部件设计。

ZXH54型铣槽机是用于加工纺织业中“针板”的专用切削机床,属于典型的组合机床,该机床具有四工位、八铣头,能同时加工八个工件,具有较高的加工效率和加工精度,同时还能实现针槽与圆弧口槽同工位一次完成,克服了以前针板加工中加工工序复杂、加工效率低、加工精度不高的缺点,有较好的应用前景。

本次设计总共分为四大部分:第一部分组合机床的概述;第二部分ZXH54铣槽机的总体设计;第三部分铣槽机立柱部件的设计;第四部分结论与展望。其中第三部分的设计是本次设计的重点,设计从机械部件设计,液压部件设计,液压系统控制设计三个方面对ZXH54铣槽机立柱部件进行的整体细致的设计,不仅从机械和液压的角度对立柱的主要部件进行了校核计算,还从控制上提出了一套可行的控制方案,较好的完成了预期的设计要求。

Abstract

Along with the unceasing development of weaving trade, automation in the application in weaving trade is more and more extensive, " pin plate "(is used in put the needle) is a important parts in weaving trade of realization automation. It's processing is special, it is higher that precision is asked, and need to have the processing of special machine tool, this is me the graduated design program of this time: ZXH54 model milling groove machine design — pillar parts design.

ZXH54 model milling groove machine is used in processing weaving trade in " pin plate " use privately cut machine tool, belong to the modular machine tool, this machine tool have 4 works position and 8 milling heads, can at the same time process 8 workpieces, have higher processing efficiency and processing precision, and can at the same time still realize needle groove and circular arc groove same work position, it surmounted the shortcoming of that machining process complex, processing efficiency low and process precision do not be in height of the processing of pin plate beforetime, so it have better application prospect.

This design divide into 4 in all: the first part is the general state of machine tool; second part with the whole design of ZXH54 model milling groove machine; the part of 3rd is the design of milling groove machine pillar parts; conclusion and look ahead is the partial of 4th. In which, the design of the part of 3rd is the focal point of the design, design from mechanical parts design, hydraulic parts design, hydraulic systematic autocontrol design 3 aspects for ZXH54 model milling groove machine pillar parts to have a overall careful design, not only from machinery and the angle of hydraulic pressure check calculate for the major parts of pillar, but also have still made a set of feasible control scheme from autocontrol. It is better have completed the design requirement of expection.

目 录

前 言……………………………………………………………………1

第一章 组合机床概述……………………………………………………1

1-1组合机床及其特点………………………………………………………1

1-2组合机床的工艺范围……………………………………………………4

1-3组合机床通用部件及其选用……………………………………………4

1-3-1通用部件分类………………………………………………………4

1-3-2 通用部件的选用…………………………………………………5

1、通用部件选用的方法和原则……………………………………5

2、通用部件的选用…………………………………………………6

第二章 组合机床总体设计………………………………………………8

2-1组合机床的设计步骤……………………………………………………8

2-1-1调查研究……………………………………………………………8

2-1-2总体方案设计………………………………………………………9

2-1-3技术设计…………………………………………………………10

2-1-4工作设计…………………………………………………………10

2-2“三图一卡”……………………………………………………………10

2-2-1被加工零件工序图………………………………………………10

2-2-2加工示意图………………………………………………………11

2-2-3机床联系尺寸总图………………………………………………11

2-2-4机床生产率计算卡………………………………………………12

2-3组合机床设计方案……………………………………………………13

2-4拟定方案“三图一卡”制作…………………………………………15

第三章 立柱部分设计…………………………………………………21

3-1整体设计………………………………………………………………21

3-2机械部分设计…………………………………………………………21

3-2-1支承件设计………………………………………………………21

3-2-2.导轨设计…………………………………………………………21

1、类型………………………………………………………………21

2、组合形式…………………………………………………………23

3、材料………………………………………………………………24

4、间隙调整…………………………………………………………24

5、润滑………………………………………………………………25

6、导轨验算…………………………………………………………25

7、爬行现象及消除措施……………………………………………30

3-3液压系统部分设计……………………………………………………30

3-3-1工况分析…………………………………………………………31

3-3-2拟定液压系统原理图……………………………………………33

3-3-3液压系统的计算和选择液压元件………………………………38

1、液压缸主要尺寸的确定…………………………………………38

2、计算在各工作阶段液压缸所需流量……………………………41

3、确定液压泵的流量、压力和选择泵的规格……………………41

4、液压阀的选择……………………………………………………43

5、确定管道尺寸……………………………………………………43

6、液压油箱容积的确定……………………………………………44

3-3-4液压缸的结构设计………………………………………………44

3-4系统自动控制设计……………………………………………………45

3-4-1控制方案拟定……………………………………………………45

3-4-2 ZXH54铣槽机自动控制的技术要求……………………………45

3-4-3程序流程图………………………………………………………46

3-4-4主程序……………………………………………………………48

3-4-5电器控制原理图…………………………………………………51

3-4-6控制元件选用……………………………………………………51

第四章 结论与展望……………………………………………………52

4-1结论……………………………………………………………………52

4-2展望……………………………………………………………………53

4-3致谢……………………………………………………………………53

参考文献…………………………………………………………………55