设计简介

摘要

离合器是汽车传动系的一个重要部件,其设计的成功与否决定着车辆的动力性、平顺性、经济性等多方面的设计要求。设计出结构简单、工作可靠、造价低廉的离合器,能大大降低整车生产的总成本,推动汽车经济的发展。本文以ZZ1141H5315W型重型载货汽车为例,根据重型载货汽车离合器的设计要求和车辆动力传动系统自身的特点,通过参考多篇文献资料,以及国内外离合器设计手册,从经济性和实用性方面着手分析,对其做了详细的设计。

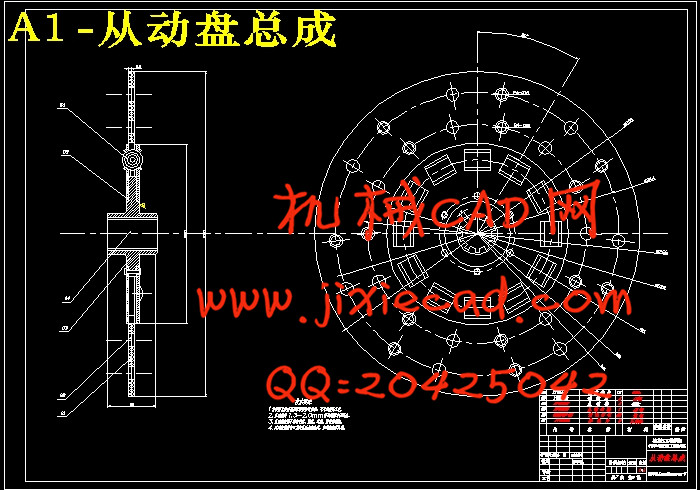

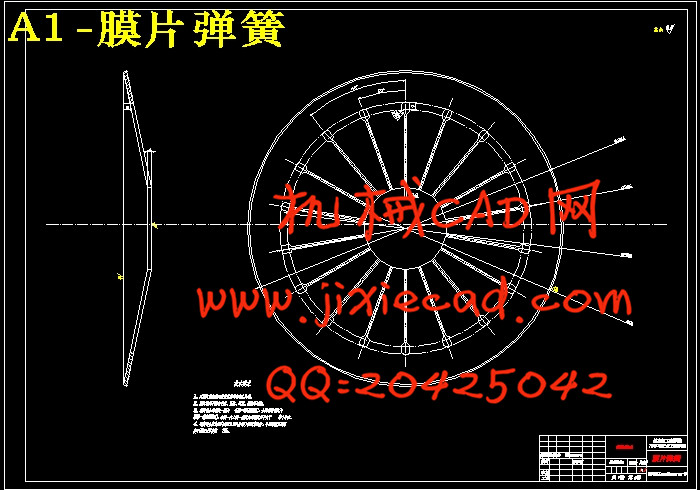

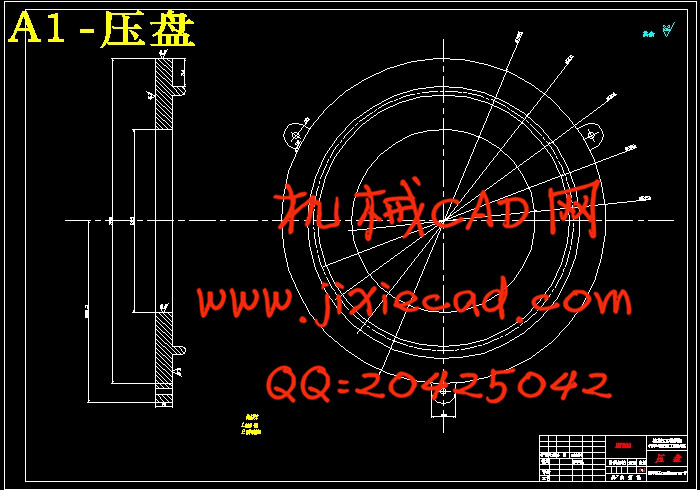

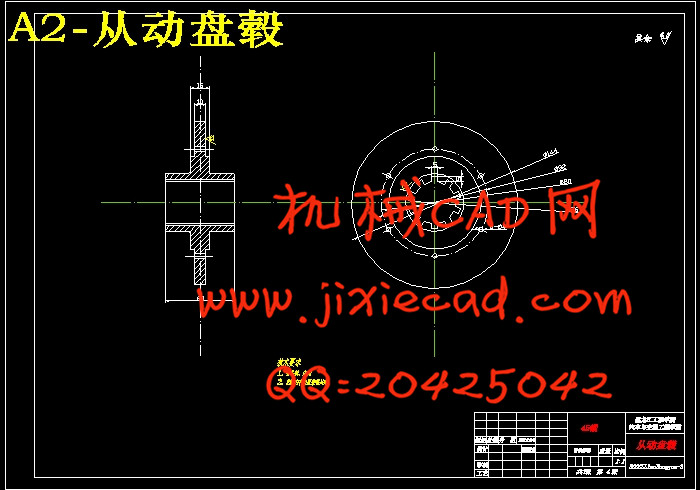

该设计分别从离合器总体方案的选择、膜片弹簧的设计、从动盘总成的设计和离合器盖总成的计算设计着手,从而确定了离合器基本的结构类型并计算了各零部件的参数尺寸,经校核,符合结构设计要求。

关键词: 离合器;传动系;重型载货汽车;总成;结构设计

ABSTRACT

Clutch auto transmission system, its design is an important part of the success of the power, determines the vehicle smooth, economy, and other aspects of the design requirements. Design a simple structure, reliable operation and low cost, can greatly reduce the clutch atvproduce total cost, promote the development of car economy. Based on ZZ1141H5315W type heavy cargo cars for example, according to the heavy cargo clutch design requirements and vehicle power transmission system characteristic of oneself, through reference documents many articles, and domestic and foreign clutch design manual, from economy and practicability aspects of its analysis, to do a detailed design.

This design separately from the clutch of choice, the overall design of diaphragm spring design, the design of the platen assembly and clutch cover assembly design to the calculation of, so as to determine the basic structure and the calculation of parts of the parameters, check with the size, structure the design requirements.

Key words:The clutch; The transmission; Heavy cargo car; Assembly; Structure design

目 录离合器是汽车传动系的一个重要部件,其设计的成功与否决定着车辆的动力性、平顺性、经济性等多方面的设计要求。设计出结构简单、工作可靠、造价低廉的离合器,能大大降低整车生产的总成本,推动汽车经济的发展。本文以ZZ1141H5315W型重型载货汽车为例,根据重型载货汽车离合器的设计要求和车辆动力传动系统自身的特点,通过参考多篇文献资料,以及国内外离合器设计手册,从经济性和实用性方面着手分析,对其做了详细的设计。

该设计分别从离合器总体方案的选择、膜片弹簧的设计、从动盘总成的设计和离合器盖总成的计算设计着手,从而确定了离合器基本的结构类型并计算了各零部件的参数尺寸,经校核,符合结构设计要求。

关键词: 离合器;传动系;重型载货汽车;总成;结构设计

ABSTRACT

Clutch auto transmission system, its design is an important part of the success of the power, determines the vehicle smooth, economy, and other aspects of the design requirements. Design a simple structure, reliable operation and low cost, can greatly reduce the clutch atvproduce total cost, promote the development of car economy. Based on ZZ1141H5315W type heavy cargo cars for example, according to the heavy cargo clutch design requirements and vehicle power transmission system characteristic of oneself, through reference documents many articles, and domestic and foreign clutch design manual, from economy and practicability aspects of its analysis, to do a detailed design.

This design separately from the clutch of choice, the overall design of diaphragm spring design, the design of the platen assembly and clutch cover assembly design to the calculation of, so as to determine the basic structure and the calculation of parts of the parameters, check with the size, structure the design requirements.

Key words:The clutch; The transmission; Heavy cargo car; Assembly; Structure design

摘 要 I

Abstract II

第1章 绪论 1

1.1选题的依据、目的及意义 1

1.2重型载货汽车离合器发展现状 1

1.3主要设计内容 3

第2章 离合器总体方案的确定 4

2.1离合器的功用及设计要求 4

2.2离合器的类型 5

2.3重型载货汽车原始参数 6

2.4从动盘的选择 6

2.5膜片弹簧离合器的结构形式选择 7

2.6压盘的驱动方式 7

2.7本章小结 7

第3章 膜片弹簧的设计 8

3.1膜片弹簧主要参数的选择 8

3.2约束条件 9

3.3膜片弹簧的载荷与变形关系 10

3.4膜片弹簧强度计算 11

3.5本章小结 12

第4章 离合器从动盘总体设计 13

4.1从动盘设计 13

4.1.1从动片设计 13

4.1.2从动盘毂的设计 13

4.2摩擦片的设计 14

4.2.1摩擦片主要参数的选择 14

4.2.2离合器基本参数的校核 15

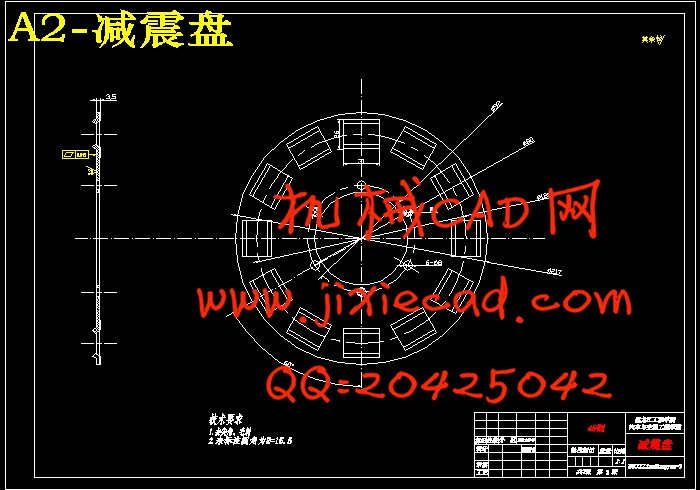

4.3扭转减震器的设计 16

4.3.2减震弹簧设计 18

4.3.3从动盘减震器在特性上的局限性 18

4.4本章小结 20

第5章 离合器盖总成设计 21

5.1离合器盖总成设计 21

5.2本章小结 23

结论 24

参考文献 25

致谢 26