设计简介

Φ300研磨机设计

摘 要

研磨是超精密加工中一种重要加工方法,其优点是加工精度高,加工材料范围广。由于传统研磨存在加工效率低、加工成本高、加工精度和加工质量不稳定等缺点,这使得传统研磨应用受到了一定限制,为了提高研磨加工效率,机械研磨机已经取代了传统的手工研磨。研磨机从加工精度上基本分为两种:一种是加工不仅对精度要求较高并对面形精度也有所要求的工件;另外一种是加工只要求表面粗糙度的零件,例如各种材质的机械密封环、陶瓷片、硅、石英晶体、石墨、蓝宝石、光学水晶、玻璃、铌酸锂、硬质合金、不锈钢等金属材料的平面研磨。这种研磨机适合加工一些尺寸较小,而且数量较大的零件。

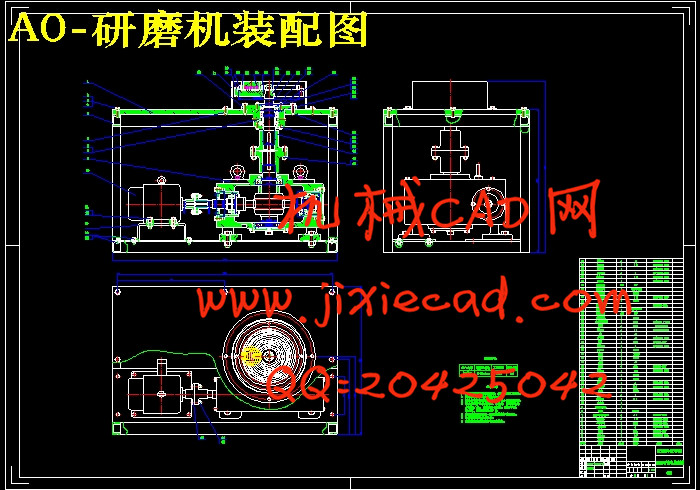

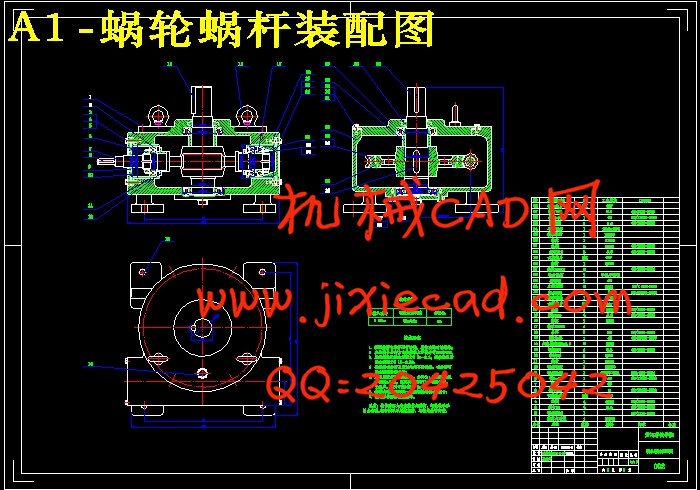

本文主要是合理的分析了研磨机的传动系统和研磨机械原理,本研磨机设计由电动机、减速装置、传动装置、研磨盘组成,根据研磨功率选择了合理的电动机,并设计了减速装置和主要的传动零件及研磨盘主轴。为了使研磨机具有足够的刚度、强度和稳定性,对蜗轮蜗杆减速器上的主要零部件进行了寿命校核,同时还对研磨盘主轴上的主要零部件进行了强度校核。

关键词:平面磨削,研磨,主轴,星型轮系传动

Φ300 Grinding Machine Design

Abstract

Grinding is a kind of important ultra-precision processing method, its advantage is processing precision is high, wide range of materials. As the traditional grinding existence processing efficiency is low, the manufacturing cost is high, the processing precision and processing quality is not stable shortcomings, this makes the traditional grinding application subject to a certain limit, in order to improve the grinding machining efficiency, mechanical grinding machine have replaced the traditional manual polishing. From processing precision grinding machine on basic divided into two kinds: one kind is processing not only to higher accuracy and precision to form across the requirements of the workpiece; Another is only required processing surface roughness of parts, such as all kinds of material mechanical sealing rings, ceramics, silicon, quartz crystal, graphite, sapphire, optic crystal, glass, lithium niobate, hard alloy, stainless steel and other metal material plane grinding. This kind of grinding machine is suitable for processing some smaller, and the greater number of parts.

This paper is mainly reasonable analysis the grinding machine transmission system and grind mechanical principle, the grinding machine design from motor, slow, device, gearing, grinding plate composition, according to grinding chosen the reasonable motor power, and design a slowdown and the main transmission device parts and grinding plate spindle. In order to make it has enough stiffness, strength and stability of worm gear and worm reducer is the main parts were checking service life, and at the same time also on grinding plate spindle is the main parts were strength check.

Key words:Flat surface grinding, Grinding,Principal axis, Star gear transmission

摘 要

研磨是超精密加工中一种重要加工方法,其优点是加工精度高,加工材料范围广。由于传统研磨存在加工效率低、加工成本高、加工精度和加工质量不稳定等缺点,这使得传统研磨应用受到了一定限制,为了提高研磨加工效率,机械研磨机已经取代了传统的手工研磨。研磨机从加工精度上基本分为两种:一种是加工不仅对精度要求较高并对面形精度也有所要求的工件;另外一种是加工只要求表面粗糙度的零件,例如各种材质的机械密封环、陶瓷片、硅、石英晶体、石墨、蓝宝石、光学水晶、玻璃、铌酸锂、硬质合金、不锈钢等金属材料的平面研磨。这种研磨机适合加工一些尺寸较小,而且数量较大的零件。

本文主要是合理的分析了研磨机的传动系统和研磨机械原理,本研磨机设计由电动机、减速装置、传动装置、研磨盘组成,根据研磨功率选择了合理的电动机,并设计了减速装置和主要的传动零件及研磨盘主轴。为了使研磨机具有足够的刚度、强度和稳定性,对蜗轮蜗杆减速器上的主要零部件进行了寿命校核,同时还对研磨盘主轴上的主要零部件进行了强度校核。

关键词:平面磨削,研磨,主轴,星型轮系传动

Φ300 Grinding Machine Design

Abstract

Grinding is a kind of important ultra-precision processing method, its advantage is processing precision is high, wide range of materials. As the traditional grinding existence processing efficiency is low, the manufacturing cost is high, the processing precision and processing quality is not stable shortcomings, this makes the traditional grinding application subject to a certain limit, in order to improve the grinding machining efficiency, mechanical grinding machine have replaced the traditional manual polishing. From processing precision grinding machine on basic divided into two kinds: one kind is processing not only to higher accuracy and precision to form across the requirements of the workpiece; Another is only required processing surface roughness of parts, such as all kinds of material mechanical sealing rings, ceramics, silicon, quartz crystal, graphite, sapphire, optic crystal, glass, lithium niobate, hard alloy, stainless steel and other metal material plane grinding. This kind of grinding machine is suitable for processing some smaller, and the greater number of parts.

This paper is mainly reasonable analysis the grinding machine transmission system and grind mechanical principle, the grinding machine design from motor, slow, device, gearing, grinding plate composition, according to grinding chosen the reasonable motor power, and design a slowdown and the main transmission device parts and grinding plate spindle. In order to make it has enough stiffness, strength and stability of worm gear and worm reducer is the main parts were checking service life, and at the same time also on grinding plate spindle is the main parts were strength check.

Key words:Flat surface grinding, Grinding,Principal axis, Star gear transmission

目 录

前 言 1

1 研磨机的发展史 3

1.1研磨技术发展状况 3

1.2 固着磨料高速研磨的研究现状 4

1.3 研磨机的发展情况 5

2 研磨原理分析 7

2.1 研磨机的工作原理 7

2.2 研磨网纹分析 9

2.3 研磨速度分析 9

3 研磨机传动系统分析 11

3.1 电动机的选择 11

3.1.1 选择电动机的类型 11

3.1.2 选择电动机的功率 11

3.1.3 确定电动机的转速 12

3.2 计算总传动比 13

3.3 研磨盘主轴的运动和动力参数 13

3.3.1 研磨盘主轴的转速 13

3.3.2 研磨盘主轴的功率 13

3.3.3 研磨盘主轴转速 13

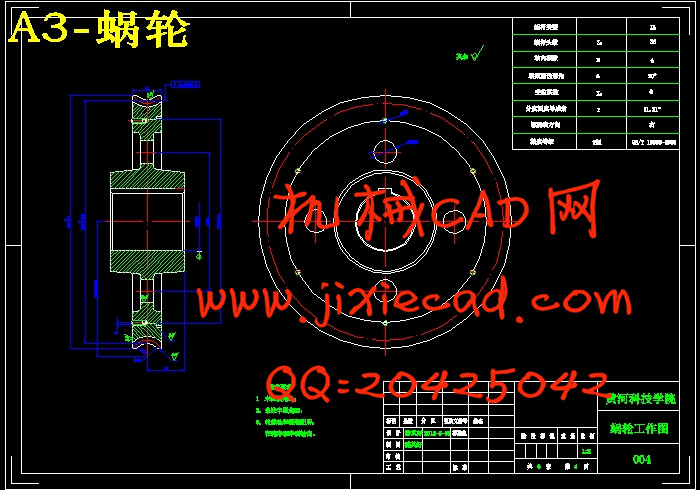

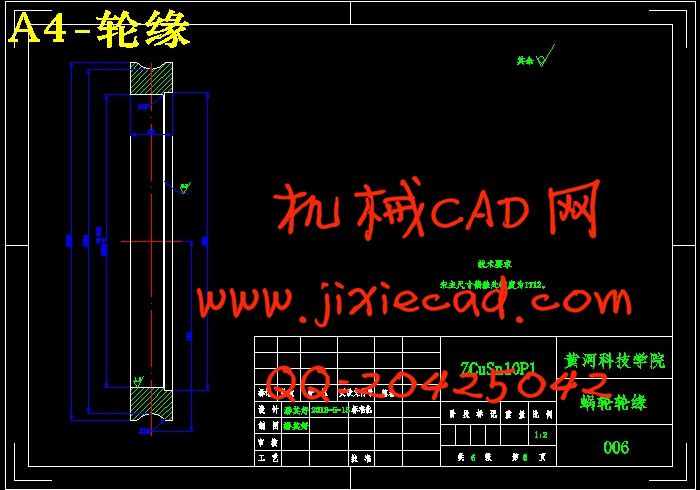

4 蜗轮蜗杆减速器设计 14

4.1 蜗杆传动设计计算 14

4.1.1蜗杆传动材料的选择 14

4.1.3 验算滑动速度 14

4.1.5 热平衡计算 15

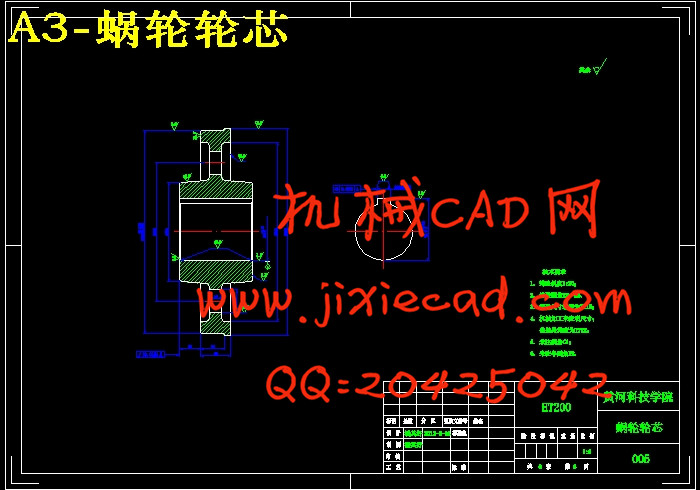

4.2 轴的设计和校核 16

4.2.1 蜗轮轴的设计 16

4.2.2 蜗杆轴的设计 21

4.3 滚动轴承寿命的校核 26

4.3.1 轴承的受力分析 26

4.3.2 轴承的选择及寿命校核 26

4.4 减速器箱体的设计计算 29

4.4.1 箱体的结构形式和材料 29

4.4.2 铸铁箱体主要结构尺寸 29

5 研磨盘主轴设计 31

5.1 主轴的设计 31

5.1.1 选择轴的材料 31

5.1.2 按许用扭转剪应力初估轴的直径 31

5.1.3 轴的结构设计 31

5.2 轴的校核 32

5.3 主轴轴承的选择及寿命校核 36

5.3.1 轴承的受力分析 36

5.3.2 主轴轴承的选择及寿命校核 36

6 键等相关标准的选择 38

6.1 键的选择 38

6.2 联轴器的选择 38

6.3 螺栓,螺母,螺钉的选择 38

结 论 40

致 谢 41

参考文献 42

前 言 1

1 研磨机的发展史 3

1.1研磨技术发展状况 3

1.2 固着磨料高速研磨的研究现状 4

1.3 研磨机的发展情况 5

2 研磨原理分析 7

2.1 研磨机的工作原理 7

2.2 研磨网纹分析 9

2.3 研磨速度分析 9

3 研磨机传动系统分析 11

3.1 电动机的选择 11

3.1.1 选择电动机的类型 11

3.1.2 选择电动机的功率 11

3.1.3 确定电动机的转速 12

3.2 计算总传动比 13

3.3 研磨盘主轴的运动和动力参数 13

3.3.1 研磨盘主轴的转速 13

3.3.2 研磨盘主轴的功率 13

3.3.3 研磨盘主轴转速 13

4 蜗轮蜗杆减速器设计 14

4.1 蜗杆传动设计计算 14

4.1.1蜗杆传动材料的选择 14

4.1.3 验算滑动速度 14

4.1.5 热平衡计算 15

4.2 轴的设计和校核 16

4.2.1 蜗轮轴的设计 16

4.2.2 蜗杆轴的设计 21

4.3 滚动轴承寿命的校核 26

4.3.1 轴承的受力分析 26

4.3.2 轴承的选择及寿命校核 26

4.4 减速器箱体的设计计算 29

4.4.1 箱体的结构形式和材料 29

4.4.2 铸铁箱体主要结构尺寸 29

5 研磨盘主轴设计 31

5.1 主轴的设计 31

5.1.1 选择轴的材料 31

5.1.2 按许用扭转剪应力初估轴的直径 31

5.1.3 轴的结构设计 31

5.2 轴的校核 32

5.3 主轴轴承的选择及寿命校核 36

5.3.1 轴承的受力分析 36

5.3.2 主轴轴承的选择及寿命校核 36

6 键等相关标准的选择 38

6.1 键的选择 38

6.2 联轴器的选择 38

6.3 螺栓,螺母,螺钉的选择 38

结 论 40

致 谢 41

参考文献 42