设计简介

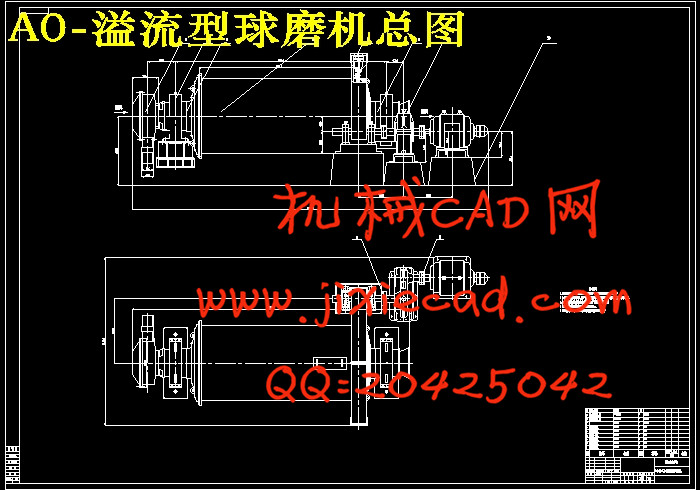

Φ900×900溢流型球磨机传动系统设计

摘 要

球磨机是通过圆筒内的钢球在材料之上作用来碾磨材料的,是一种能有效的碾磨多种材料的工具。其被广泛地被用于建材、化工、选矿等行业。

球磨机的能量利用率很低,这和物料在磨内分布情况有极大的关系。越靠近筒体的外层运动轨迹,研磨作用越大。而磨机实际生产时,物料进入筒体就直接落入内层,内层的物料要经过较长时间才能进入外层充分碾磨,从而损失了大量能量。

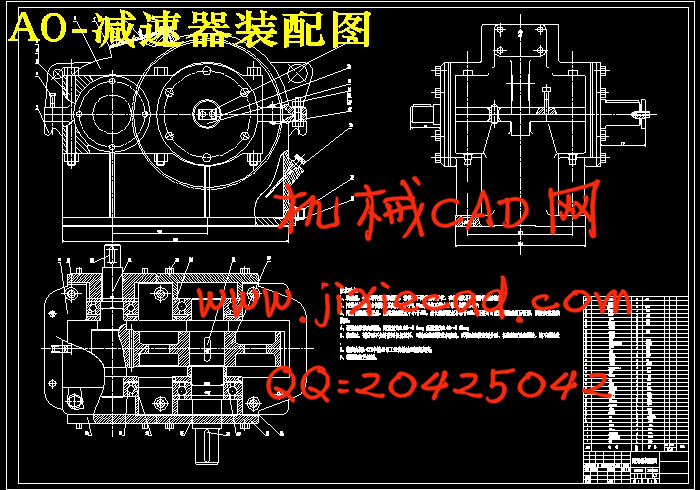

我根据一些原始的数据通过计算来完成传动系统的设计,首先计算总传动比确定传动方案,然后根据传动方案的参数,选择齿轮的齿数,模数等来完成减速器的设计,最后再完成边缘传动的设计,并对各轴的刚度和强度进行校核,以完成传动系统的设计。

关键词:球磨机,传动系统,校核

The Design of Φ900×900 Grid board type

The ball mill energy use factor is low, the distribution situation has the enormous relations with the material in grinding. Therefore discovered more approached the grinding machine outer layer, the abrasive action is bigger. When grinding machine actual production, the materials entered the mill to fall directly the inner layer, the process dynamics analysis, the inner layer material had to through the long time to enter the outer layer, reduced the production efficiency greatly.

I according to the number of original data through calculation to design the drive system, first calculate the total transmission ratio to determine the transmission scheme, then according to the parameter selection scheme of transmission, the gear teeth, modulus to complete the design of speed reducer, finally finished edge transmission design, and the axial stiffness and strength check, to complete the design of transmission system. I according to the number of original data through calculation to design the drive system, first calculate the total transmission ratio to determine the transmission scheme, then according to the parameter selection scheme of transmission, the gear teeth, modulus to complete the design of speed reducer, finally finished edge transmission design, and the axial stiffness and strength check, to complete the design of transmission system.

Key words: ball mill, drive system, check

目 录

1绪论 1

1.1课题的背景及研究目的 1

1.2国内外球磨机的发展状况 2

2传动方案的设计 3

2.1确定传动装置的总传动比及分配级传动比 3

2.2传动方案的设计 3

3减速器的设计 4

3.1齿轮齿数的确定 4

3.2确定公式内的各计算数值 4

3.3计算 4

3.4几何尺寸计算 7

4轴的设计计算 8

4.1基本参数计算 8

4.2轴的材料选择及最小直径估算 8

4.2.1高速轴最小直径的确定 8

4.2.2低速轴最小直径的确定 9

4.3高速轴的结构设计 9

4.3.1各轴段的直径的确定 9

4.3.2各轴段长度的确定 10

4.3.3高速轴的校核 10

4.3.4轴承的校核 13

4.3.5 键的设计与校核 13

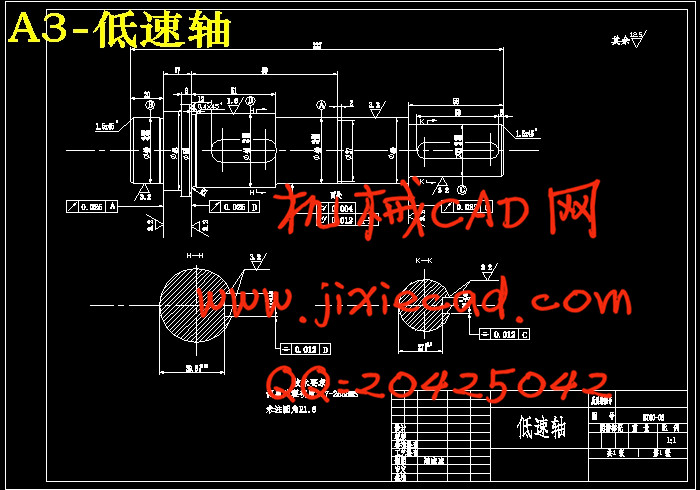

4.4低速轴的结构设计 14

4.4.1各轴段的直径的确定 14

4.4.2各轴段长度的确定 15

4.4.3校核低速轴 15

4.4.4 轴承的校核 18

4.4.5键的选择与校核 19

5 联轴器的选择 20

5.1联轴器的功用 20

5.2联轴器的类型特点 20

5.3 联轴器的选用 20

5.4联轴器材料 21

6边缘传动的设计 22

6.1球磨机边缘齿数的确定 22

6.2轮齿数的确定 22

6.3尺寸的计算 22

结 论 23

致 谢 24

参考文献 25

摘 要

球磨机是通过圆筒内的钢球在材料之上作用来碾磨材料的,是一种能有效的碾磨多种材料的工具。其被广泛地被用于建材、化工、选矿等行业。

球磨机的能量利用率很低,这和物料在磨内分布情况有极大的关系。越靠近筒体的外层运动轨迹,研磨作用越大。而磨机实际生产时,物料进入筒体就直接落入内层,内层的物料要经过较长时间才能进入外层充分碾磨,从而损失了大量能量。

我根据一些原始的数据通过计算来完成传动系统的设计,首先计算总传动比确定传动方案,然后根据传动方案的参数,选择齿轮的齿数,模数等来完成减速器的设计,最后再完成边缘传动的设计,并对各轴的刚度和强度进行校核,以完成传动系统的设计。

关键词:球磨机,传动系统,校核

The Design of Φ900×900 Grid board type

Abstract

Ball mill winch grinds material by rotating a cylinder with steel grinding balls, is an efficient tool for grinding many materials into fine powder. It is widely used in building material, chemical industry, etc.The ball mill energy use factor is low, the distribution situation has the enormous relations with the material in grinding. Therefore discovered more approached the grinding machine outer layer, the abrasive action is bigger. When grinding machine actual production, the materials entered the mill to fall directly the inner layer, the process dynamics analysis, the inner layer material had to through the long time to enter the outer layer, reduced the production efficiency greatly.

I according to the number of original data through calculation to design the drive system, first calculate the total transmission ratio to determine the transmission scheme, then according to the parameter selection scheme of transmission, the gear teeth, modulus to complete the design of speed reducer, finally finished edge transmission design, and the axial stiffness and strength check, to complete the design of transmission system. I according to the number of original data through calculation to design the drive system, first calculate the total transmission ratio to determine the transmission scheme, then according to the parameter selection scheme of transmission, the gear teeth, modulus to complete the design of speed reducer, finally finished edge transmission design, and the axial stiffness and strength check, to complete the design of transmission system.

Key words: ball mill, drive system, check

目 录

1绪论 1

1.1课题的背景及研究目的 1

1.2国内外球磨机的发展状况 2

2传动方案的设计 3

2.1确定传动装置的总传动比及分配级传动比 3

2.2传动方案的设计 3

3减速器的设计 4

3.1齿轮齿数的确定 4

3.2确定公式内的各计算数值 4

3.3计算 4

3.4几何尺寸计算 7

4轴的设计计算 8

4.1基本参数计算 8

4.2轴的材料选择及最小直径估算 8

4.2.1高速轴最小直径的确定 8

4.2.2低速轴最小直径的确定 9

4.3高速轴的结构设计 9

4.3.1各轴段的直径的确定 9

4.3.2各轴段长度的确定 10

4.3.3高速轴的校核 10

4.3.4轴承的校核 13

4.3.5 键的设计与校核 13

4.4低速轴的结构设计 14

4.4.1各轴段的直径的确定 14

4.4.2各轴段长度的确定 15

4.4.3校核低速轴 15

4.4.4 轴承的校核 18

4.4.5键的选择与校核 19

5 联轴器的选择 20

5.1联轴器的功用 20

5.2联轴器的类型特点 20

5.3 联轴器的选用 20

5.4联轴器材料 21

6边缘传动的设计 22

6.1球磨机边缘齿数的确定 22

6.2轮齿数的确定 22

6.3尺寸的计算 22

结 论 23

致 谢 24

参考文献 25