设计简介

摘 要

液压传动是用液体作为工作介质来传递能量和进行控制的传动方式。液压传动和气压传动称为流体传动,是根据17世纪帕斯卡提出的液体静压力传动原理而发展起来的一门新兴技术,是工农业生产中广为应用的一门技术。如今,流体传动技术水平的高低已成为一个国家工业发展水平的重要标志。液压传动凭借与其他传动方式相比较具有独特的技术优势,应用领域几乎囊括了国民经济各工业部门。近30年来,由于控制技术、微电子技术、计算机技术、传感检测技术及材料科学的发展,极大的推动了液压传动与控制技术的发展,使其成为集传动、控制、计算机、传感检测、机电液为一体化的全新的自动控制技术。

本设计根据液压系统的技术指标对数控车床液压传动系统进行整体方案设计,对其功能和工作原理进行动力分析和运动分析,初步确定了系统各回路的基本结构及主要元件,按照所给机构性能参数和液压性能参数进行元件的选择计算,通过对系统性能的验算和发热校核,以满足该车床所要达到的要求。

关键词:液压;数控车床;尾座

Abstract

hydraulic transmission is to use liquid as working medium to transmit energy and control mode of transmission. Hydraulic and pneumatic transmission called fluid drive, which is based on PASCAL hydrostatic pressure transmission principle put forward by the 17th century and developed a new technology, is a technology widely used in industrial and agricultural production.

Nowadays, the level of fluid transmission technology has become a national industrial development level of important symbol. Hydraulic transmission by compared with other driving mode has its unique technical advantages, applications almost covers the national economy each industry sector. For nearly 30 years, due to the control technology, microelectronics technology, computer technology, sensing detection technology and the development of materials science, greatly promoted the development of the hydraulic transmission and control technology, making it a set of transmission, control, computer, sensor detection, mechanical and electrical hydraulic automatic control technology for the integration of the new.

According to the technical index of the hydraulic system of CNC milling machine two location clamping device hydraulic system overall plan design, dynamic analysis on the function and working principle and motion analysis, and preliminarily determines the system's basic structure and main components of each circuit, and according to the given institutional performance parameters and performance parameters of the hydraulic components selection calculation, through calculating the performance of the system and heating, in order to meet the requirements as to the milling machine.

Key words: hydraulic pressure; tailstock;CNC lathe

目 录

摘 要 III

Abstract IV

目 录 V

1 绪论 1

1.1 研究背景和意义 1

1.2 国内外数控机床的发展现状 1

1.2.1 国外数控机床发展现状 1

1.2.2 国内数控机床发展现状 2

1.3 液压传动的发展趋势 4

2 数控车床的介绍 6

2.1 数控车床的总体方案 6

2.2 数控车床总体布局图 7

3 数控车床对液压系统的要求 8

3.1 液压控制的动作 8

3.1.1 卡盘的松开,卡紧 8

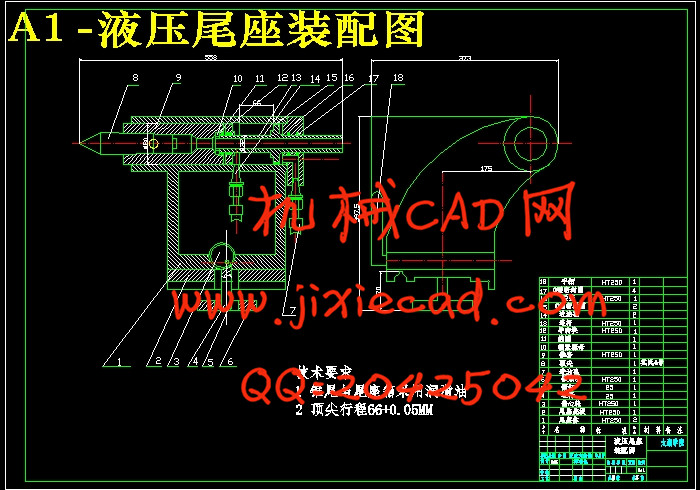

3.1.2 尾座套筒的伸缩运动 8

3.2 需要设计的内容 8

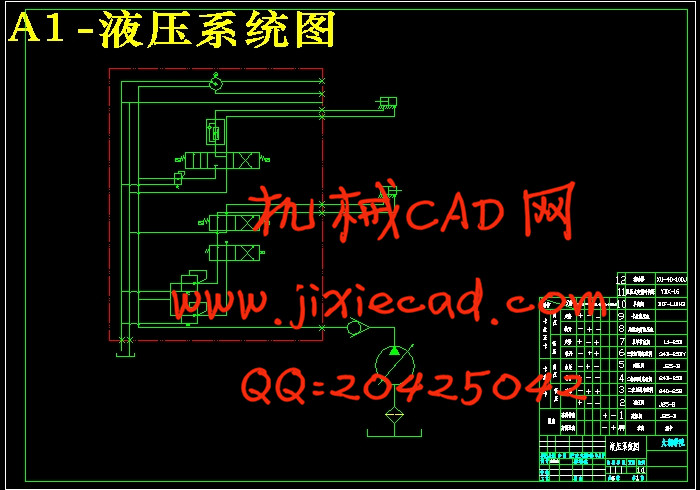

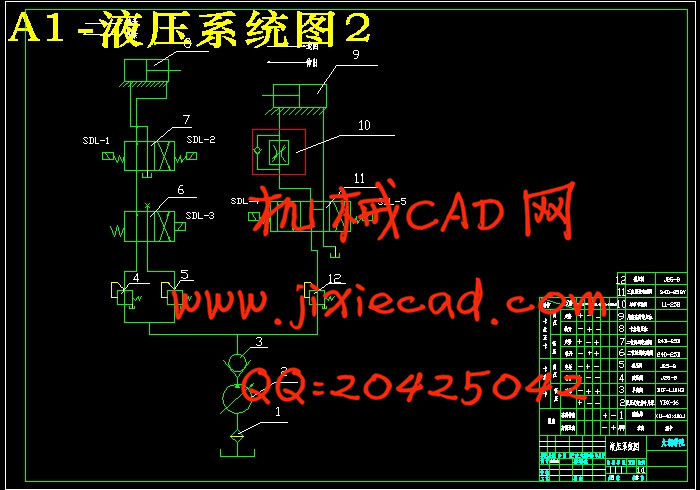

3.2.1 液压系统图 8

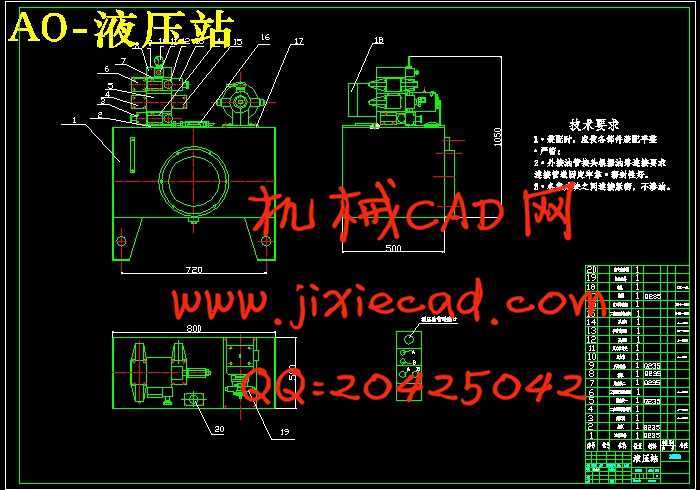

3.2.2 液压站装置图 9

3.2.3 尾座设计 9

4 液压控制部分的设计 11

4.1 基本方案的确定 11

4.1.1 油路循环方式的分析与选择 11

4.1.2 调速方案的分析与选择 12

4.1.3 油路形式的分析和选择 13

4.1.4 液压回路的分析,选择与合成 13

4.1.5 液压原理图的拟定于设计 13

4.2 液压装置的设计 15

4.2.1 液压控制方式确定 15

4.2.2 液压站设计 16

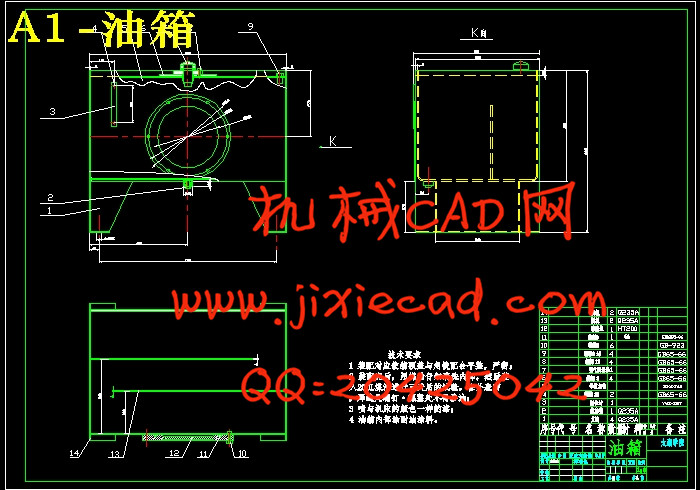

5 液压油箱的设计 17

5.1 液压油箱有效容积的确定 17

5.2 液压油箱的外形尺寸 17

5.3 液压油箱的结构设计 17

5.3.1 隔板 17

5.3.2 吸油管与回油管 17

5.3.3 防止杂质侵入 20

5.3.4 顶盖及清洗孔 22

5.3.5 液压指示 23

5.3.6 液压油箱得起吊 23

5.3.7 液压油箱得防锈 23

5.3.8 液压油箱的加热与冷却 23

6 结 论 25

致 谢 26

参考文献 29

附 录 30