设计简介

摘 要

本次设计任务来源于校企合作开发课题。先调研数控车床的发展状况,随着科学技术的发展,机械产品结构越来越合理,其性能、精度和效率日趋提高更新换代频繁,生产类型由大批大量生产向多品种小批量生产转化。因此,对机械产品的加工相应得提出了高精度、高柔性与高度自动化的要求。数字控制机床就是为了解决单件、小批量、特别是复杂型面零件加工的自动化并保证质量要求而产生的。

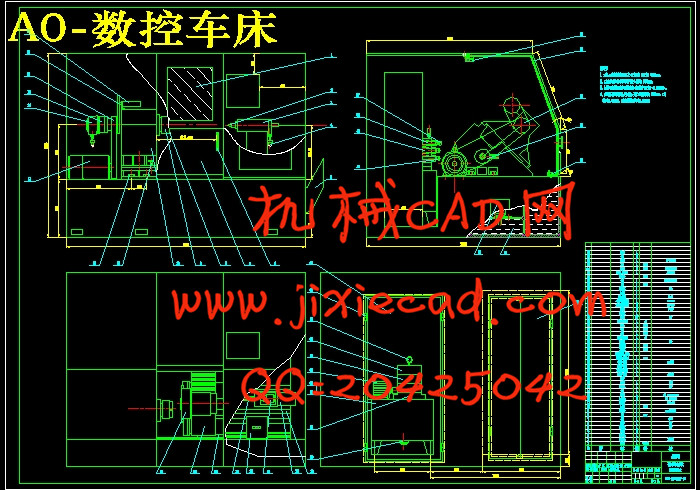

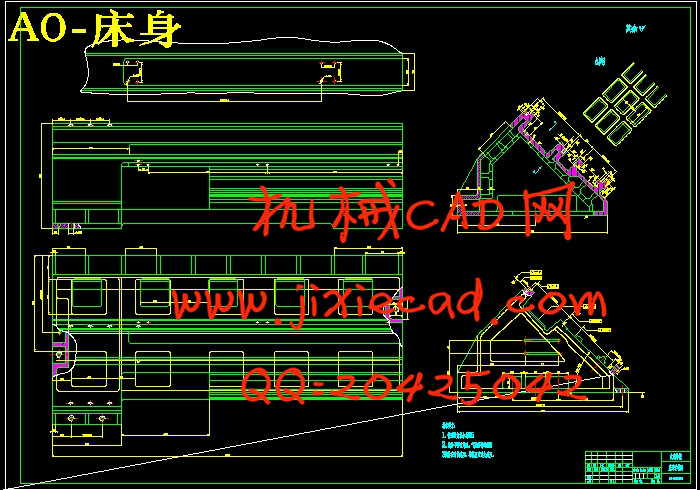

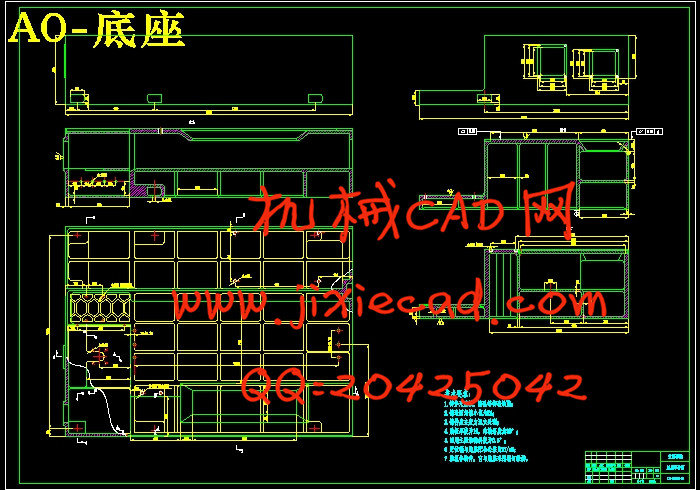

该设计主要考虑两大方面:数控部分和机械部件。首先进行数控车床总体方案的比较,然后确定最佳方案,完成半闭环数控车床的总体布局,绘制出半闭环数控车床的传动系统图,数控车床总体的尺寸联系图。通过对切削力的计算来设计进给系统、刀架、主轴卡盘的夹紧、液压尾座的行程等。完成该数控车床总体设计,总体布局,绘制尺寸联系总图一份,以及床身设计,绘制床身零件图,底座设计,绘制底座零件图。对车床振动的分析来提出加强机床刚度的方法,还有设计该数控机床的排屑装置及尾架装置。最后叙述该机床平时的维护及保养,有利于机床的正常运转。

预期成果设计出符合机械厂要求的通用型的,半闭环,斜床身,双轴联动,卧式数控车床,尽量满足生产需要,使我们设计的数控机床可靠性,加工精度,变速范围,操作宜人性,工作效率及防护结构,造型等诸多方面更加适合实际的使用要求。

关键词:半闭环;数控车床;总体设计;

Abstract

This design task comes from the school-enterprise cooperation and development issues. Development of the first investigation of CNC lathe, with the development of science and technology, mechanical product structure more reasonable, and its performance, efficiency and precision of increasingly improved frequent replacement, production types from mass production to the many varieties of small batch production. Therefore, the processing machinery products corresponding to the high precision, high flexibility and high automation. Digital control of machine tool is to solve the one-piece, small batch, especially in the automatic processing of complex surface parts and ensure the quality requirement and produce.

This design mainly consider two aspects: numerical control part and mechanical part. First compared the overall scheme of CNC lathe, and then determine the optimal scheme, to complete the overall layout of CNC lathe, draw the diagram of transmission system semi-closed-loop CNC lathe, CNC lathe overall contact map size. To the design of feed system, turret, spindle chuck through calculation of cutting force, the clamping hydraulic tailstock travel. To complete the overall design of the CNC lathe, general layout, drawing a connection dimension in general, and the body design, drawing machine parts drawing, base design, drawing the base part drawing. Analysis on the lathe vibration proposed method to strengthen the stiffness of machine tools, as well as the design of the CNC machine tool cutting device and a tail frame device. Finally, describes the machine daily maintenance and maintenance, is conducive to the normal operation of the machine.

The expected results of design to meet the requirements of general machinery factory, half closed, slant bed lathe, CNC horizontal lathe, biaxial linkage, as far as possible to meet the need of production, reliability, CNC machine tools enable us to design the machining accuracy, speed range, operation comfort, efficiency and protection structure, other aspects are more suitable for practical use requirements.

Key words: Half closed loop; CNC lathe; The overall design;

目录

摘 要 IIIAbstract IV

目录 V

1 绪论 1

1.1 本课题的研究内容和意义 1

1.1.1 本次课题的意义 1

1.1.2 本次课题的目的 1

1.1.3 本次课题的所要达到的技术要求 1

1.2 国内外的发展概况 2

1.2.1 国内外数控机床的形势 2

1.2.2 数控机床未来发展趋势 3

1.3 本课题应达到的要求 4

2 数控机床总体方案的比较及其确定 5

2.1 调研情况 5

2.2 总体方案比较及确定 5

2.2.1 机床的总体布局 5

2.2.2 机床总体布局的基本要求 5

2.2.3 影响总体布局的因素 6

2.2.4 简述数控车床的特点 6

2.2.5 数控车床总体设计方案1 6

2.2.6 数控车床总体设计方案2 8

2.2.7 数控车床总体设计方案的确定 10

3 数控车床总体设计 11

3.1 数控机床的工作原理 11

3.2 数控机床的组成 11

3.2.1 程序编制及程序载体 11

3.2.2输入装置 11

3.2.3数控装置及强电控制装置 11

3.2.4伺服驱动系统及位置检测装置 12

3.2.5 机床的机械部件 12

3.3 参数确定 13

3.3.1 主参数和基本参数 13

3.3.2 切削用量的选择 13

3.3.3 运动参数和动力参数的计算 14

3.4 数控车床传动系统图 14

3.5 数控车床总体联系图 15

3.6 机床的润滑与维护 17

4 数控车床部件设计 18

4.1 机床底座,床身大件类的设计要求,方法 18

4.2 机床的振动和提高刚度措施 18

4.2.1 机床振动的类型 18

4.2.2 提高机床结构动刚度的措施 19

4.3 机床热变形的形成及其特点 20

4.4 床身与底座的结构设计 21

4.5 机床的隔振 22

4.6 排屑装置的设计 23

4.7 尾架装置的设计 26

5 数控机床的维护与保养 27

6 结论 29

致谢 30

参考文献 31

附录 32