设计简介

摘 要

随着中国经济的快速发展,各行各业也跟随其后发展起来,基础设施建设如火如荼地进行着。厂房、设备、交通设施需求急剧增加,各种金属管的需求已远远不能满足,许多金属管的形状要求也不断复杂化,从而催生了弯管机系统设计和开发。

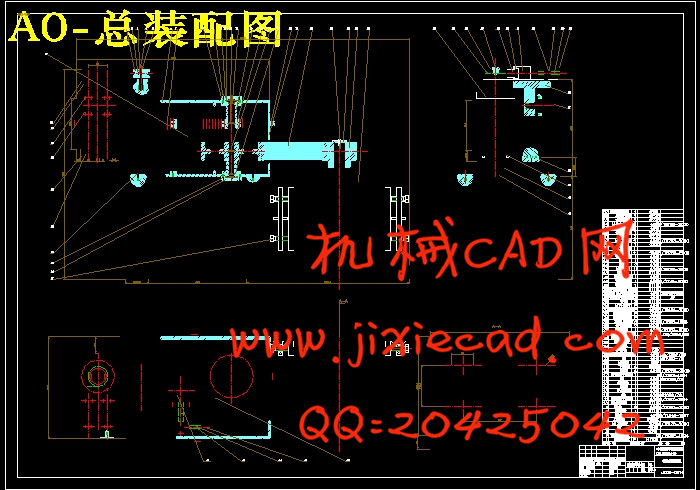

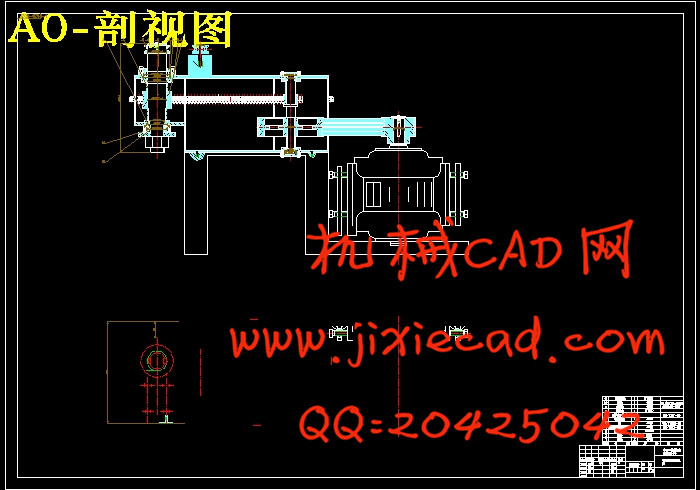

本文设计的是经济性能较好且精度较高的管材折弯机,主要针对的是直径20mm以下的管材。 此弯管机主要是用夹紧机构把管材压紧在主轴上的成型轮模的槽中,然后通过主轴的旋转来实现管材的折弯,这种折弯是二维的。优点是经济性好性好,制造使用简单,而且适用范围广,缺点就是精度较低,这种物理折弯还会产生一定反弹。

传统的手工折弯很难控制角度和距离,而且精度太低,往往很难满足需求,相反现代化的全自动数控折弯机各方面性能都比较好,但是非常昂贵,不适合中小企业,而我这个折弯机就能既保证一定的精度,也有很好的经济性,具有广泛的运用空间。

关键词:管材 折弯机 折弯 夹紧 液压

Abstract

With the rapid development of Chinese economy,every walk of china developed quickly.Many basic foundation is to be built.We need more workship,facility and transportation.The steel tube couldn’t satisfy need of.For some curling tubes are required,many engineers begin to design the curling machine.

The machine which I design is a kind of good presicion and proper price。It’s used for curling the tube which’s diameter is under 20mm. The curling process is very simple:firs the clamp equipment clamp the tube,then principal axis go round and round.The machine is easy for using and making.Also the cost is proper and it could be used in many circumstance.But the precision is not high,and this kind of curling shall have bring a bit rebound.

Taditionnal byhand curling hardly could control the curling angel and space.It has poor presicion .With the development of the industry ,traditional curling method couldn’t satisfy the presicion requirement .In the other hand,the CNC curling machine has a very good presicion ,but it’s very expensive.As my design has a good presicion and a proper price.It’s could be used in many factory.

Keywords:steel tube curling machine curl clamp hydraulic pressure

目 录

摘 要 1

1 绪论 1

2 管材折弯机的详细结构设计 3

2.1主要技术参数: 3

2.2电机选型 3

2.2.1电机功率计算 3

2.2.2电机选择 3

2.3传动机构的设计及计算 4

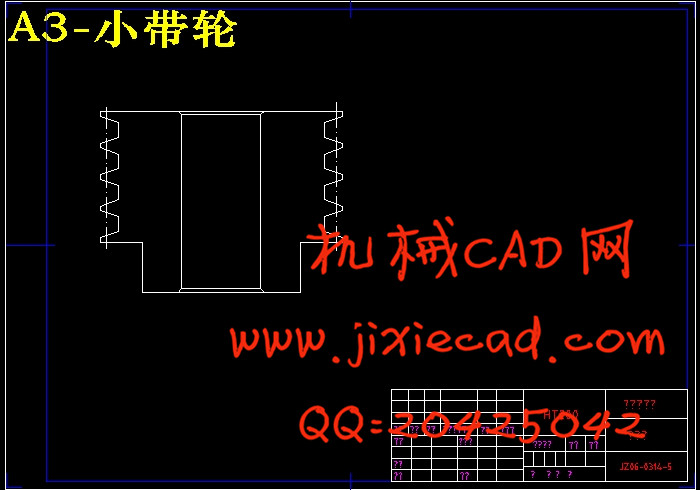

2.3.1带传动的设计计算 4

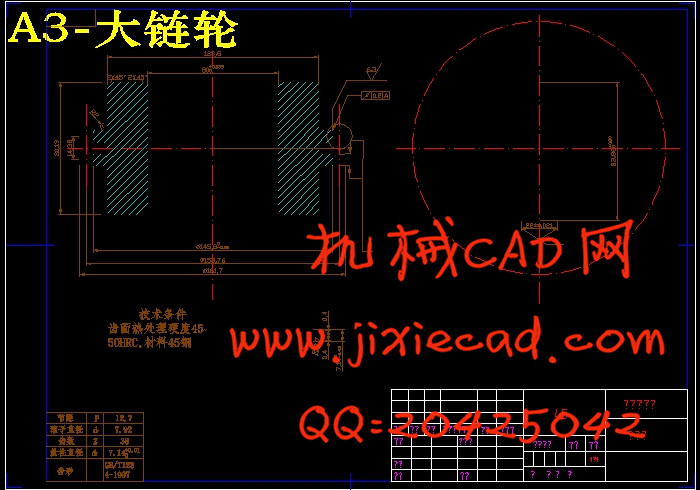

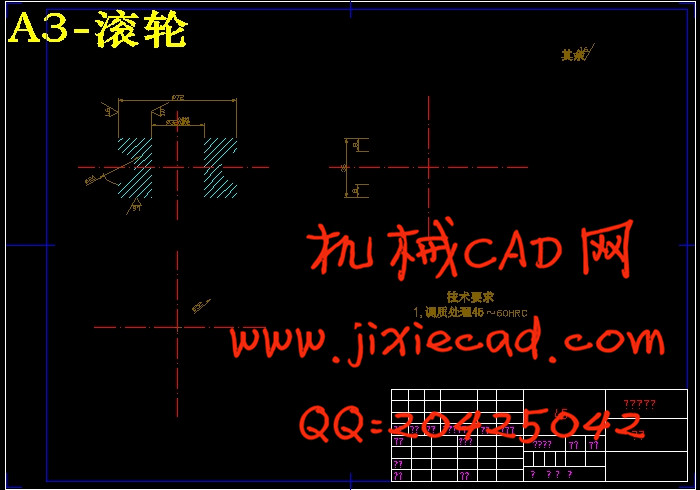

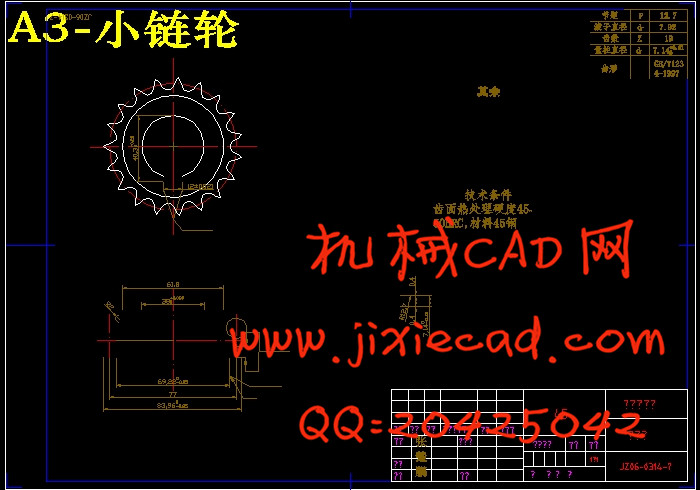

2.3.2链轮传动设计计算 7

2.4液压夹紧装置的设计 11

2.3.1夹紧装置的设计与原理 11

2.3.2丝杠传动设计与原理 13

2.4弯管机参数设计与校核 15

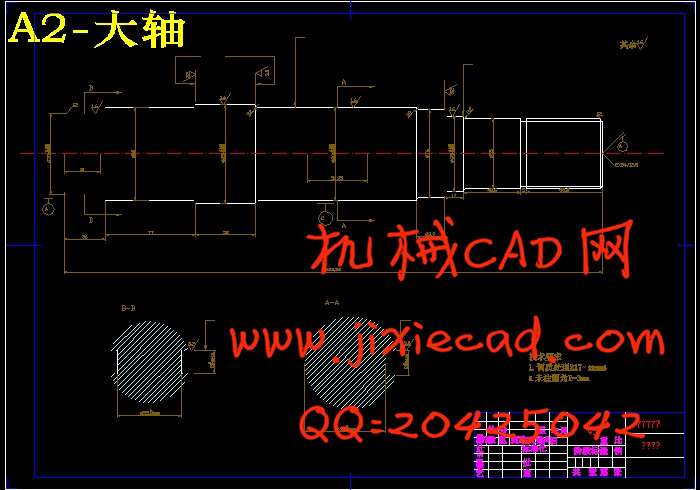

2.4.1 输入轴的结构设计及校核 15

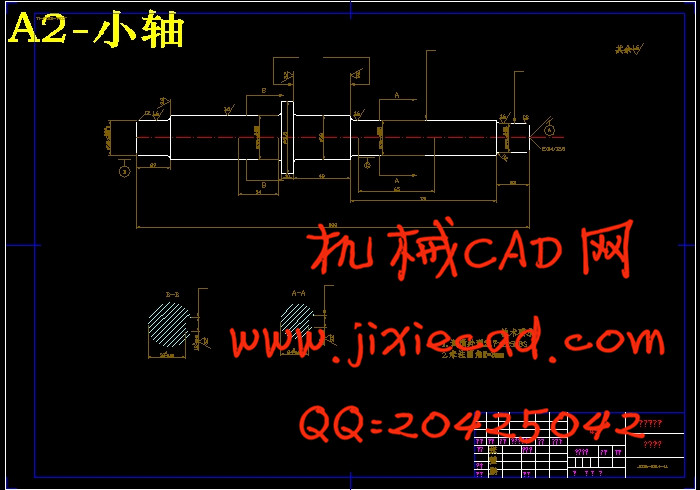

2.4.2 输出轴的结构设计及校核 16

3 结束语 18

4 致谢 19

5 参考文献 20

随着中国经济的快速发展,各行各业也跟随其后发展起来,基础设施建设如火如荼地进行着。厂房、设备、交通设施需求急剧增加,各种金属管的需求已远远不能满足,许多金属管的形状要求也不断复杂化,从而催生了弯管机系统设计和开发。

本文设计的是经济性能较好且精度较高的管材折弯机,主要针对的是直径20mm以下的管材。 此弯管机主要是用夹紧机构把管材压紧在主轴上的成型轮模的槽中,然后通过主轴的旋转来实现管材的折弯,这种折弯是二维的。优点是经济性好性好,制造使用简单,而且适用范围广,缺点就是精度较低,这种物理折弯还会产生一定反弹。

传统的手工折弯很难控制角度和距离,而且精度太低,往往很难满足需求,相反现代化的全自动数控折弯机各方面性能都比较好,但是非常昂贵,不适合中小企业,而我这个折弯机就能既保证一定的精度,也有很好的经济性,具有广泛的运用空间。

关键词:管材 折弯机 折弯 夹紧 液压

Abstract

With the rapid development of Chinese economy,every walk of china developed quickly.Many basic foundation is to be built.We need more workship,facility and transportation.The steel tube couldn’t satisfy need of.For some curling tubes are required,many engineers begin to design the curling machine.

The machine which I design is a kind of good presicion and proper price。It’s used for curling the tube which’s diameter is under 20mm. The curling process is very simple:firs the clamp equipment clamp the tube,then principal axis go round and round.The machine is easy for using and making.Also the cost is proper and it could be used in many circumstance.But the precision is not high,and this kind of curling shall have bring a bit rebound.

Taditionnal byhand curling hardly could control the curling angel and space.It has poor presicion .With the development of the industry ,traditional curling method couldn’t satisfy the presicion requirement .In the other hand,the CNC curling machine has a very good presicion ,but it’s very expensive.As my design has a good presicion and a proper price.It’s could be used in many factory.

Keywords:steel tube curling machine curl clamp hydraulic pressure

目 录

摘 要 1

1 绪论 1

2 管材折弯机的详细结构设计 3

2.1主要技术参数: 3

2.2电机选型 3

2.2.1电机功率计算 3

2.2.2电机选择 3

2.3传动机构的设计及计算 4

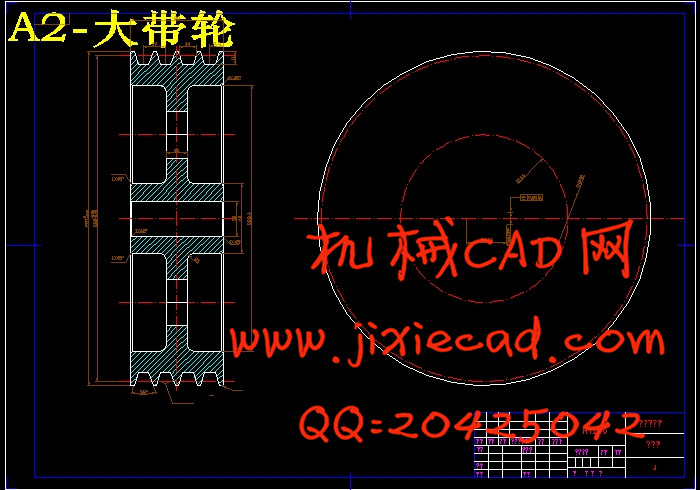

2.3.1带传动的设计计算 4

2.3.2链轮传动设计计算 7

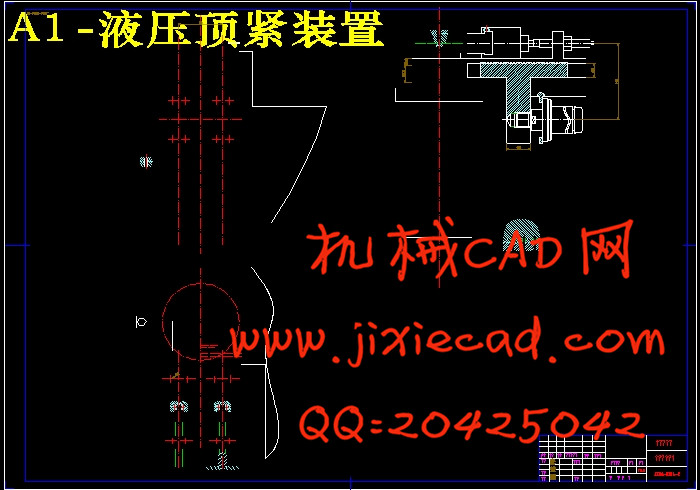

2.4液压夹紧装置的设计 11

2.3.1夹紧装置的设计与原理 11

2.3.2丝杠传动设计与原理 13

2.4弯管机参数设计与校核 15

2.4.1 输入轴的结构设计及校核 15

2.4.2 输出轴的结构设计及校核 16

3 结束语 18

4 致谢 19

5 参考文献 20