设计简介

包缝机机体钻孔组合机床总体及夹具设计

摘要:本设计课题来源于盐城市江淮动力集团。为了提高加工精度和生产效率,需要设计一种组合机床来改善加工情况。本组合机床是针对工件左面上钻4个φ5、4个φ4.2、3个φ3.3深度不一的11个孔和右面1钻φ3.3深度不一的9个孔而设计的。该设计的内容重点是总体设计和夹具设计两方面。在加工工艺路线方案中,确定装料高度,确定加工线各系列机床的基本类型及机床配置形式,确定机床部件型号及机床夹具,完成了“三图一卡”的绘制及夹具的设计。“三图一卡”主要根据自己计算切削力,切削转矩等选择相应的机床部件。而夹具设计,用 “一面两孔”定位方案消除工件的六个自由度,使工件获得稳定可靠的定位。工件夹紧装置则选用结构简单、可靠、方便的螺旋夹紧装置,使夹紧平稳可靠。该机床满足设计的要求。

关键词:组合机床;夹具;

The Overall and Fixture Design of Modular Machine Tool for Drilling Holes of BAO Sewing Machine

Abstract: The design project is from Jiangdong Group, Yancheng. In order to improve the accuracy and efficiency, it is necessary to design a modular machine tool. The machine tool is designed for the synchronous processing of four φ5 holes, four φ4.2 holes, three φ3.3 left holes of varying depth of 11 holes , and nineφ3.3 right holes of verying depth . The design is mainly focused on both the overall design and jig design. In the processing line programe ,We must establish a high degree of putting the workpiece and identify the basic types of machine tools and the configuration types of machine tools , we are also determine the kinds of parts and fixture , Meanwhile the drawing of “Three Charts and One Card” (automatic drawing process chart, size relation chart, machining schematic diagram and production calculating card) and fixture design are completed. “Three Charts and One Card” are based mainly on its own calculation of cutting force ,cutting torque and other machine tool parts .As far as jigs are concered, with the aid of one platform and two bore according to the principle of six points positioning to eliminate the six degrees of freedom of workpiece for a stable and reliable positioning, and the synchronous processing of two surfaces of parts which can simplifying the process. Simple, reliable and convenient spiral grip devices are employed for a stable and reliable grip. The Modular Machine Tool can satisfy for the requirements of the design .

Key Words: Modular machine tool; Fixture;

目 录

1 前言 1

2 组合机床总体设计 3

2.1 总体方案论证 3

2.1.1 加工对象工艺性分析 3

2.1.2 机床配置型式的选择 3

2.1.3 定位基准的选择 4

2.2 确定切削用量及选择刀具 4

2.2.1 选择切削用量 4

2.2.2 计算切削力、切削扭矩及切削功率 6

2.2.3 刀具耐用度的计算 10

2.2.4 选择刀具结构 10

2.3 三图一卡设计 10

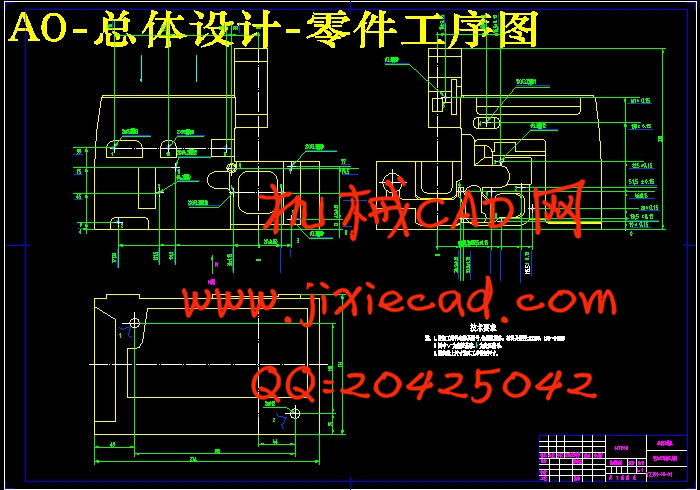

2.3.1 被加工零件工序图 10

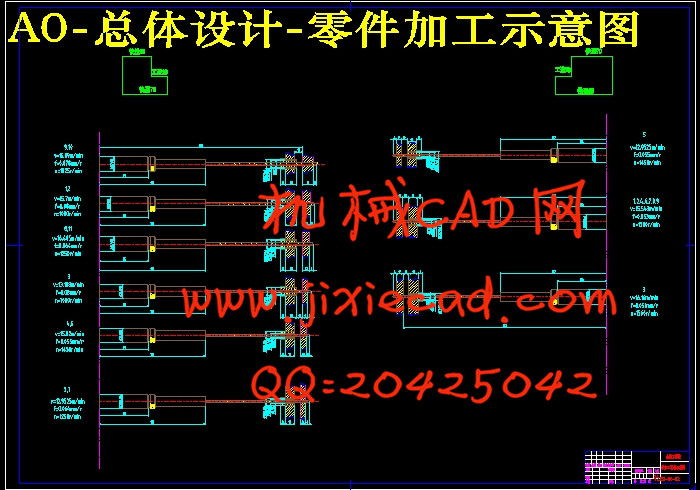

2.3.2 加工示意图 11

2.3.3 机床联系尺寸图 12

2.3.4 机床生产率计算卡 15

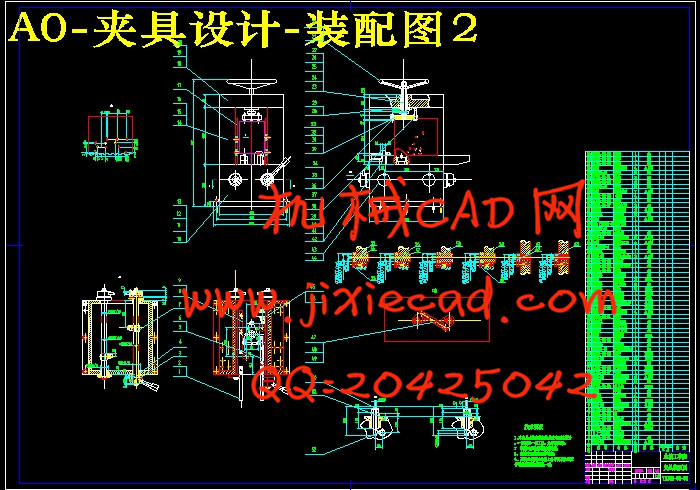

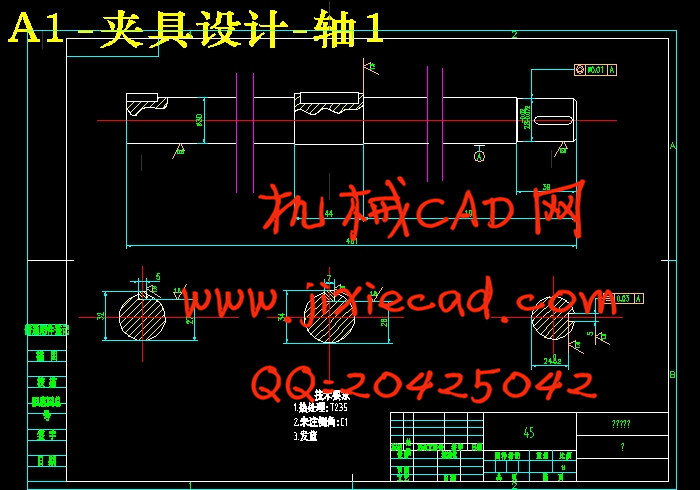

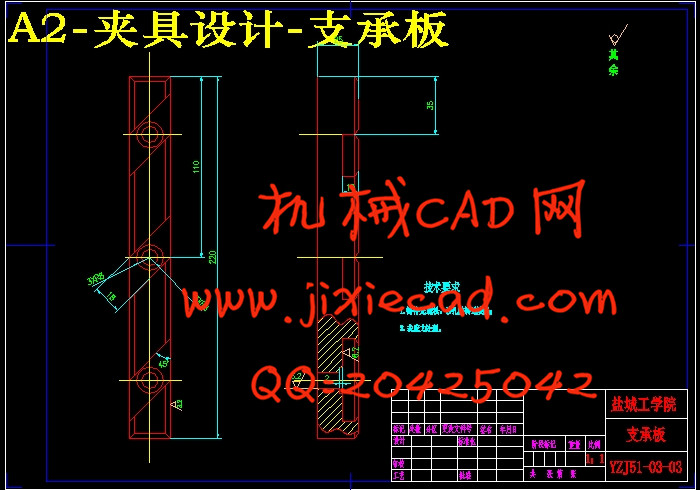

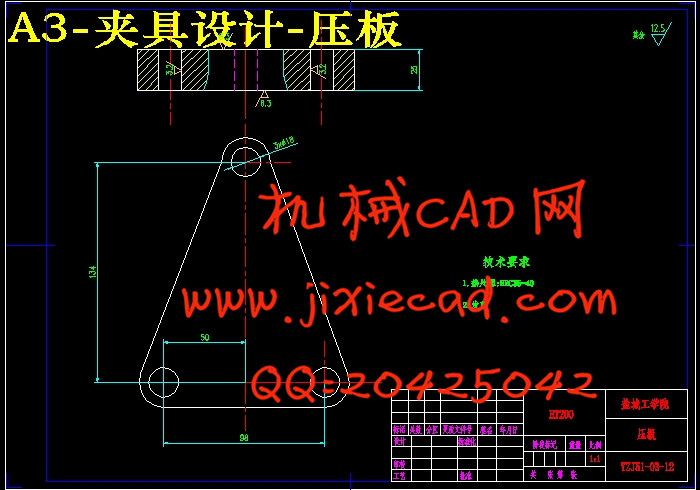

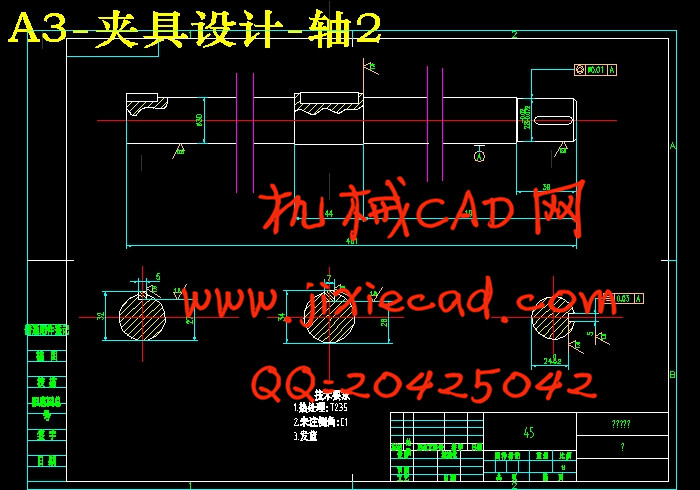

3 组合机床夹具设计 17

3.1 零件的工艺性分析 17

3.1.1 夹具设计的基本要求 17

3.1.2 夹具总体结构构思 17

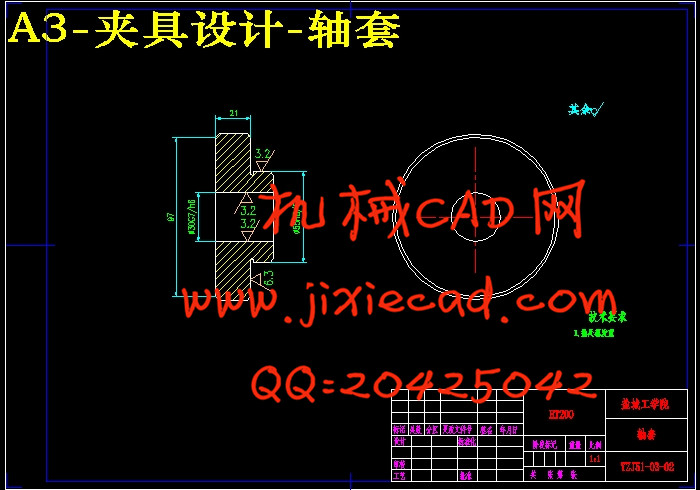

3.2 定位方案的确定 18

3.2.1 定位方案的论证 18

3.2.2 定位基准的选择 18

3.2.3 定位的实现方法 18

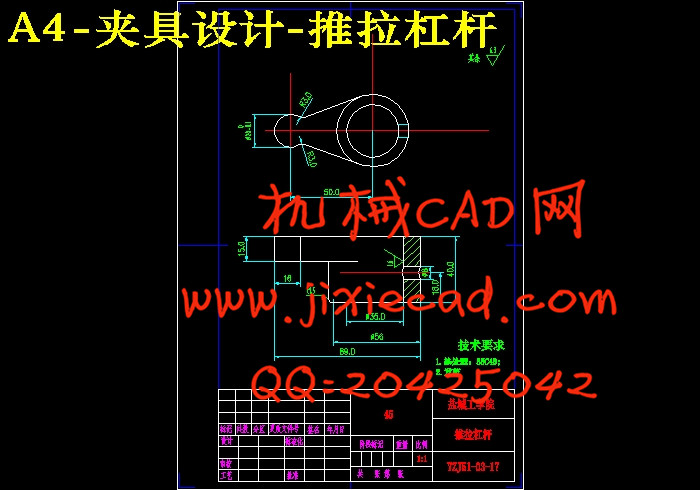

3.3 夹紧方案确定 20

3.3.1夹紧装置的确定 20

3.3.2夹紧力的确定 21

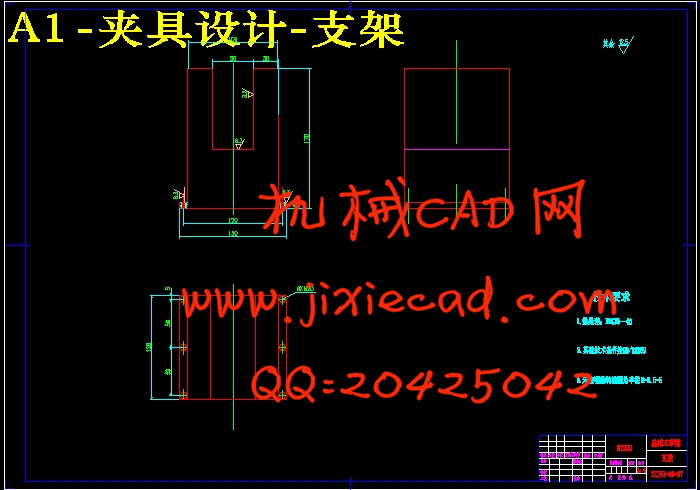

3.4 导向装置的选择 22

3.4.1钻模套型式的选择和设计 22

3.4.2钻模板的类型和设计 23

3.5 误差分析 24

3.5.1 影响加工精度的因素 24

3.5.2 保证加工精度的条件 25

3.6 夹具体确定 26

4 结论 27

参考文献 28

致 谢 29

附 录 30

摘要:本设计课题来源于盐城市江淮动力集团。为了提高加工精度和生产效率,需要设计一种组合机床来改善加工情况。本组合机床是针对工件左面上钻4个φ5、4个φ4.2、3个φ3.3深度不一的11个孔和右面1钻φ3.3深度不一的9个孔而设计的。该设计的内容重点是总体设计和夹具设计两方面。在加工工艺路线方案中,确定装料高度,确定加工线各系列机床的基本类型及机床配置形式,确定机床部件型号及机床夹具,完成了“三图一卡”的绘制及夹具的设计。“三图一卡”主要根据自己计算切削力,切削转矩等选择相应的机床部件。而夹具设计,用 “一面两孔”定位方案消除工件的六个自由度,使工件获得稳定可靠的定位。工件夹紧装置则选用结构简单、可靠、方便的螺旋夹紧装置,使夹紧平稳可靠。该机床满足设计的要求。

关键词:组合机床;夹具;

The Overall and Fixture Design of Modular Machine Tool for Drilling Holes of BAO Sewing Machine

Abstract: The design project is from Jiangdong Group, Yancheng. In order to improve the accuracy and efficiency, it is necessary to design a modular machine tool. The machine tool is designed for the synchronous processing of four φ5 holes, four φ4.2 holes, three φ3.3 left holes of varying depth of 11 holes , and nineφ3.3 right holes of verying depth . The design is mainly focused on both the overall design and jig design. In the processing line programe ,We must establish a high degree of putting the workpiece and identify the basic types of machine tools and the configuration types of machine tools , we are also determine the kinds of parts and fixture , Meanwhile the drawing of “Three Charts and One Card” (automatic drawing process chart, size relation chart, machining schematic diagram and production calculating card) and fixture design are completed. “Three Charts and One Card” are based mainly on its own calculation of cutting force ,cutting torque and other machine tool parts .As far as jigs are concered, with the aid of one platform and two bore according to the principle of six points positioning to eliminate the six degrees of freedom of workpiece for a stable and reliable positioning, and the synchronous processing of two surfaces of parts which can simplifying the process. Simple, reliable and convenient spiral grip devices are employed for a stable and reliable grip. The Modular Machine Tool can satisfy for the requirements of the design .

Key Words: Modular machine tool; Fixture;

目 录

1 前言 1

2 组合机床总体设计 3

2.1 总体方案论证 3

2.1.1 加工对象工艺性分析 3

2.1.2 机床配置型式的选择 3

2.1.3 定位基准的选择 4

2.2 确定切削用量及选择刀具 4

2.2.1 选择切削用量 4

2.2.2 计算切削力、切削扭矩及切削功率 6

2.2.3 刀具耐用度的计算 10

2.2.4 选择刀具结构 10

2.3 三图一卡设计 10

2.3.1 被加工零件工序图 10

2.3.2 加工示意图 11

2.3.3 机床联系尺寸图 12

2.3.4 机床生产率计算卡 15

3 组合机床夹具设计 17

3.1 零件的工艺性分析 17

3.1.1 夹具设计的基本要求 17

3.1.2 夹具总体结构构思 17

3.2 定位方案的确定 18

3.2.1 定位方案的论证 18

3.2.2 定位基准的选择 18

3.2.3 定位的实现方法 18

3.3 夹紧方案确定 20

3.3.1夹紧装置的确定 20

3.3.2夹紧力的确定 21

3.4 导向装置的选择 22

3.4.1钻模套型式的选择和设计 22

3.4.2钻模板的类型和设计 23

3.5 误差分析 24

3.5.1 影响加工精度的因素 24

3.5.2 保证加工精度的条件 25

3.6 夹具体确定 26

4 结论 27

参考文献 28

致 谢 29

附 录 30