设计简介

摘 要

电火花加工技术是特种加工技术的一种。从电火花创立至今,己经有61年的历史,经过世界各国学者的不断努力,电火花加工的发展非常迅速,应用范围不断扩大,基础理论和技术装备都日趋完善。电火花加工技术发展已成为现代生产上极其重要的加工手段,在制造业中发挥着不可替代的作用。

随着制造技术水平的不断提高,涌现出很多问题需要我们解决。目前,便携式电火花加工装置己成为研究的热点。在航空航天、微电子、医学、光学以及模具等各个领域中,有许多零件采用常规机床加工困难,甚至无法加工,特别是对狭小空间内的加工,还有微细孔的加工以及特殊加工材料的加工等,采用便携式电火花加工装置则会取得令人满意的效果。

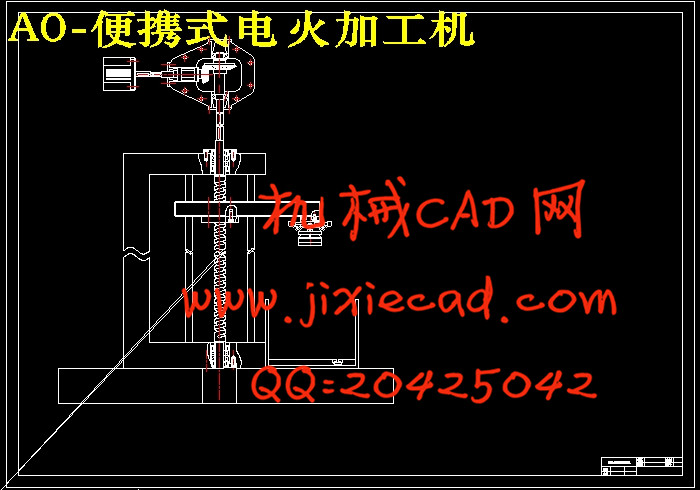

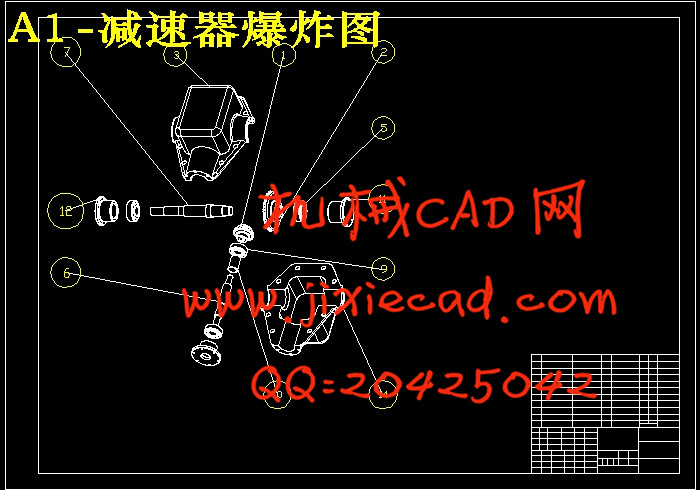

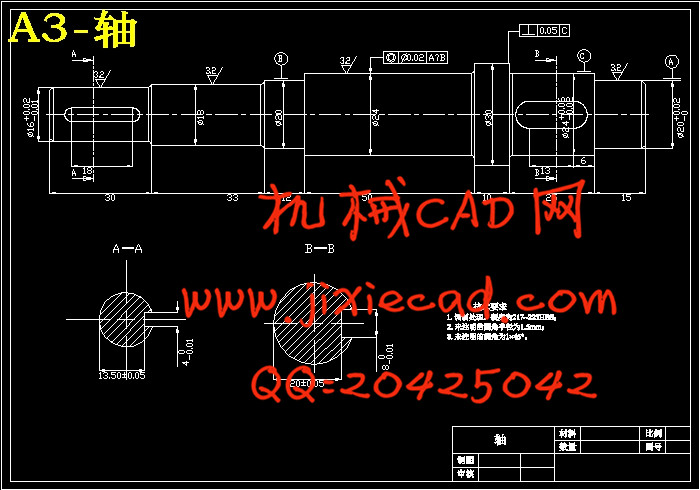

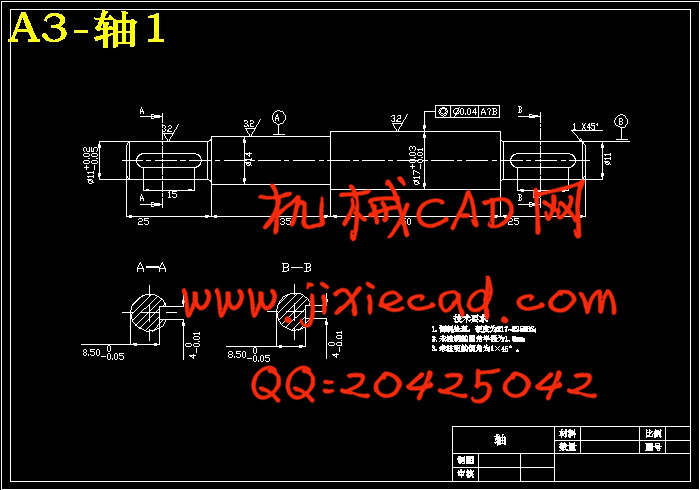

为了适应当今电火花加工技术发展的需要,本文设计了一台便携式电火花加工机,设计内容包括:电火花加工机的机械结构设计,电火花加工机的自动进给调节系统与机械装置设计,并且详细的陈述了电火花的基本工艺规律。

Abstract

EDM technology is a special processing technology. Founded from the electric spark, has 61 years of history, through the continuous efforts of scholars around the world, EDM has developed rapidly, increasing scope of application, basic theory and technical equipment are maturing. EDM technology has become extremely important modern production process means, in the manufacturing sector plays an irreplaceable role.

With increasing levels of manufacturing technology, many problems have emerged we need to solve. At present, the portable device EDM has become a research hotspot. In the aerospace, microelectronics, medical, optical, and mold and other fields, there are many parts using conventional machining difficult, if not processing, particularly for small space processing, as well as micro-hole machining and special processing of materials processing, using EDM equipment will be portable to achieve satisfactory results.

To meet the current needs of the development of EDM technology, the paper design of a portable EDM machine, the design includes: Electrical Discharge Machining of Mechanical Design, Electrical Discharge Machining of automatic feed-conditioning and mechanical equipment design, and a detailed statement of the basic technology of EDM law.

目 录

摘要…Ⅰ

1 绪论 1

1.1 课题研究的背景 1

1.2 课题研究的意义 1

1.3 国内外发展现状 3

2 加工机的原理和组成 5

2.1 电火花的基本原理 5

2.2 电火花加工机床的组成 7

3 自动进给调节系统与机械装置设计 12

3.1 自动进给调节系统的设计 12

3.2 机械装置的设计 15

4 电火花加工的基本工艺规律 25

4.1 影响放电蚀除量的主要因素 25

4.2 电火花加工的加工速度和工具的损耗速度 28

4.3 影响加工精度的主要因素 30

4.4 电火花加工表面完整性 32

5 总 结 34

致 谢 35

参 考 资 料 36

电火花加工技术是特种加工技术的一种。从电火花创立至今,己经有61年的历史,经过世界各国学者的不断努力,电火花加工的发展非常迅速,应用范围不断扩大,基础理论和技术装备都日趋完善。电火花加工技术发展已成为现代生产上极其重要的加工手段,在制造业中发挥着不可替代的作用。

随着制造技术水平的不断提高,涌现出很多问题需要我们解决。目前,便携式电火花加工装置己成为研究的热点。在航空航天、微电子、医学、光学以及模具等各个领域中,有许多零件采用常规机床加工困难,甚至无法加工,特别是对狭小空间内的加工,还有微细孔的加工以及特殊加工材料的加工等,采用便携式电火花加工装置则会取得令人满意的效果。

为了适应当今电火花加工技术发展的需要,本文设计了一台便携式电火花加工机,设计内容包括:电火花加工机的机械结构设计,电火花加工机的自动进给调节系统与机械装置设计,并且详细的陈述了电火花的基本工艺规律。

Abstract

EDM technology is a special processing technology. Founded from the electric spark, has 61 years of history, through the continuous efforts of scholars around the world, EDM has developed rapidly, increasing scope of application, basic theory and technical equipment are maturing. EDM technology has become extremely important modern production process means, in the manufacturing sector plays an irreplaceable role.

With increasing levels of manufacturing technology, many problems have emerged we need to solve. At present, the portable device EDM has become a research hotspot. In the aerospace, microelectronics, medical, optical, and mold and other fields, there are many parts using conventional machining difficult, if not processing, particularly for small space processing, as well as micro-hole machining and special processing of materials processing, using EDM equipment will be portable to achieve satisfactory results.

To meet the current needs of the development of EDM technology, the paper design of a portable EDM machine, the design includes: Electrical Discharge Machining of Mechanical Design, Electrical Discharge Machining of automatic feed-conditioning and mechanical equipment design, and a detailed statement of the basic technology of EDM law.

目 录

摘要…Ⅰ

1 绪论 1

1.1 课题研究的背景 1

1.2 课题研究的意义 1

1.3 国内外发展现状 3

2 加工机的原理和组成 5

2.1 电火花的基本原理 5

2.2 电火花加工机床的组成 7

3 自动进给调节系统与机械装置设计 12

3.1 自动进给调节系统的设计 12

3.2 机械装置的设计 15

4 电火花加工的基本工艺规律 25

4.1 影响放电蚀除量的主要因素 25

4.2 电火花加工的加工速度和工具的损耗速度 28

4.3 影响加工精度的主要因素 30

4.4 电火花加工表面完整性 32

5 总 结 34

致 谢 35

参 考 资 料 36