设计简介

摘 要

众所周知,笔记本电脑主板的生产分为SMT和PCBA两部分,目前,SMT

已实现全自动生产,而PCBA则主要进行人工作业.为了提高工作效率,节

省时间,增加经济效益和社会效益,故进行笔记本电脑主板装配线(输送带)

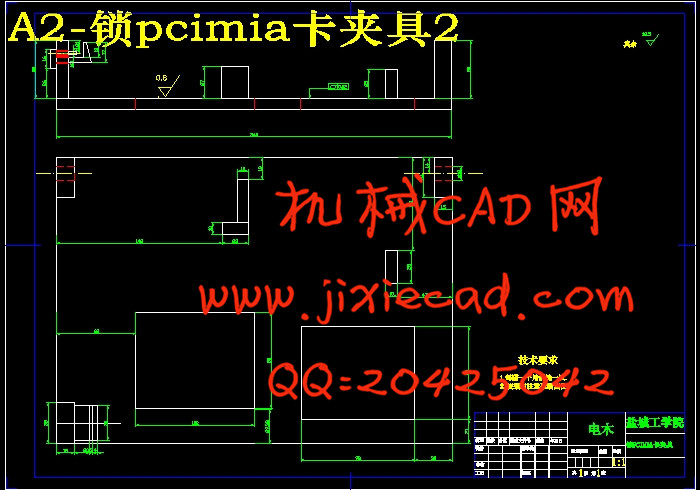

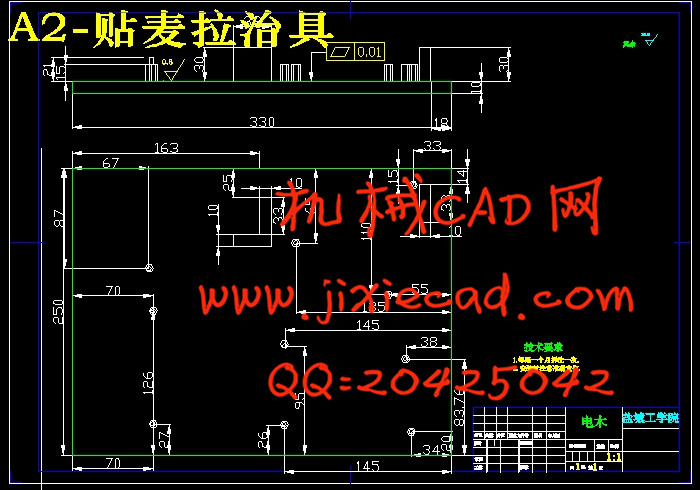

及主要夹具设计

本设计主要包括以下内容:

一. 确定主板装配线各工位之间的间距及装配线总长

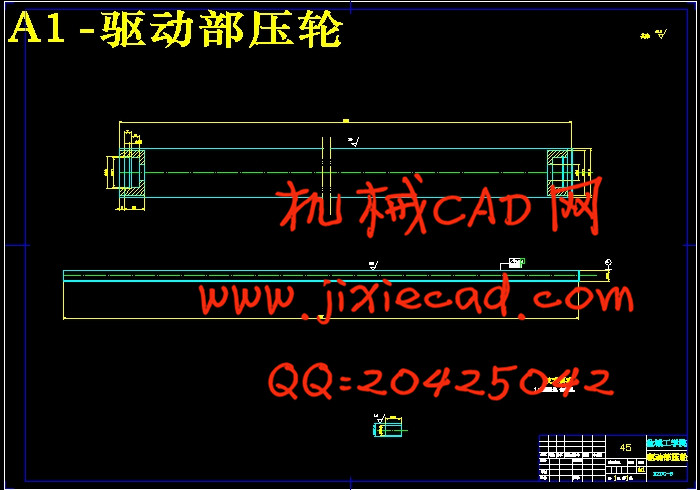

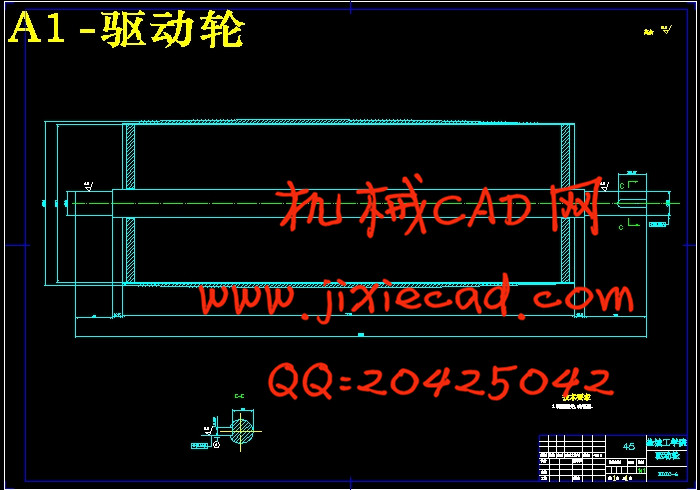

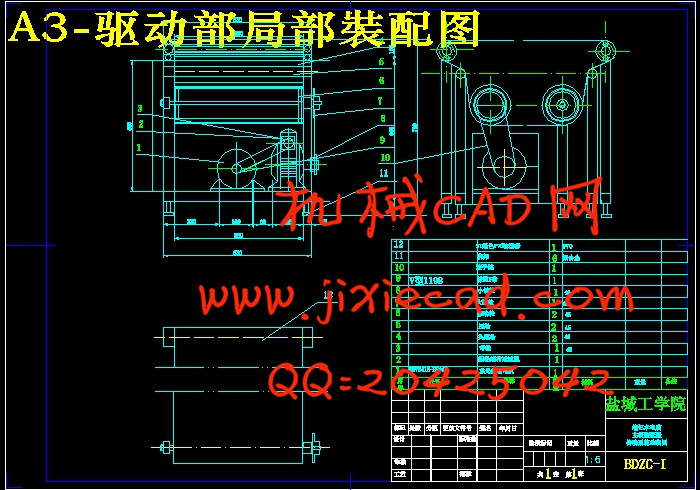

二. 确定装配线的调速方法,设计传动系统.

三. 输送带材料的选择及其结构.

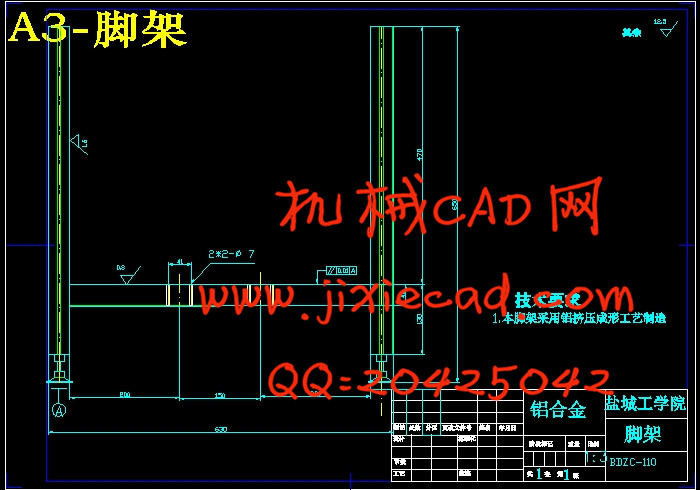

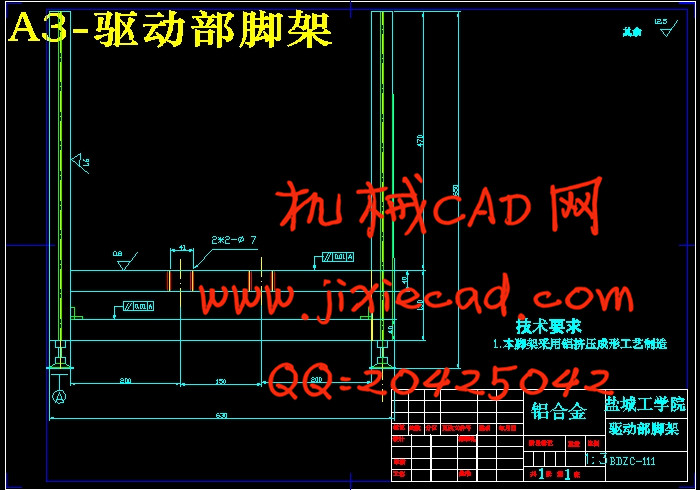

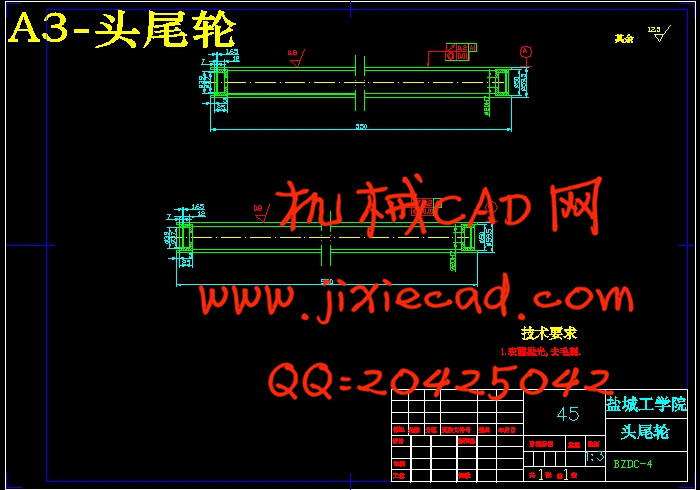

四. 皮带输送机的支架及其张紧装置的设计.

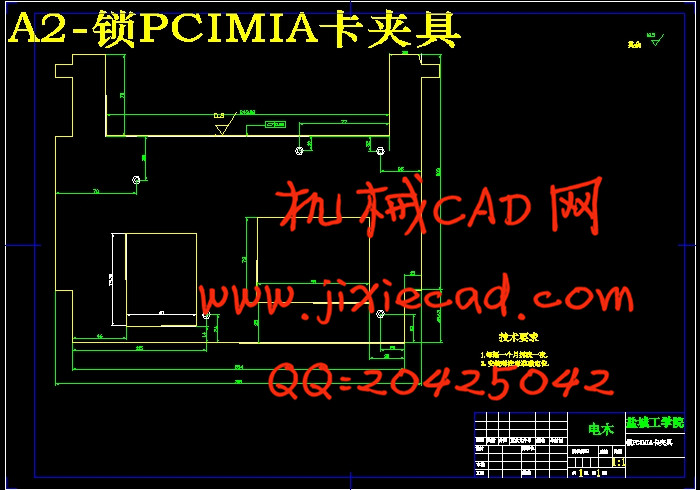

五. 确定主要夹具的安装位置及定位夹紧形式,且进行结构设计

各工位之间的间距由各工位中的较长时间,即所谓的瓶頸时间与输送带速来确定,用公式表示为S=V*T, 装配线总长由间距与工位数共同确定.

本装配线的调速方法采用调频电机调节电机的转速,从而间接调节输

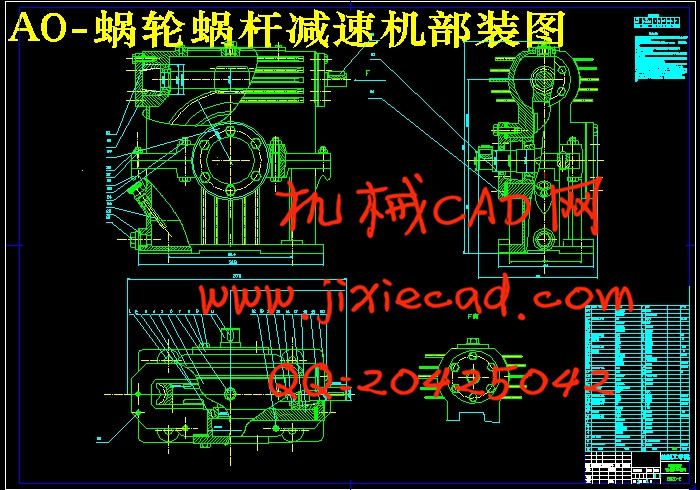

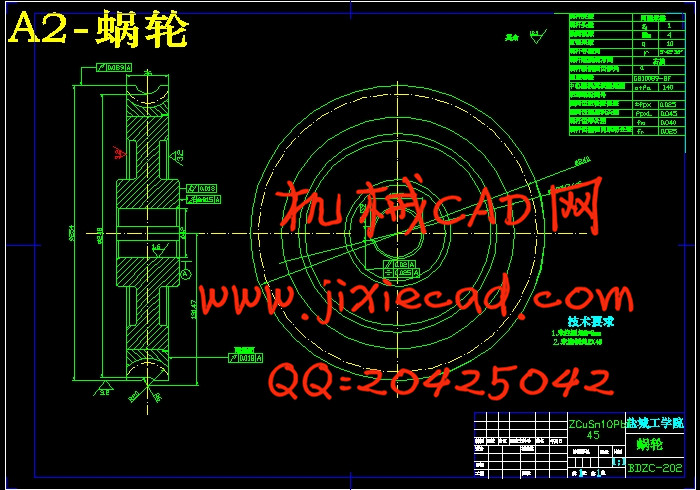

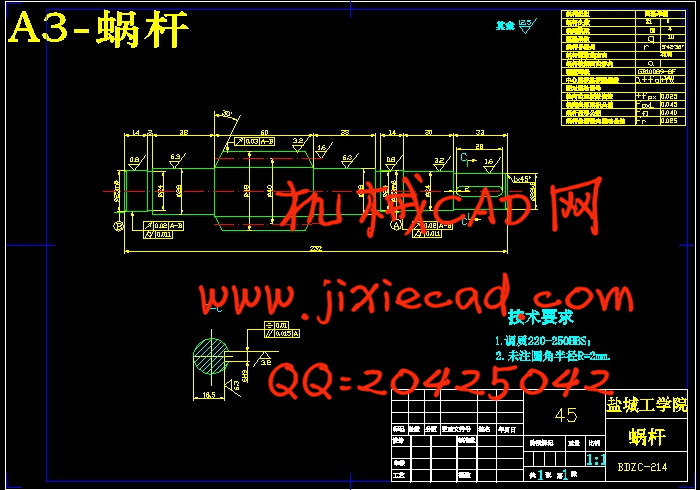

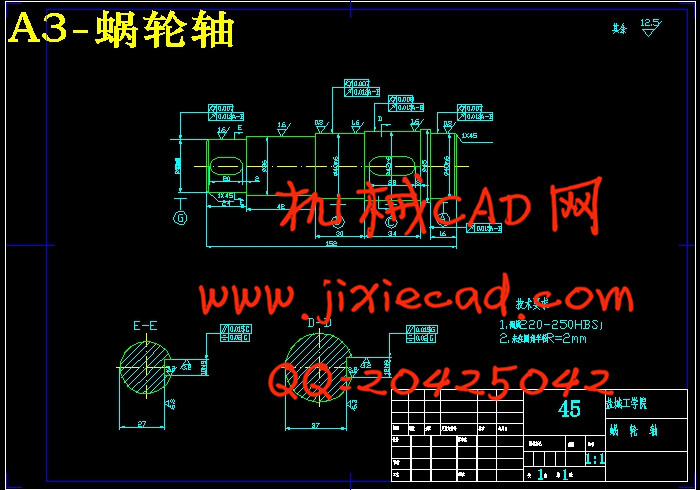

送带速. 本系统采用蜗杆减速机,电机与蜗杆减速机之间采用普通V带传

动, 蜗杆减速机与输送带的驱动滚筒之间采用链传动.

因为笔记本电脑主板上附有许多电子元件,其本身也是印刷电路板,

因此对输送带提出了防静电的特殊要求,所以本输送带采用绿色PVC材料

关键字:笔记本电脑主板 输送带 传动 夹具

Abstract

As everyone knows the production of the main board of the notebook computer is divided into SMT and PCBA two parts, At present, SMT has already realized that has been produced full- automatically, but PCBA carries on the artificial homework mainly . For working efficiency of raising, saves time, increase the economic benefits and social benefit, Carry on notebook computer main board assembly line( conveyer belt) and the main jig is designedded Originally design and include the following content mainly: First. confirm main board assembly line interval and the assembly line two of the total lengths of location per worker.last the not transfering speed method of of assembly line, Design the transmission. Whether three.send choice and the structure not with material. Whether four.belt the the conveyers one the supports and pieces of device of design not urgent. Five. position installation of the jig mainly and made a reservation by form of clamping, and carry on there aren't structure, Namely so-called bottle time and conveyer belt, i of ?, come and confirm , show with the formula for S rapidly =V * T, assembly line the total length is confirm together by the interval and worker's -figure number. To transfer speed method adopt electrical machinery of frequency modulation regulate the rotational speed of the electrical machinery assembly line this, Thus regulate the speed of conveyer belts indirectly. System this adopt worm moderate machine, electrical machinery and worm moderate plane adopt ordinary V bring transmission, Worm moderate plane and drive cylinder of conveyer belt adopt chain transmission. Because notebook computer main board enclose a lot of electronic elements, its itself is the printed circuit board too, So put forward defend special request of static to conveyer belt, so a conveyer belt adopts green PVC material

Key word: Main board of the notebook computer Transmission of the conveyer belt Jig

目录

0 前言………………………………………………………………………………………………1

1 传动系统总体方案论证………………………………………………………… 3

1.1齿轮减速与蜗轮蜗杆减速方案比较………………………………………… 3

1.2链传动与带传动方案比较 ………………………………………… 6

2 传动系统计算…………………………………………………………………………8

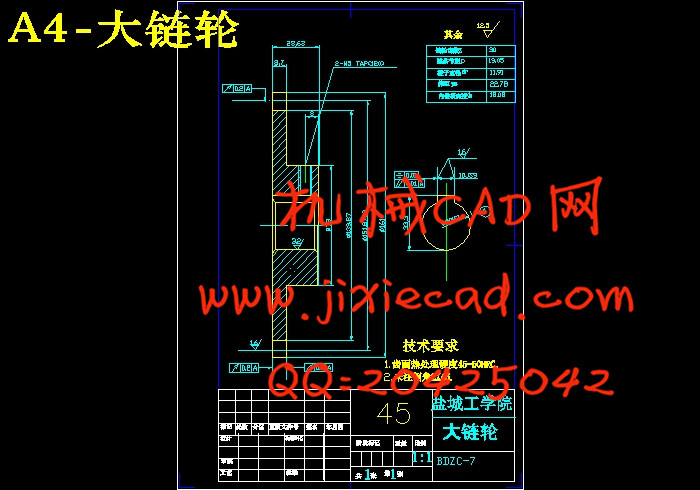

2.1链传动设计计算 …………………………………………………………… 8

2.1.1滚子链链轮的基本参数和尺寸………………………………………………… 9

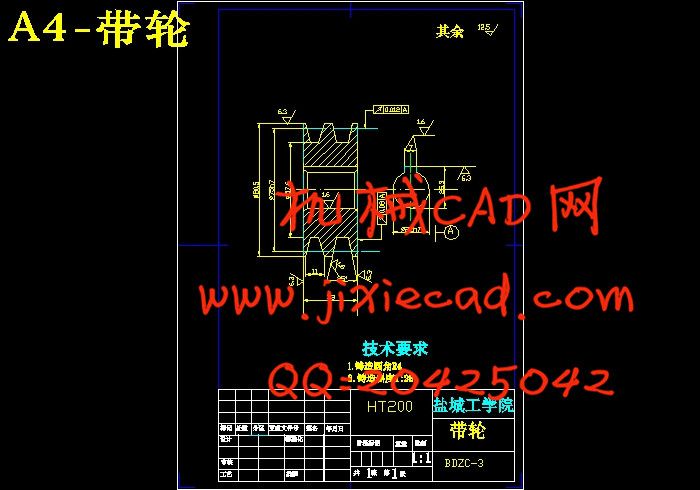

2.2普通V带传动设计计算……………………………………………………………11

2.2.1普通V带轮几何尺寸……………………………………………………………………12

2.3蜗轮蜗杆减速机设计计算 …………………………………………………………… 14

2.3.1普通圆柱蜗杆传动的主要几何尺寸…………………………………………………17

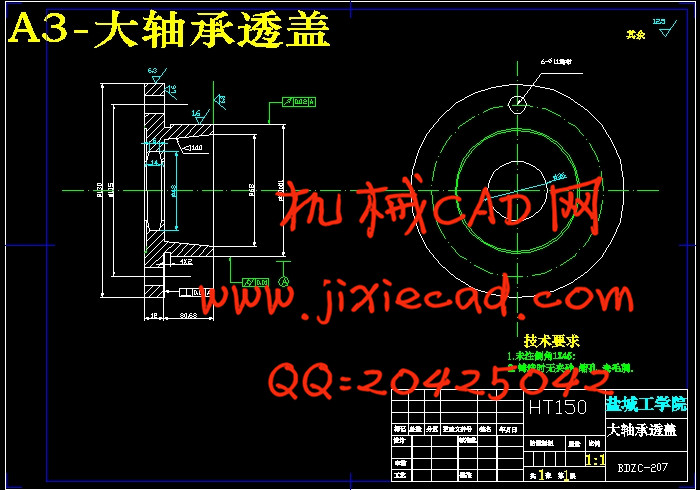

3.蜗杆减速器整体设计……………………………………………………………………… 18

4 夹具的设计…………………………………………………………………………………… 21

5 马达及控制装置………………………………………………………………………… 22

6 绿色防静电皮带技术参数…………………………………………………………… 23

7 输送设备保养……………………………………………………………………………… 24

8 设备备品明细表……………………………………………………………… 25

9 结论 ……………………………………………………………………………… 26

致谢 ……………………………………………………………………………… 27

参考文献……………………………………………………………………………… 28

附件清单……………………………………………………………………………… 29

众所周知,笔记本电脑主板的生产分为SMT和PCBA两部分,目前,SMT

已实现全自动生产,而PCBA则主要进行人工作业.为了提高工作效率,节

省时间,增加经济效益和社会效益,故进行笔记本电脑主板装配线(输送带)

及主要夹具设计

本设计主要包括以下内容:

一. 确定主板装配线各工位之间的间距及装配线总长

二. 确定装配线的调速方法,设计传动系统.

三. 输送带材料的选择及其结构.

四. 皮带输送机的支架及其张紧装置的设计.

五. 确定主要夹具的安装位置及定位夹紧形式,且进行结构设计

各工位之间的间距由各工位中的较长时间,即所谓的瓶頸时间与输送带速来确定,用公式表示为S=V*T, 装配线总长由间距与工位数共同确定.

本装配线的调速方法采用调频电机调节电机的转速,从而间接调节输

送带速. 本系统采用蜗杆减速机,电机与蜗杆减速机之间采用普通V带传

动, 蜗杆减速机与输送带的驱动滚筒之间采用链传动.

因为笔记本电脑主板上附有许多电子元件,其本身也是印刷电路板,

因此对输送带提出了防静电的特殊要求,所以本输送带采用绿色PVC材料

关键字:笔记本电脑主板 输送带 传动 夹具

Abstract

As everyone knows the production of the main board of the notebook computer is divided into SMT and PCBA two parts, At present, SMT has already realized that has been produced full- automatically, but PCBA carries on the artificial homework mainly . For working efficiency of raising, saves time, increase the economic benefits and social benefit, Carry on notebook computer main board assembly line( conveyer belt) and the main jig is designedded Originally design and include the following content mainly: First. confirm main board assembly line interval and the assembly line two of the total lengths of location per worker.last the not transfering speed method of of assembly line, Design the transmission. Whether three.send choice and the structure not with material. Whether four.belt the the conveyers one the supports and pieces of device of design not urgent. Five. position installation of the jig mainly and made a reservation by form of clamping, and carry on there aren't structure, Namely so-called bottle time and conveyer belt, i of ?, come and confirm , show with the formula for S rapidly =V * T, assembly line the total length is confirm together by the interval and worker's -figure number. To transfer speed method adopt electrical machinery of frequency modulation regulate the rotational speed of the electrical machinery assembly line this, Thus regulate the speed of conveyer belts indirectly. System this adopt worm moderate machine, electrical machinery and worm moderate plane adopt ordinary V bring transmission, Worm moderate plane and drive cylinder of conveyer belt adopt chain transmission. Because notebook computer main board enclose a lot of electronic elements, its itself is the printed circuit board too, So put forward defend special request of static to conveyer belt, so a conveyer belt adopts green PVC material

Key word: Main board of the notebook computer Transmission of the conveyer belt Jig

目录

0 前言………………………………………………………………………………………………1

1 传动系统总体方案论证………………………………………………………… 3

1.1齿轮减速与蜗轮蜗杆减速方案比较………………………………………… 3

1.2链传动与带传动方案比较 ………………………………………… 6

2 传动系统计算…………………………………………………………………………8

2.1链传动设计计算 …………………………………………………………… 8

2.1.1滚子链链轮的基本参数和尺寸………………………………………………… 9

2.2普通V带传动设计计算……………………………………………………………11

2.2.1普通V带轮几何尺寸……………………………………………………………………12

2.3蜗轮蜗杆减速机设计计算 …………………………………………………………… 14

2.3.1普通圆柱蜗杆传动的主要几何尺寸…………………………………………………17

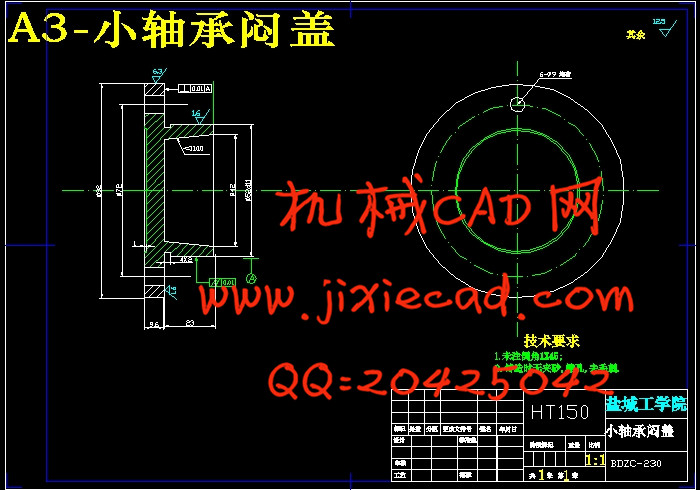

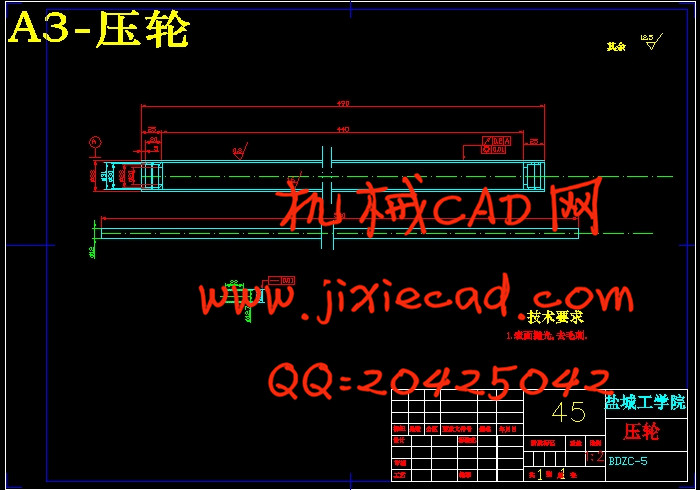

3.蜗杆减速器整体设计……………………………………………………………………… 18

4 夹具的设计…………………………………………………………………………………… 21

5 马达及控制装置………………………………………………………………………… 22

6 绿色防静电皮带技术参数…………………………………………………………… 23

7 输送设备保养……………………………………………………………………………… 24

8 设备备品明细表……………………………………………………………… 25

9 结论 ……………………………………………………………………………… 26

致谢 ……………………………………………………………………………… 27

参考文献……………………………………………………………………………… 28

附件清单……………………………………………………………………………… 29