设计简介

摘 要

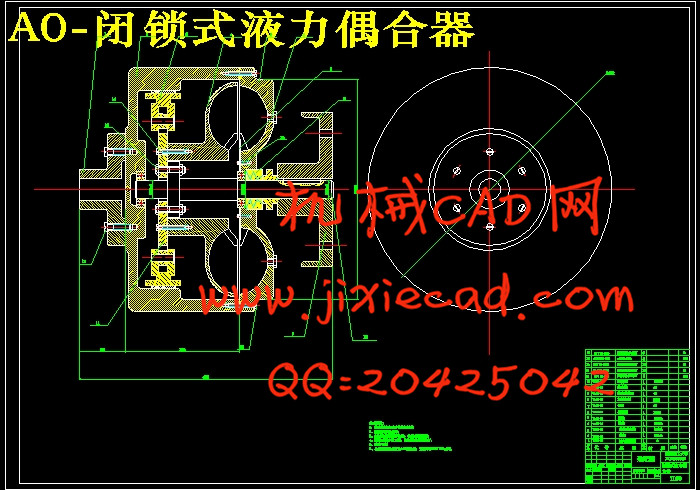

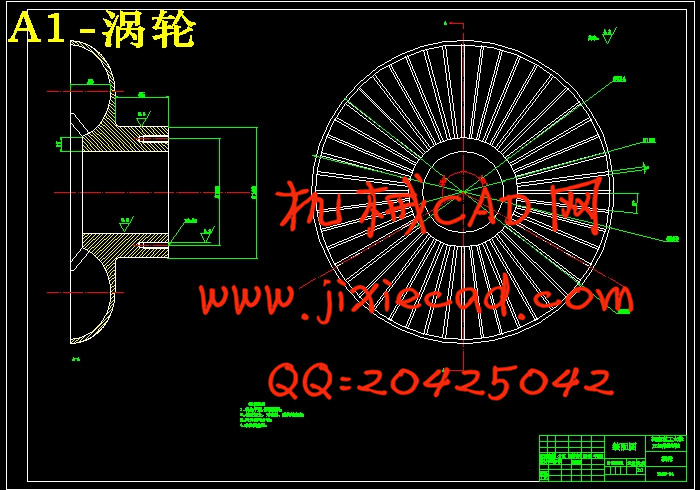

液力偶合器的实质是离心泵与涡轮机的组合,主要由输入轴、输出轴、泵轮、涡轮、外壳、辅室及安全保护装置等构成。目前对液力偶合器的设计有三种——研发类的全新型设计、相似设计和选型设计。工程中运用最多的是选型设计。本文试图在结合行业中液力偶合器的设计惯例,结合工作要求,进行选型设计和相似设计,并做重要部分的结构设计。

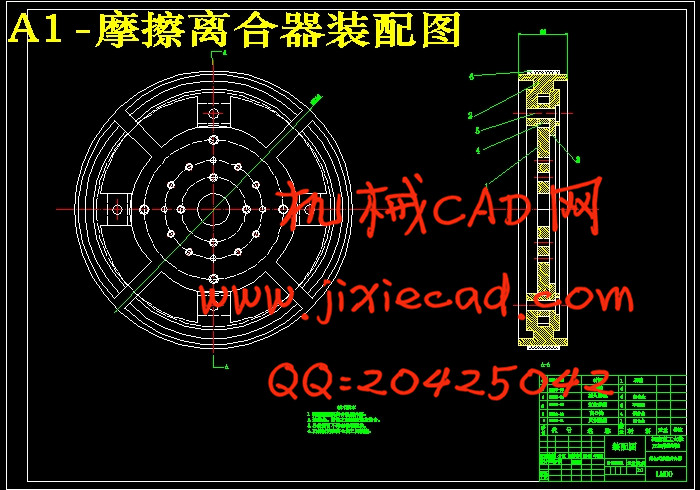

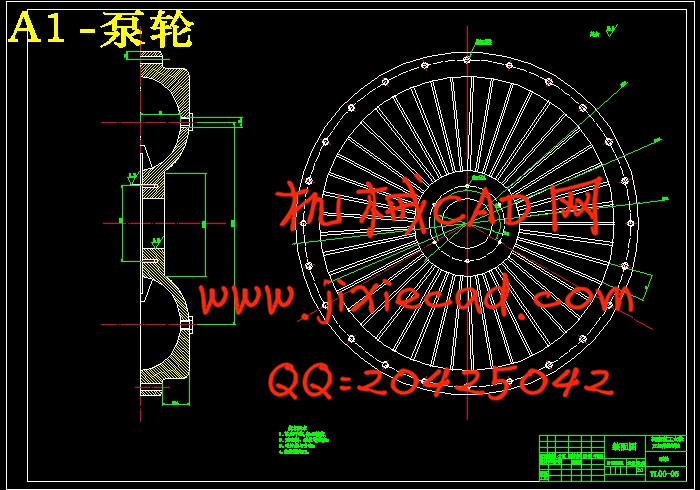

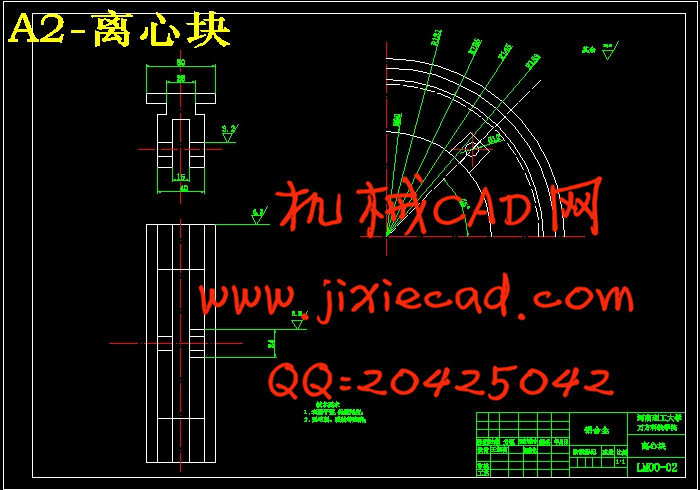

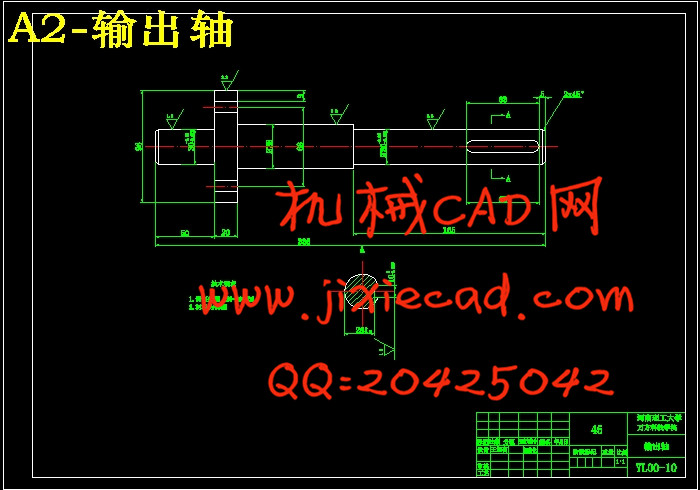

对输出轴孔和输入轴孔进行结构设计与校核,包括轴孔的强度校核和轴孔上的配合螺栓组强度校核。从各种液力偶合器的结构介绍中我们可以了解到,各种液力偶合器均需在转速差方面传递动力,转速差使输出转矩和功率均有损失,这是液力偶合器的内在缺陷。本次设计的闭锁式液力偶合器就可以有效地的弥补这方面的缺陷。闭锁式液力偶合器就是在限矩形液力偶合器上加装离心式摩擦离合器组成。本文也对输出轴孔的轴承进行了选择和校核。确定了泵轮和涡轮的厚度及合金材料成分。

关键词:液力偶合器 选型设计 相似设计 结构设计

ABSTRACT

Hydraulic coupling, in essence, is centrifugal pump and turbine combination. Enter from the main shaft, the output shaft, pumping round, turbine, shell, auxiliary rooms and pose a security device. Coupled with the current hydraulic design of the three-research and development of new types of design, similar to the design and type design. Engineering is the largest use of type design. This paper attempts to combine industry in the hydraulic coupling in the design practice, the combination of work requirements, selection and design of similar design, and to do important part of the structural design.

The output shaft hole and input shaft hole for structural design and verification, including the shaft hole and check the strength of the shaft with bolt holes on the group strength checking. From all kinds of hydraulic coupler introduced the structure, we can see that, all kinds of hydraulic coupler are to be in the rotation speed difference in power transmission, speed job torque and power are loss, this is hydraulic coupler inner defects. The design of the closure type hydraulic coupler can effectively to make up for the defect. Atresia type hydraulic coupler is limited in rectangular hydraulic coupler on centrifugal friction of the clutch.In this paper, check the option of the output shaft hole’s bearings. Determine the pump and turbine wheel of alloy material composition and thickness.

Key words: hydraulic coupler; Selection design; similar design, structure design

前 言

4.5.2 单位摩擦面积传递的转矩

4.5.3 单位压力

4.6.10 疲劳强度极限

致 谢

参考文献

液力偶合器的实质是离心泵与涡轮机的组合,主要由输入轴、输出轴、泵轮、涡轮、外壳、辅室及安全保护装置等构成。目前对液力偶合器的设计有三种——研发类的全新型设计、相似设计和选型设计。工程中运用最多的是选型设计。本文试图在结合行业中液力偶合器的设计惯例,结合工作要求,进行选型设计和相似设计,并做重要部分的结构设计。

对输出轴孔和输入轴孔进行结构设计与校核,包括轴孔的强度校核和轴孔上的配合螺栓组强度校核。从各种液力偶合器的结构介绍中我们可以了解到,各种液力偶合器均需在转速差方面传递动力,转速差使输出转矩和功率均有损失,这是液力偶合器的内在缺陷。本次设计的闭锁式液力偶合器就可以有效地的弥补这方面的缺陷。闭锁式液力偶合器就是在限矩形液力偶合器上加装离心式摩擦离合器组成。本文也对输出轴孔的轴承进行了选择和校核。确定了泵轮和涡轮的厚度及合金材料成分。

关键词:液力偶合器 选型设计 相似设计 结构设计

ABSTRACT

Hydraulic coupling, in essence, is centrifugal pump and turbine combination. Enter from the main shaft, the output shaft, pumping round, turbine, shell, auxiliary rooms and pose a security device. Coupled with the current hydraulic design of the three-research and development of new types of design, similar to the design and type design. Engineering is the largest use of type design. This paper attempts to combine industry in the hydraulic coupling in the design practice, the combination of work requirements, selection and design of similar design, and to do important part of the structural design.

The output shaft hole and input shaft hole for structural design and verification, including the shaft hole and check the strength of the shaft with bolt holes on the group strength checking. From all kinds of hydraulic coupler introduced the structure, we can see that, all kinds of hydraulic coupler are to be in the rotation speed difference in power transmission, speed job torque and power are loss, this is hydraulic coupler inner defects. The design of the closure type hydraulic coupler can effectively to make up for the defect. Atresia type hydraulic coupler is limited in rectangular hydraulic coupler on centrifugal friction of the clutch.In this paper, check the option of the output shaft hole’s bearings. Determine the pump and turbine wheel of alloy material composition and thickness.

Key words: hydraulic coupler; Selection design; similar design, structure design

前 言

1 液力偶合器的基础知识

1.1 传动机构及液力传动

1.2 液力传动的基本原理

1.3 液力传动的分类

2 液力偶合器的工作原理

3 闭锁式液力偶合器的结构

3.1 液力偶合器的分类

3.2 限矩型液力偶合器

3.2.1 静压泄液式液力偶合器

3.2.2 动压泄液式液力偶合器

3.2.3 复合泄液式液力偶合器

3.2.4 闭锁式液力偶合器

4 闭锁式液力偶合器的参数设计

4.1 设计原始参数及其分析

4.1.1 所传功率和转速

4.1.2 额定转速比与效率

4.2 工作腔型参数设计及其选择

4.2.1 液力偶合器有效直径D的确定

4.2.2 工作腔模型选择及设计4.2.3 轮叶设计

4.2.4 挡板的设计选择

4.3 轴的设计

4.3.1 轴上各轴段直径和长度的确定

4.3.2 强度校核

4.3.3 刚度校核

4.3.4 键的选择

4.3.5 轴承的选择

4.4.2 后备系数β

4.4.3 离合器传递的最大静摩擦力矩Tc

4.4.4 单位压力P0

4.5 离合器基本参数的校核

4.5.1 最大圆周速度

4.5.2 单位摩擦面积传递的转矩

4.5.3 单位压力

4.6 弹簧的设计

4.6.1 选择材料和确定许用应力

4.6.2 计算弹簧直径

4.6.3 弹簧圈直径

4.6.4 计算弹簧所需刚度

4.6.5 弹簧圈数和实际刚度

4.6.6 弹簧的初拉力4.6.7 弹簧的试验载荷

4.6.8 弹簧的试验载荷

4.6.9 特性校核4.6.10 疲劳强度极限

4.6.11 钩环的强度验算

4.6.12 结构参数4.7 连接盘的设计

4.8 滑块的设计

4.9 离合器片的结构尺寸确定

4.10 壳体设计和螺栓螺钉选择

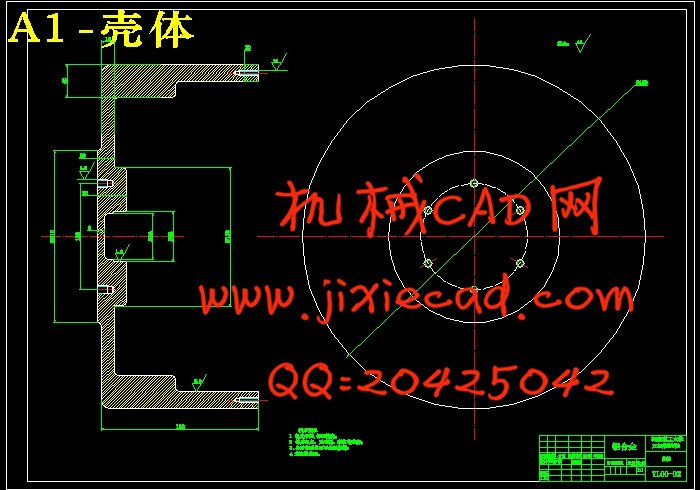

4.10.1 壳体设计

4.10.2 螺栓螺钉选择与强度计算

4.11 发热和散热计算

4.12 辅助系统

结束语致 谢

参考文献