设计简介

摘 要

纸张裁剪机是一种通用的设备,应用范围非常广泛,几乎每个印刷企业都要配置纸张裁剪机,纸张裁剪机在印刷机械产品中占重要的地位。随着社会的进步和科学的发展,造纸业、印刷业对纸张裁剪机提出了更高要求。该文针对国内纸张裁剪机只能单方向剪裁、只能剪裁固定尺寸纸张的缺陷,将横向剪裁与纵向剪裁分开,从纵向滚刀的安装方式和横刀的剪裁时间控制为突破口,设计了一种可以纵横双向剪裁、可以按照商家要求剪裁可变尺寸纸张的纸张裁剪机。用于从事商标、名片和各种印刷制品的剪裁工作。该纸张裁剪机结构简单、动作简洁快速,全套工作流程由PLC控制,具有剪裁质量高,生产效率高的优点。整个设计过程详细论证了其原理方案的可行性和机构的合理性,结构设计全用先进的CATIA软件造型、装配,真实地展示了整个系统的结构尺寸和工作原理。在设计过程中,通过对实际应用产品的设计,增强了对所学专业知识的掌握,提高了对设计思想理念的理解和实际运用能力,同时培养了自己独立完成设计任务的能力,认识到了严谨的工作态度对设计产品质量的重要作用。当然,在本设计中,仍然存在许多不完善的地方,在以后的设计中会加以借鉴,逐步改进。

关键词:变尺寸;双向剪裁;CATIA软件;纸张裁剪机

Abstract

Paper's cutting machine is a kind of general used equipments, its application is very extensive, almost each printing business enterprises have installed paper cutting machine, the paper cutting machine has an important position in printing machine product. Along with the progress of the society and the development of science, there will be a higher request to the paper in paper making industry and print. This text aim at the limitation that the local paper cutting machine can cut only one side and only fixed dimension, separating across cutting and vertical cutting, breaking from the installation of the vertical hob and the time control of the across hob .Design a kind of cutting machine which can cut from both across and vertical and can cut alterable size according to the request of the merchant. Used in the work of cutting label, business card and many kinds of presswork. The structure of this kind of cutting machine is very simple and its motion is prompt. The complete workflow is controlled by the PLC system, having the advantage of high quality of cutting and working with efficiency. The whole design process demonstrates the feasibility of this theory and the rationality of the institution. All of the structure design use the CATIA software to shape and assemble, displaying the size of the structure and work principle of the whole system really. During the design, through the design of the actual apply product, enhance the comprehension of specialty acknowledge and improve the comprehension and actual apply ability of the design idea. At the same time ,develop the ability of completing design mission oneself and understand the important effect of the religious working attitude to design the quality of the product .Certainly, there must be some places not perfect in this design .I will use them for reference in the later design to improve greatly.

Key words: Variation size; bidirectional cutting;

CATIA software; the paper cutting machine

目 录

摘 要 1

Abstract 2

第一章.前言 1

1.1 纸张裁剪机的简介 1

1.2 纸张裁剪机国内外情况介绍 1

1.2.1 国内情况 1

1.2.2 进口情况 2

1.3 纸张裁剪机市场前景 2

1.4 纸张裁剪机的发展趋势 3

第二章.可调尺寸纸张裁剪机原理方案的设计 4

2.1 现有纸张裁剪机的结构原理分析 4

2.1.1 模切机 4

2.1.2 直刃裁纸机 5

2.1.3 滚刀裁剪机 7

2.2 可调尺寸纸张裁剪机原理方案的设计 8

2.2.1 功能原理分析: 9

2.2.2 运动原理分析: 11

2.2.3 总结分析: 11

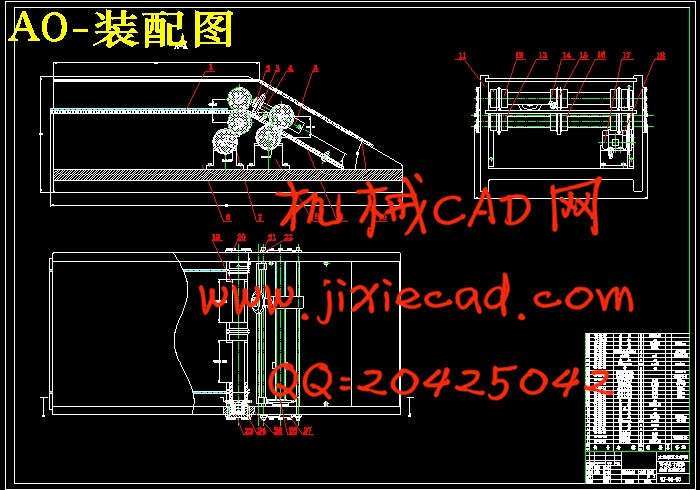

第三章.可调尺寸纸张裁剪机结构尺寸的设计 12

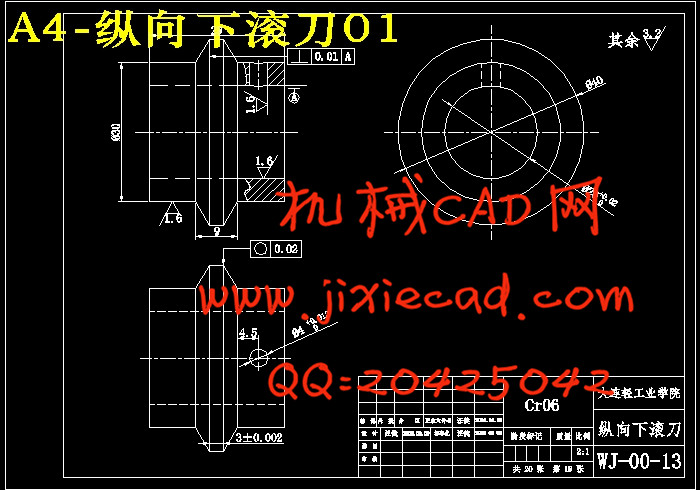

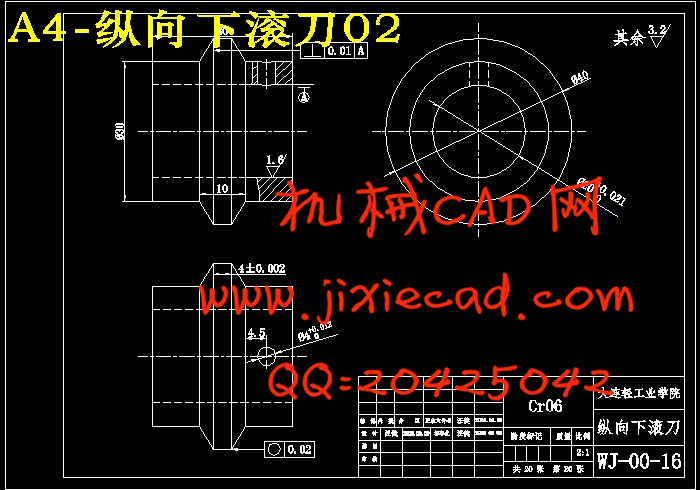

3.1 纵向裁纸机构设计 13

3.1.1 纵向裁纸刀的结构设计 13

3.1.2 纵向裁纸刀的安装设计 14

3.2 横向裁纸机构设计 15

3.2.1 横向裁纸刀的结构设计 15

3.2.2 横向裁纸刀的安装设计 17

3.3 控制装置、总体结构的设计 18

3.3.1 控制装置的设计 18

3.3.2 总体结构的设计 18

第四章.零部件设计 25

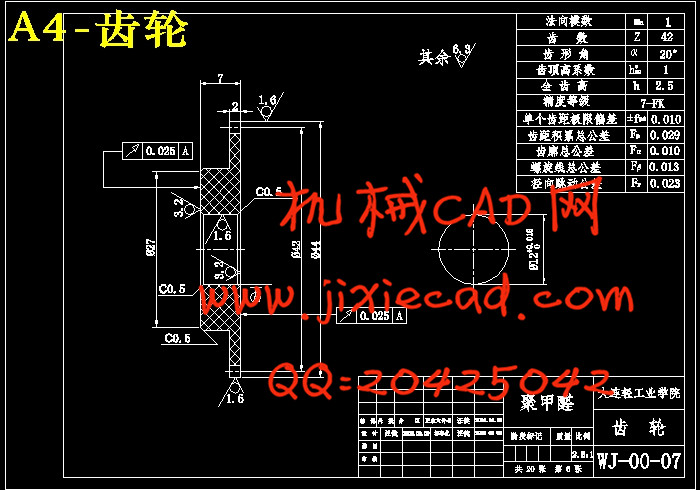

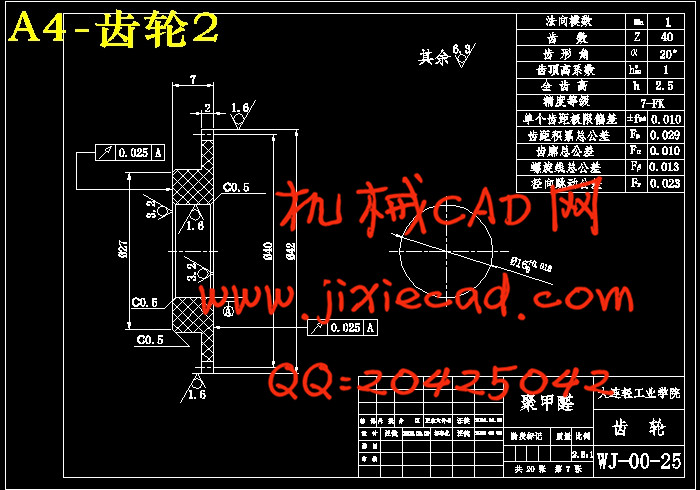

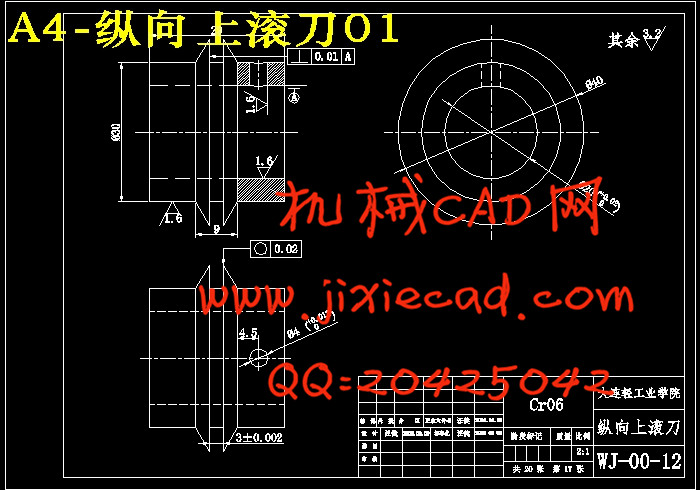

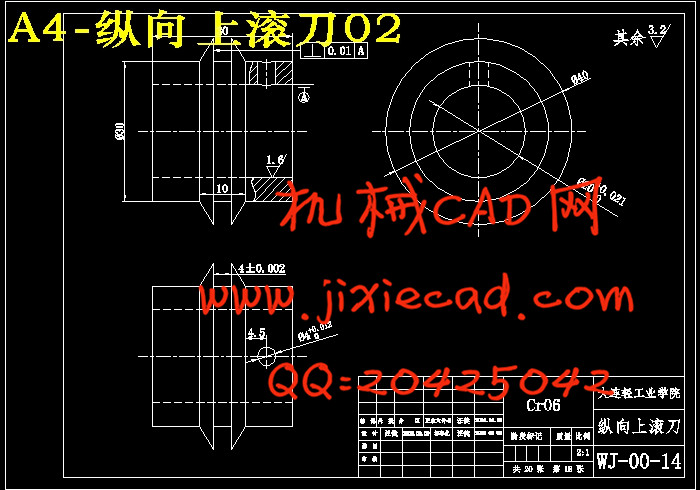

4.1 纵向裁纸机构零件尺寸的设计 25

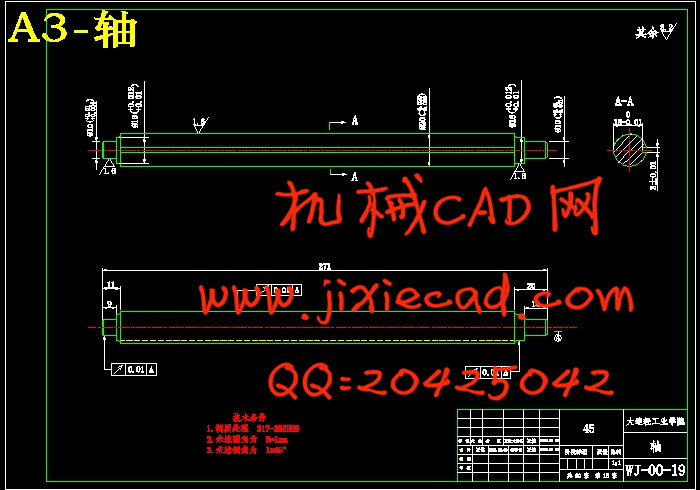

4.1.1 轴的设计 25

4.1.2 电动机功率选择: 27

4.1.3 刀具设计: 27

4.1.5 仪器仪表滚动轴承的选择 29

4.2 横向裁纸机构零件尺寸的设计 29

4.2.1 丝杠设计 29

4.2.2 光杠设计 31

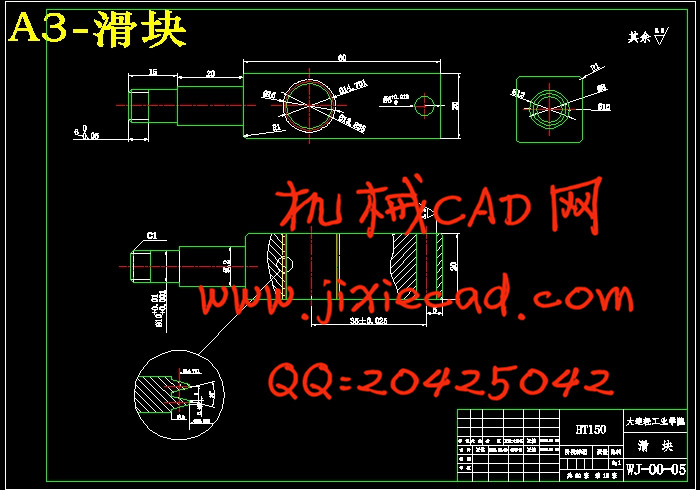

4.2.3 滑块的尺寸设计 31

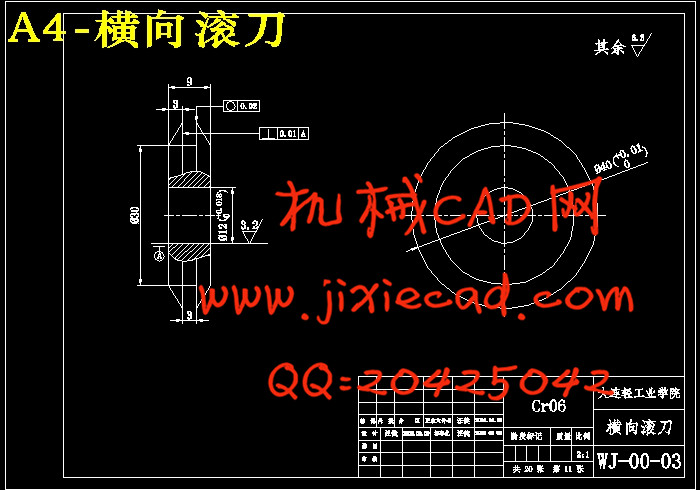

4.2.4 横向滚刀设计 32

4.2.5 滚动轴承的选择 33

4.3 控制装置、底板和外壳结构尺寸的设计 33

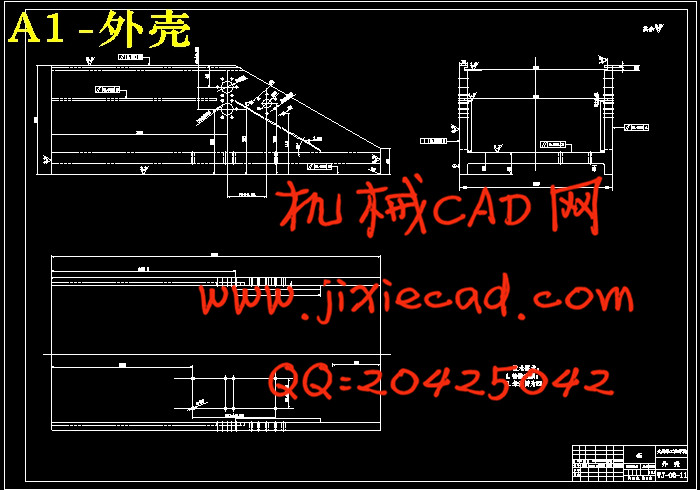

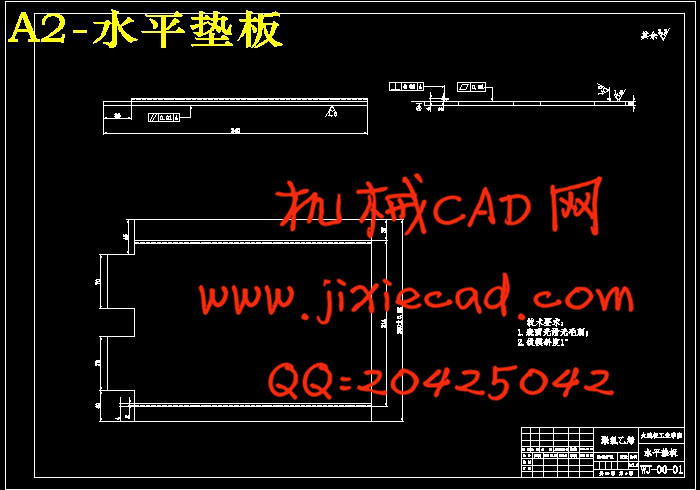

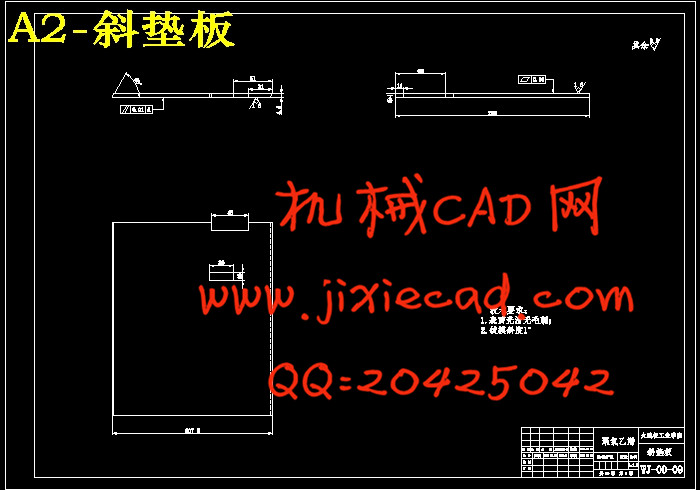

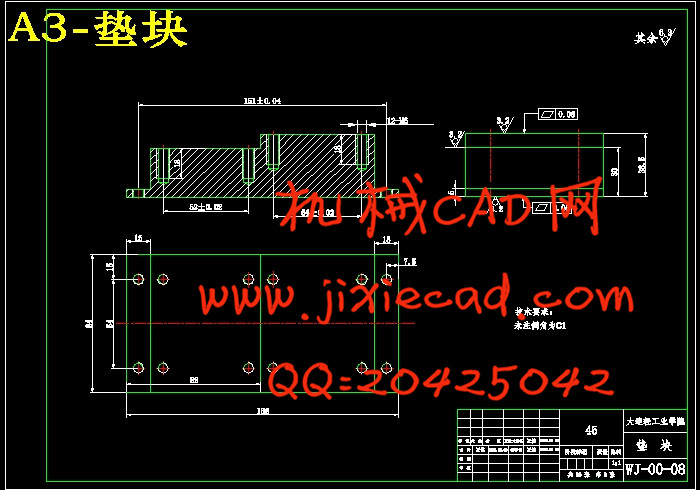

4.3.1外壳、垫板的设计 33

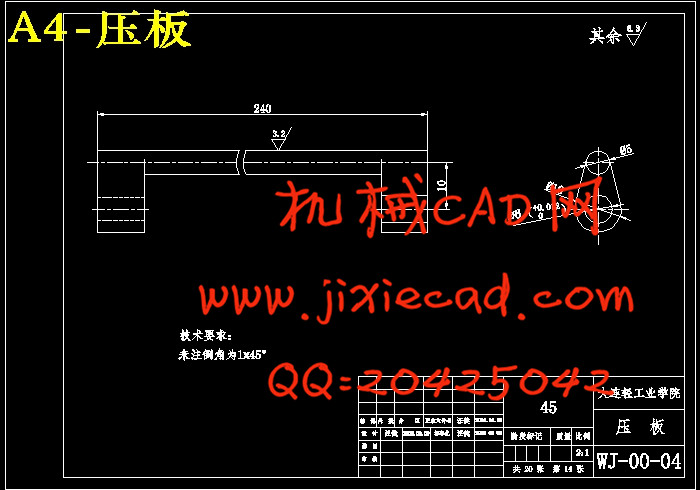

4.3.2 压板的设计 36

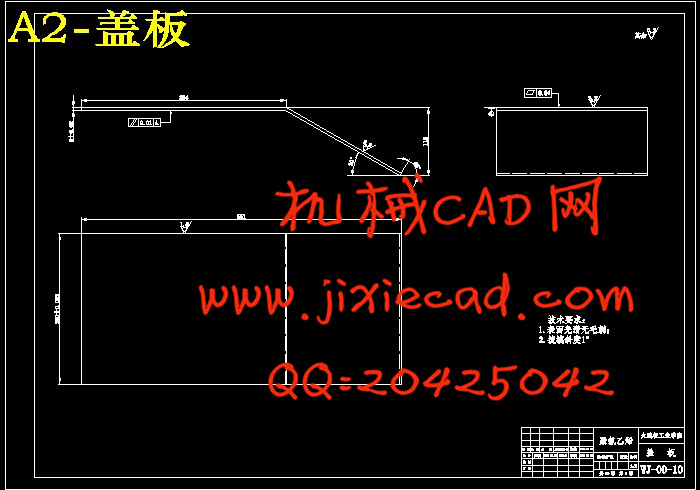

4.3.3 盖板的设计 36

第五章.其他38

5.1技术经济性分析.38

5.2结 论 38

参考文献 40

致 谢 41

纸张裁剪机是一种通用的设备,应用范围非常广泛,几乎每个印刷企业都要配置纸张裁剪机,纸张裁剪机在印刷机械产品中占重要的地位。随着社会的进步和科学的发展,造纸业、印刷业对纸张裁剪机提出了更高要求。该文针对国内纸张裁剪机只能单方向剪裁、只能剪裁固定尺寸纸张的缺陷,将横向剪裁与纵向剪裁分开,从纵向滚刀的安装方式和横刀的剪裁时间控制为突破口,设计了一种可以纵横双向剪裁、可以按照商家要求剪裁可变尺寸纸张的纸张裁剪机。用于从事商标、名片和各种印刷制品的剪裁工作。该纸张裁剪机结构简单、动作简洁快速,全套工作流程由PLC控制,具有剪裁质量高,生产效率高的优点。整个设计过程详细论证了其原理方案的可行性和机构的合理性,结构设计全用先进的CATIA软件造型、装配,真实地展示了整个系统的结构尺寸和工作原理。在设计过程中,通过对实际应用产品的设计,增强了对所学专业知识的掌握,提高了对设计思想理念的理解和实际运用能力,同时培养了自己独立完成设计任务的能力,认识到了严谨的工作态度对设计产品质量的重要作用。当然,在本设计中,仍然存在许多不完善的地方,在以后的设计中会加以借鉴,逐步改进。

关键词:变尺寸;双向剪裁;CATIA软件;纸张裁剪机

Abstract

Paper's cutting machine is a kind of general used equipments, its application is very extensive, almost each printing business enterprises have installed paper cutting machine, the paper cutting machine has an important position in printing machine product. Along with the progress of the society and the development of science, there will be a higher request to the paper in paper making industry and print. This text aim at the limitation that the local paper cutting machine can cut only one side and only fixed dimension, separating across cutting and vertical cutting, breaking from the installation of the vertical hob and the time control of the across hob .Design a kind of cutting machine which can cut from both across and vertical and can cut alterable size according to the request of the merchant. Used in the work of cutting label, business card and many kinds of presswork. The structure of this kind of cutting machine is very simple and its motion is prompt. The complete workflow is controlled by the PLC system, having the advantage of high quality of cutting and working with efficiency. The whole design process demonstrates the feasibility of this theory and the rationality of the institution. All of the structure design use the CATIA software to shape and assemble, displaying the size of the structure and work principle of the whole system really. During the design, through the design of the actual apply product, enhance the comprehension of specialty acknowledge and improve the comprehension and actual apply ability of the design idea. At the same time ,develop the ability of completing design mission oneself and understand the important effect of the religious working attitude to design the quality of the product .Certainly, there must be some places not perfect in this design .I will use them for reference in the later design to improve greatly.

Key words: Variation size; bidirectional cutting;

CATIA software; the paper cutting machine

目 录

摘 要 1

Abstract 2

第一章.前言 1

1.1 纸张裁剪机的简介 1

1.2 纸张裁剪机国内外情况介绍 1

1.2.1 国内情况 1

1.2.2 进口情况 2

1.3 纸张裁剪机市场前景 2

1.4 纸张裁剪机的发展趋势 3

第二章.可调尺寸纸张裁剪机原理方案的设计 4

2.1 现有纸张裁剪机的结构原理分析 4

2.1.1 模切机 4

2.1.2 直刃裁纸机 5

2.1.3 滚刀裁剪机 7

2.2 可调尺寸纸张裁剪机原理方案的设计 8

2.2.1 功能原理分析: 9

2.2.2 运动原理分析: 11

2.2.3 总结分析: 11

第三章.可调尺寸纸张裁剪机结构尺寸的设计 12

3.1 纵向裁纸机构设计 13

3.1.1 纵向裁纸刀的结构设计 13

3.1.2 纵向裁纸刀的安装设计 14

3.2 横向裁纸机构设计 15

3.2.1 横向裁纸刀的结构设计 15

3.2.2 横向裁纸刀的安装设计 17

3.3 控制装置、总体结构的设计 18

3.3.1 控制装置的设计 18

3.3.2 总体结构的设计 18

第四章.零部件设计 25

4.1 纵向裁纸机构零件尺寸的设计 25

4.1.1 轴的设计 25

4.1.2 电动机功率选择: 27

4.1.3 刀具设计: 27

4.1.5 仪器仪表滚动轴承的选择 29

4.2 横向裁纸机构零件尺寸的设计 29

4.2.1 丝杠设计 29

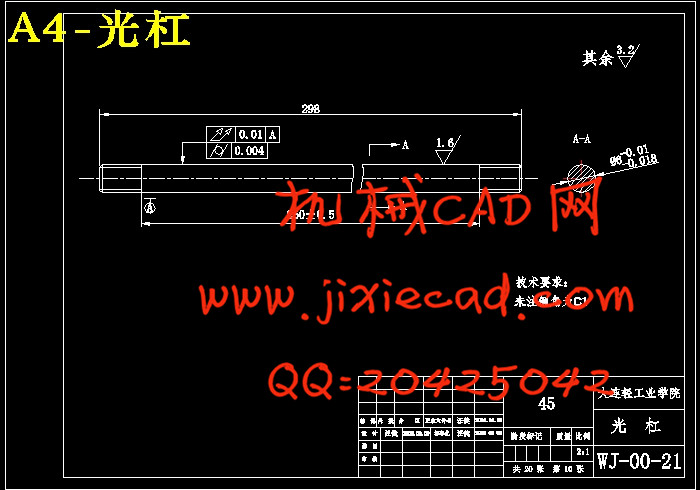

4.2.2 光杠设计 31

4.2.3 滑块的尺寸设计 31

4.2.4 横向滚刀设计 32

4.2.5 滚动轴承的选择 33

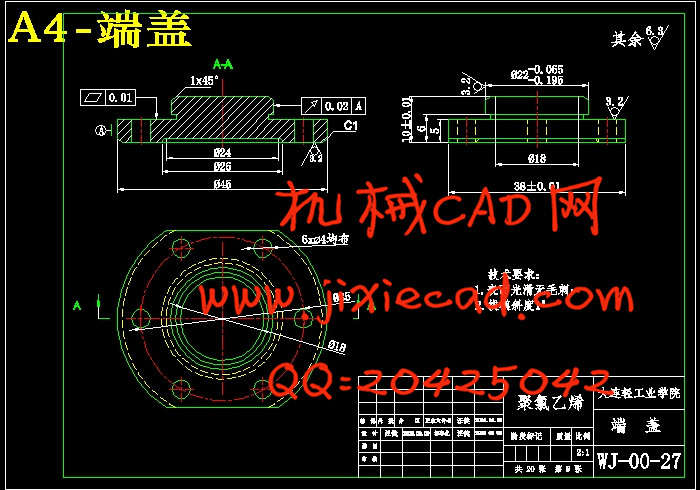

4.3 控制装置、底板和外壳结构尺寸的设计 33

4.3.1外壳、垫板的设计 33

4.3.2 压板的设计 36

4.3.3 盖板的设计 36

第五章.其他38

5.1技术经济性分析.38

5.2结 论 38

参考文献 40

致 谢 41