设计简介

摘要

本文简要介绍了PLC,变频器和人机界面的特点及其在国内外的发展状况,并介绍了PLC和变频器通讯的概念。

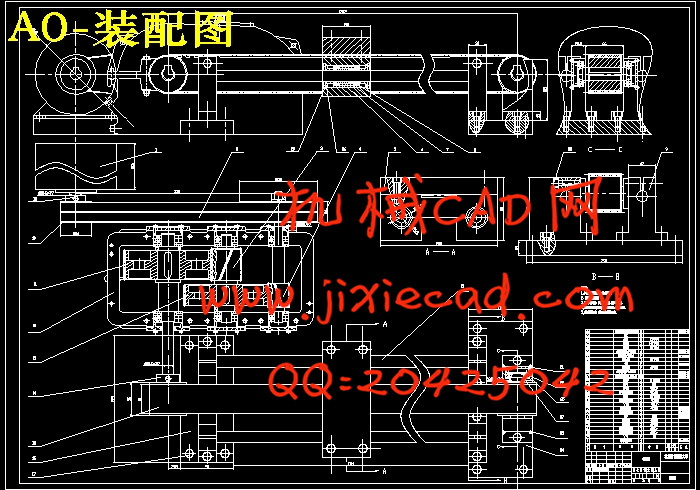

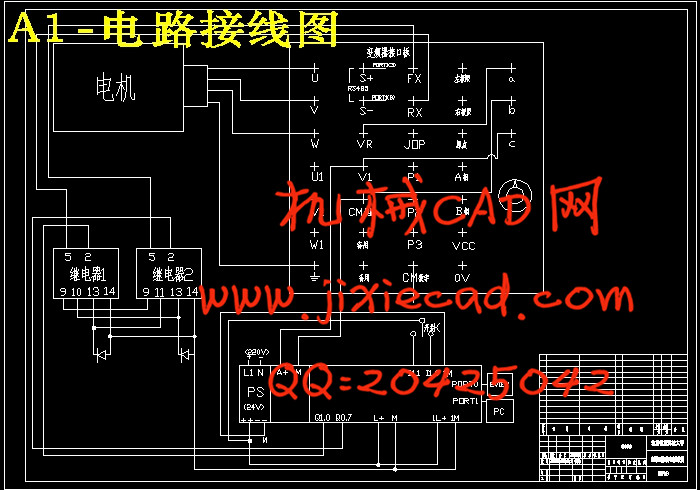

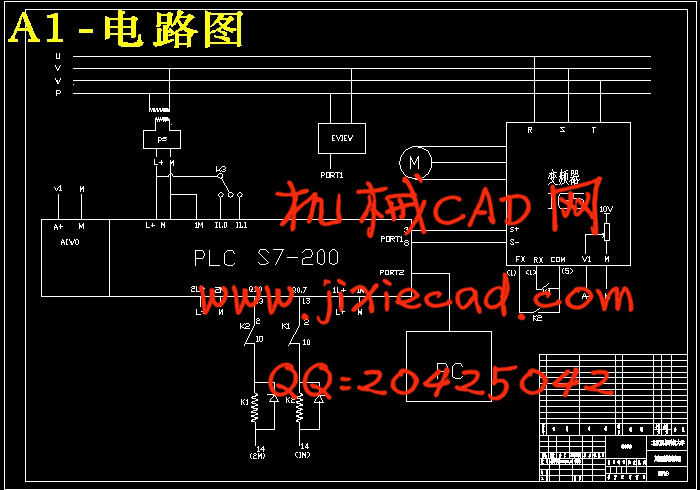

本文对变频试验台直线运动结构,以及基于S7-200速度示教系统进行了总体方案的设计,并对其进行了分布方案的划分,设计出了整体机械控制台,并绘制出了电路原理图和机械设计图。在这基础上计算编写出了变频器的通讯协议,设置了PLC的自由口方式通讯,整体上控制了电机的起停,正反转等。

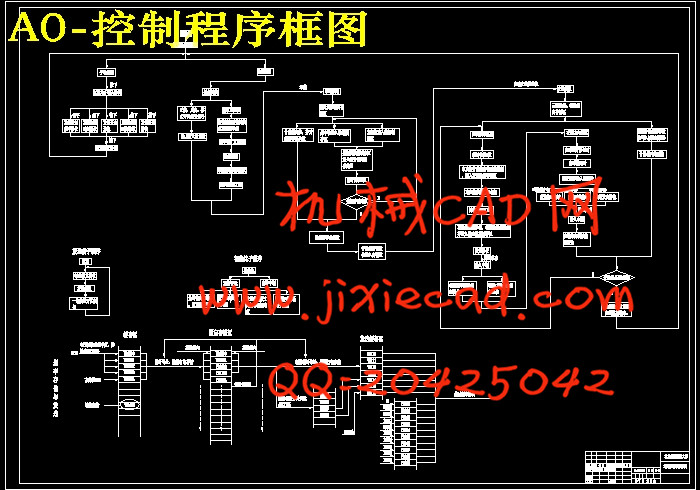

由于模拟操作在工程上应用越来越广,本文设计出了通过可编程控制器,即PLC对变频器的实时数据存储,并将其发送出去的程序,实现了PLC对手控操作变频器的模拟。并绘制出了程序框图。

关键词:可编程控制器(plc),变频器,通讯,协议,模拟

Abstract

This paper introduces the characteristics and the development of the situation at home and abroad of the PLC, converter and man-machine interface,and introduces the concept of Communication between the plc and converter.

In this paper, line motion agencies of the converter’s test-bed,and the teaching design of rate based on the S7-200 systems have been designed for overall programme,and the the distribution of its programme have been divised.And then, the overall design of the machine’ test-bed have been designde too,the map of the circuit’s methed,and the mechanical’s design have been drawed. On the basis of these,the communication’s agreements of the converter have been calculated and writed. And the way of the plc’s communication with the freedom port has been set up.For these,the running,stoping and the direction of the motor have been controled.

Because of the simulated operation have applied more and more widely on the project,the programming of controller have been designed to store the data of the converter on the real-time ,and send the data out in this paper. On the basis of these,the contorling of people to converter have simulated by plc,and the map of the Procedures have been drawed.

Key words: PLC, inverter, communication, agreement, simulation

目 录

中文文摘

Abstract

第一章 绪论 1

1.1 变频器的概述 1

1.2 可编程控制器PLC的概述 2

1.3 可编程控制器和变频器通讯的概述 2

1.4 人机界面的概述 3

第二章 方案设计与准备工作 4

2.1 设计准备及方案设计 4

2.2 电路的设计 5

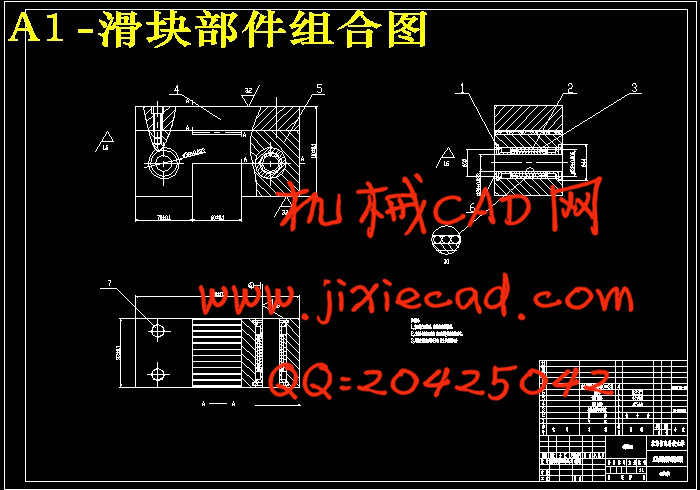

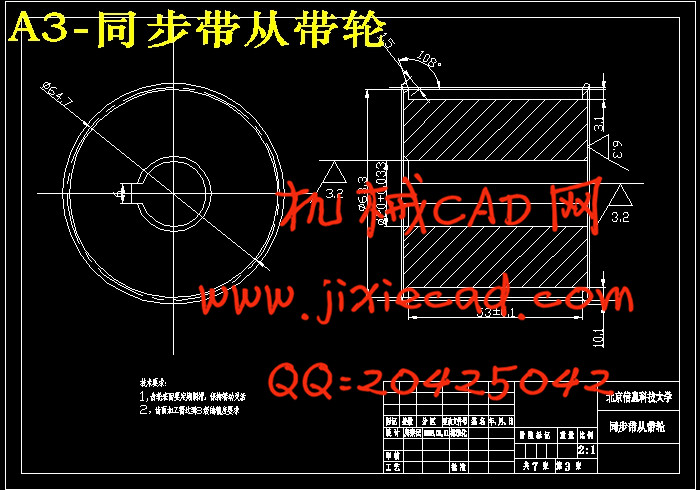

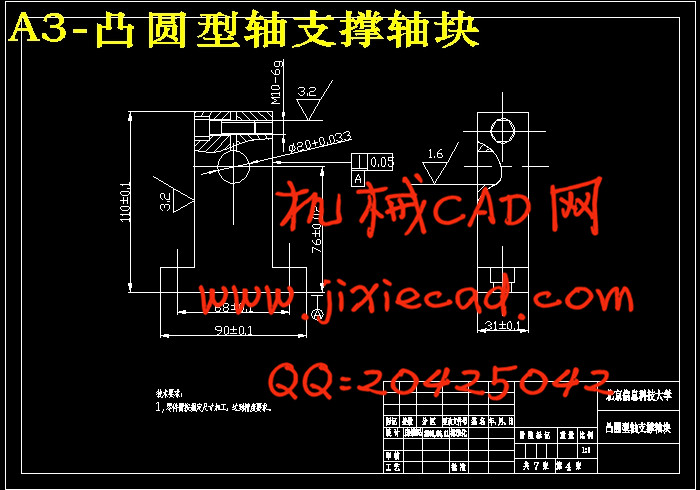

2.3 机械部分的设计 6

第三章 通讯协议的编写与计算 12

3.1 变频器的参数设置 12

3.2 变频器调频调速 13

3.3 变频器外部电压控制调速 13

3.4 协议的撰写 13

第四章 可编程控制器的编程及通讯 20

4.1 可编程控制器plc编程对变频器的控制 20

4.2 可编程控制器对变频器的数据的实时存储 22

4.3 存储数据的管理 23

4.4 数据的取出 25

4.5 存储数据的发送 26

4.6 人机界面控制设计 28

结束语 29

参考文献 30

本文简要介绍了PLC,变频器和人机界面的特点及其在国内外的发展状况,并介绍了PLC和变频器通讯的概念。

本文对变频试验台直线运动结构,以及基于S7-200速度示教系统进行了总体方案的设计,并对其进行了分布方案的划分,设计出了整体机械控制台,并绘制出了电路原理图和机械设计图。在这基础上计算编写出了变频器的通讯协议,设置了PLC的自由口方式通讯,整体上控制了电机的起停,正反转等。

由于模拟操作在工程上应用越来越广,本文设计出了通过可编程控制器,即PLC对变频器的实时数据存储,并将其发送出去的程序,实现了PLC对手控操作变频器的模拟。并绘制出了程序框图。

关键词:可编程控制器(plc),变频器,通讯,协议,模拟

Abstract

This paper introduces the characteristics and the development of the situation at home and abroad of the PLC, converter and man-machine interface,and introduces the concept of Communication between the plc and converter.

In this paper, line motion agencies of the converter’s test-bed,and the teaching design of rate based on the S7-200 systems have been designed for overall programme,and the the distribution of its programme have been divised.And then, the overall design of the machine’ test-bed have been designde too,the map of the circuit’s methed,and the mechanical’s design have been drawed. On the basis of these,the communication’s agreements of the converter have been calculated and writed. And the way of the plc’s communication with the freedom port has been set up.For these,the running,stoping and the direction of the motor have been controled.

Because of the simulated operation have applied more and more widely on the project,the programming of controller have been designed to store the data of the converter on the real-time ,and send the data out in this paper. On the basis of these,the contorling of people to converter have simulated by plc,and the map of the Procedures have been drawed.

Key words: PLC, inverter, communication, agreement, simulation

目 录

中文文摘

Abstract

第一章 绪论 1

1.1 变频器的概述 1

1.2 可编程控制器PLC的概述 2

1.3 可编程控制器和变频器通讯的概述 2

1.4 人机界面的概述 3

第二章 方案设计与准备工作 4

2.1 设计准备及方案设计 4

2.2 电路的设计 5

2.3 机械部分的设计 6

第三章 通讯协议的编写与计算 12

3.1 变频器的参数设置 12

3.2 变频器调频调速 13

3.3 变频器外部电压控制调速 13

3.4 协议的撰写 13

第四章 可编程控制器的编程及通讯 20

4.1 可编程控制器plc编程对变频器的控制 20

4.2 可编程控制器对变频器的数据的实时存储 22

4.3 存储数据的管理 23

4.4 数据的取出 25

4.5 存储数据的发送 26

4.6 人机界面控制设计 28

结束语 29

参考文献 30