设计简介

摘要:喂料器是用于向管道内均匀添加物料的设备,它在粮食加工行业、饲料工业中广泛应用。它主要用于输送原料,同时能清除原料中的铁性杂质,以保证机器设备的正常运行,延长设备使用寿命。因此,设计制造不易堵塞,输送量可在一定范围内调整的磁性皮带喂料器,在粮食加工,饲料生产等行业中有着重要的意义。

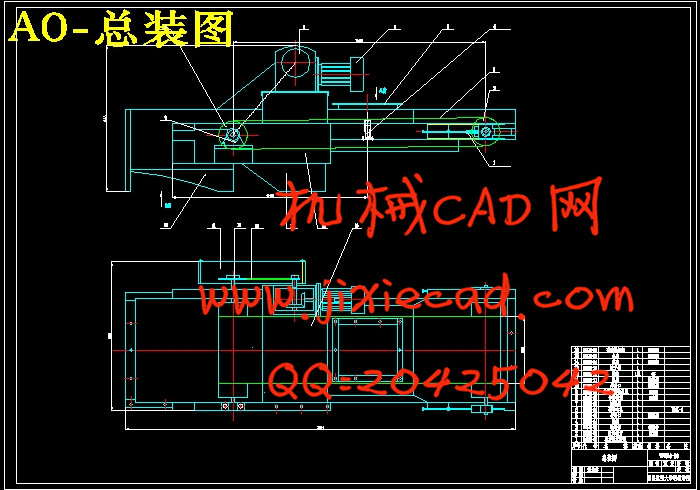

变频调速磁性皮带喂料器是在带式输送机为基础上,配上可进行磁选的永磁滚筒和可调速的变频器改造而成的。带式输送机是一种摩擦驱动以连续方式运输物料的机械。它既可以进行碎散物料的输送,也可以进行成件物品的输送。除进行纯粹的物料输送外,还可以与各工业企业生产流程中的工艺过程的要求相配合,形成有节奏的流水作业运输线。而永磁滚筒则是在传统的传动滚筒上进行改造的,使其具有磁选的功能。其中变频器是应用变频技术与微电子技术,通过改变电机工作电源频率方式来控制交流电动机转速的电力控制设备。

该喂料器的特点是能够变频调速和磁选。喂料器设计主要分为两步,第一步简单介绍了带式输送机的一些主要零部件,并对该喂料器的零部件进行了设计和计算;第二步对该喂料器进行了总体设计,其中有永磁滚筒的设计,并且对变频调速系统进行了设计。

关键字:变频调速 磁性皮带 喂料器 带式输送机

Abstract:. The feeder is the equipment used to add material into the pipeline evenly. It’s widely used in the food processing industry and feed industry . It’s mainly used to transport raw material. And it can remove impurities of metal in the material in order to ensure the normal operation of the machine equipment, prolonging the service life of equipment. Therefore, it’s significative to design and manufacture the magnetic belt feeder of not easy jamming and throughputing in a certain area of adjustment for the food processing, feed production, and other industries.

The frequency conversion magnetic belt feeder is based in the belt conveyor, matched up with the permanent magnetic cylinder that can separate the metal and the speed of the converted frequency converter. Belt conveyor is a mechane of transferring material in a way of friction drive. It can convey not only the broken material but also pieces of items. Besides the material conveying, it still can be fitted with the requirement of the crafting process in the process flow of industrial enterprise production, to form the rhythmic transport Line of flow operation.. The permanent magnet roller is changed in the base of traditional transmission roller to make it have the function of the magnetic separation. And the inverter is applied with the technology of frequency conversion and microelectronics technology.It’s the equipment to control the speed of the alternating-current motor by changing the working frequency of the motor power.

The feeder is characteristic of changing the speed by changing the frequency and magnetic separation.The design of feeder are divided into two parts. Firstly, some main components of the belt conveyor is introduced simply , and the parts of the feeder were designed and calculated. Then the whole design of the feeder is done, including the design of permanent magnet roller and the system of frequency conversion and speed governing.

keyword: Frequency conversion and speed governing Magnetic belt Feeder Belt conveyor

目 录

序 言 3

1 带式输送机的介绍 4

1.1 带式输送机的概述 4

1.1.1带式输送机的工作原理 4

1.1.2带式输送机的特点 4

1.1.3带式输送机的种类 5

1.1.4带式输送机的应用 6

1.1.5通用带式输送机的结构组成 7

1.2 部件的介绍及选用 9

1.2.1输送带 9

1.2.2驱动装置 12

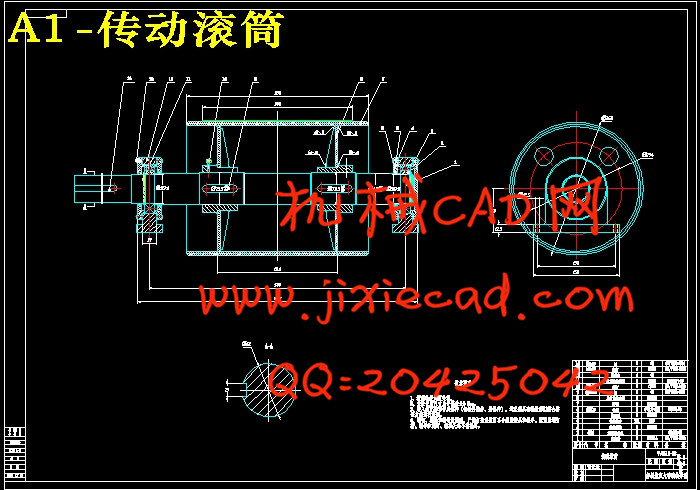

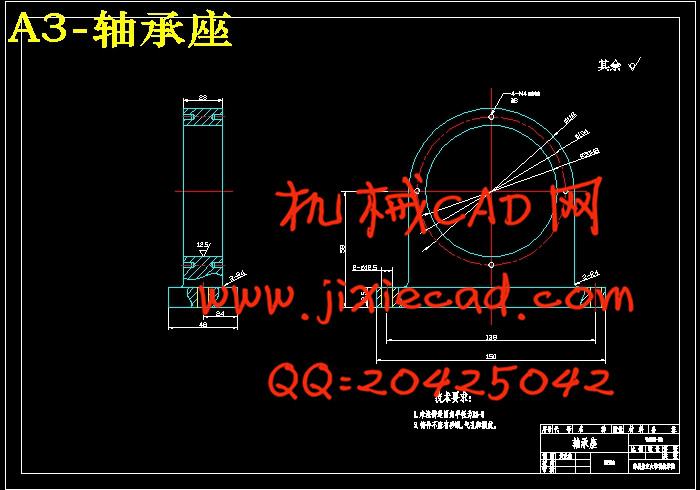

1.2.3传动滚筒及改向滚筒 13

1.2.4托辊 14

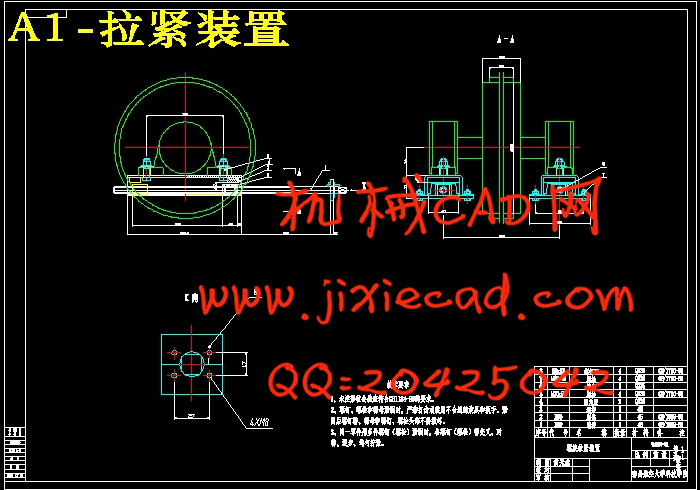

1.2.5拉紧装置 17

2 喂料器的总体设计 18

2.1 喂料器的介绍 18

2.2 喂料器永磁滚筒的确定 21

2.2.1湿式永磁滚筒式磁选机原理 21

2.2.2 永磁滚筒技术参数的确定 22

2.2.3喂料器减速器的选择 24

2.3 异步电动机变频调速 24

2.3.1喂料器对驱动装置的要求 24

2.3.2交流电动机变频调速 24

2.3.3异步电动机调速方式 25

2.3.4变频调速设计原理 26

2.4 喂料器的传动系统 26

3 变频调速磁性皮带喂料器主要部件及其设计计算 27

3.1 原始数据及设计技术要求 27

3.2 喂料器对输送带的要求 27

3.2.1对输送带的要求 27

3.2.2输送带设计需考虑的问题 28

3.3 输送带选择计算 28

3.3.1带宽 28

3.3.2每米胶带重 29

3.3.3输送带层数Z 29

3.3.4带长 29

3.4 输送能力的计算 30

3.4.1输送带上物料流横截面面积S的计算 30

3.4.2额定质量输送量 32

3.4.3额定体积输送量 32

3.5 滚筒组的选型与设计计算 32

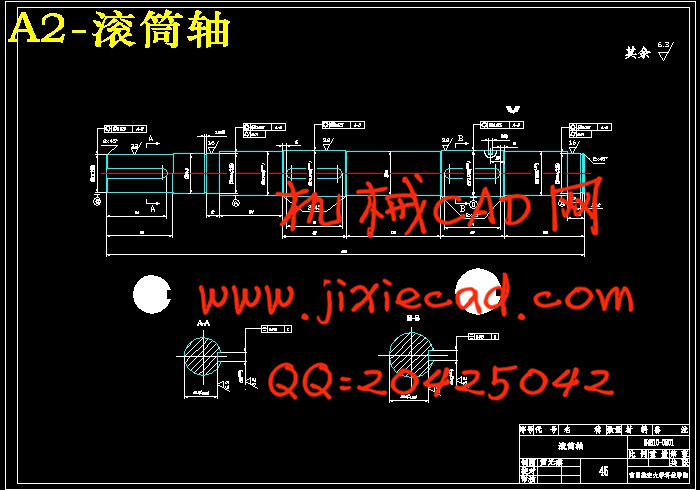

3.5.1传动滚筒轴的强度计算和校核 33

3.5.2传动滚筒轴承的寿命计算 34

3.6 圆周驱动力和传动功率计算 36

3.6.1圆周驱动力(N) Fu 36

3.6.2主要阻力F 36

36

3.6.3主要特征阻力 (N) 37

(N) 37

3.6.4附加特种阻力Fs与倾斜阻力Fst 38

3.6.5传动功率的计算及电动机型号选定 38

3.7 托辊的选用计算 38

3.7.1静载计算 38

3.7.2运载计算 39

3.8 拉紧装置的选择计算 39

3.8.1张紧力的确定 39

3.8.2拉紧行程的确定 40

3.8.3固定拉紧装置张紧力计算 40

3.9 张力计算 41

3.9.1限制输送带下垂度的最小张力: 41

3.9.2各特性点张力(N) 41

3.9.3输送带工作时不打滑需保持的最小张力 41

4 变频调速磁性皮带喂料器的机电保护装置 42

4.1 防止跑偏保护装置 42

4.2 带速检测保护装置 42

5 安全操作和维护保养 43

5.1 安全操作 43

5.2 维护保养 43

结 论 44

参考文献 45

致 谢 46

附录 47

变频调速磁性皮带喂料器是在带式输送机为基础上,配上可进行磁选的永磁滚筒和可调速的变频器改造而成的。带式输送机是一种摩擦驱动以连续方式运输物料的机械。它既可以进行碎散物料的输送,也可以进行成件物品的输送。除进行纯粹的物料输送外,还可以与各工业企业生产流程中的工艺过程的要求相配合,形成有节奏的流水作业运输线。而永磁滚筒则是在传统的传动滚筒上进行改造的,使其具有磁选的功能。其中变频器是应用变频技术与微电子技术,通过改变电机工作电源频率方式来控制交流电动机转速的电力控制设备。

该喂料器的特点是能够变频调速和磁选。喂料器设计主要分为两步,第一步简单介绍了带式输送机的一些主要零部件,并对该喂料器的零部件进行了设计和计算;第二步对该喂料器进行了总体设计,其中有永磁滚筒的设计,并且对变频调速系统进行了设计。

关键字:变频调速 磁性皮带 喂料器 带式输送机

Abstract:. The feeder is the equipment used to add material into the pipeline evenly. It’s widely used in the food processing industry and feed industry . It’s mainly used to transport raw material. And it can remove impurities of metal in the material in order to ensure the normal operation of the machine equipment, prolonging the service life of equipment. Therefore, it’s significative to design and manufacture the magnetic belt feeder of not easy jamming and throughputing in a certain area of adjustment for the food processing, feed production, and other industries.

The frequency conversion magnetic belt feeder is based in the belt conveyor, matched up with the permanent magnetic cylinder that can separate the metal and the speed of the converted frequency converter. Belt conveyor is a mechane of transferring material in a way of friction drive. It can convey not only the broken material but also pieces of items. Besides the material conveying, it still can be fitted with the requirement of the crafting process in the process flow of industrial enterprise production, to form the rhythmic transport Line of flow operation.. The permanent magnet roller is changed in the base of traditional transmission roller to make it have the function of the magnetic separation. And the inverter is applied with the technology of frequency conversion and microelectronics technology.It’s the equipment to control the speed of the alternating-current motor by changing the working frequency of the motor power.

The feeder is characteristic of changing the speed by changing the frequency and magnetic separation.The design of feeder are divided into two parts. Firstly, some main components of the belt conveyor is introduced simply , and the parts of the feeder were designed and calculated. Then the whole design of the feeder is done, including the design of permanent magnet roller and the system of frequency conversion and speed governing.

keyword: Frequency conversion and speed governing Magnetic belt Feeder Belt conveyor

目 录

序 言 3

1 带式输送机的介绍 4

1.1 带式输送机的概述 4

1.1.1带式输送机的工作原理 4

1.1.2带式输送机的特点 4

1.1.3带式输送机的种类 5

1.1.4带式输送机的应用 6

1.1.5通用带式输送机的结构组成 7

1.2 部件的介绍及选用 9

1.2.1输送带 9

1.2.2驱动装置 12

1.2.3传动滚筒及改向滚筒 13

1.2.4托辊 14

1.2.5拉紧装置 17

2 喂料器的总体设计 18

2.1 喂料器的介绍 18

2.2 喂料器永磁滚筒的确定 21

2.2.1湿式永磁滚筒式磁选机原理 21

2.2.2 永磁滚筒技术参数的确定 22

2.2.3喂料器减速器的选择 24

2.3 异步电动机变频调速 24

2.3.1喂料器对驱动装置的要求 24

2.3.2交流电动机变频调速 24

2.3.3异步电动机调速方式 25

2.3.4变频调速设计原理 26

2.4 喂料器的传动系统 26

3 变频调速磁性皮带喂料器主要部件及其设计计算 27

3.1 原始数据及设计技术要求 27

3.2 喂料器对输送带的要求 27

3.2.1对输送带的要求 27

3.2.2输送带设计需考虑的问题 28

3.3 输送带选择计算 28

3.3.1带宽 28

3.3.2每米胶带重 29

3.3.3输送带层数Z 29

3.3.4带长 29

3.4 输送能力的计算 30

3.4.1输送带上物料流横截面面积S的计算 30

3.4.2额定质量输送量 32

3.4.3额定体积输送量 32

3.5 滚筒组的选型与设计计算 32

3.5.1传动滚筒轴的强度计算和校核 33

3.5.2传动滚筒轴承的寿命计算 34

3.6 圆周驱动力和传动功率计算 36

3.6.1圆周驱动力(N) Fu 36

3.6.2主要阻力F

3.6.3主要特征阻力

3.6.4附加特种阻力Fs与倾斜阻力Fst 38

3.6.5传动功率的计算及电动机型号选定 38

3.7 托辊的选用计算 38

3.7.1静载计算 38

3.7.2运载计算 39

3.8 拉紧装置的选择计算 39

3.8.1张紧力的确定 39

3.8.2拉紧行程的确定 40

3.8.3固定拉紧装置张紧力计算 40

3.9 张力计算 41

3.9.1限制输送带下垂度的最小张力: 41

3.9.2各特性点张力(N) 41

3.9.3输送带工作时不打滑需保持的最小张力 41

4 变频调速磁性皮带喂料器的机电保护装置 42

4.1 防止跑偏保护装置 42

4.2 带速检测保护装置 42

5 安全操作和维护保养 43

5.1 安全操作 43

5.2 维护保养 43

结 论 44

参考文献 45

致 谢 46

附录 47