设计简介

冰刀研磨机设计

摘 要

冰上运动的发展对冰刀质量提出了更高的要求,可是冰刀的手工研磨自动化程度低,研磨质量和效率难以得到保证。在国内,本文首次将数控方法应用到冰刀研磨当中去。冰刀的数控研磨需满足设备便携、工艺简单、控制精确、研磨精度高等方面的要求。本文结合国家体育总局冬奥会攻关项目“便携式数控冰刀测量与研磨机的研制”,围绕上述要求进行了系统的深入研究,具体内容如下:

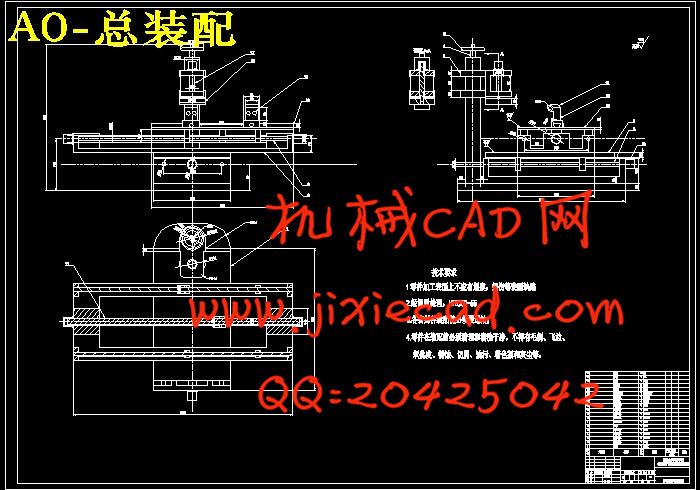

首先,冰刀数控研磨机的便携性主要体现在其设备本身的质量和体积上。本文针对影响冰刀研磨设备便携性的因素,提出了两点实现设备便携性的方法。确定了冰刀研磨机的总体布局和关键元部件的选取,冰刀采取立式,工作台采取卧式,尽量缩小设备的尺寸。PC 机通过打印机接口直接连接冰刀研磨设备,实现 PC 机直接数控,从而去掉了传统数控设备中的工控机,以满足冰刀研磨机便携性的要求。

其次,本文分析了影响冰刀加工质量的因素。结合这些因素,制定了冰刀研磨的加工工艺。冰刀采取粗磨、精磨、抛光磨三级研磨,控制系统根据研磨总量自动生成研磨工艺。研究设计了冰刀研磨的专用砂轮,同时根据砂轮的磨损机理,提出了砂轮修整方法。

最后,在基于华中开放数控平台的基础上,开发了冰刀研磨的系统控制软件。设计了冰刀研磨砂轮的特殊运动方式采用 CNC-PLC 模拟量单元的数据及信号处理环节,用变频器来实现对砂轮主轴电机的控制从而保证砂轮以恒定的线速度进行研磨加工。将面向对象编程技术应用到冰刀的数控编程中,使数控编程变得简单易懂。系统软件提供了友好的人机界面,使人机交互变得容易,更适合于运动员操作使用,同时,系统还提供了加工在线仿真功能,使研磨加工过程变得形象而具体。

关键词:冰刀 数控研磨机 便携式 砂轮修整 面向对象编程

Abstract

The development of ice-sports brings more demands to the quality of skates. Aiming at the disadvantages of skates hand-whetting which are poor quality, low automation and efficiency, skates numerical control whetting is proposed in this thesis. Combining with the project of “Development and Research of Portable Numerical Control Skates Muller” from National P.H general bureau, systemic research on the portability and precision and whetting process of skates is madden in this thesis.

Firstly, portability is a very important key demand of skates muller, it is mainly embodied in its equipment. After the analysis of effect factors of portability, two methods are put forward according to equipment portability. The general layout of skates muller and its key parts are brought out. Skates are equipped upright, workbench is mounted horizontally,shorten the size of equipment as possible as can. Through the self-made circuit board that connected with the print port, skates muller is treated as peripheral equipment and is controlled by PC directly. Special skates clamp is developed in order to ensure the fastness rigidity.

Secondly, the factors that influence the precision of skates, are analyzed. Based on these analyses and general amounts of skates, the process of whetting can be created automatically by control system. The whetting can be carved off three steps: rough whetting, accurate whetting, and polishing whetting. the researches on the grade whet of skates, the structure of grinding wheel are given. The adjustment method of grinding wheel is given based on the research of wear and tear mechanism.

Finally, on the basis of hardware system of HNC ( Numerical Control ), the control system of whetting of skates is brought out. the special motion of grinding wheel is proposed. Through CNC-PLC data and tache of signal disposals of simulation unit, principal axis AC motors is controlled by transducer. hence, the constant thread speed of grinding wheel combining with the principal axis motor is gained. the object-oriented programming is used in the muller’s control system, which provides the friendly interface that causes the alternations between machine and operator to become easier, and suits for athletes. And system also provides online simulation of machining process which makes the whetting process more visually.

Keywords: Skates NC muller Portable Adjustment of grinding wheel

Object-Oriented Programming

目 录

摘 要.............................................................................................................................1

ABSTRACT...................................................................................................................2 1绪论.............................................................................................................................3

1.1 研究的背景、目的和现实意义.............................................................................3

1.2 冰刀研磨技术概述.................................................................................................4

1.3 国内外研究状况.....................................................................................................6

1.4 主要内容.................................................................................................................6

2 冰刀研磨机总体结构...............................................................................................8

2.1 冰刀研磨机的主要指标.........................................................................................8

2.2 冰刀研磨机的基本要求........................................................................................8

2.3 冰刀研磨机总体布局............................................................................................8

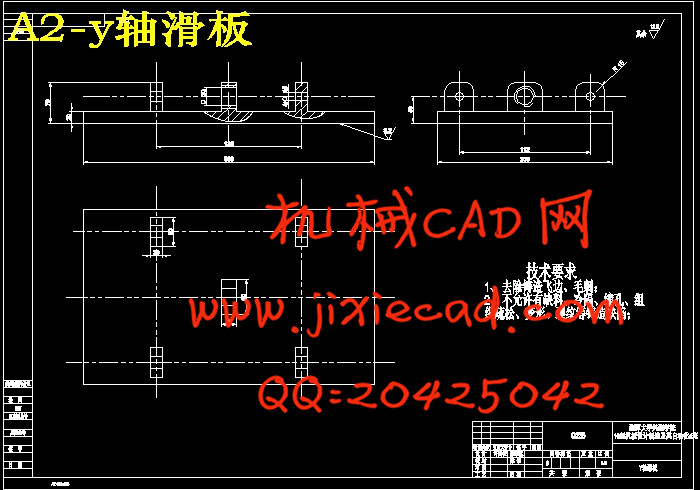

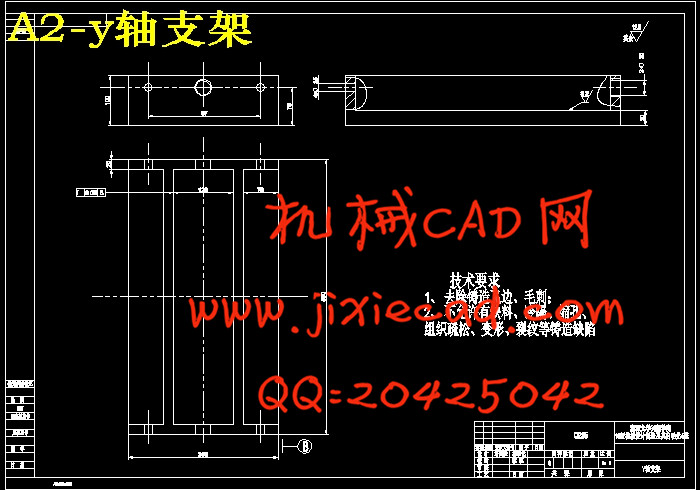

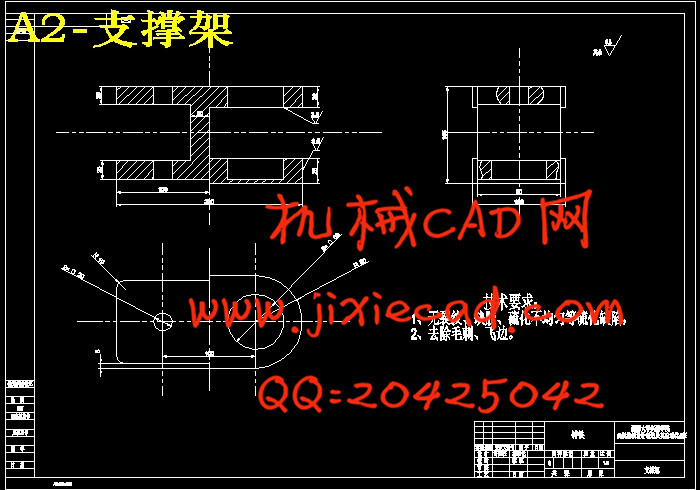

2.4 主要部件的设计和选择...................................................................................... 10

2.5 磨削力的计算 .....................................................................................................12

2.6 冰刀的裝夹技术.................................................................................................. 12

2.7 本章小结.............................................................................................................. 15

3 冰刀研磨的数控加工工艺.................................................................................... 16

3.1 数控研磨的特点.................................................................................................. 16

3.2 影响冰刀研磨质量的因素.................................................................................. 16

3.3 磨料的选择.......................................................................................................... 18

3.4 砂轮的结构........................................................................... ...............................19

3.5冰刀与砂轮位置关系............................................................................................19

3.6 砂轮的修整.......................................................................................................... 20

3.7 本章小结...............................................................................................................22

4 冰刀研磨机控制系统方案.....................................................................................23

4.1 系统的硬件结构.................................................................................................. 23

4.2 研磨的运动控制分析.......................................................................................... 23

4.3 砂轮恒线速度的控制.......................................................................................... 24

4.4本章小结................................................................................................................25

5 冰刀研磨机机械结构的几何建模.........................................................................26

5.1 SOLID Edge软件简介 .....................................................................................26

5.2 冰刀研磨机机械结构实体建模过程...................................................................26

5.3 本章小结 ............................................................................................................27

6 总结与展望............................................................................................................. 32

7 参考文献..................................................................................................................33