设计简介

摘要

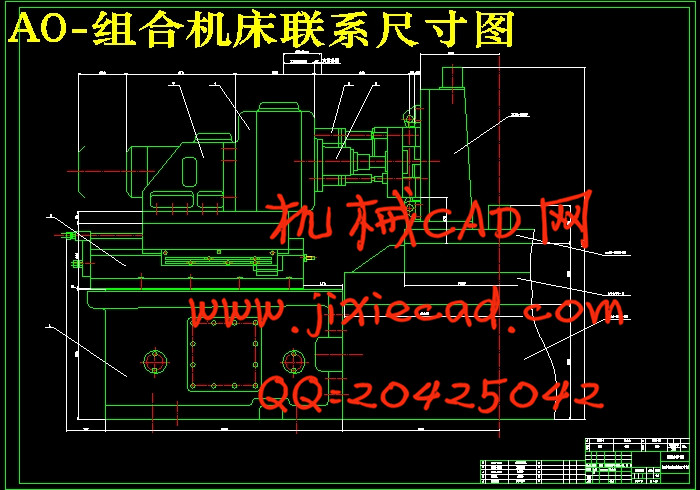

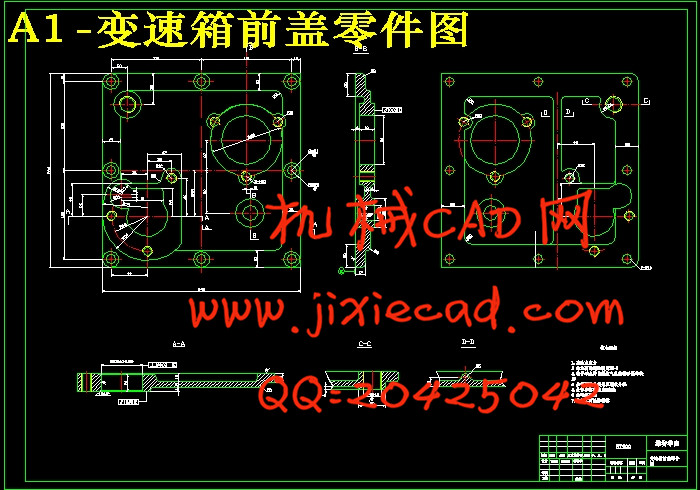

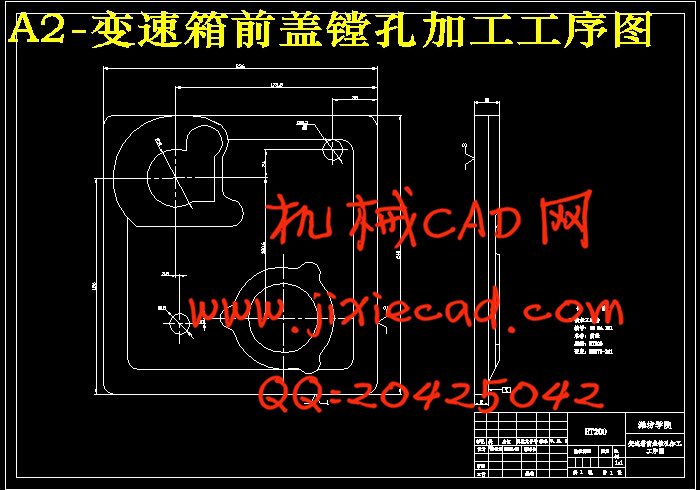

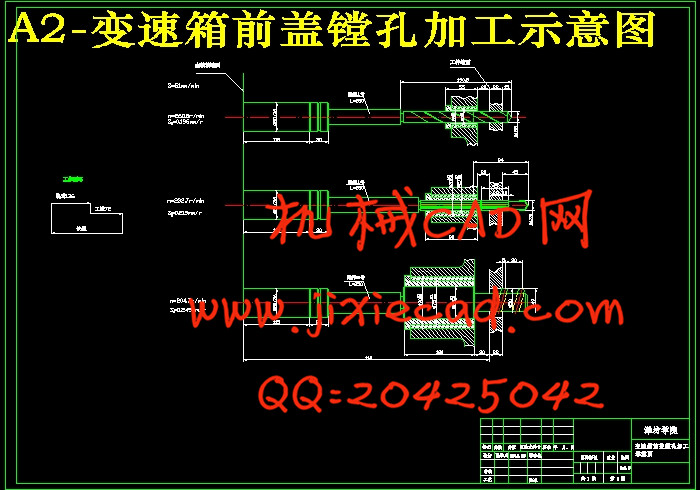

组合机床与传统的机床相比具有效率高、精度高、成本低等优点。组合机床是按高度集中的原则设计的。本设计设计说明书针对泰山-12拖拉机变速箱前端盖镗孔组合机床设计的设计进行说明。本次设计通过了解被加工零件的加工特点、精度和技术要求、定位夹紧情况、生产效率及机床的结构特点等,确定在组合机床上完成的工艺内容及加工方法即加工工艺,并绘制被加工零件工序图。通过查阅相关标准和计算,选择组合机床的通用部件,计算切削用量及机床生产率。最终确定机床各部件之间的相互关系,绘制机床的尺寸联系图、加工示意图和生产率计算卡。最后完成组合机床总体设计。理论计算数值标表明该设计能够满足实际生产的需要。关键词:组合机床设计 工序图 加工示意图 生产率计算卡

ABSTRACT

Transfer and unit machine is more efficient, more accurate and lower cost. Combination machine is designed according the fundamental, which highly centralized, or, more correctly. The topic of design is that the design of combination machine, which can boring the TaiShan-12 front gearbox. We,ve learned the characteristic of the part designed ,accuracy and specification ,locating and fixing ,productivity and machining structure by the practice .Then the technological operation and work order can be determined which can be finished in combination machine. We can referent some standard books to select general parts, compute cut feed and productivity. Finally we will determind the relationship of every part, draw a sketch map of the machine and productivity card. Finally we finish the design. The theoreticalCalculation of productivity indicates that the design can satisfy the production request.

Keywords: frame design; process diagram; processing schematic; productivity card

中文摘要 Ⅰ

英文摘要 Ⅱ

前言 1

第1章 组合机床概述 2

1.1 组合机床的概述 2

1.2 组合机床的技术发展趋势 3

第2章 组合机床工艺方案的制定 4

2.1零件的工艺分析 4

2.2组合机床切削用量的选择 5

2.3组合机床配置形式的选择 6

第3章 组合机床的总体设计 6

3.1被加工零件工序图 6

3.2 加工示意图 7

3.3 动力部件的选择 9

3.4 组合机床生产率的计算 11

3.5 机床联系尺寸图的绘制 14

3.5.1 机床装料高度的确定 14

3.5.2 夹具轮廓尺寸的确定 14

3.5.3 侧底座轮廓尺寸的确定 14

3.5.4 主轴箱轮廓尺寸的确定 14

结束语 17

参考文献 18

致谢 19