设计简介

摘要

组合机床是以通用部件为基础,配以工件特定外形和加工工艺设计的专用部件和夹具组成的半自动或自动专用机床。它一般采用多轴、多刀、多工序、多面或多工位同时加工的方式,生产效率比通用机床高几倍至几十倍。组合机床兼有低成本和高效率的优点,在大批量生产中得到广泛应用,并可用以组成自动生产线。

本课题针对变速箱壳体端面上锪孔这一特定工序而设计的一台专用卧式组合机床。本组合机床效率高、成本低、加工精度高和操作使用方便,同时减轻了工人的劳动强度,提高了劳动生产率。

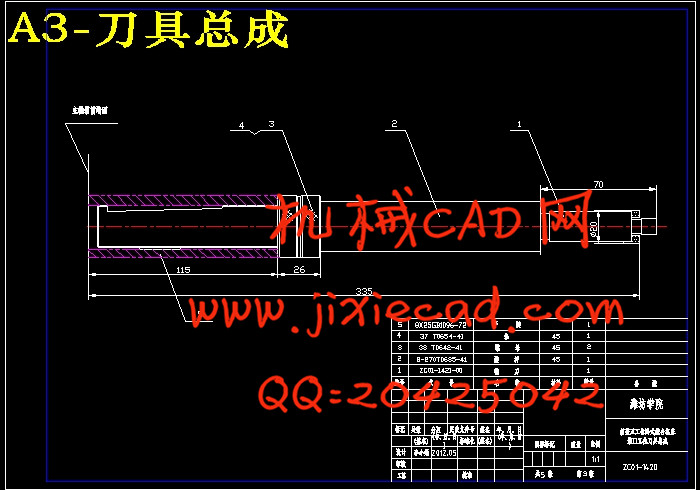

本设计中,在数据计算的基础上对标准通用零件做了仔细选择,并依据被加工零件的结构特点、加工部位的尺寸精度、表面粗糙度要求以及定位夹紧方式、工艺方法和加工过程中所采用的刀具,生产率和切削用量情况等设计了结构合理的组合机床。

关键词:组合机床 刀具 三图一卡 锪孔

ABSTRACT

Combination of more occasions is based on general parts, match with work piece specific shape and process design of special components and fixtures, which is composed of semi-automatic or automatic special machine. It usually adopts the multiracial, knife, processes, and multi-faceted or multistage and processing, production efficiency than general machine high several times or more. The combination machine has the advantages of low cost and high efficiency, in large,

mass production is widely used, and the automatic production line can be used to composition.

This paper introduces a special horizontal combination machine tools designed for gearbox shell holes on the surface countersinking this specific process. This modular mechanical tool has such advantages which is high efficiency. It is easy to operate because of the low cost and the processing precision. It reduces the worker’s labor intensity and it enhanced the productivity.

In this design, all the standard parts selection based on the carefully data calculation, and according to the characteristics of the structure by processing components, precision machining parts size, surface roughness, and the localization way, clamping technology and processing process using tools, cutting dosages as productivity, the structure design of reasonable spindle box.

Key Words:combined machine tool;Gross assembly drawing;Three graphs and one card;countersinking

目录

中文摘要 I

英文摘要 II

第1章 前言 1

1.1 组合机床的组成 1

1.2 组合机床的特点 1

1.3组合机床的发展现状 1

第2章 工艺方案设计 3

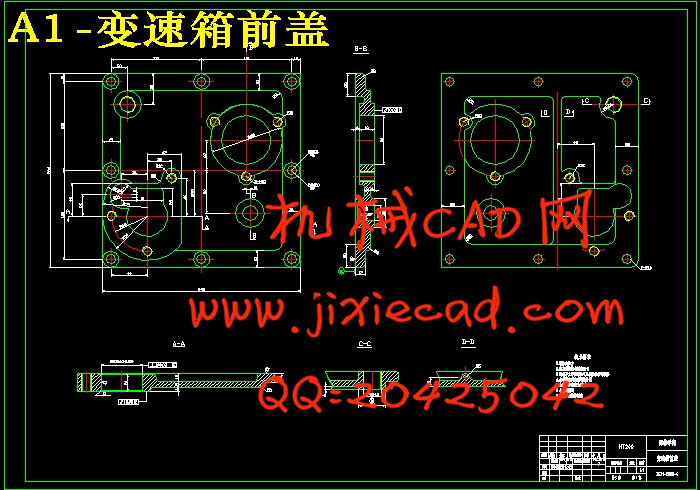

2.1 零件的工艺分析 3

2.2 确定机床的配置形式 4

2.3组合机床主要技术参数的确定 4

第3章 三图一卡设计 7

3.1被加工零件工序图 7

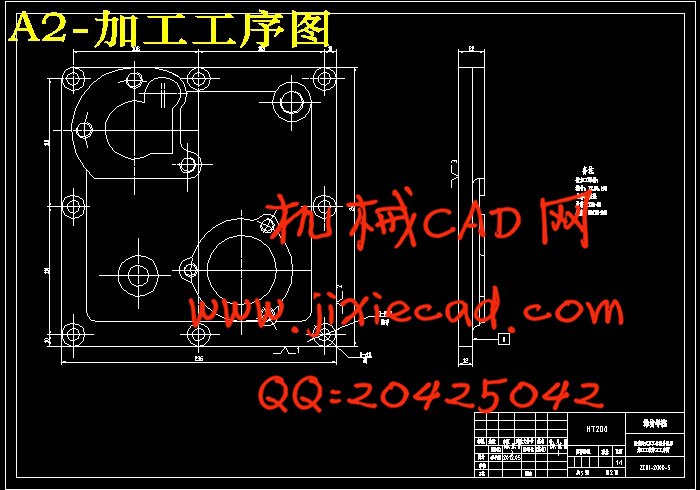

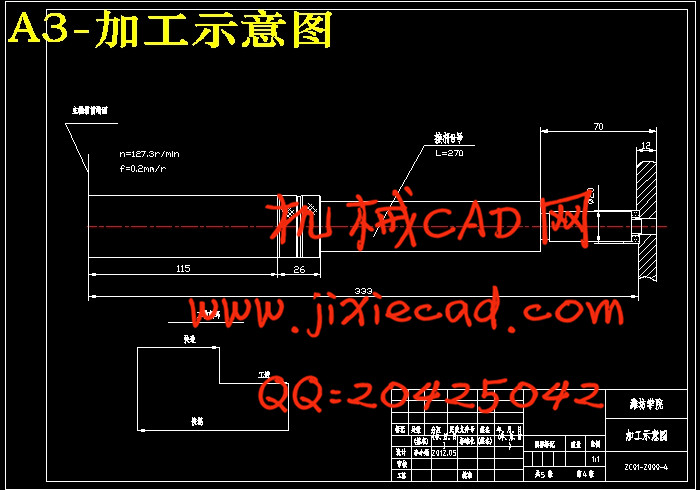

3.2 加工示意图 7

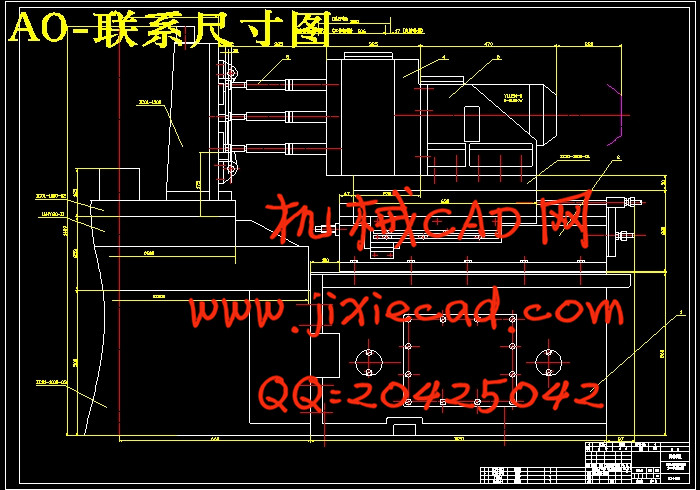

3.3 机床联系尺寸图 10

3.3.1动力部件的选择 10

3.3.2 机床的装料高度 11

3.3.3 多轴箱轮廓尺寸 11

3.3.4 确定夹具轮廓尺寸 11

3.4机床生产率计算卡 12

结 论 15

参考文献 16

致 谢 17